Feeding device of thread rolling machine

A tooth rolling machine and machine body technology, which is applied in the field of tooth rolling machine feeding devices, can solve problems such as abnormal transportation, high efficiency of tooth rolling machines, and high labor consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

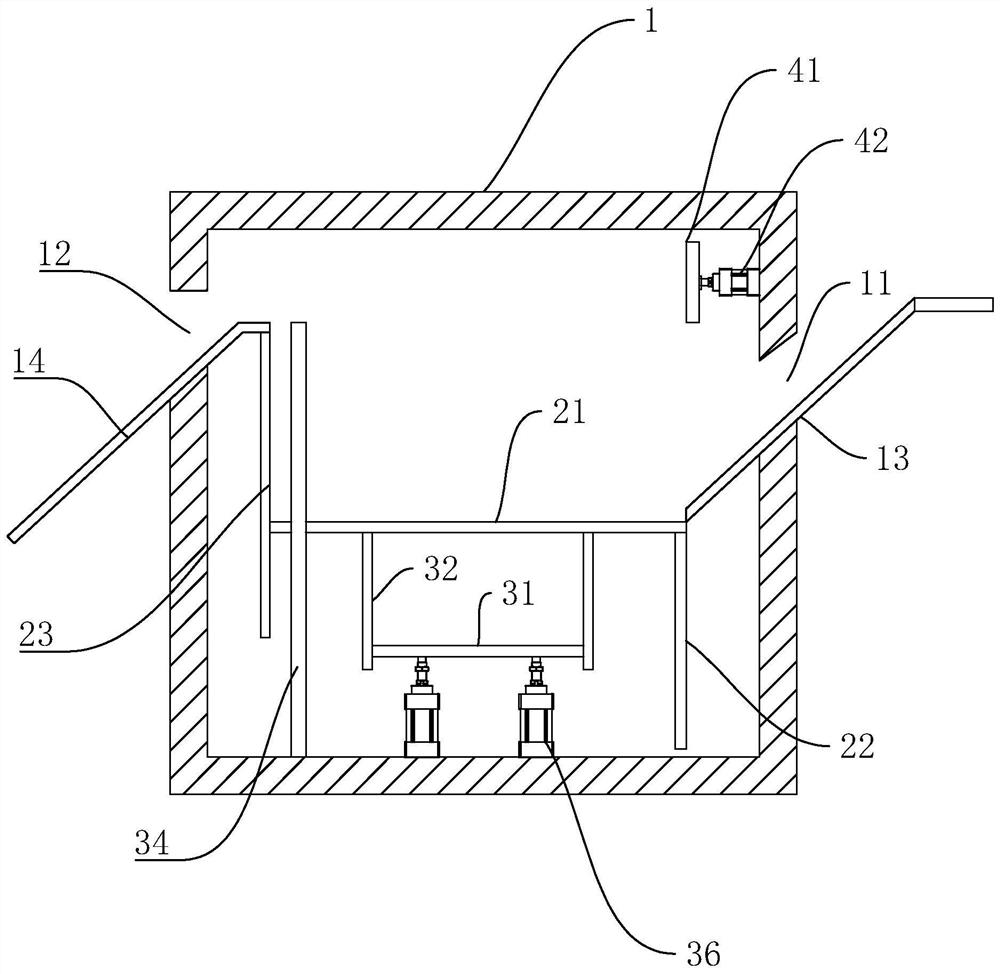

[0032] Embodiment 2, a kind of tooth rubbing machine feeding device, such as image 3 As shown, the difference with Embodiment 1 is that the lifting member 3 includes a lifting cylinder 36, the bottom of the lifting cylinder 36 is fixed on the bottom of the body 1, the output shaft of the lifting cylinder 36 is fixed to the bottom surface of the conveying plate 21, and the lifting cylinder 36 surrounds the conveying plate There are four groups in the 21 center and they rise and fall synchronously.

[0033] The invention can realize the automatic feeding of semi-finished parts, transport the semi-finished parts to the feeding channel at a constant speed and without stopping, ensure that the tooth rubbing machine is always in working condition, and does not need manual handling, which saves a lot of manpower consumption and improves the While improving the overall processing efficiency, the overall degree of mechanization and automation of the tooth rolling machine is improved, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com