Continuous hot bending furnace for front windshield of large passenger car

A front windshield and hot bending furnace technology, applied in glass forming, glass reshaping, glass manufacturing equipment, etc., can solve problems that affect product quality and production efficiency, trouble loading or unloading glass, and increase production costs, etc. , to achieve the effect of avoiding glass breakage, convenient operation and control, and saving heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0047] The same serial numbers in the figure represent the same functions and meanings.

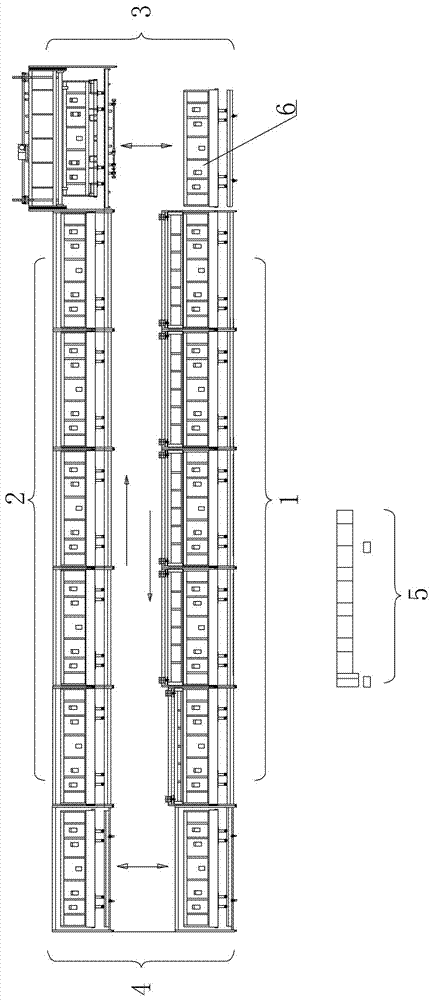

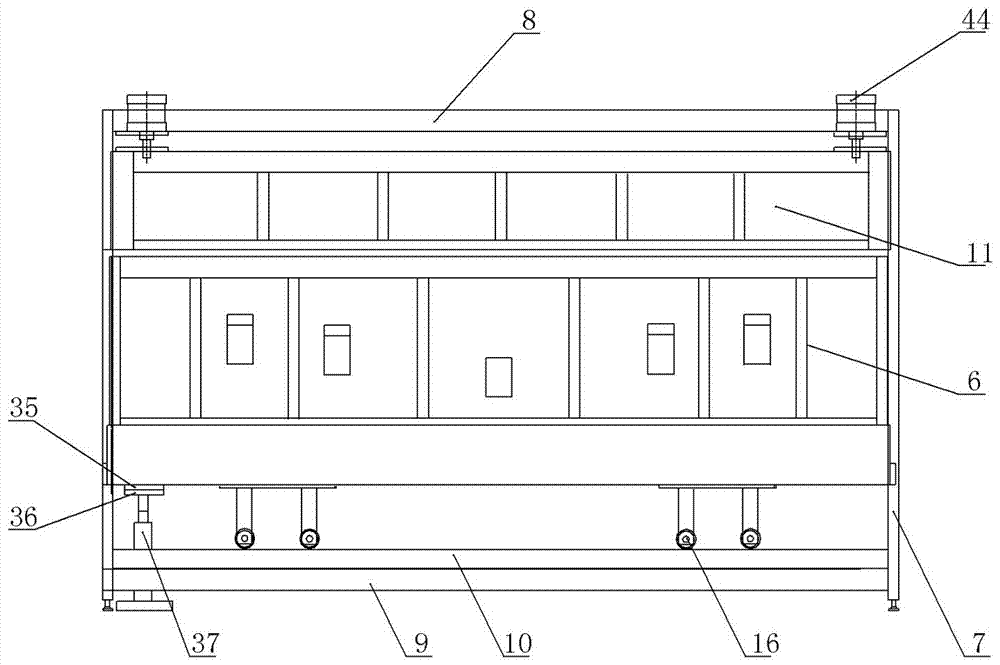

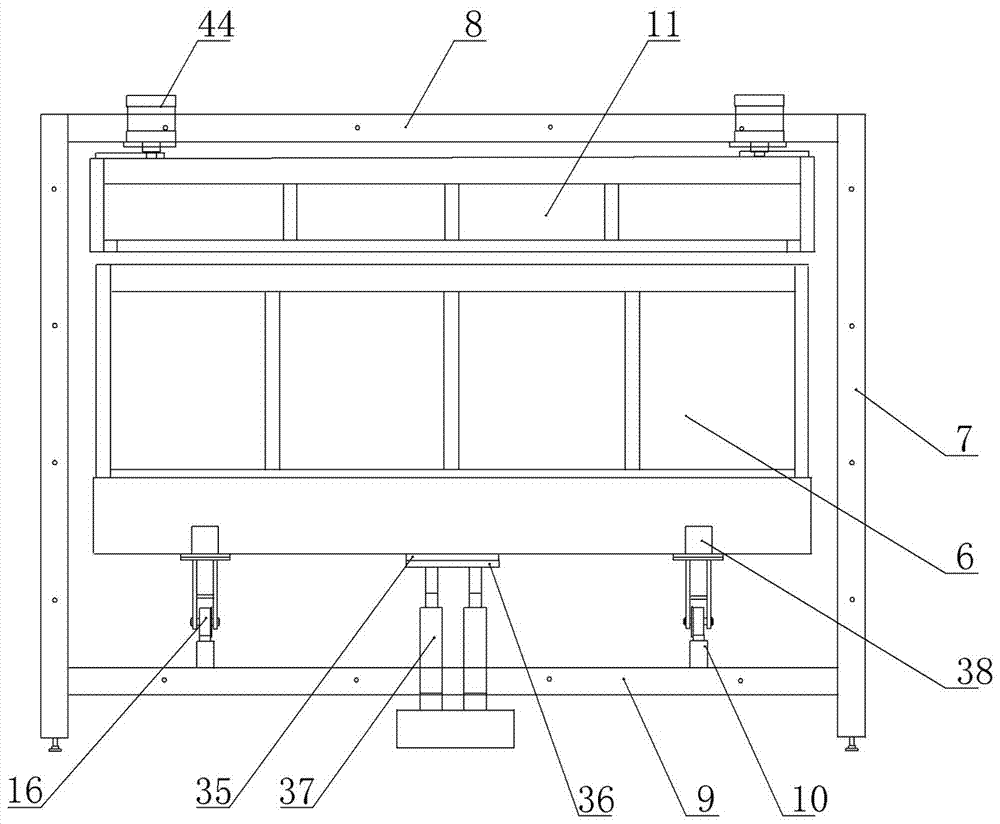

[0048] see Figure 1-Figure 23 , the present invention is a continuous hot bending furnace for the front windshield of a large passenger car. The continuous hot bending furnace is in the shape of a circular rectangular ring, and it includes 5 heating chamber units 1, 5 and 5 heating chamber units arranged side by side in a horizontal direction. 1 Cooling chamber unit 2 arranged in parallel, upper sheet ferry unit 3 and ferry passage unit 4 arranged at both ends of heating chamber unit 1 and cooling chamber unit 2, glass car 6 and automatic control system 5, each heating chamber unit and A glass car is provided correspondingly in the cooling room unit, and each glass car is connected end to end, and a glass car 6 is arranged on one of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com