Multi-sprayer foam concrete spreading device and operation method

A foam concrete and material distribution device technology, which is applied in the processing of building materials, complex mathematical operations, construction, etc., can solve the problems of increasing the distribution ratio of large pores, large kinetic energy of slurry, and affecting the solidification quality of foam concrete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The embodiments of the present invention will be described in detail below according to the above-mentioned drawings.

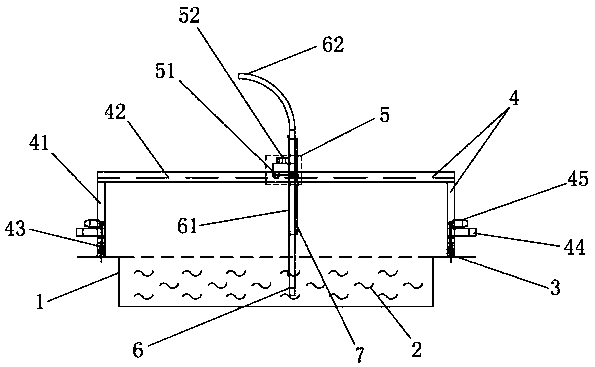

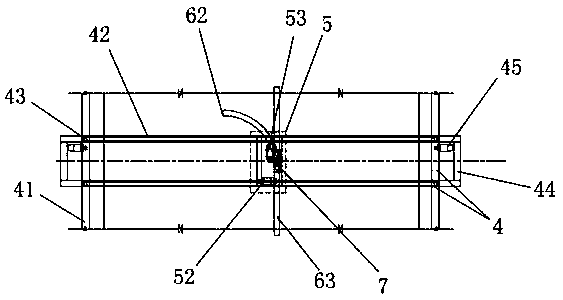

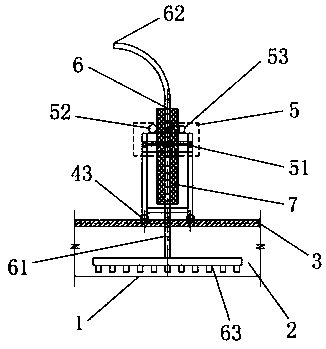

[0058] Such as Figure 1~Figure 8 As shown, 1. U-shaped foundation, 2. Foam concrete grout, 3. Channel steel track, 4. Mobile frame, 41. Gate post, 42. Beam, 43. Longitudinal moving wheel, 44. Motor seat, 45. Longitudinal motor , 5. Mobile platform, 51. Horizontal moving wheel, 52. Horizontal motor, 53. Lifting motor, 531. Motor teeth, 6. Boom, 61. Rack, 62. Conveying hose, 63. Nozzle, 64. Vertical Tube, 65. horizontal tube, 7. chute.

[0059] Multi-nozzle foam concrete distributing device and operation method, such as Figure 1~Figure 3 As shown, it belongs to the field of foam concrete construction. It is a construction device that uses a mechanical distribution device to replace manual foam concrete distribution. Its structure is mainly composed of a door-shaped mobile frame and a mobile platform installed on the mobile frame. constitute.

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com