Patents

Literature

44results about How to "Improve solidification quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

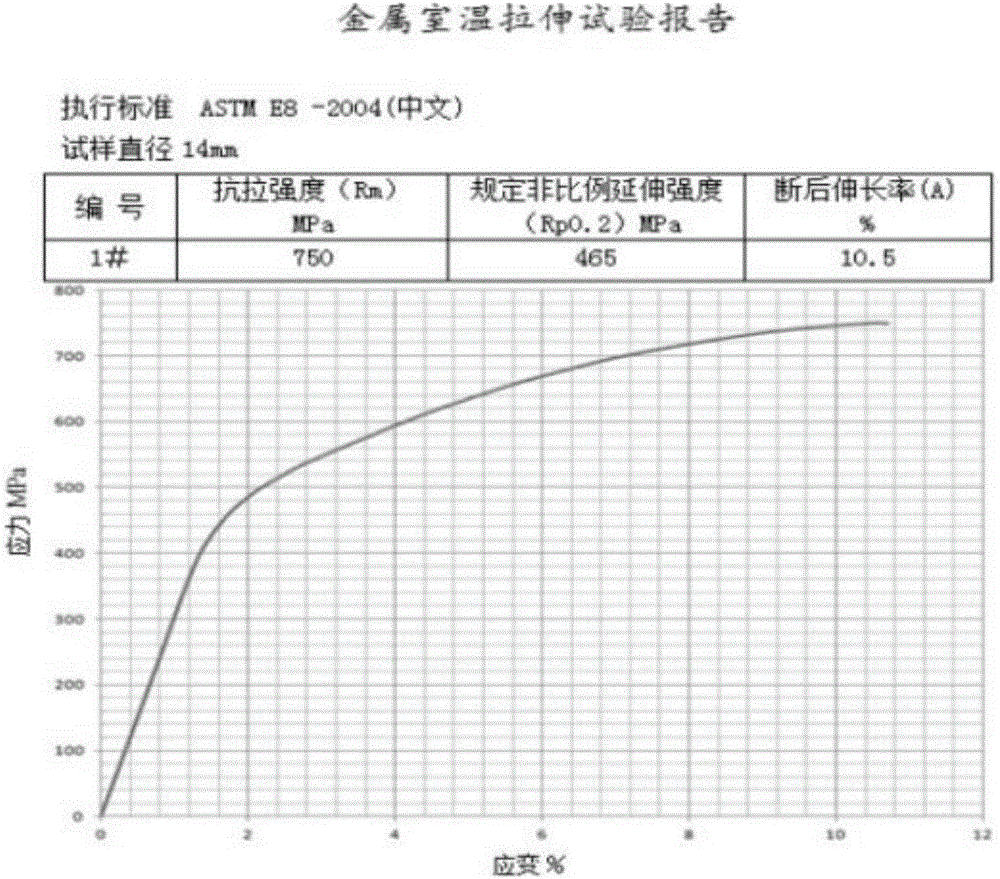

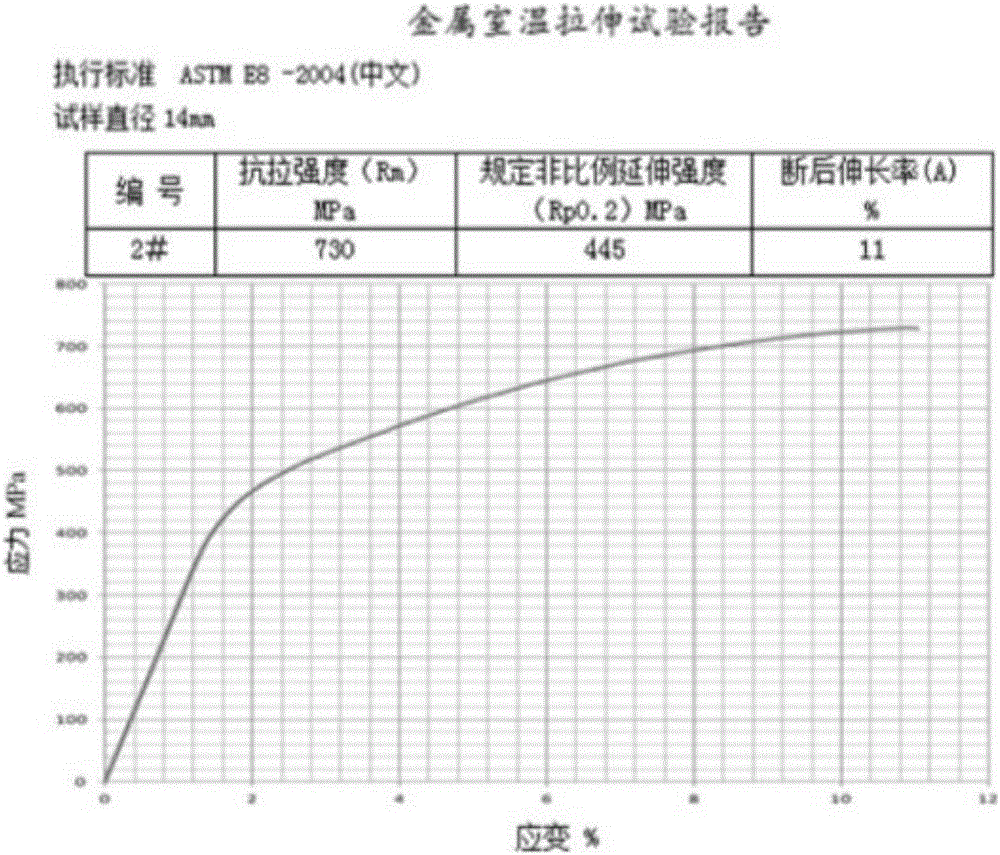

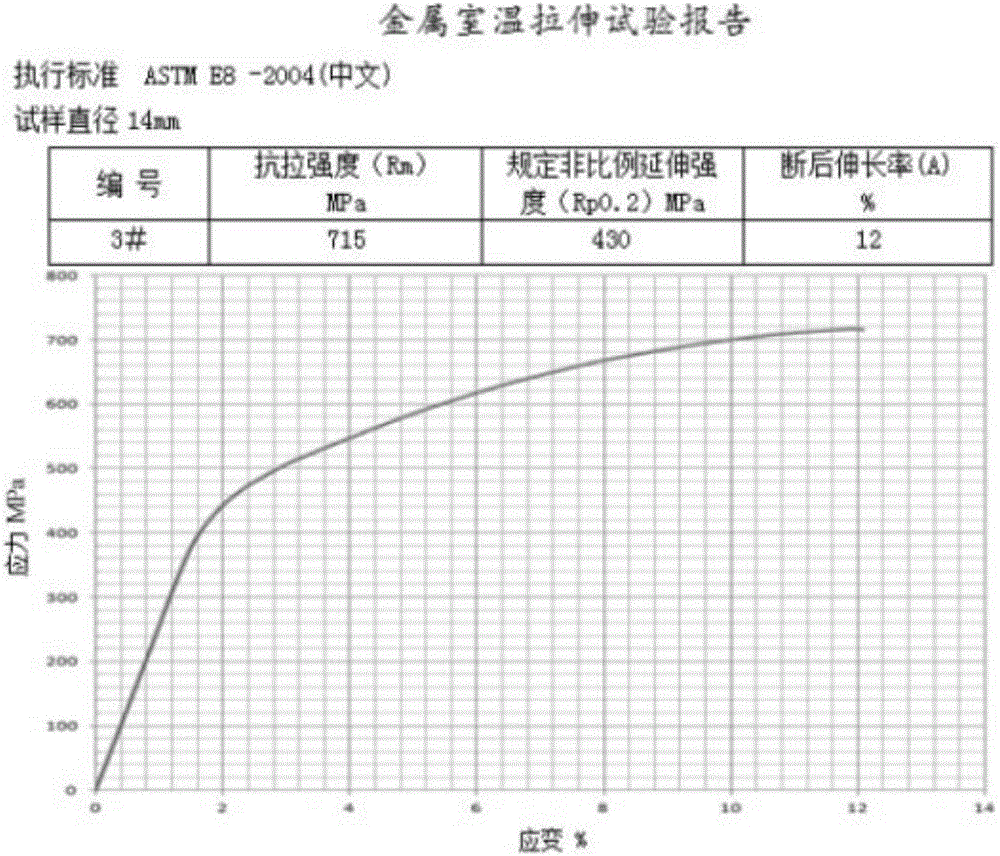

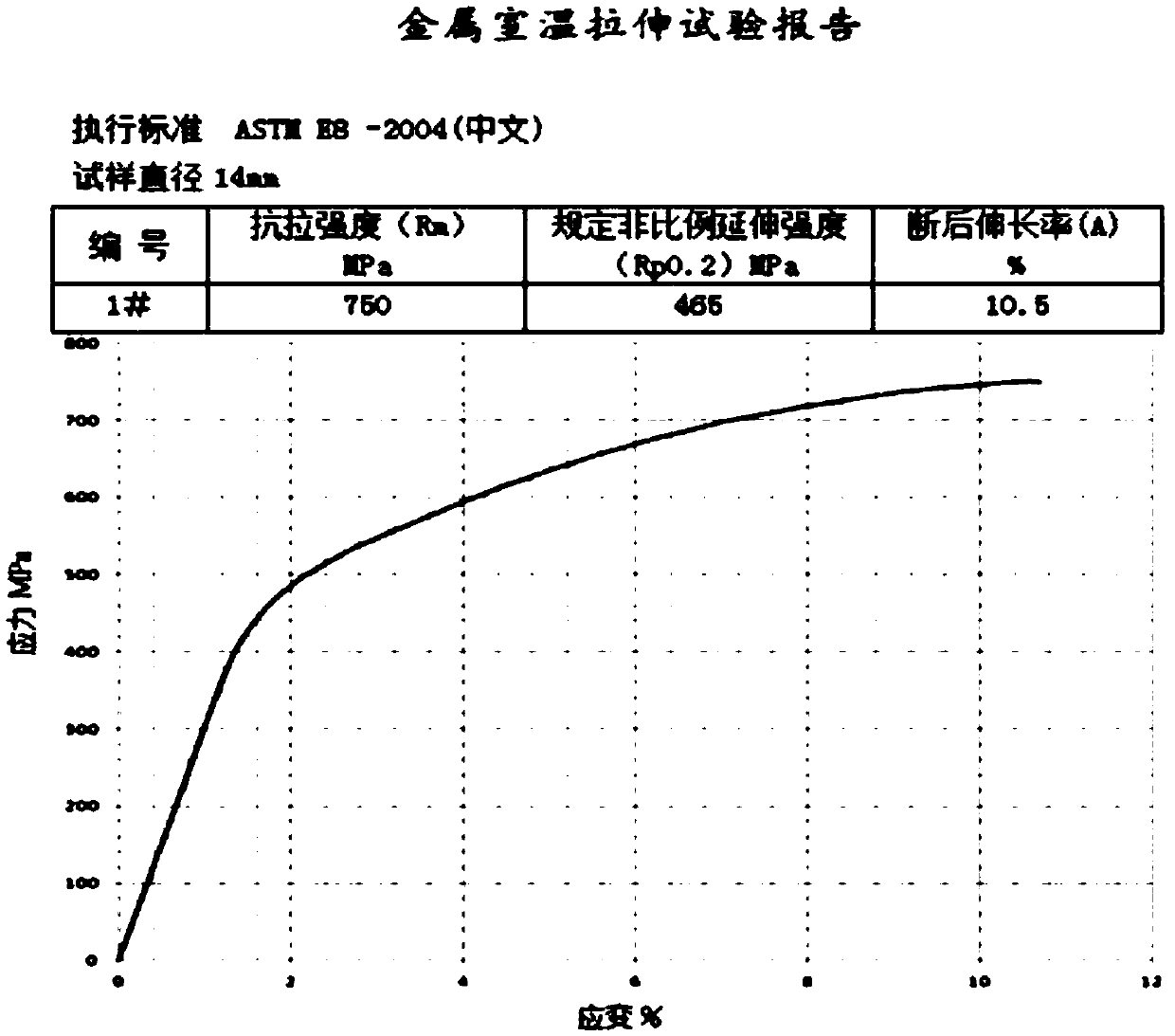

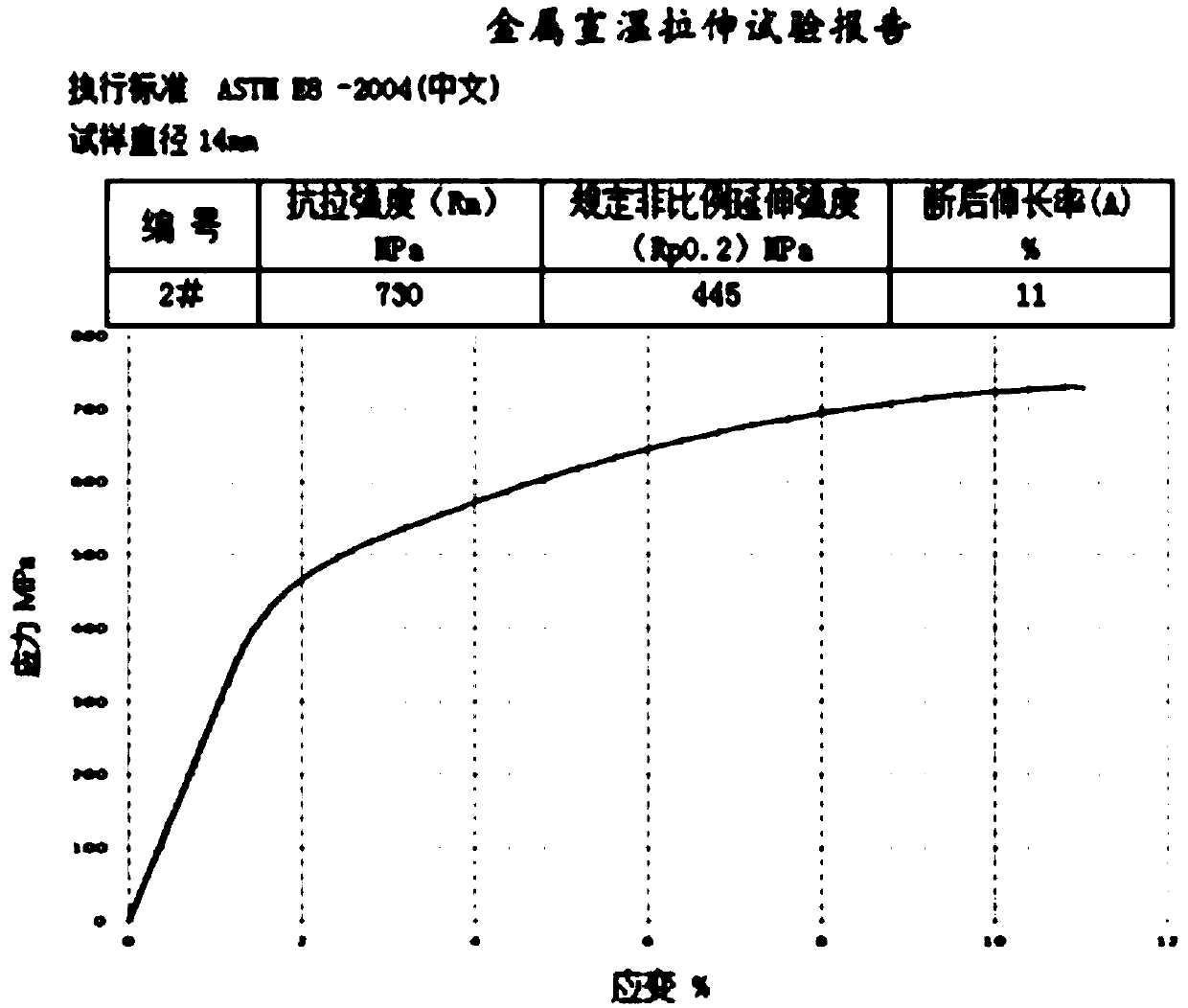

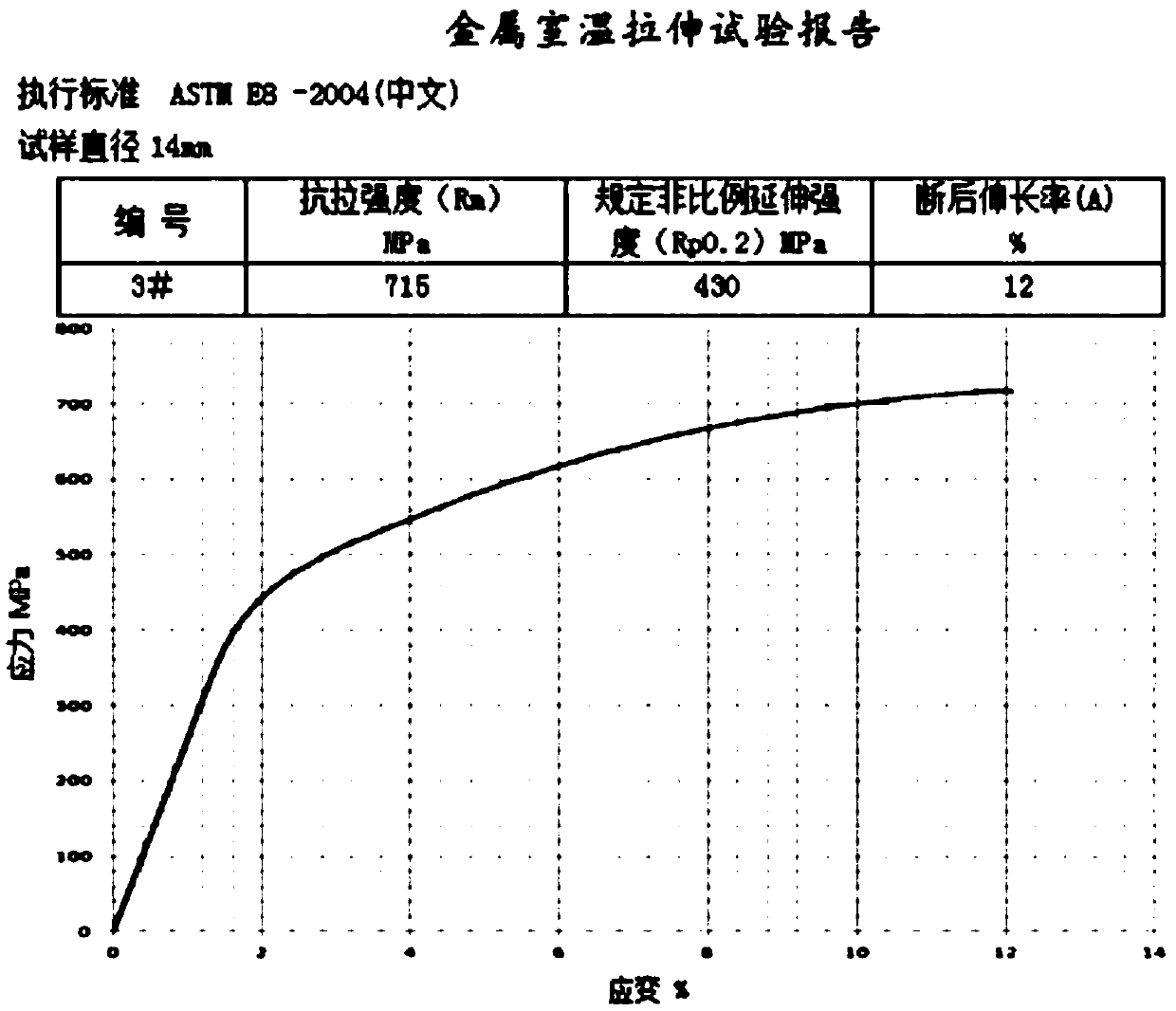

High-strength high-tenacity cast-state QT700-10 and production method thereof

ActiveCN106811676AIncrease the number ofReduce oxidation burnProcess efficiency improvementHigh intensityDuctile iron

The invention belongs to the field of casting technologies and new materials and particularly relates to a high-strength high-tenacity cast-state QT700-10 and a production method thereof. Compared with ductile iron produced in the prior art, the high-strength high-tenacity cast-state QT700-10 has high strength and a high elongation rate, heat treatment is not needed, heavy metal, such as, Ni and Mo are not added in production, the tensile strength Rm in the cast state is larger than or equal to 700 MPa, the elongation rate A is larger than or equal to 10%, compared with the standard brand QT 450-10, the lowest tensile strength is improved by 55% under the same elongation rate; and compared with the standard brand QT 700-2, the lowest elongation rate is improved by four times under the same tensile strength. The high-strength high-tenacity cast-state QT700-10 can meet requirements of automobile ductile iron castings with high requirements for safety and comprehensive mechanical properties.

Owner:山东汇金股份有限公司

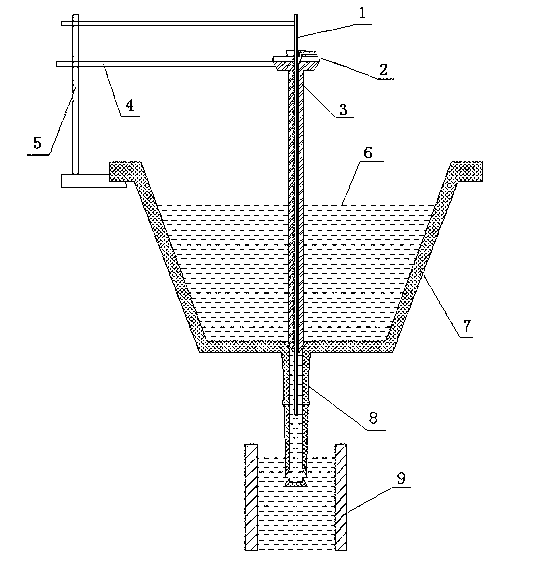

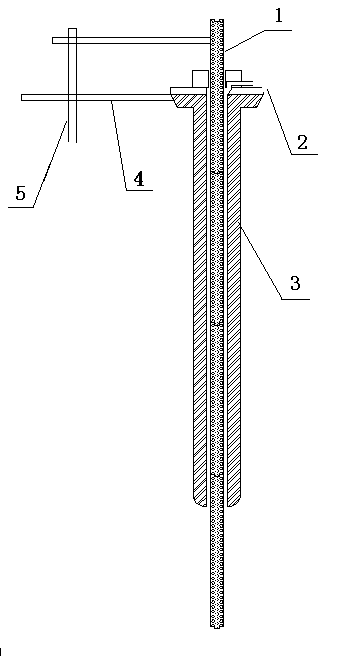

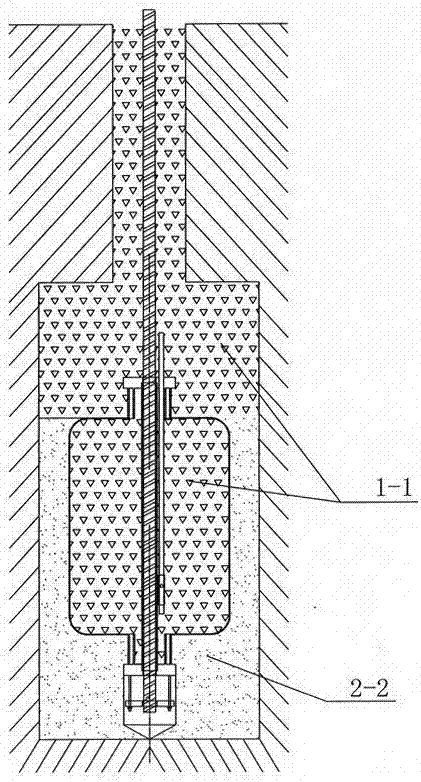

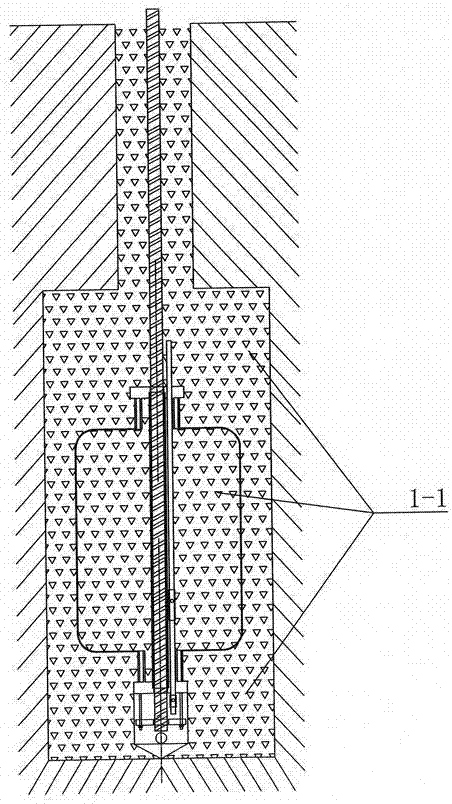

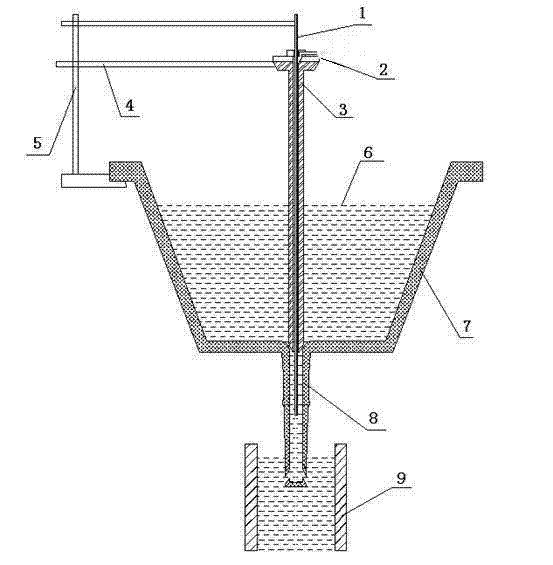

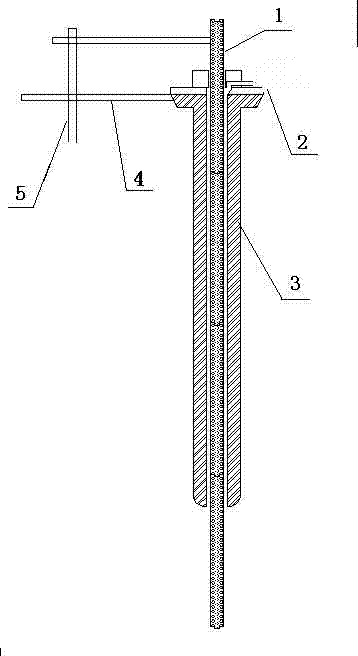

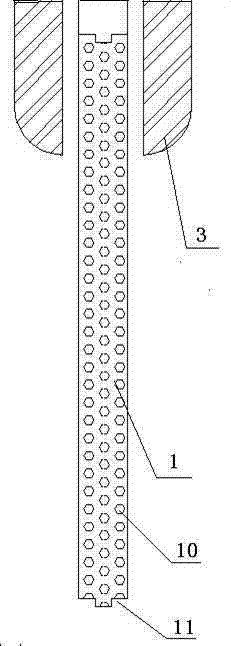

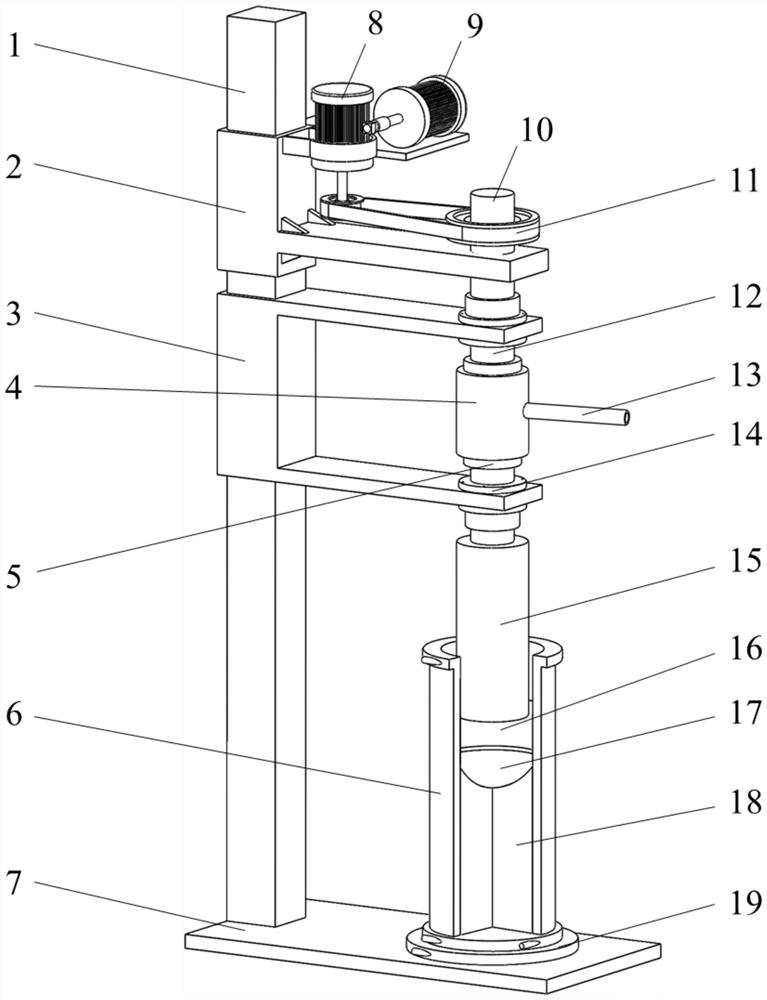

Gun insertion type stopper rod device and method using same for absorbing inclusions at gate

ActiveCN103008636AStructural Design ScienceEasy to adjustMelt-holding vesselsNodulationsMolten steel

The invention provides a gun insertion type stopper rod device and a method using the same for absorbing inclusions at a gate. The device mainly comprises an absorption gun, a hollow stopper rod, a hot argon blowing device, horizontal clamps and a vertical lifting frame, the absorption gun is of a hollow bamboo-shaped structure and inserted into the hollow stopper rod of a long cylindrical structure, the upper end of the hollow stopper rod is fixed by the corresponding horizontal clamp, one end of the hot argon blowing device is connected on an external hot argon pipeline while the other end of the hot argon blowing device is inserted into a hollow pipe at the top of the hollow stopper rod, one end of the stopper rod horizontal clamp is connected with the vertical lifting frame while the other end thereof is mutually clamped with the hollow stopper rod, and one end of the absorption gun horizontal clamp is connected with the vertical lifting frame while the other end thereof is mutually clamped with the absorption gun. The method using the device for absorbing the inclusions at the gate includes the steps of gun insertion, argon sealing, gun descending, absorption and gun replacement. The device is scientific in structural design, part of time for gate changing is saved, smooth pouring of continuous casting is benefitted by using the device for absorbing sundries, molten steel cleanliness is improved, and gate nodulation probability is decreased.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

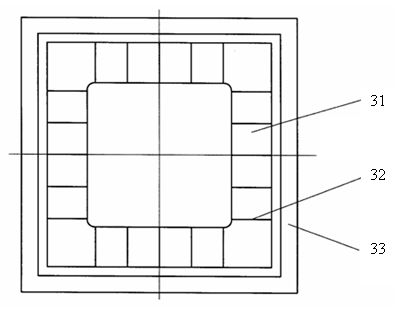

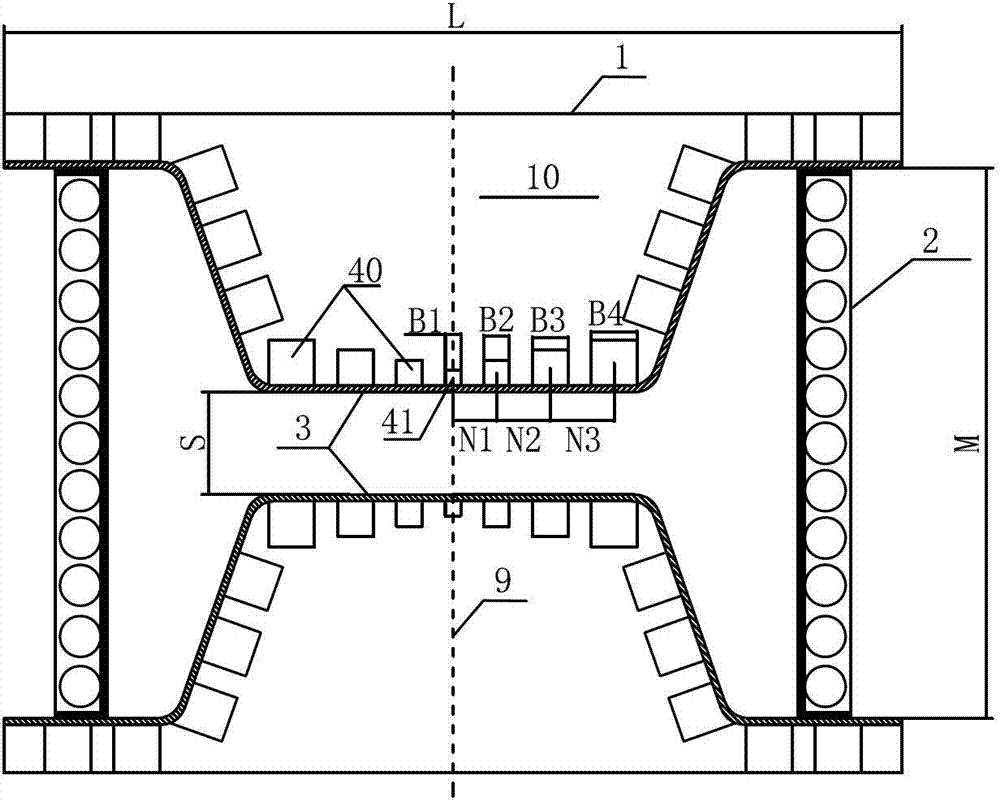

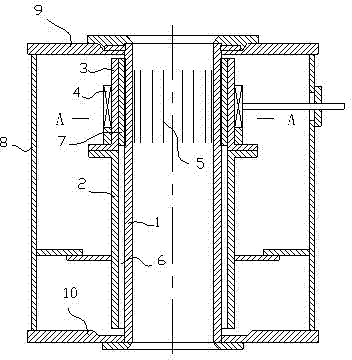

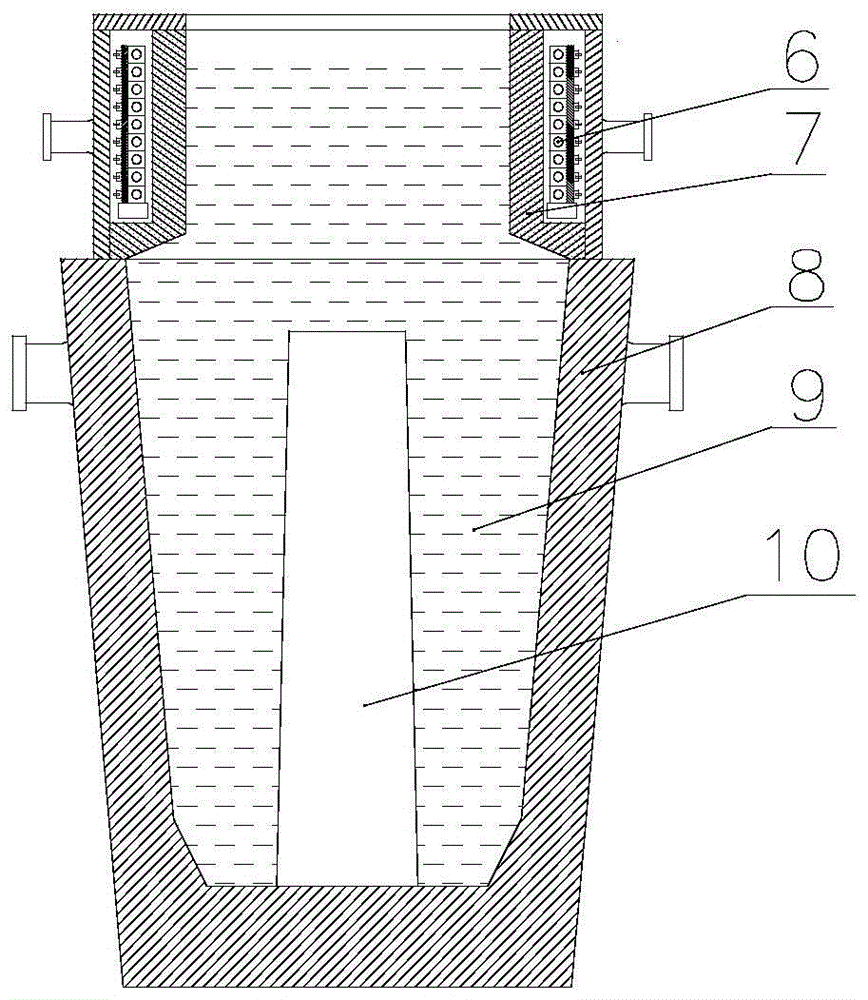

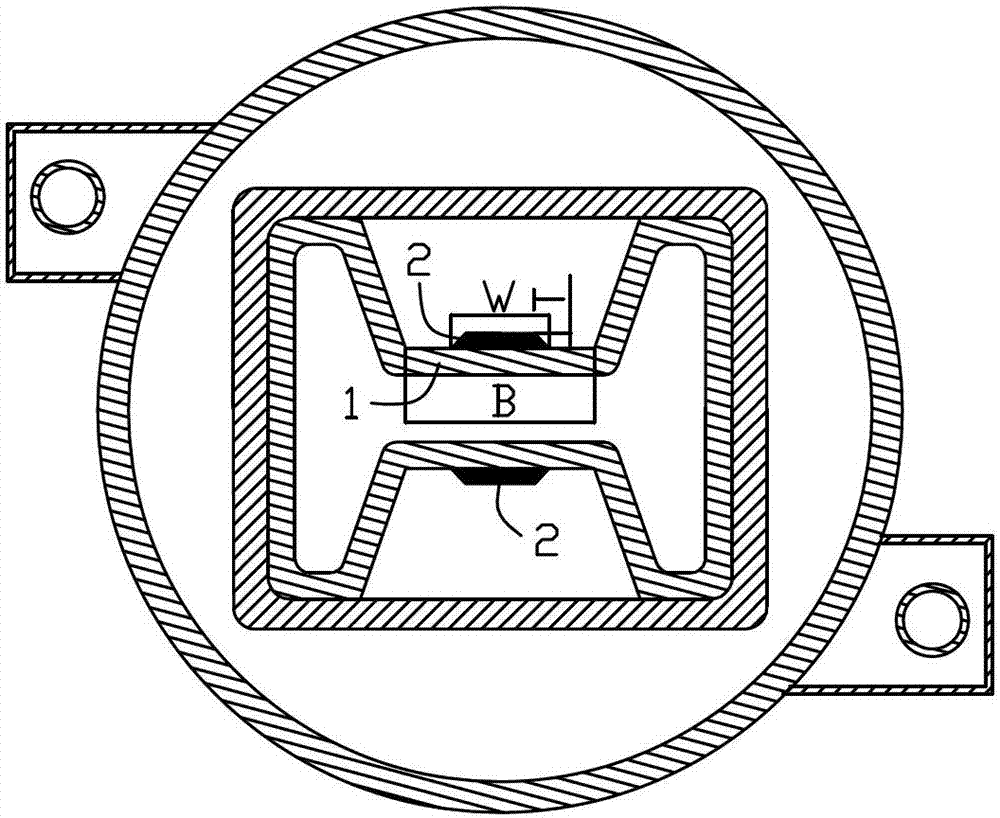

Electromagnetic soft contact continuous casting crystallizer

ActiveCN102371348AGuaranteed electromagnetic permeabilityGuaranteed service lifeEngineering plasticEngineering

The invention relates to a kerf-valving external water-cooled type electromagnetic soft contact continuous casing crystallizer, comprising a kerf copper pipe (1), an upper-section inner water jacket (3), a lower-section inner water jacket (2), an electromagnetic induction coil (4), a shell (8), an upper flange (9) and a lower flange (10), wherein the shell (8), the upper flange (9) and the lower flange (10) constitute a crystallizer assembly structure; the upper-section inner water jacket is made of engineering plastics and is sleeved in the electromagnetic induction coil; a groove (12) is machined on the outer wall of the outer wall surface of the kerf copper pipe along each kerf (5); a high-temperature resisting insulation sheet (11) is inserted into each kerf; bonding glue (120) is coated and filled in the groove; the edge of the inserted tail end of the insulation sheet slightly protrudes out of the bottom plane of the groove; and the high-temperature resisting insulation sheets and the serf copper pipe are fixed by the binding glue. A top rib sealing bar (8) which aims at each kerf is arranged between the outer wall of the kerf copper pipe and the upper-section inner water jacket. The invention has the advantages of strong electromagnetic permeability and safe and reliable cooling water path.

Owner:BAOSHAN IRON & STEEL CO LTD

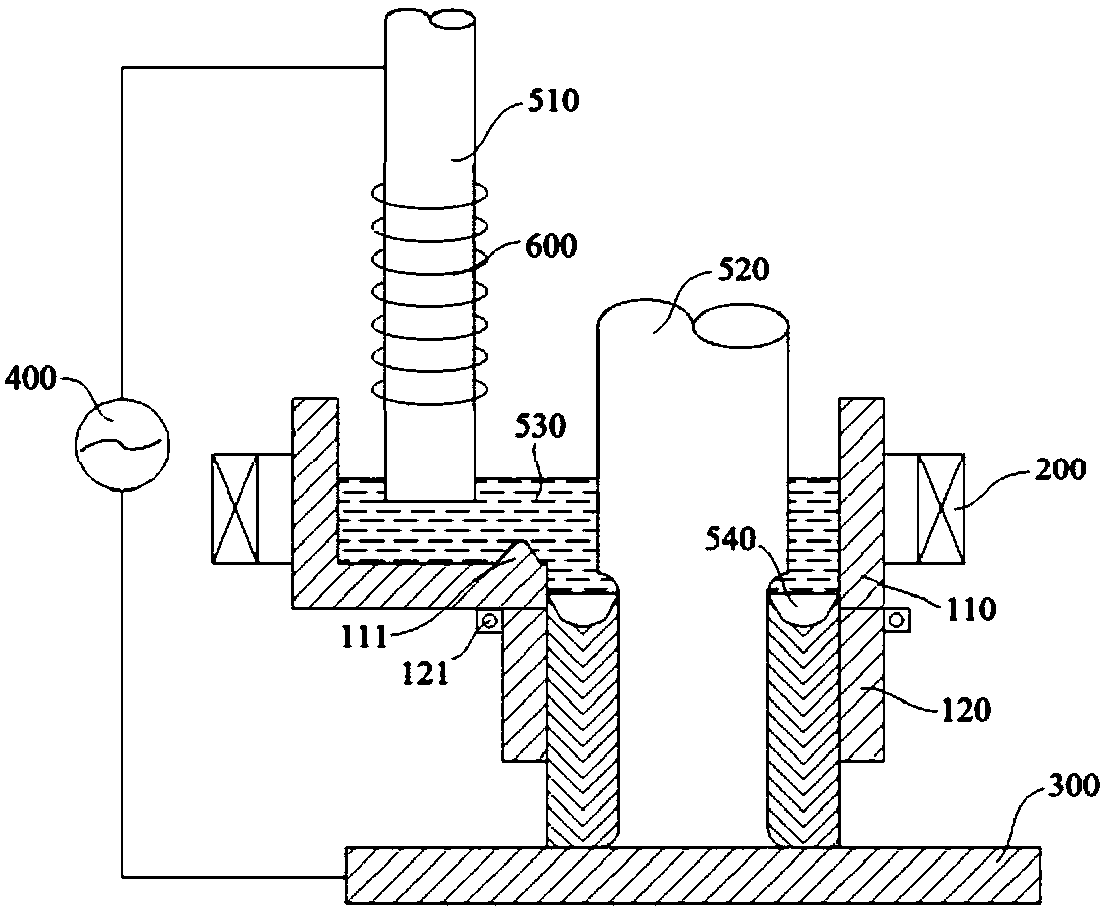

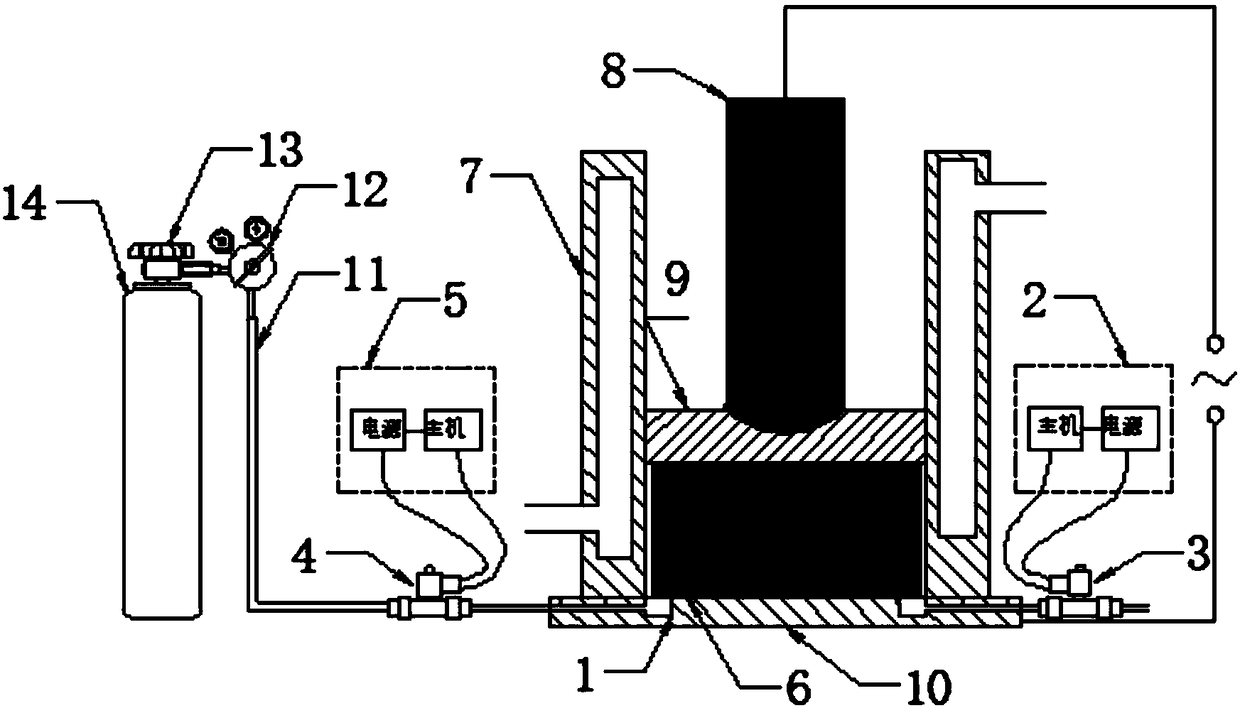

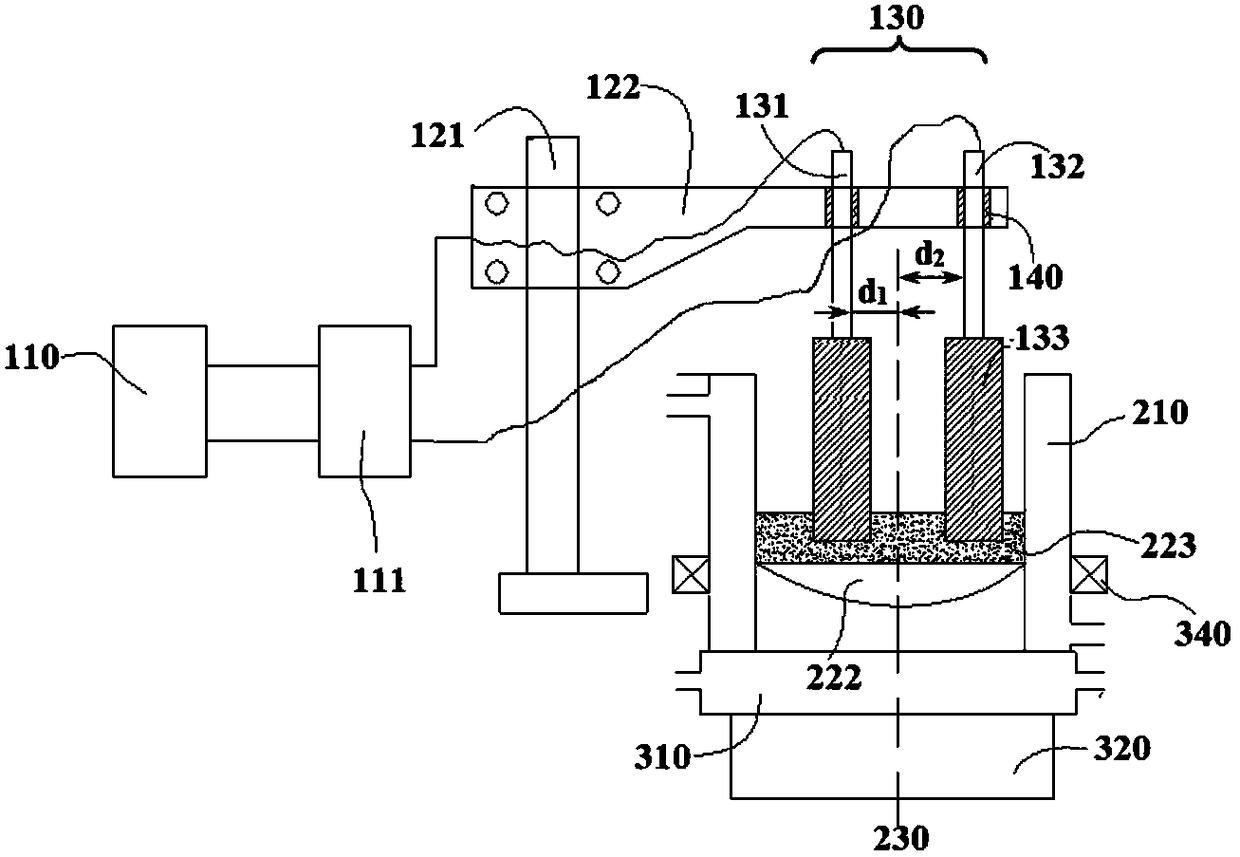

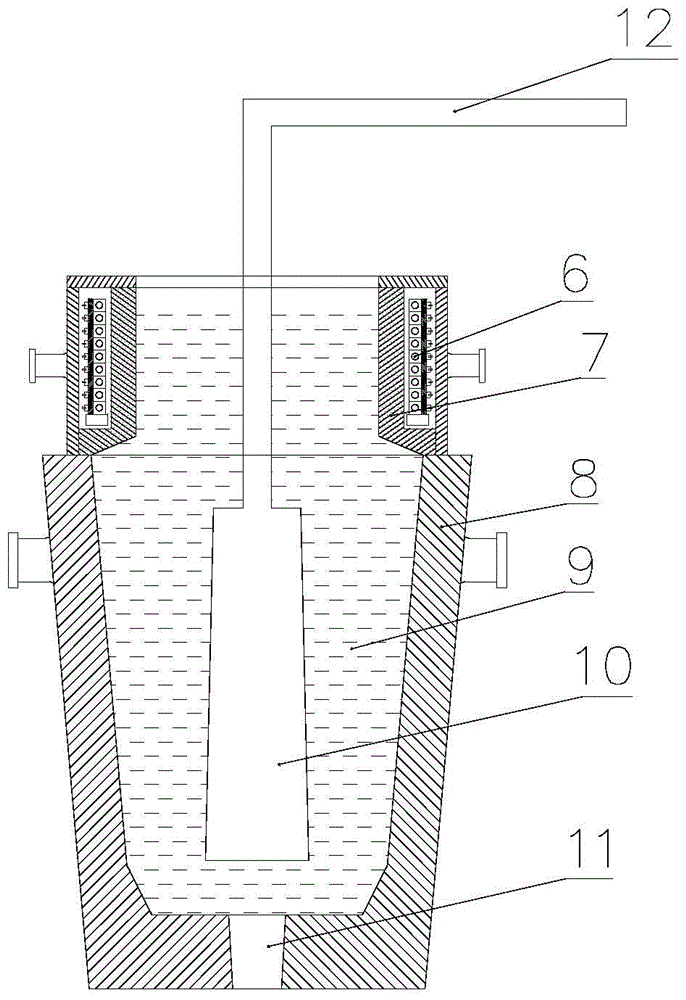

Method for producing composite roll by preheating consumable electrode electroslag remelting

The invention discloses a method for producing a composite roll by preheating consumable electrode electroslag remelting and belongs to the technical field of electroslag remelting. The method for producing the composite roll comprises an eccentric crystallizer, a bottom water tank and a metal consumable electrode. The eccentric crystallizer comprises an upper crystallizer and a lower crystallizer, the diameter of the lower crystallizer is smaller than the diameter of the upper crystallizer, the lower crystallizer is arranged under the upper crystallizer, and axes of the upper crystallizer andthe lower crystallizer are not on the same straight line; the metal consumable electrode is arranged above the upper crystallizer, the bottom water tank is arranged below the lower crystallizer, andthe metal consumable electrode and the bottom water tank are respectively connected with two poles of a power supply. The material thickness of a working surface can be adjusted flexibly with eccentric design of the electroslag remelting crystallizer; the metal consumable electrode is externally surrounded by an induction coil, so that the consumable electrode can be preheated in the remelting process, electrode melting is accelerated, mass melting of a surface layer of a roll core is avoided, and therefore the roll core and a roll body are effectively welded.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

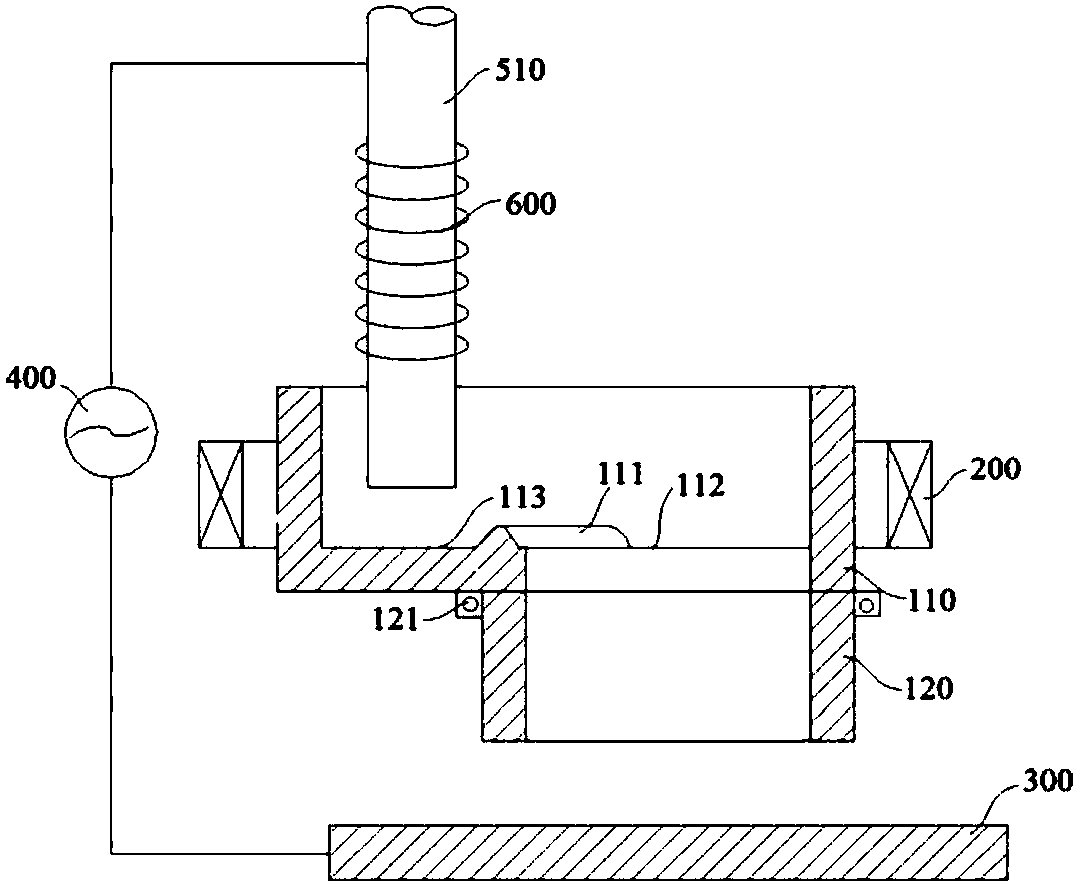

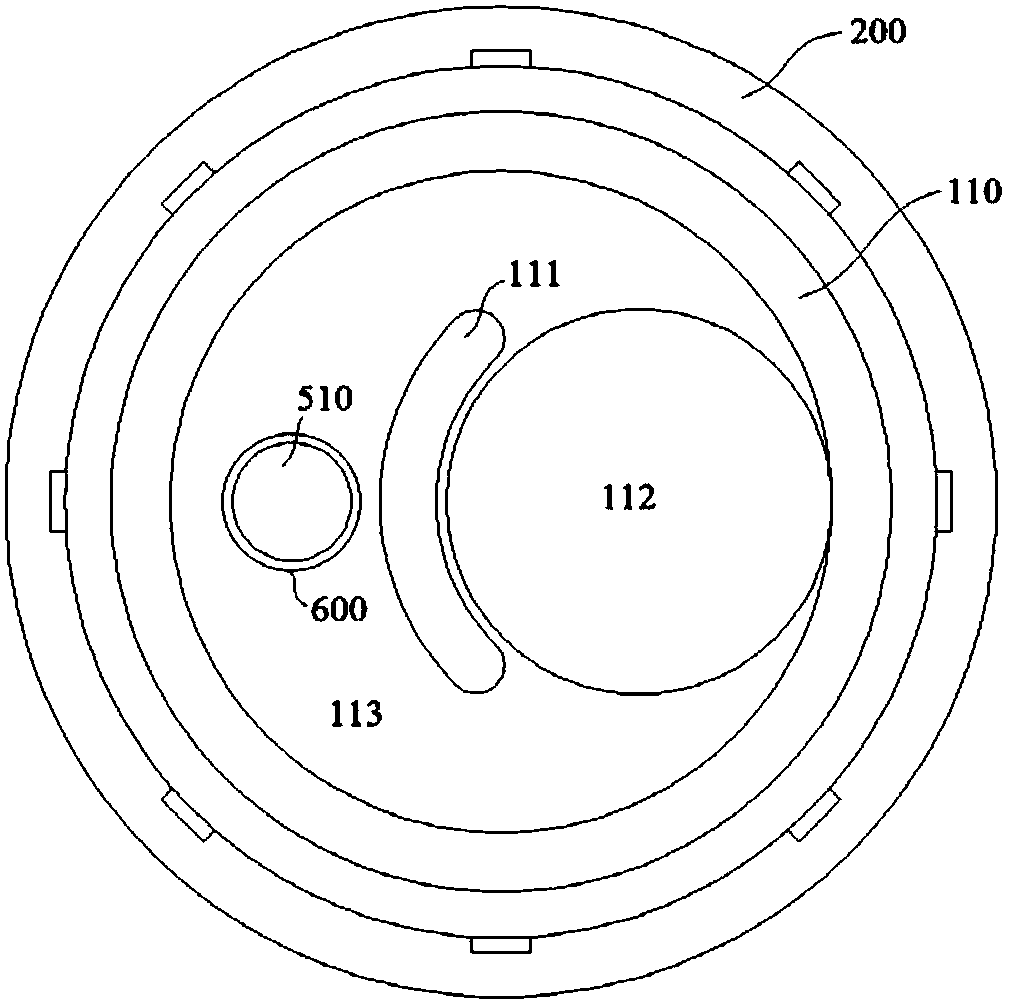

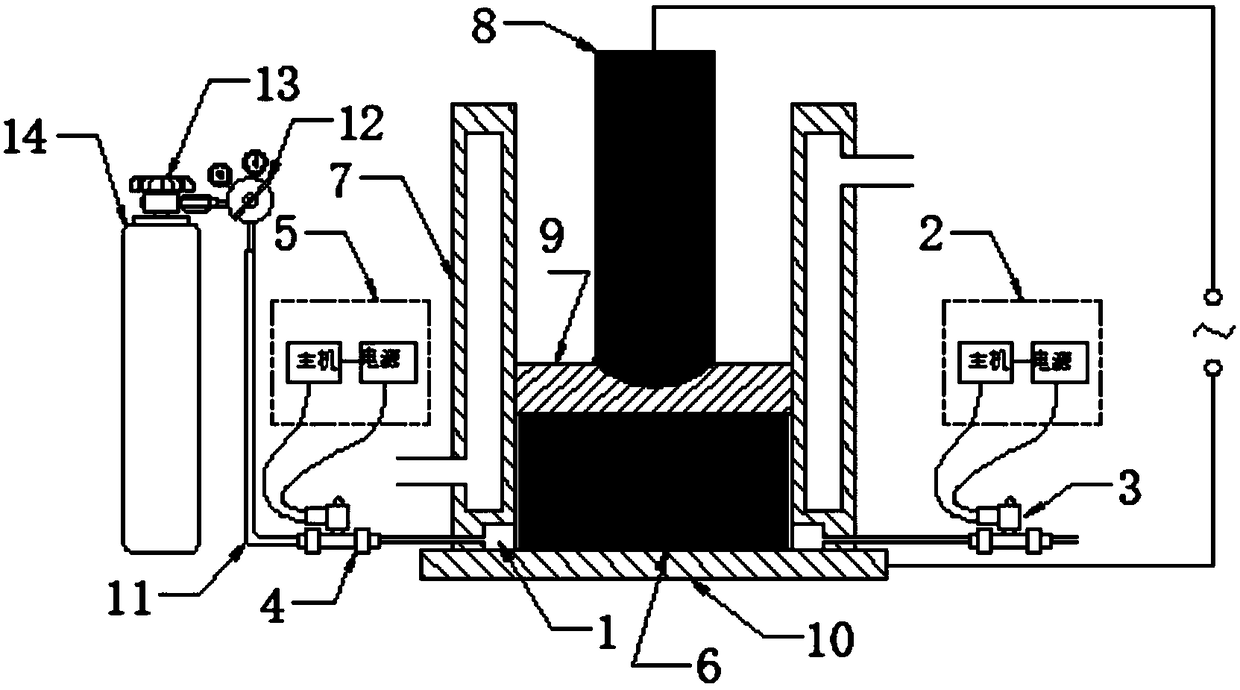

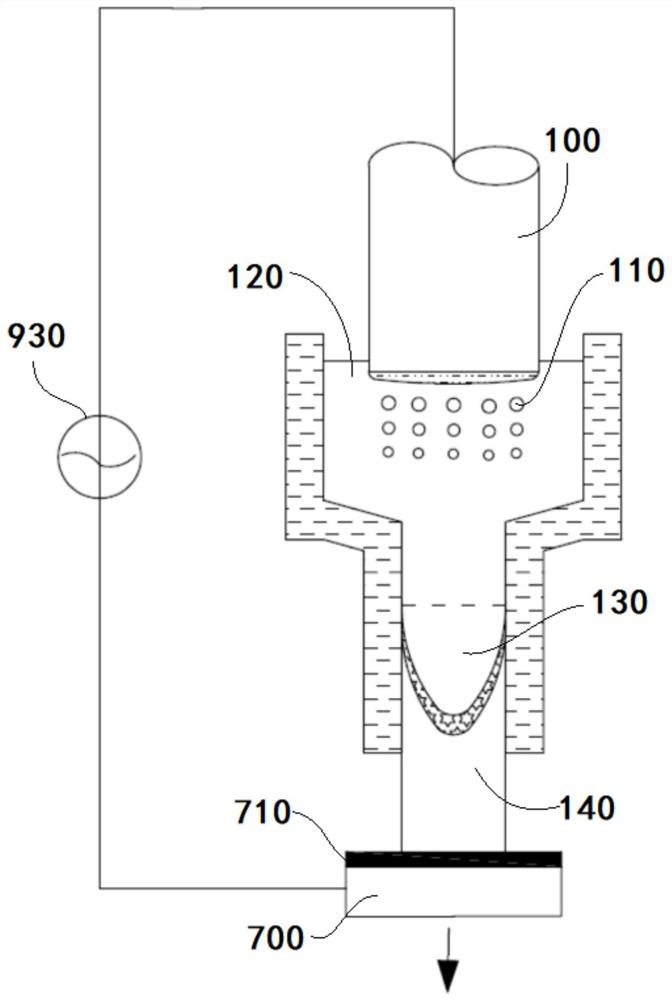

Method for improving solidification quality of electroslag remelting steel ingot

InactiveCN108411120AImprove solidification qualityUniform temperature fieldLiquid stateSmelting process

The invention discloses a method for improving solidification quality of an electroslag remelting steel ingot and relates to the technical field of electroslag remelting. The method for improving thesolidification quality of the electroslag remelting steel ingot. When a smelting device is adopted for smelting, consumable metal of a metal electrode is inserted into liquid state slag of a smeltingcrystallizer, a positive pole of a pulse power source is connected with the metal electrode, a negative pole of the pulse power source is connected with a bottom water tank, the pulse power source iselectrified and an electric circuit is formed, and the consumable metal of the metal electrode is re-smelted and re-solidified, so that the steel ingot is obtained. When the smelting device is adoptedfor smelting, the metal electrode leads pulse current of the pulse power source to the smelting process, the pulse power source is electrified and an electric circuit is formed, and the consumable metal of the metal electrode is re-smelted and re-solidified, so that the steel ingot is obtained.

Owner:MAANSHAN HUASHENG METALLURGICAL SCI & TECH DEV

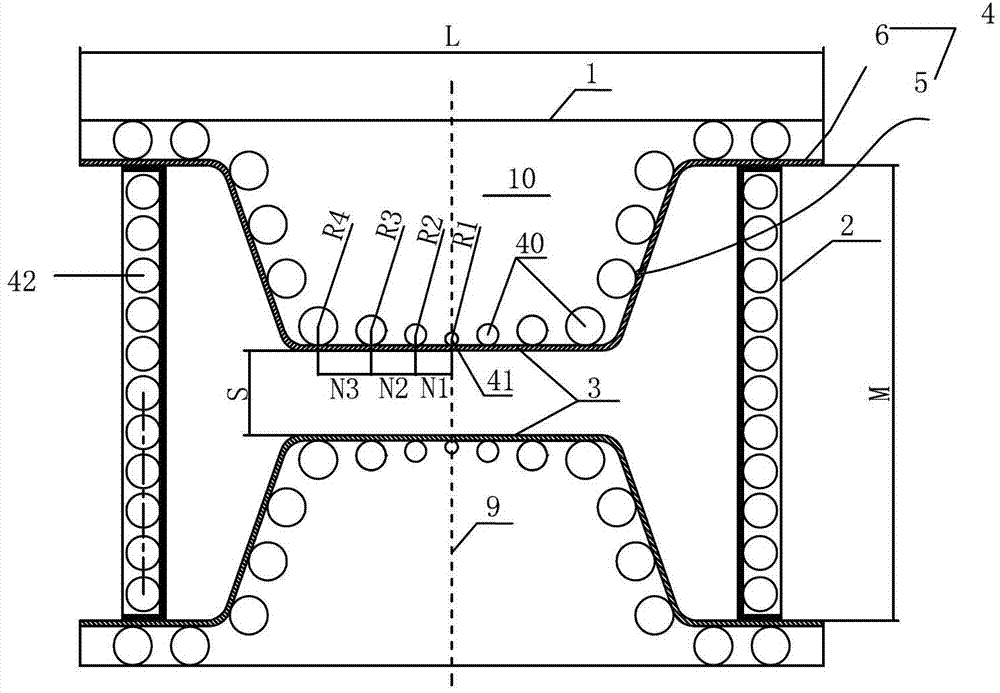

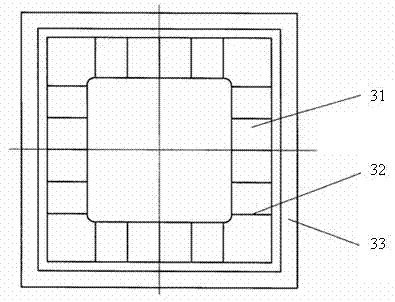

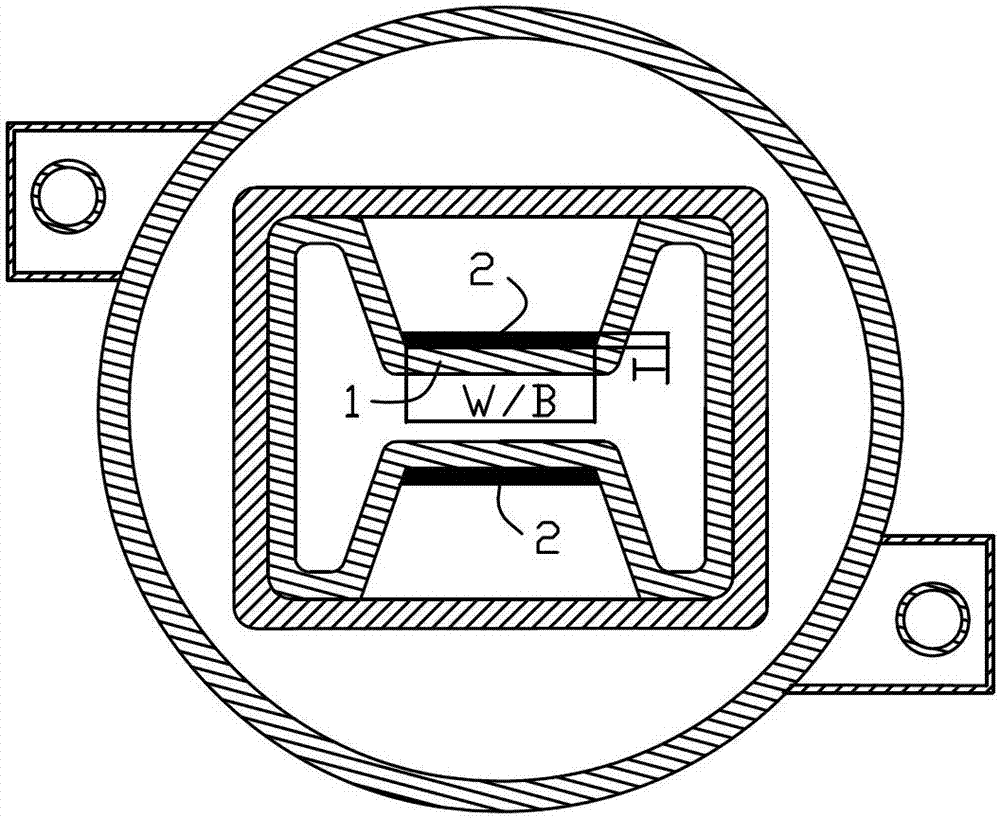

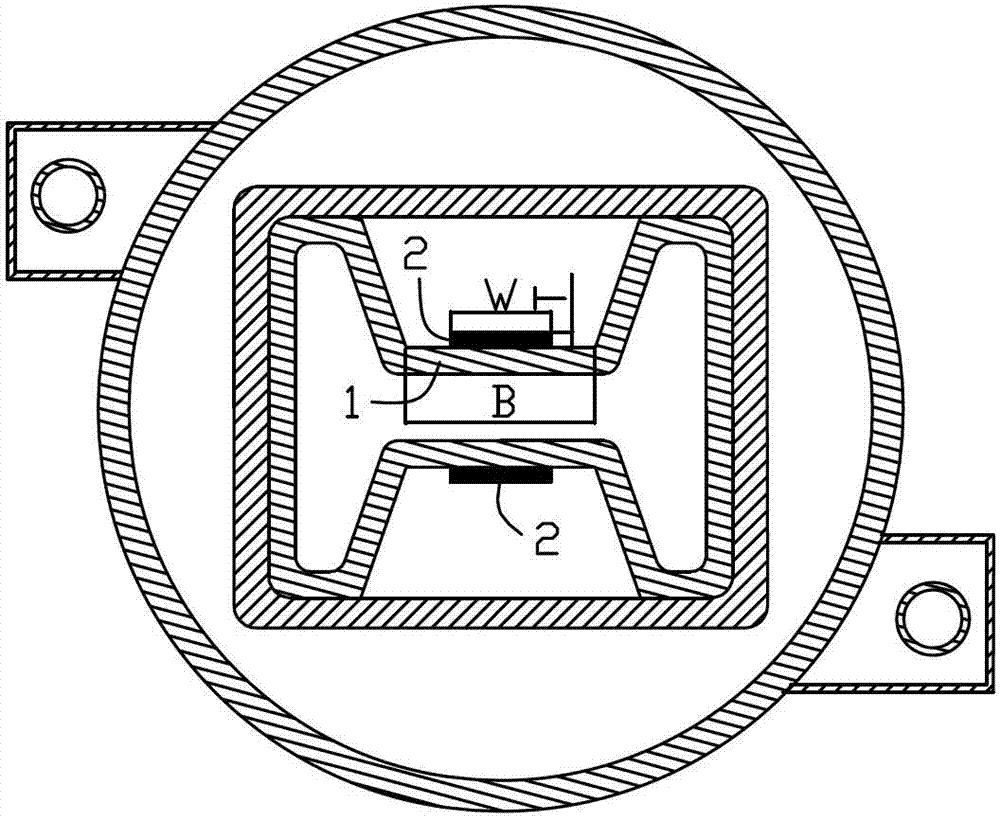

H-shaped combined crystallizer

The invention provides an H-shaped combined crystallizer which comprises two flange wide plates and two narrow plates, wherein each of the flange wide plates comprises a web plate formed by protruding in the middle and flanges positioned on two sides of the web plate; the web plates are used for limiting and forming web plate parts of H-shaped casting blanks when casting the blanks; the flanges and the narrow plates coact when blanks are cast so as to limit and form flange parts of the H-shaped casting blanks; the flanges comprise winglets and flange inclined surface parts positioned between the web plates and the winglets; the narrow plates are arranged inside two opposite winglets, wherein a plurality of water pipes are arranged on the outer sides of working walls of the narrow plates, and a plurality of water pipes are arranged on the outer sides of working walls of the web plates and the flanges along the length direction of the flange wide plates; and the sectional areas of the water pipes close to center lines of the web plates are the smallest. The H-shaped combined crystallizer provided by the invention prevents center parts of the web plates from being influenced and damaged by stress caused by rapid cooling, so that the web plates of blank casings are cooled evenly, and the solidification quality of the cast blanks is improved.

Owner:LAIWU IRON & STEEL GRP

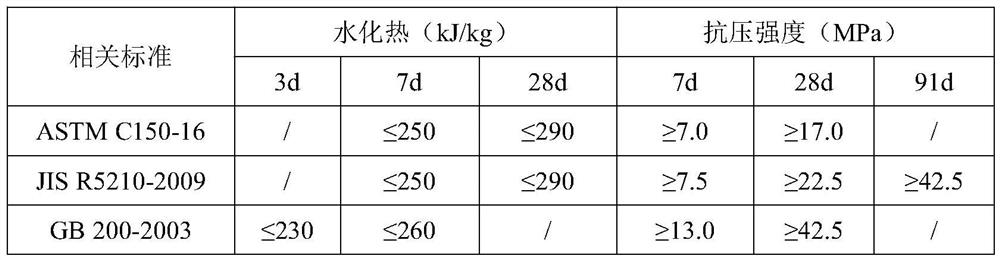

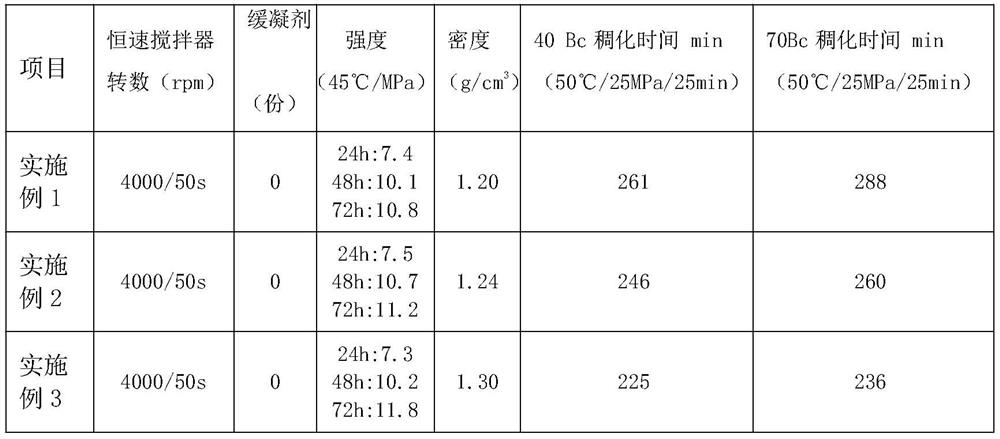

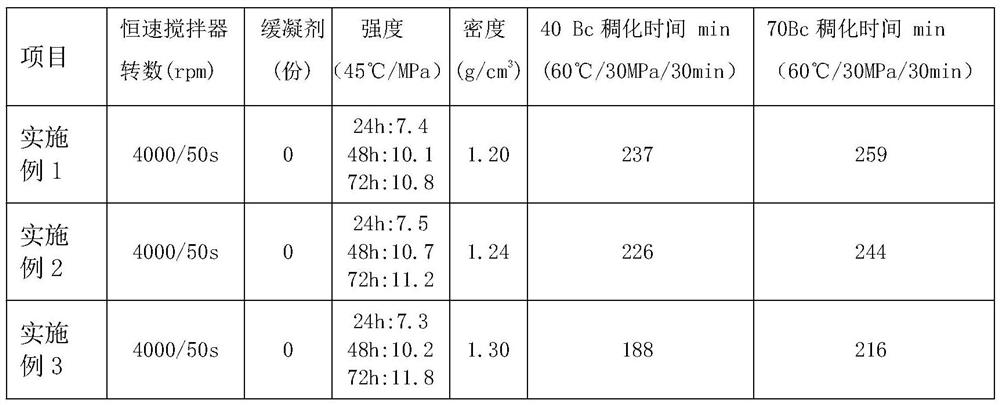

High-strength low-hydration-heat low-density cement paste system for well cementation, and preparation method thereof

ActiveCN112707709AReduce distractionsHigh strengthSolid waste managementDrilling compositionSodium metasilicateSodium sulfate

The invention provides a high-strength low-hydration-heat low-density cement paste system for well cementation, and a preparation method thereof. The high-strength low-hydration-heat low-density cement paste system comprises, in parts by weigh, 25-35 parts of low-hydration-heat Portland cement, 20-25 parts of glass beads, 25-30 parts of slag powder, 8-10 parts of silica fume, 3-5 parts of calcined gypsum, 1-2 parts of sodium sulfate, 1-2 parts of quick lime, 2-3 parts of slaked lime, 2-3 parts of sodium metasilicate, 0.5-1.5 parts of sodium carbonate and 65-75 parts of water. Admixtures such as a retarder, a fluid loss agent and a drag reducer can be added into the system as required. The prepared cement paste system is low in density (1.20-1.30 g / cm<3>), and it is ensured that a wellbore annulus is completely sealed through one-time upward returning; the strength of the system is high (the strength at a normal pressure and a temperature of 45 DEG C within 24 h or within 48 h is larger than 7 or 10 MPa), and a sleeve can be better supported; and the cement paste system is suitable for cementing operation of oil and gas wells within a temperature range of 50-90 DEG C. The performance conflict between a retarder and a coagulation accelerating activator used in an existing cement paste system is eliminated, the thickening time of the system is convenient and adjustable, and the well cementation quality of oil and gas wells is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

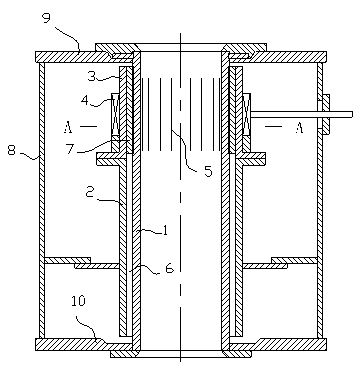

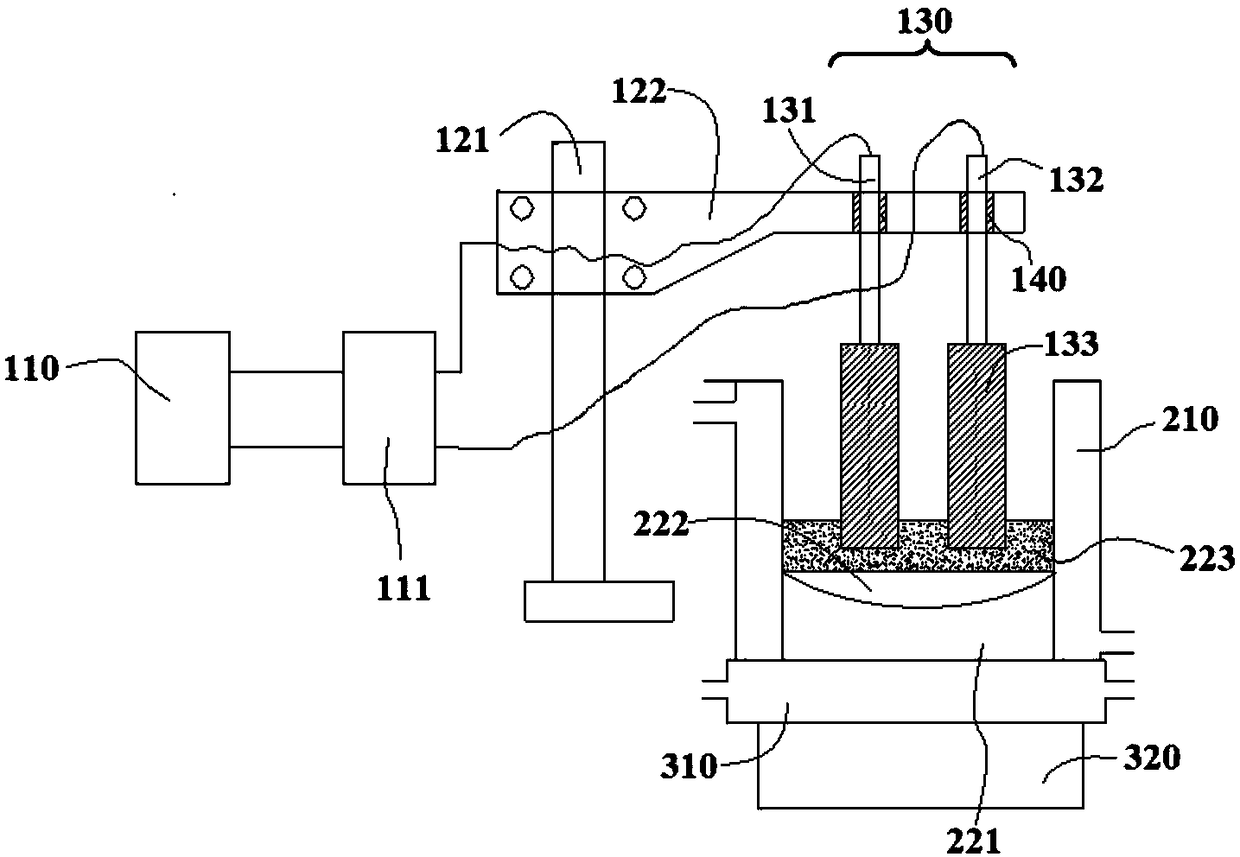

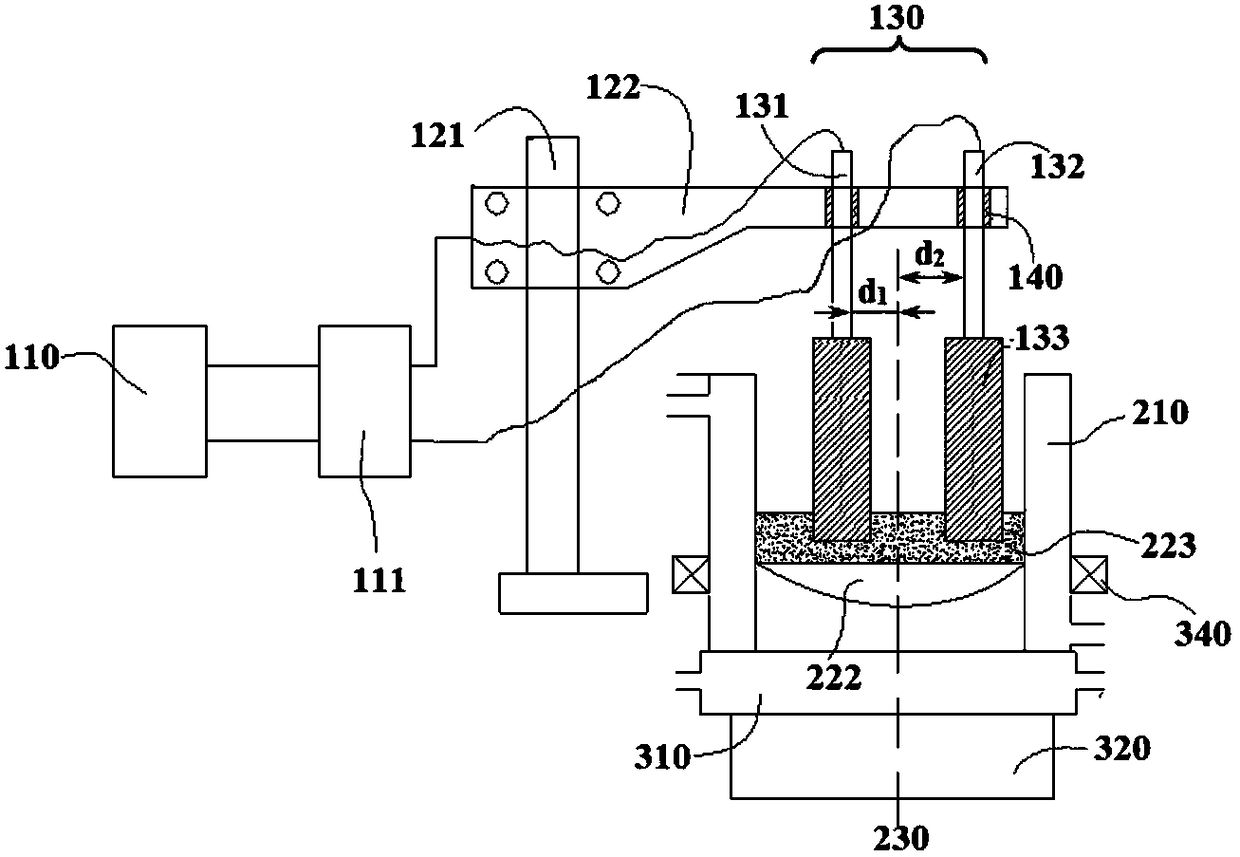

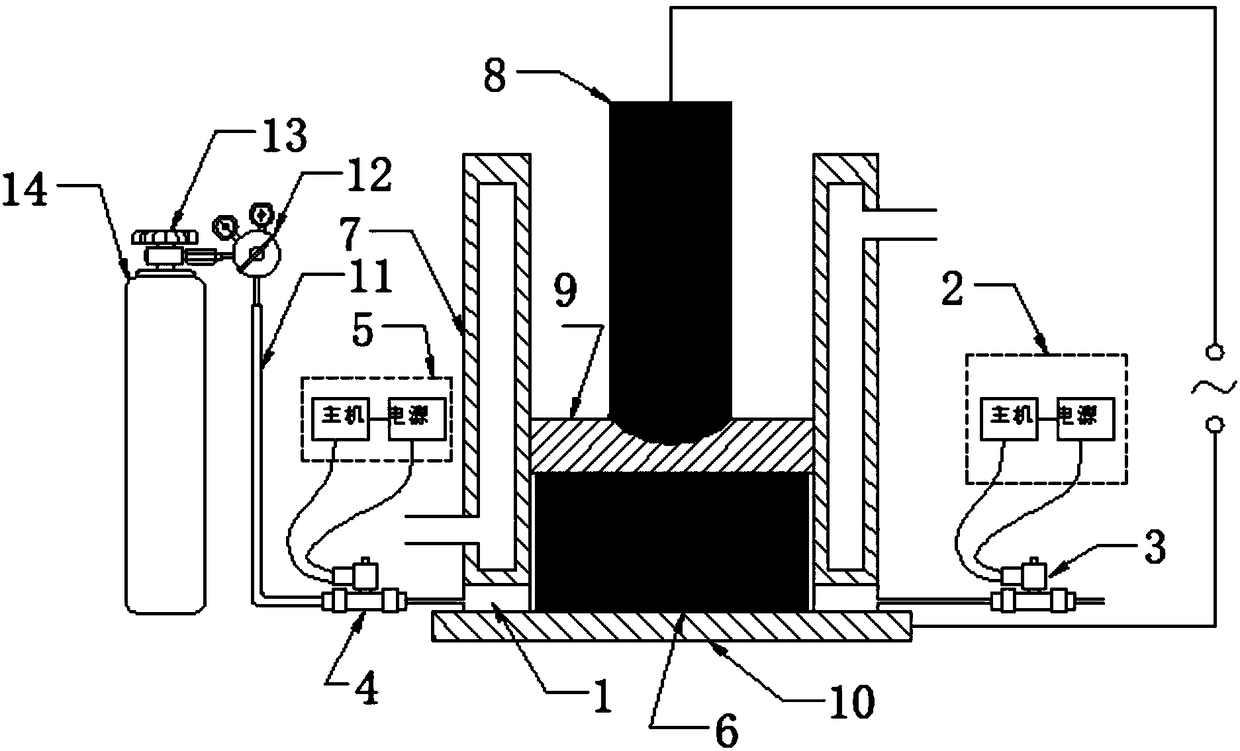

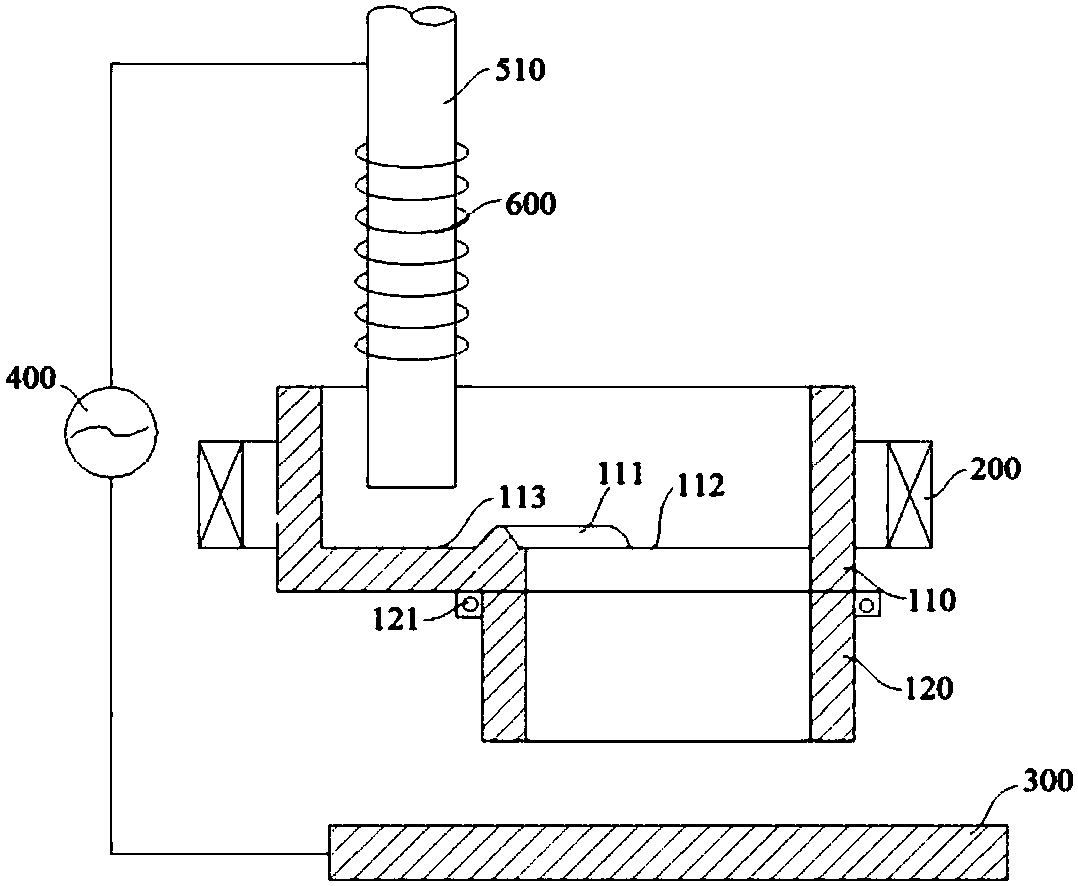

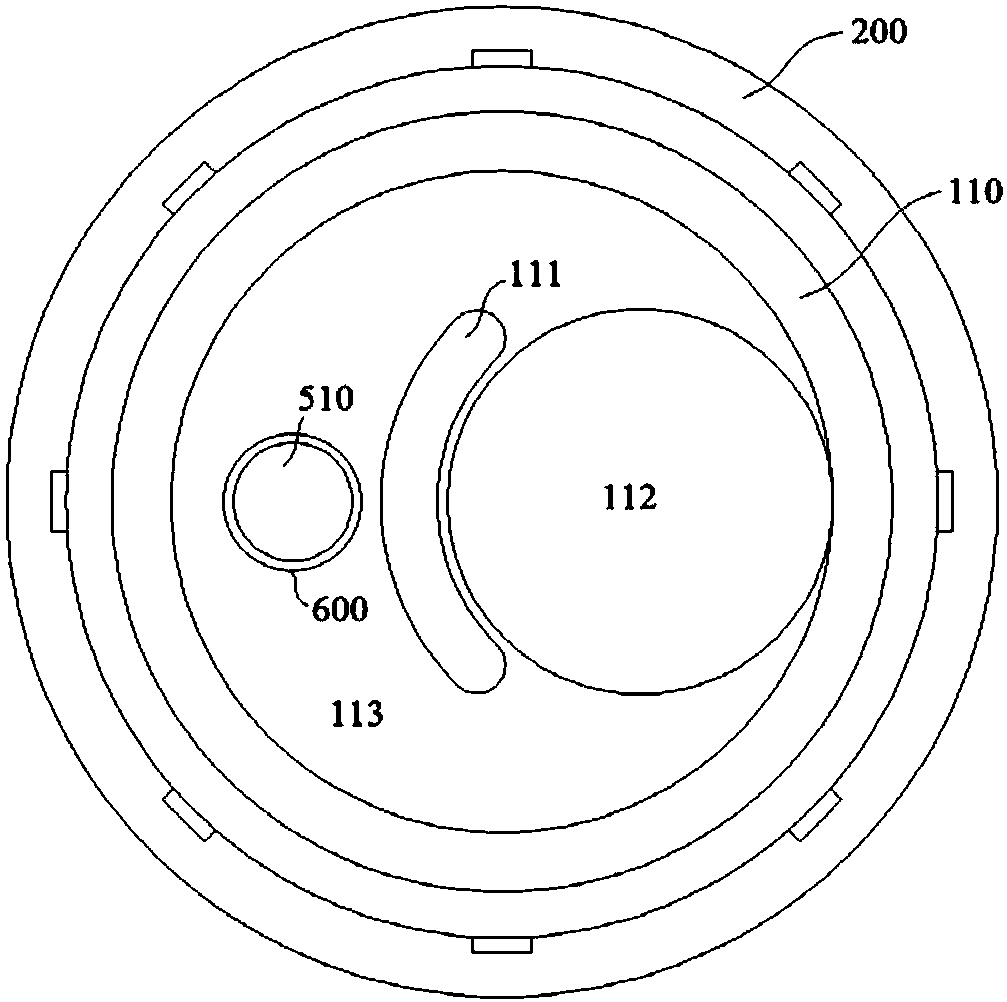

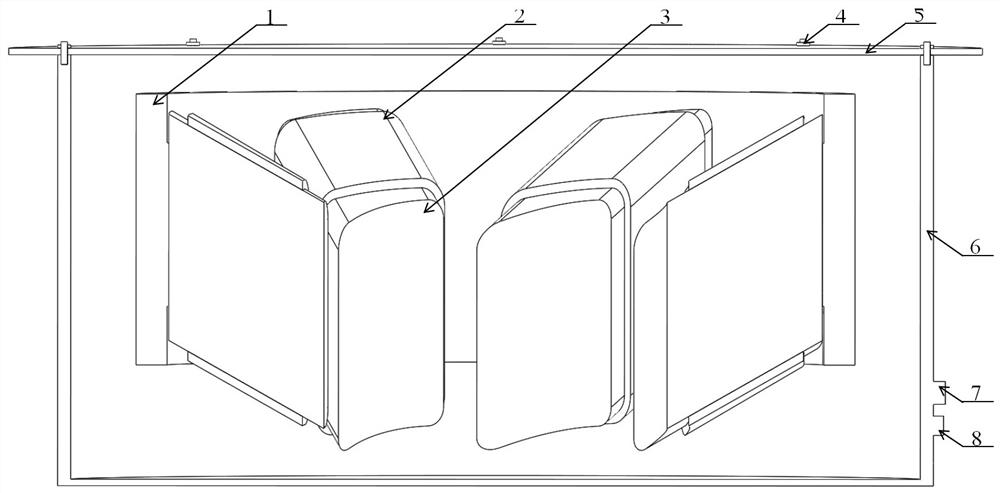

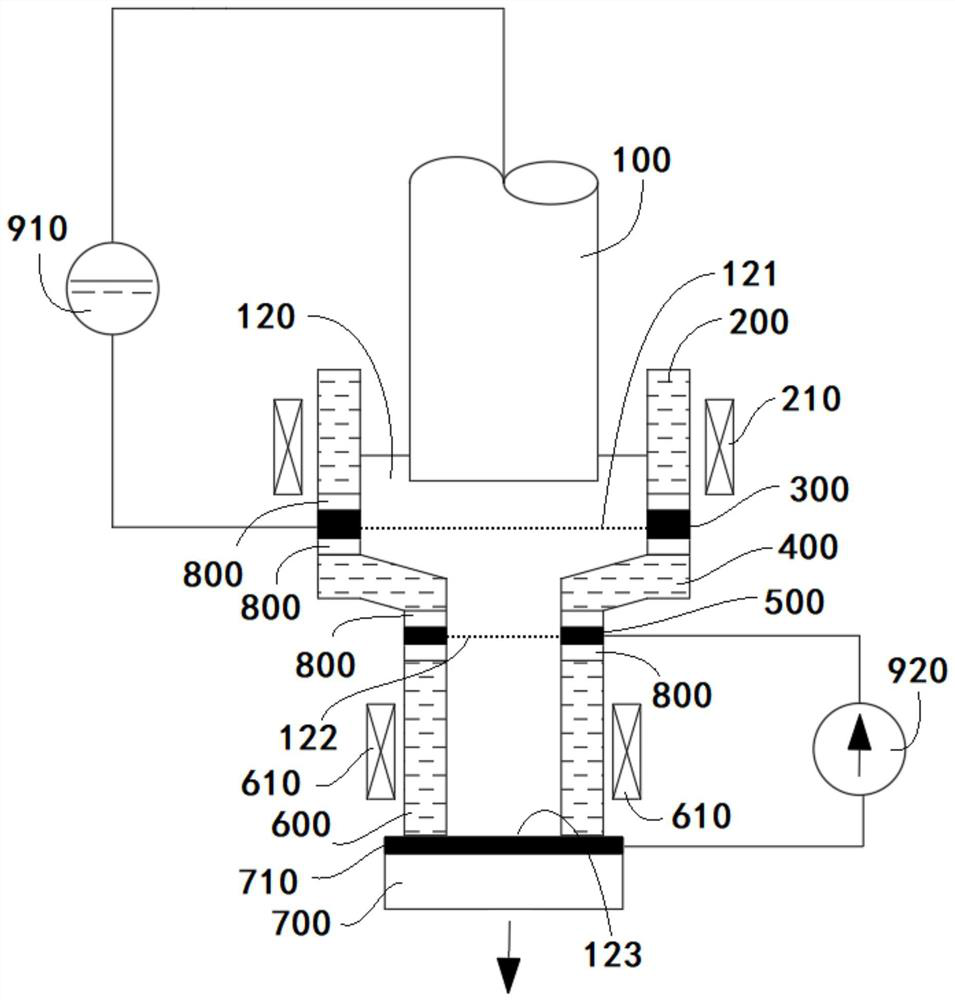

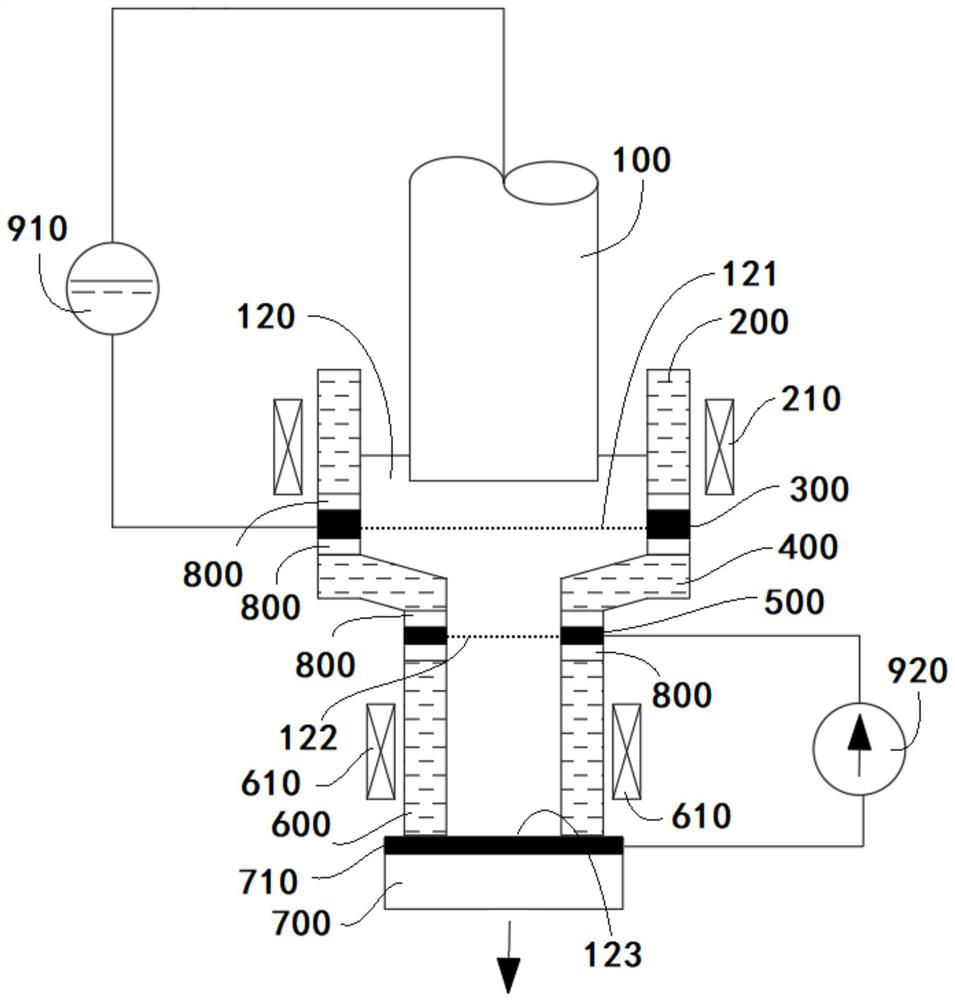

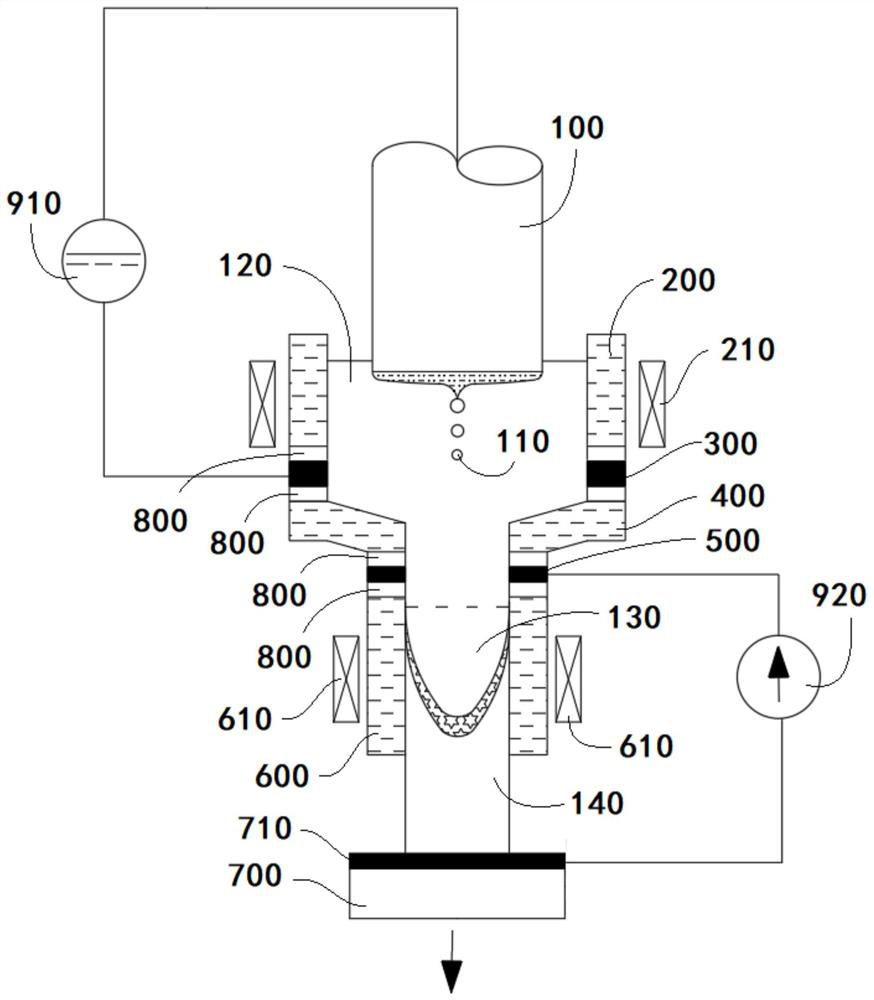

Equipment and method for improving solidifying quality of electroslag steel and reducing element segregation

ActiveCN109136582AImprove solidification qualityImprove cooling effectAdditive ingredientCooling effect

The invention discloses a piece of equipment and a method for improving the solidifying quality of electroslag steel and reducing the element segregation. The equipment comprises a gas supply system,a looped pipeline system and a smelting system; the gas supply system comprises a gas storage cylinder, a reducing valve, a voltage stabilizer and a gas guide pipe; the looped pipeline system comprises a gas inlet end electromagnetic valve, a gas inlet end electromagnetic valve controller, a looped pipeline, a gas outlet end electromagnetic valve and a gas outlet end electromagnetic valve controller; the smelting system comprises a crystallizer, and a bottom plate is arranged at the bottom part of the crystallizer; the gas guide pipe and the looped pipeline are connected; and the looped pipeline system is fitted between the crystallizer and the bottom plate, or embedded in the crystallizer, or embedded in the bottom plate. The method is as follows: when a gap is formed between an ingot andthe crystallizer because of the ingot formed in a molten pool in the smelting, the looped pipeline system is used to introduce helium into the gap from the bottom part of the crystallizer, and the relatively strong thermal conductance of the helium is used to improve the cooling effect of cooling water on the ingot, so that the high-quality electroslag steel even in ingredients and relatively high in solidifying quality is obtained.

Owner:NORTHEASTERN UNIV

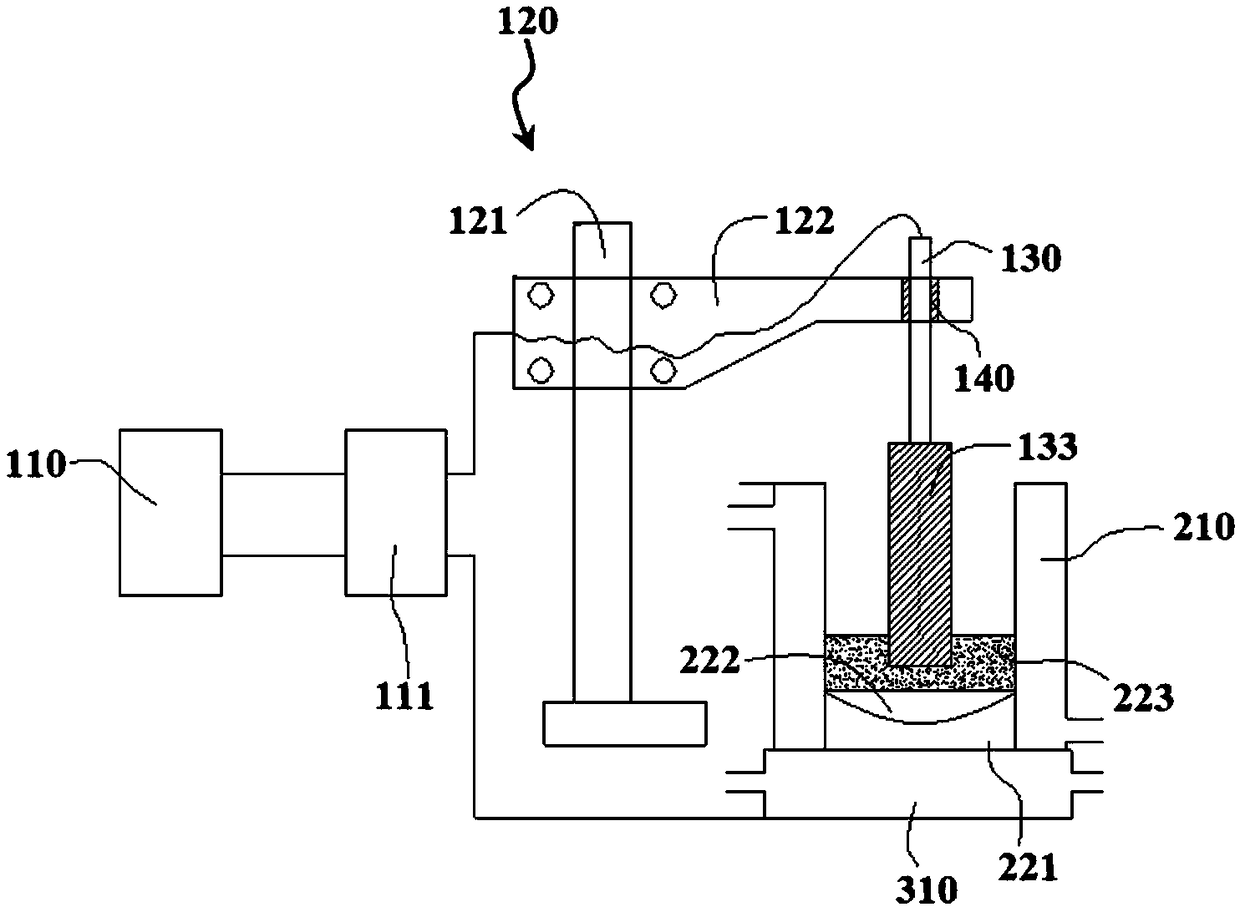

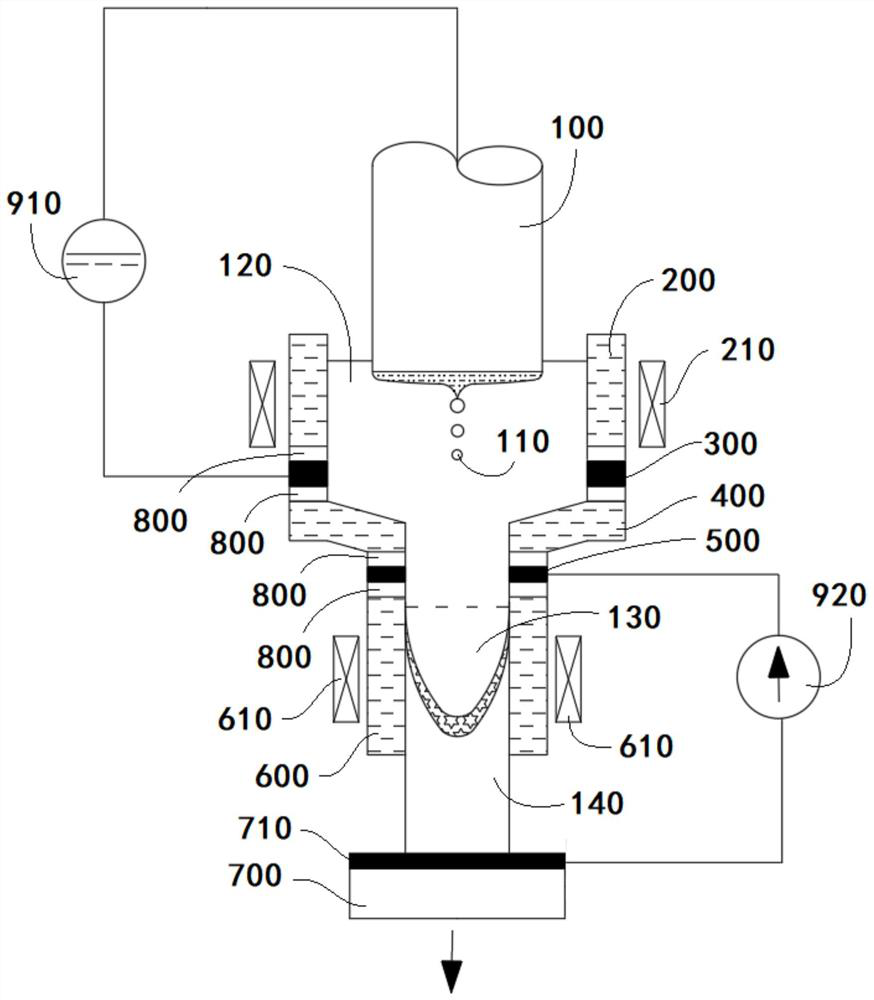

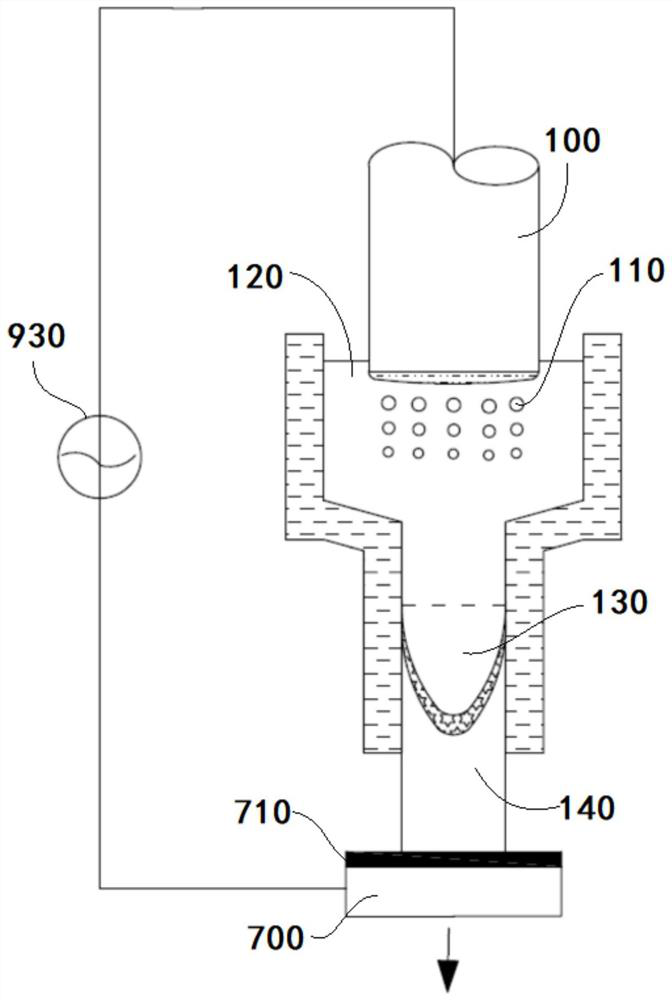

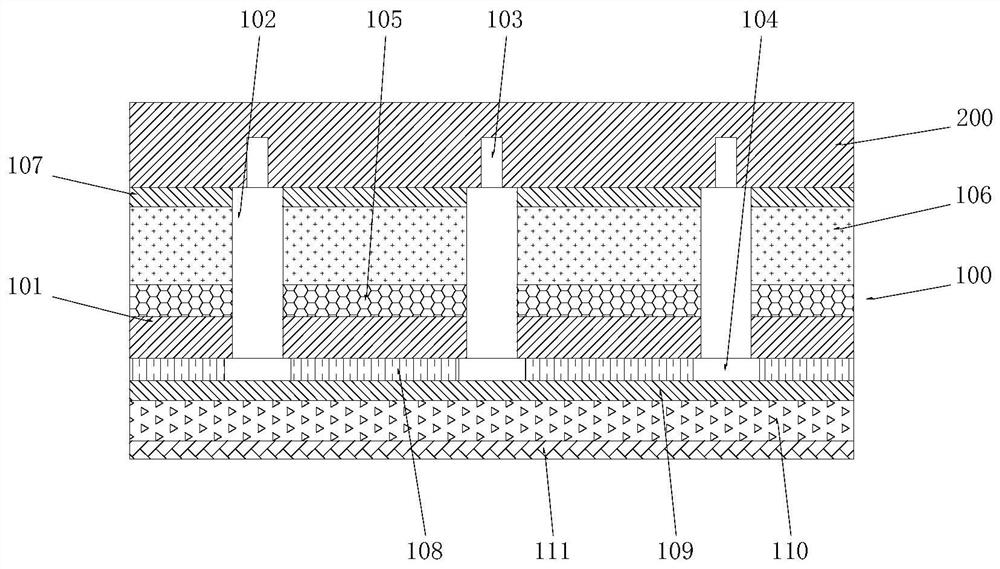

Melting device for improving solidification quality of electroslag re-melting steel ingot

The invention discloses a melting device for improving the solidification quality of an electroslag re-melting steel ingot and belongs to the technical field of electroslag re-melting. The melting device comprises a pulse power supply, a melting crystallizer, a metal electrode and a bottom water tank, wherein the bottom water tank is arranged at the bottom of the melting crystallizer, the interiorof the melting crystallizer is used for accommodating a metal molten pool and an electroslag layer; a metal electrode is inserted inside the melting crystallizer, consumable metal at the bottom of the metal electrode is inserted in the electroslag layer, a positive electrode of the pulse power supply is connected with the metal electrode, and a negative electrode of the pulse power supply is connected with the bottom water tank. The melting device disclosed by the invention has the benefits that the positive electrode of the pulse power supply is connected with the metal electrode, and the negative electrode of the pulse power supply is connected with the bottom water tank; the pulse power supply applies pulse current to the metal molten pool and generates weak disturbance to the molten metal pool, so that the uniformity of a temperature field of the molten metal pool can be promoted. Therefore, the characteristic similar to directional solidification growth is realized, and the solidification quality of the steel ingot is improved.

Owner:MAANSHAN HUASHENG METALLURGICAL SCI & TECH DEV

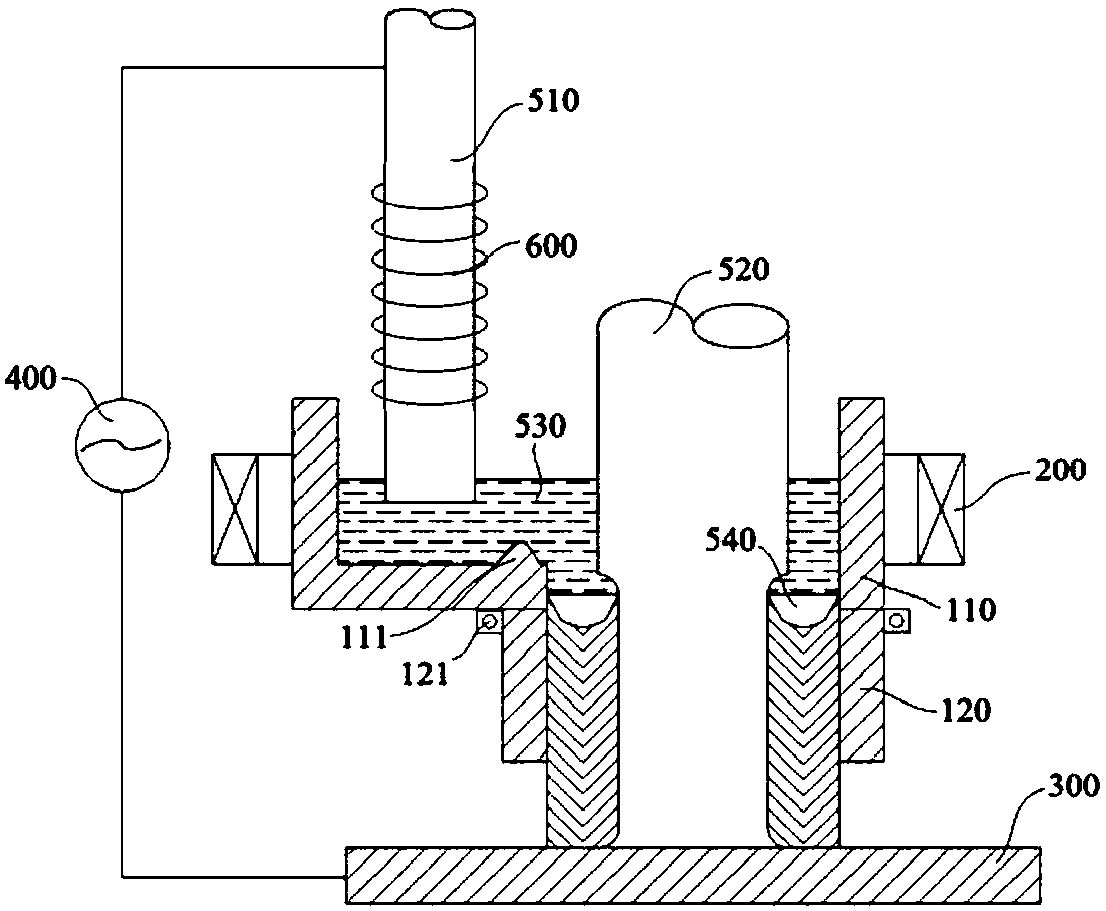

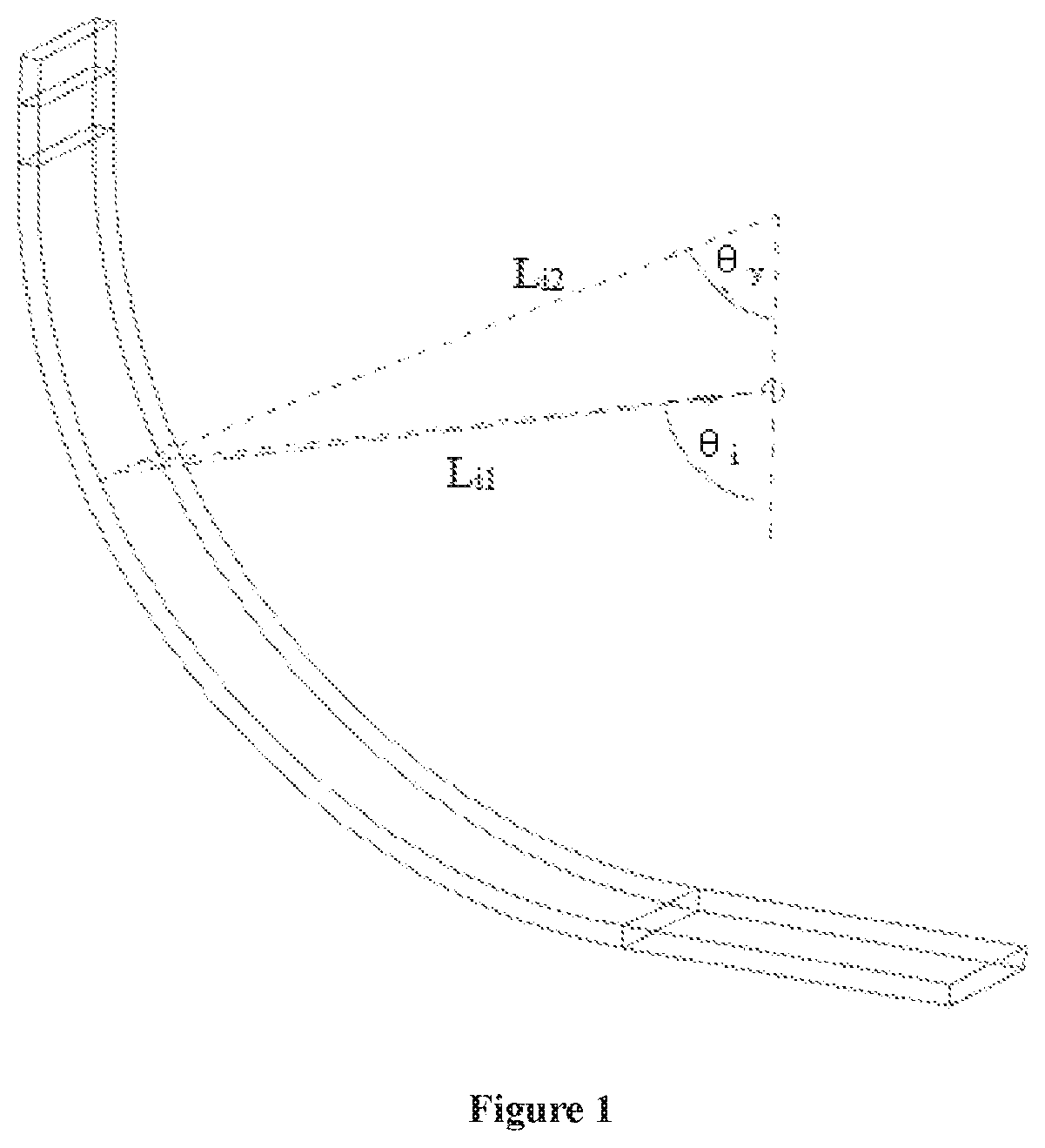

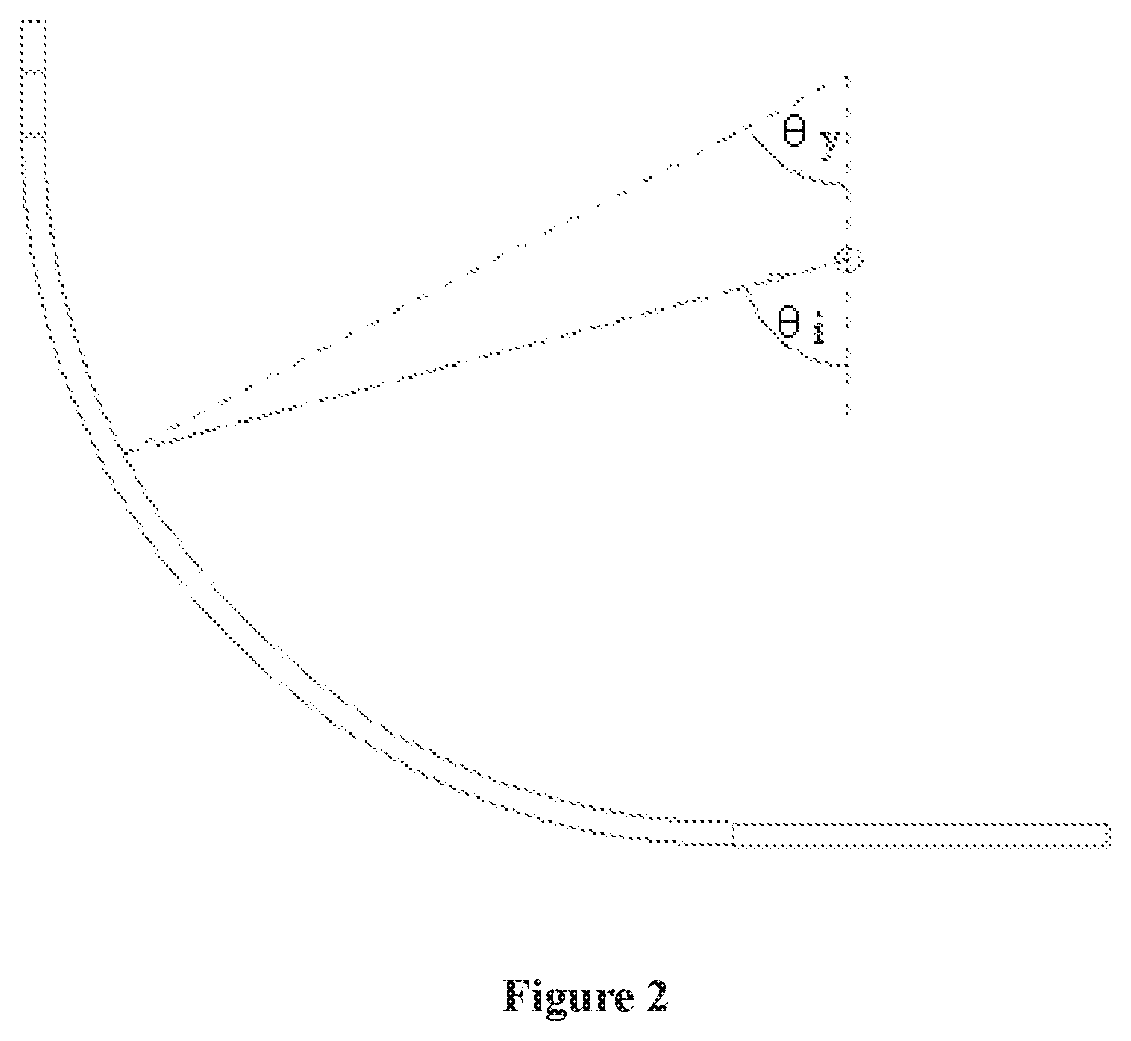

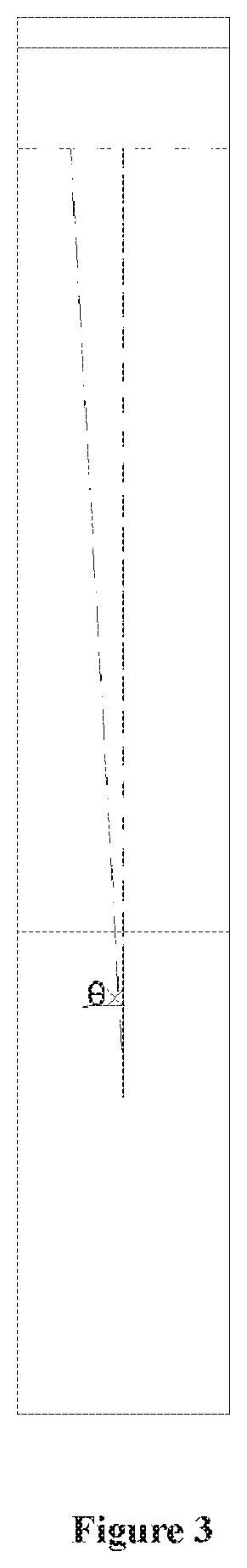

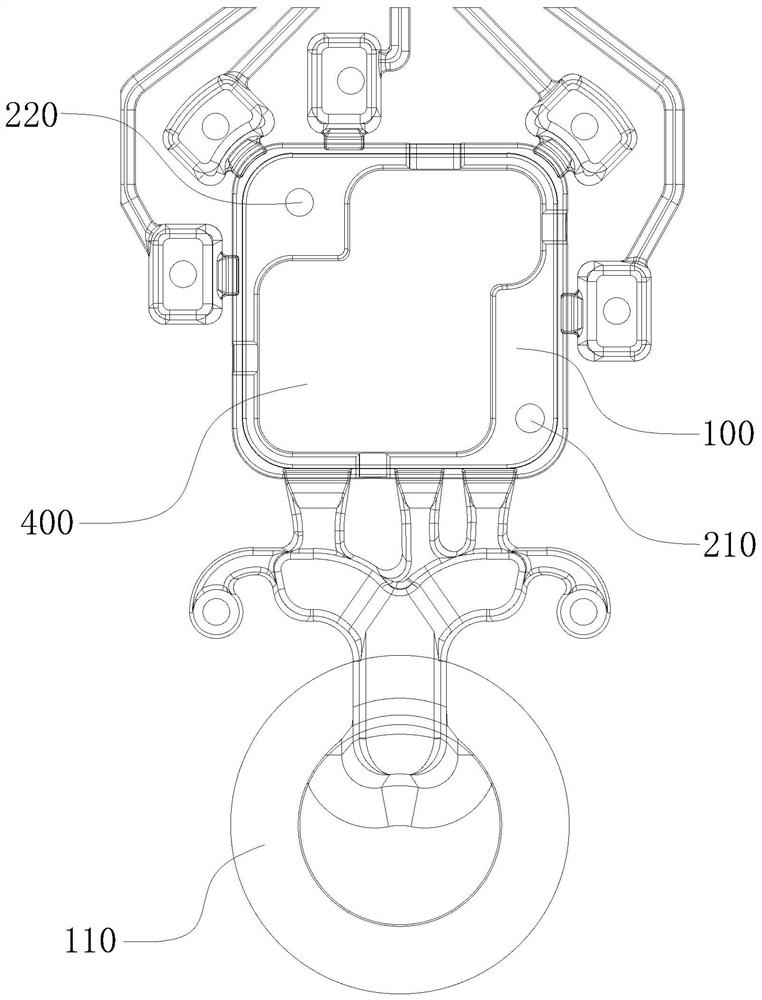

Electroslag remelting device for producing composite roll by preheating consumable electrode and method of electroslag remelting device

The invention discloses an electroslag remelting device for producing a composite roll by preheating a consumable electrode and a method of the electroslag remelting device, belonging to the technicalfield of electroslag remelting. The electroslag remelting device comprises an eccentric type crystallizer, a bottom water tank and a metal consumable electrode, wherein the eccentric type crystallizer comprises an upper crystallizer and a lower crystallizer, the diameter of the lower crystallizer is smaller than that of the upper crystallizer, the lower crystallizer is arranged at the lower partof the upper crystallizer, and the axle centers of the upper crystallizer and the lower crystallizer are not located on the same straight line; and the metal consumable electrode is arranged at the upper part of the upper crystallizer, the bottom water tank is arranged at the lower part of the lower crystallizer, and the metal consumable electrode and the bottom water tank are respectively connected with two poles of the power supply. By utilizing an eccentric design of the electroslag remelting device, the thickness of the material of a working surface can be flexibly adjusted; the metal consumable electrode is externally wound with an induction coil and can be preheated in the remelting process, so that the melting of the electrode is accelerated, the substantial melting of surface layers of a roll core is avoided, and the roll core and a roll body are effectively welded.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A system for on-line measuring the thickness of a continuous casting billet and adjusting a rolling reduction amount

PendingUS20210086243A1Accurate and constant and rapid feedbackMaximize functionalityUsing optical meansMetal rolling arrangementsMetallurgyMechanical engineering

A system for on-line measuring the thickness of a continuous casting billet and adjusting a rolling reduction amount, is capable of giving an accurate, constant and rapid feedback on the thickness of the billet in the continuous casting process online, avoiding the deviation of the rolling reduction amount of the billet in the continuous casting production process which is triggered by the factors such as the capacity of the continuous casting equipment, the execution deviation of the rolling reduction process, the metal solidification attribute such as non-preset expansion and contraction, so as to maximize the function of the continuous casting rolling reduction and improve the solidification quality of the billet.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

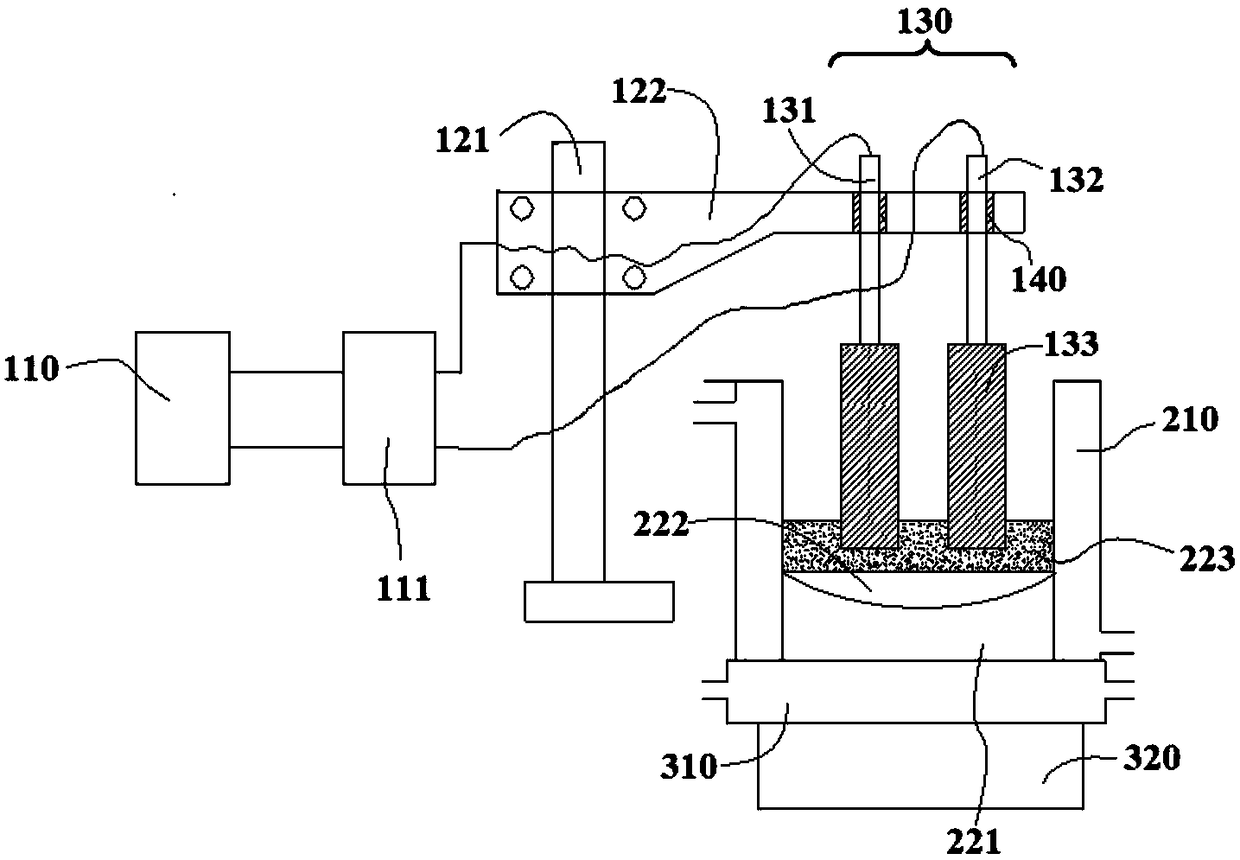

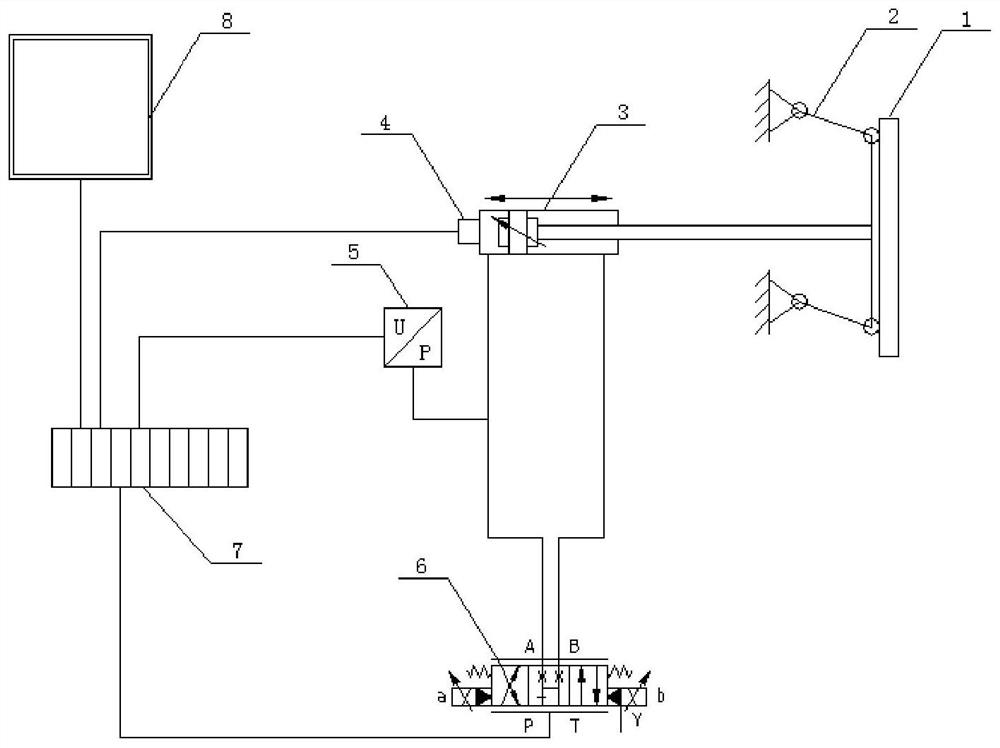

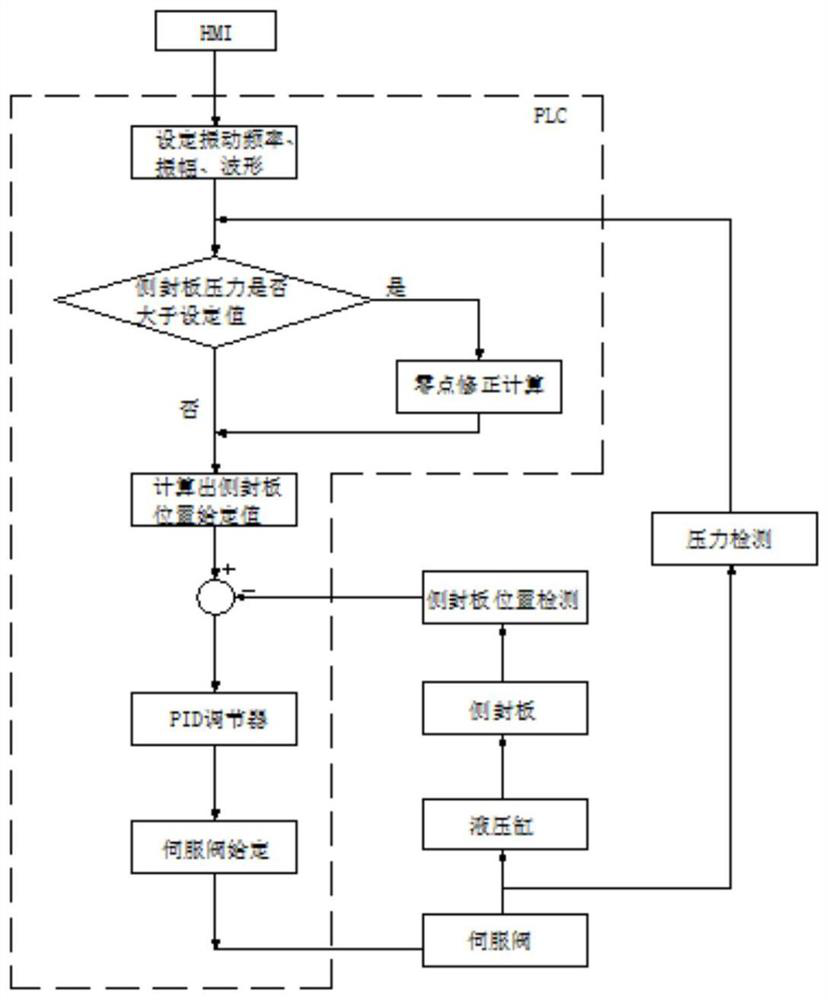

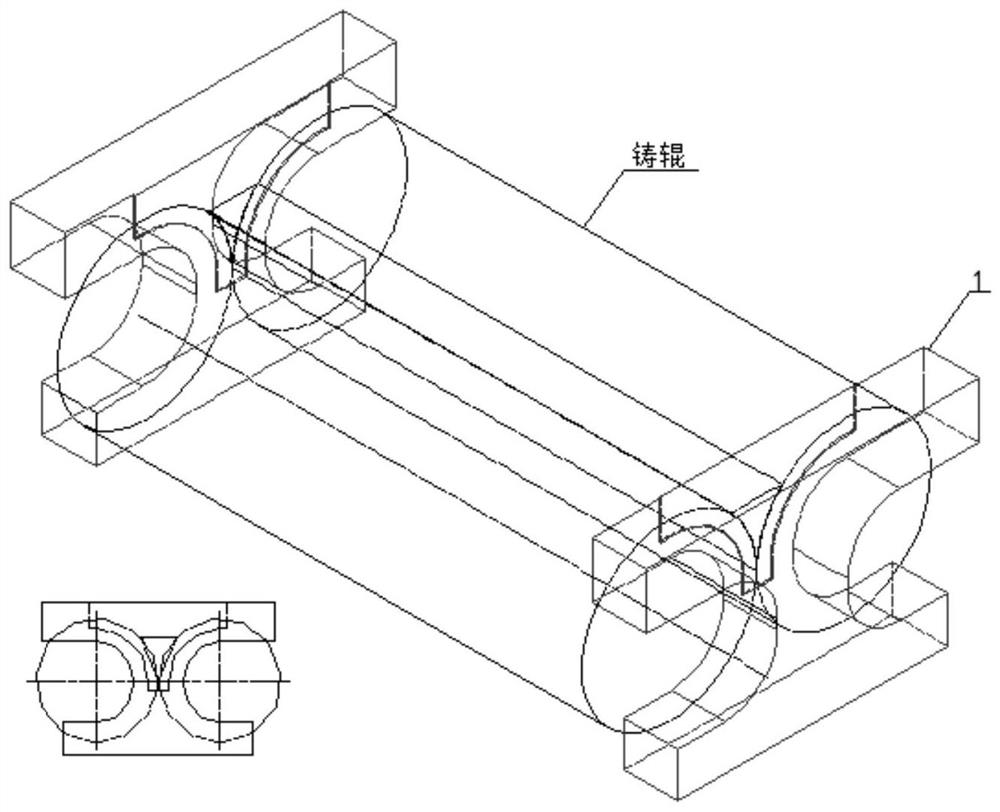

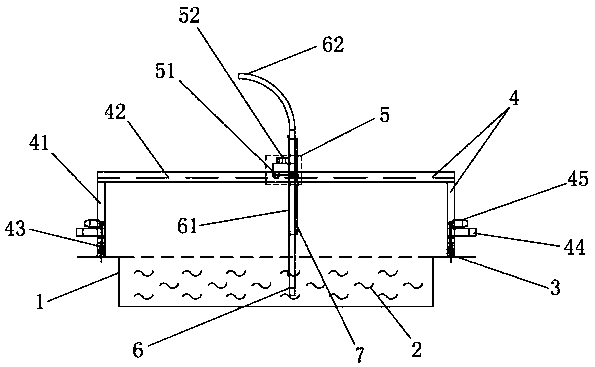

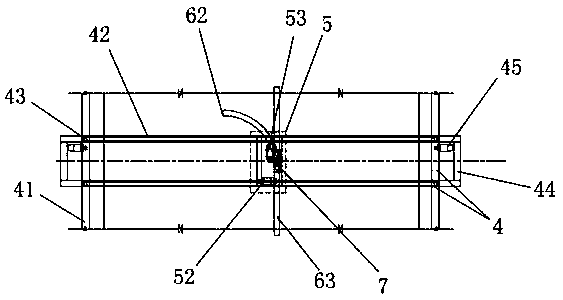

Adaptive control device for double-roll thin-strip continuous casting casting-roll side sealing plate

The invention provides a novel control method of the vibration of a double-roll thin-strip continuous casting casting-roll side sealing plate. Side sealing plate vibration self-adaptive control equipment is composed of side sealing plates, a four-bar linkage, a hydraulic cylinder, a servo valve, a displacement sensor, a proximity switch, a pressure sensor, a programmable controller (PLC), a human-machine interface (HMI) and the like. In a continuous casting process, two casting rolls and two side sealing plates located on the end surfaces of the casting rolls form a molten pool, and molten steel is poured in and condensed into strip steel to be sent out of the molten pool through the rotation of the casting rolls and cooling. Through the reciprocating movement of the side sealing plates, the molten steel on the end surfaces of the casting rolls and the condensed steel strip are beaten, the vibration force generated by the beating can improve the condensing quality of the strip steel, through adaptive control, gaps between the side sealing plates and the end surfaces of the casting rolls are guaranteed, the friction between the side sealing plates and the end surfaces of the castingrolls is reduced, and the service life of the casting rollers and the side sealing plates is prolonged.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

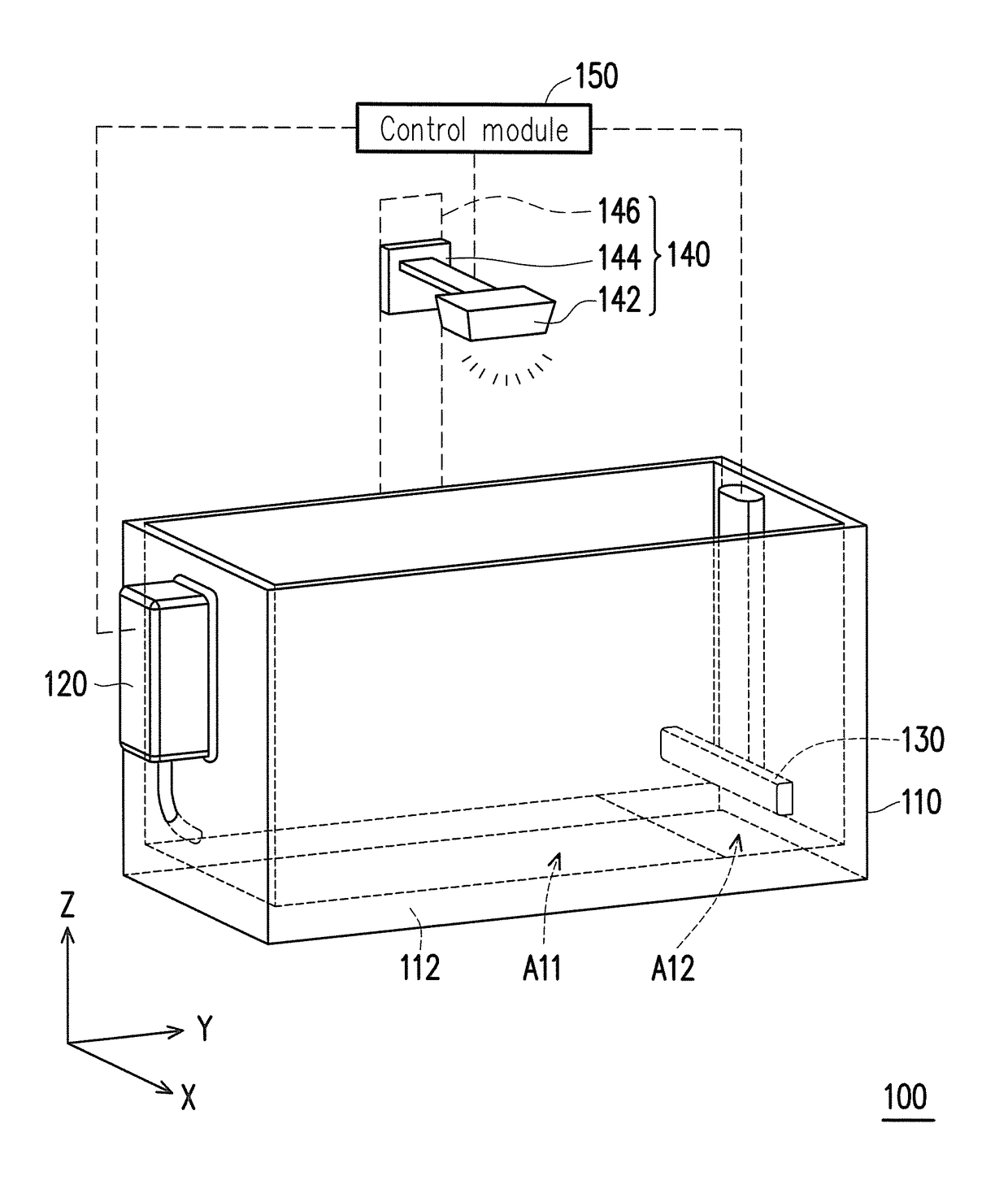

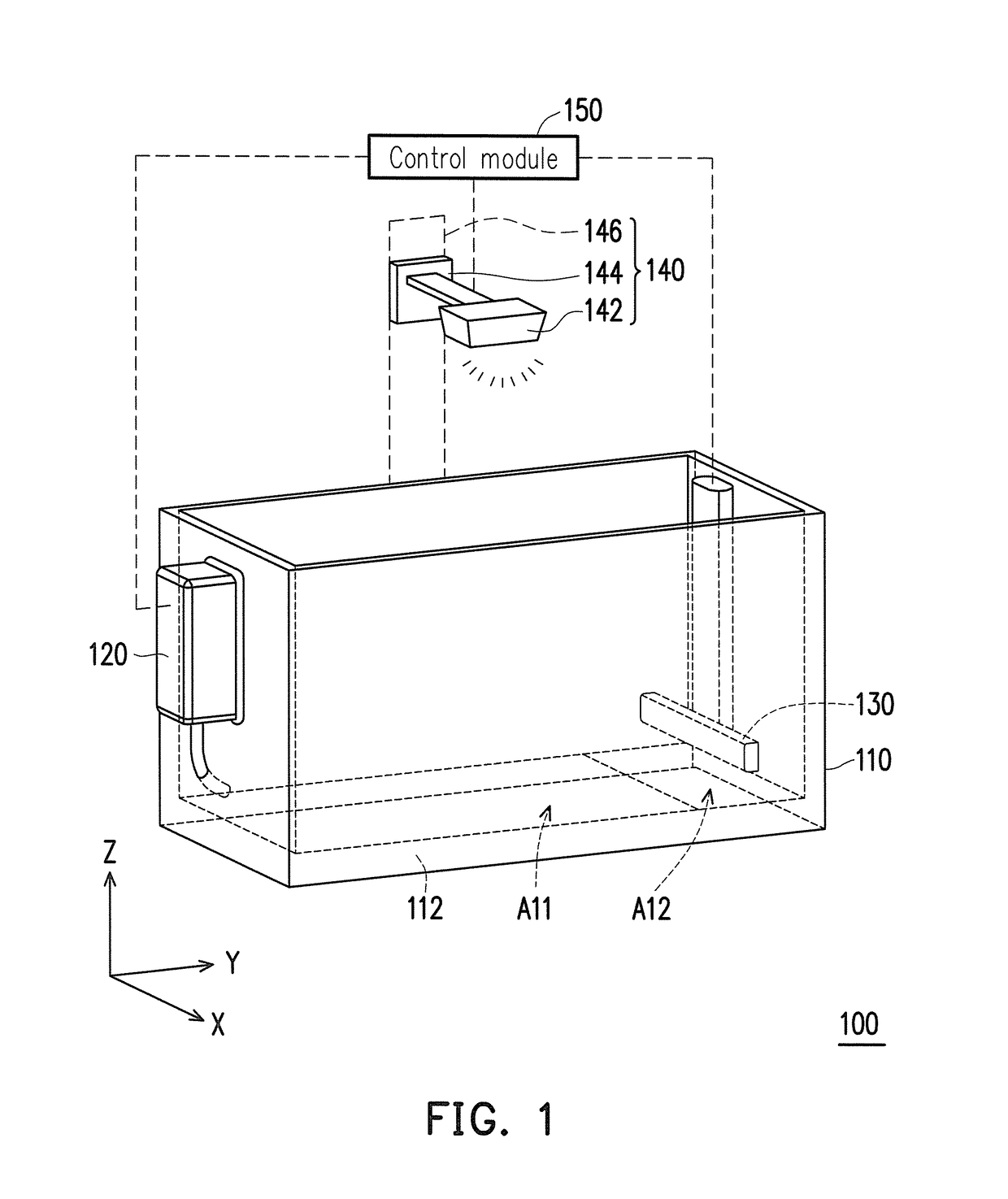

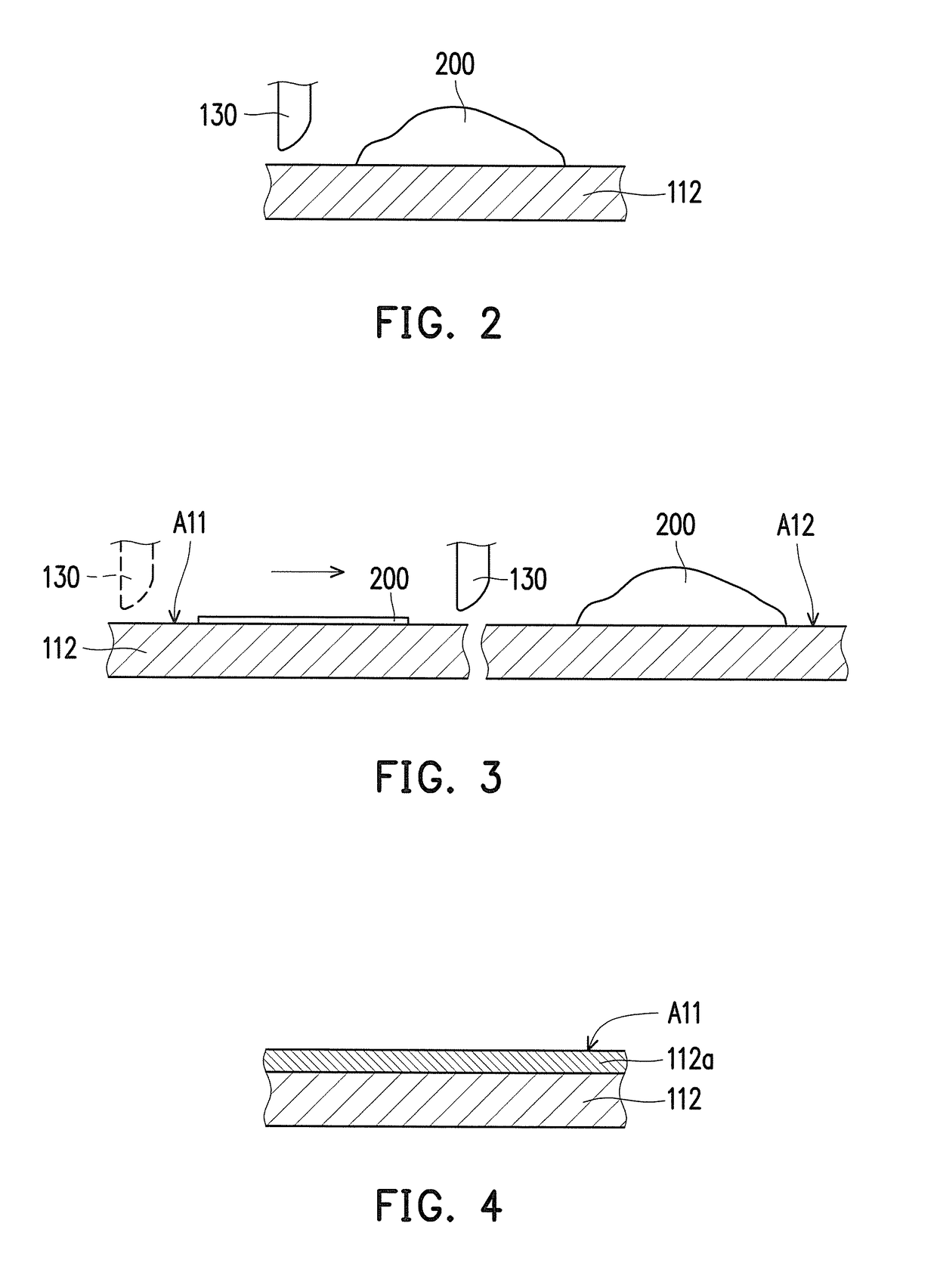

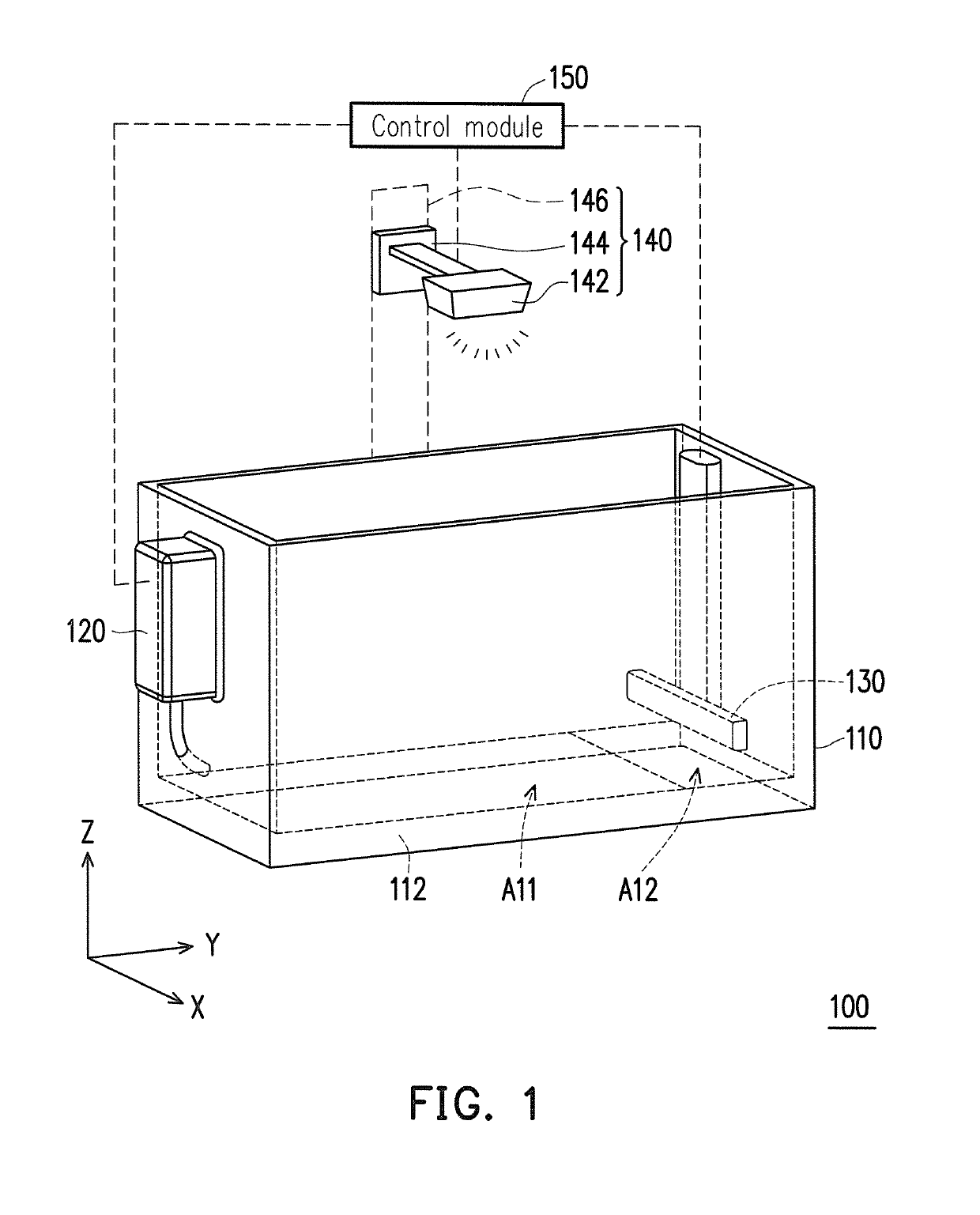

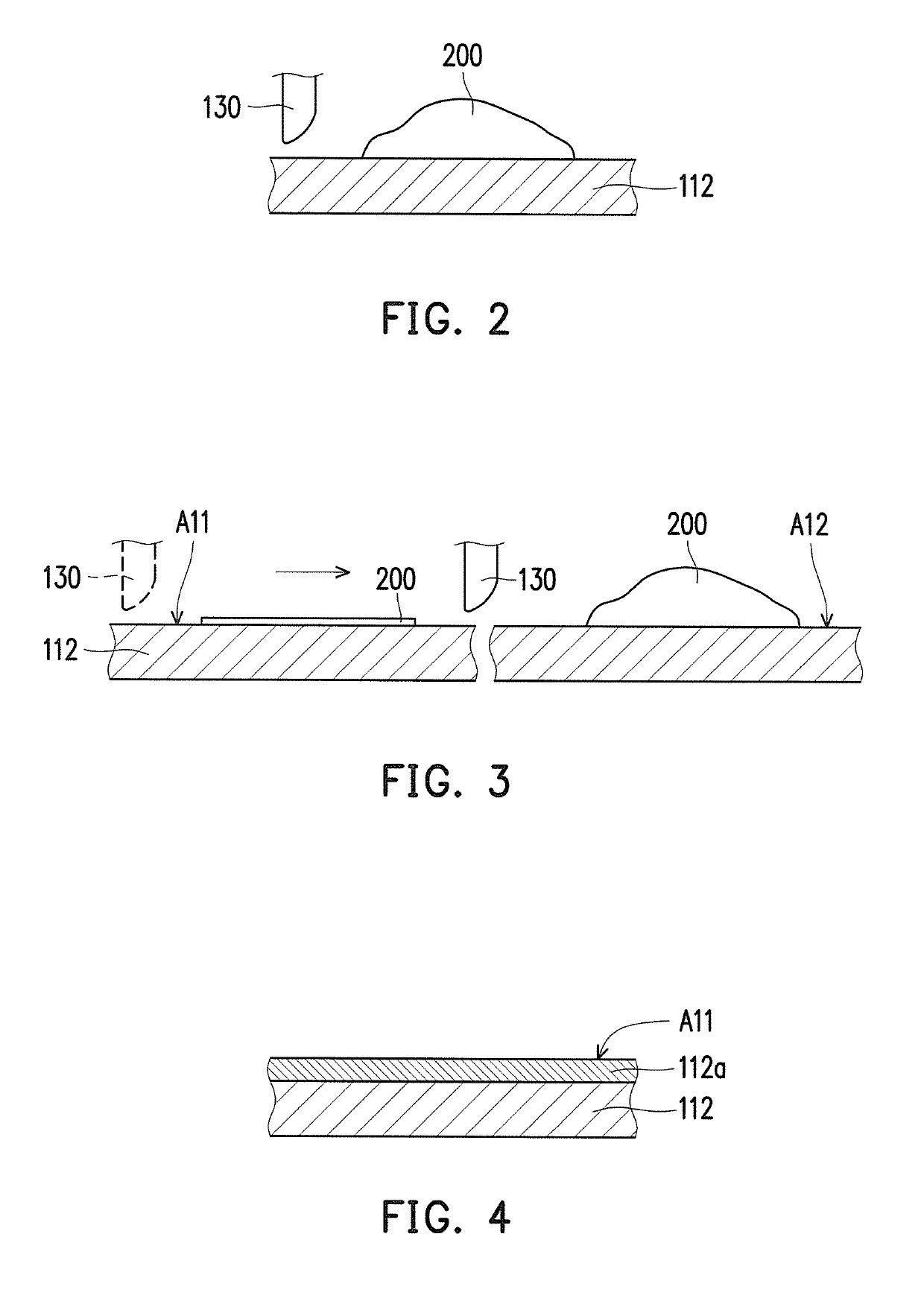

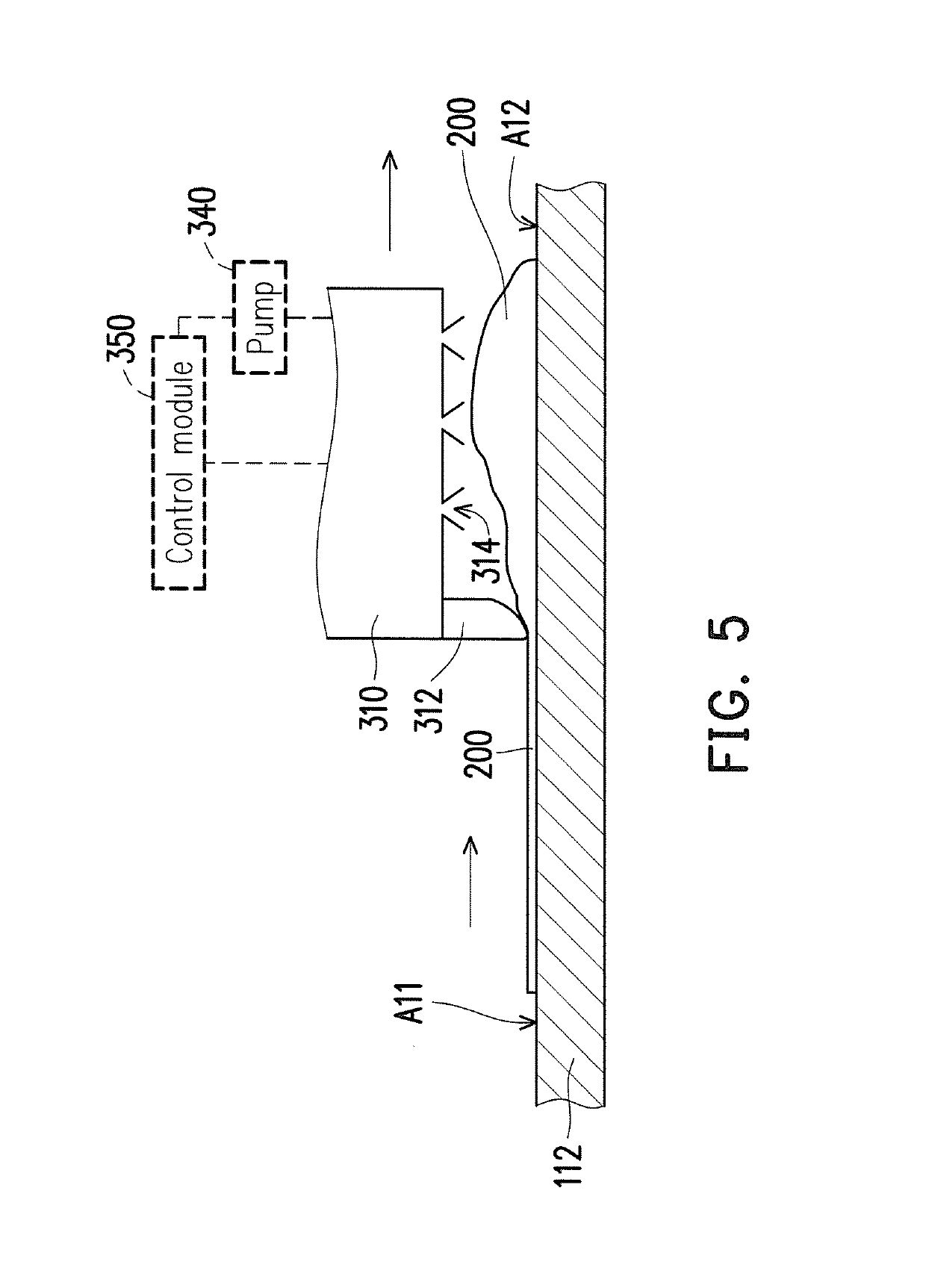

Three dimensional printing apparatus

InactiveUS20180236721A1Improve solidification qualityImprove performanceAdditive manufacturing apparatusAdditive manufacturing with liquids3 dimensional printingMechanical engineering

Owner:XYZPRINTING +1

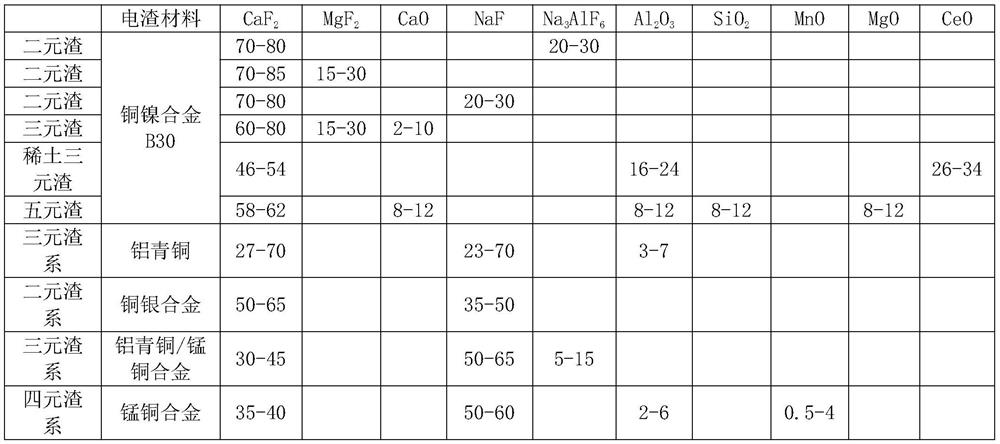

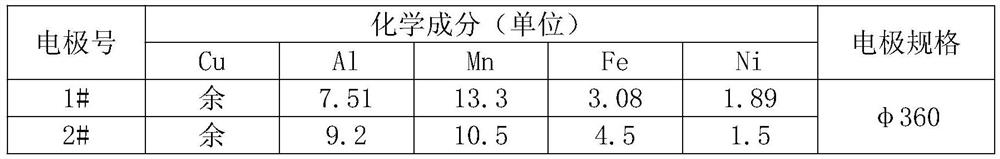

Smelting method of manganese-aluminum-iron-nickel bronze alloy

The invention provides a smelting method of a manganese-aluminum-iron-nickel bronze alloy ingot. The smelting method comprises the following steps: firstly, cleaning the defects of burnt-on sand and flash on the surface of a copper alloy electrode; then, the copper alloy electrode is connected to an electrode chuck through a welding or mechanical connection method, and the copper alloy electrode is baked to be completely dried; then, the slag materials of the CaF2-NaF-AlF3 ternary slag system or the CaF2-NaF-BaF2 ternary slag system are independently baked, and the slag materials obtained after baking are weighed according to the proportion and mixed to be uniform; the evenly-mixed slag materials are laid to the bottom in a crystallizer, and the slag materials are electrically polarized through graphite; electroslag remelting is conducted by exchanging the copper alloy electrode, inert atmosphere protection is conducted in the whole remelting process, power is cut off after electroslag remelting is completed, and the protective atmosphere is maintained for slow cooling; and finally, the crystallizer is removed, slag crust on the surface of the electroslag ingot is removed, and the manganese-aluminum-iron-nickel bronze alloy ingot is obtained. According to the method, the defects of air holes and segregation generated during casting of the manganese-aluminum-iron-nickel bronze alloy and the defect of high control difficulty can be effectively overcome, and production of high-homogeneity and low-microporosity cast ingots is achieved.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

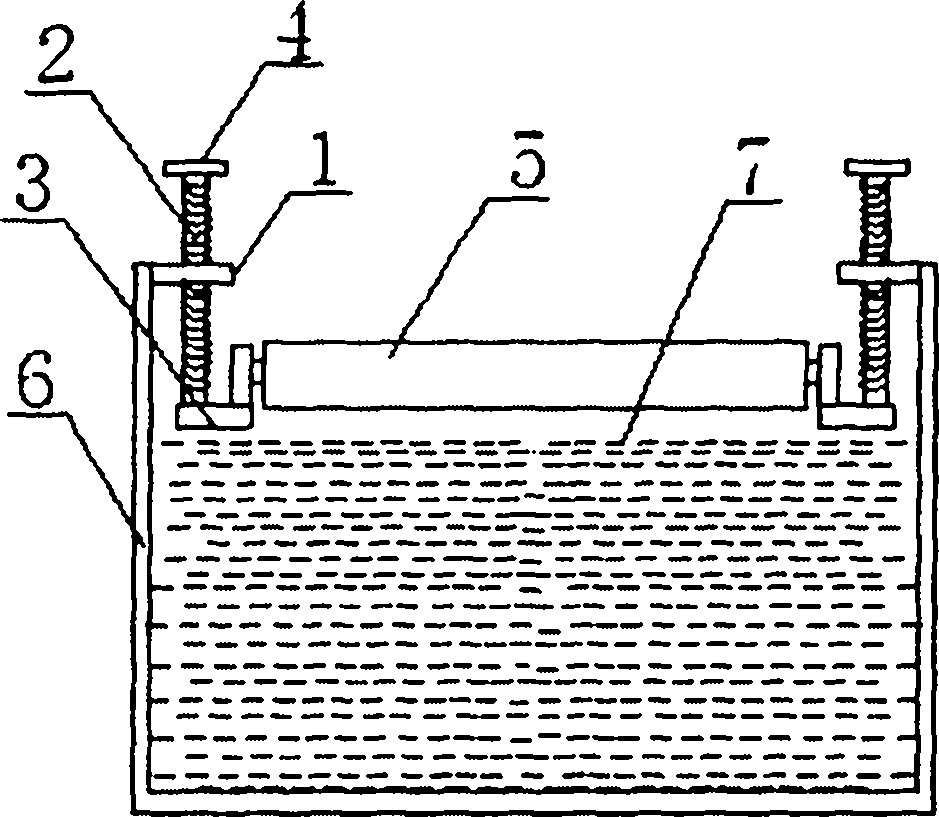

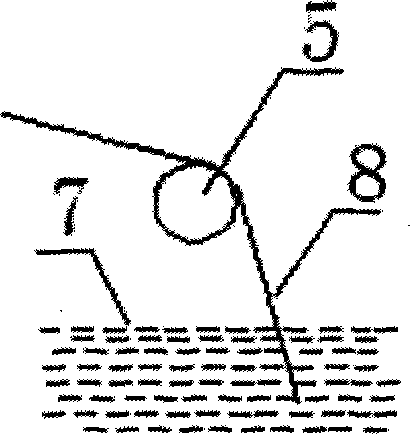

Bass water entry regulator based on wet method synthetic leather production line

The invention discloses a bass water entry regulator based on a wet method synthetic leather production line. The bass water entry regulator comprises support arms, lifting rods and bearing assemblies, wherein the support arms are correspondingly fixed on the upper edge of a solidification tank and provided with threaded holes with internal threads; the lifting rods are provided with external threads corresponding to the internal threads and penetrate through the threaded holes for being connected with the bearing assemblies; the bearing assemblies are connected with a guide roller; handles are arranged at the upper ends of the lifting rods. Via arranging the bass water entry regulator on the solidification tank, the water entry time and the water entry angle of bass can be conveniently regulated without parking, so that higher solidification quality is realized. The bass water entry regulator is simple in structure and convenient to operate.

Owner:山东众兴泽辉新材料股份有限公司

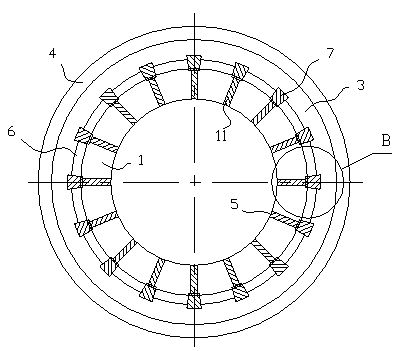

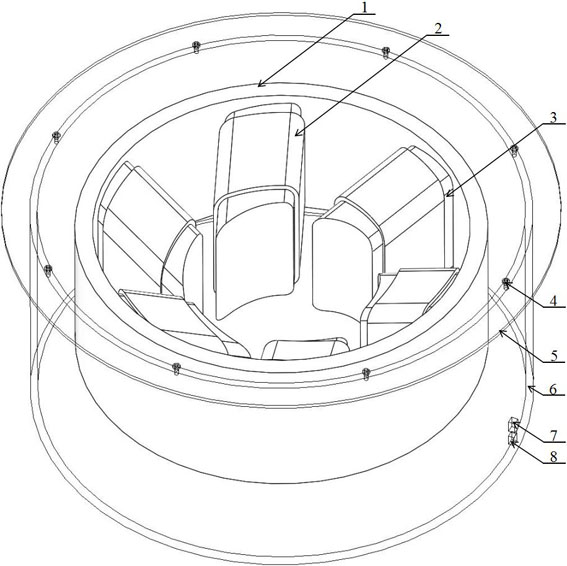

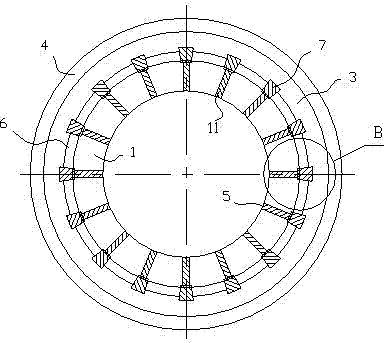

Side spiral electromagnetic stirring device

The invention belongs to the technical field of continuous casting and semi-continuous casting, and particularly relates to a side spiral electromagnetic stirring device which comprises a box body, amagnet yoke fixing plate arranged in the box body, a magnet yoke connected with the magnet yoke fixing plate, a coil wound outside the magnet yoke, a box body cover fixed at the top of the box body through a fixing bolt, a power supply device and a cooling device arranged at the side part of the box body, and is characterized in that the longitudinal inclination angle of a magnet yoke body rangesfrom -80 degrees to 80 degrees, the transverse inclination angle of the magnet yoke body ranges from -40 degrees to 40 degrees, the coil winding is arranged on the obliquely cut magnet yoke; and the end surface of the magnet yoke is parallel to the wall surface of the magnet yoke fixing plate. According to the side spiral electromagnetic stirring device provided by the invention, the flowing rangeof a circulation can be expanded, the flowability of molten metal in a casting blank is effectively improved, the grain structure is refined, the element segregation degree is reduced, metal feedingat the solidification tail end is promoted, and particularly, molten steel flowing, heat transfer solidification, solute segregation and other behaviors in the solidification process of the large-section continuous casting blank are directly affected, so that the solidification quality of a large-section casting blank core is improved.

Owner:UNIV OF SCI & TECH LIAONING

Multi-sprayer foam concrete spreading device and operation method

PendingCN108691417AEasy to operateGood fabric effectBuilding material handlingComplex mathematical operationsFoam concreteSprayer

The invention discloses a multi-sprayer foam concrete spreading device and operation method, and belongs to the field of foam concrete construction. The multi-sprayer foam concrete spreading device mainly comprises a moving frame, a mobile station, a spreading rod and the like; and is characterized in that 1, the number and inner diameters of sprayers can be selected from multiple schemes, the universality is high, the device is suitable for various types of foaming machines and delivery pumps, the flow velocity of foam concrete slurry is adjustable, and a best foam concrete spreading effect can be achieved; 2, the sprayers disperse the kinetic energy of the slurry intensively ejected from the tail end of a delivery hose, weaken the impact force, reduce the probability that multiple smallpores are communicated with one other to form big pores, and improve the compressive strength of foam concrete; 3, the mechanical automation degree is high, operators are reduced, the labor intensityis reduced, the sanitary conditions of environmental protection are improved, artificial disturbance is avoided, and the solidification quality of the foam concrete is improved. The multi-sprayer foamconcrete spreading device is combined with the corresponding operation method, so that the spreading efficiency and quality can be improved, energy is saved, emission is reduced, and the economic benefits and social benefits are significant.

Owner:NINGBO COMM ENG CONSTR GRP

Electromagnetic soft contact continuous casting crystallizer

ActiveCN102371348BGuaranteed electromagnetic permeabilityGuaranteed service lifeEngineering plasticEngineering

Owner:BAOSHAN IRON & STEEL CO LTD

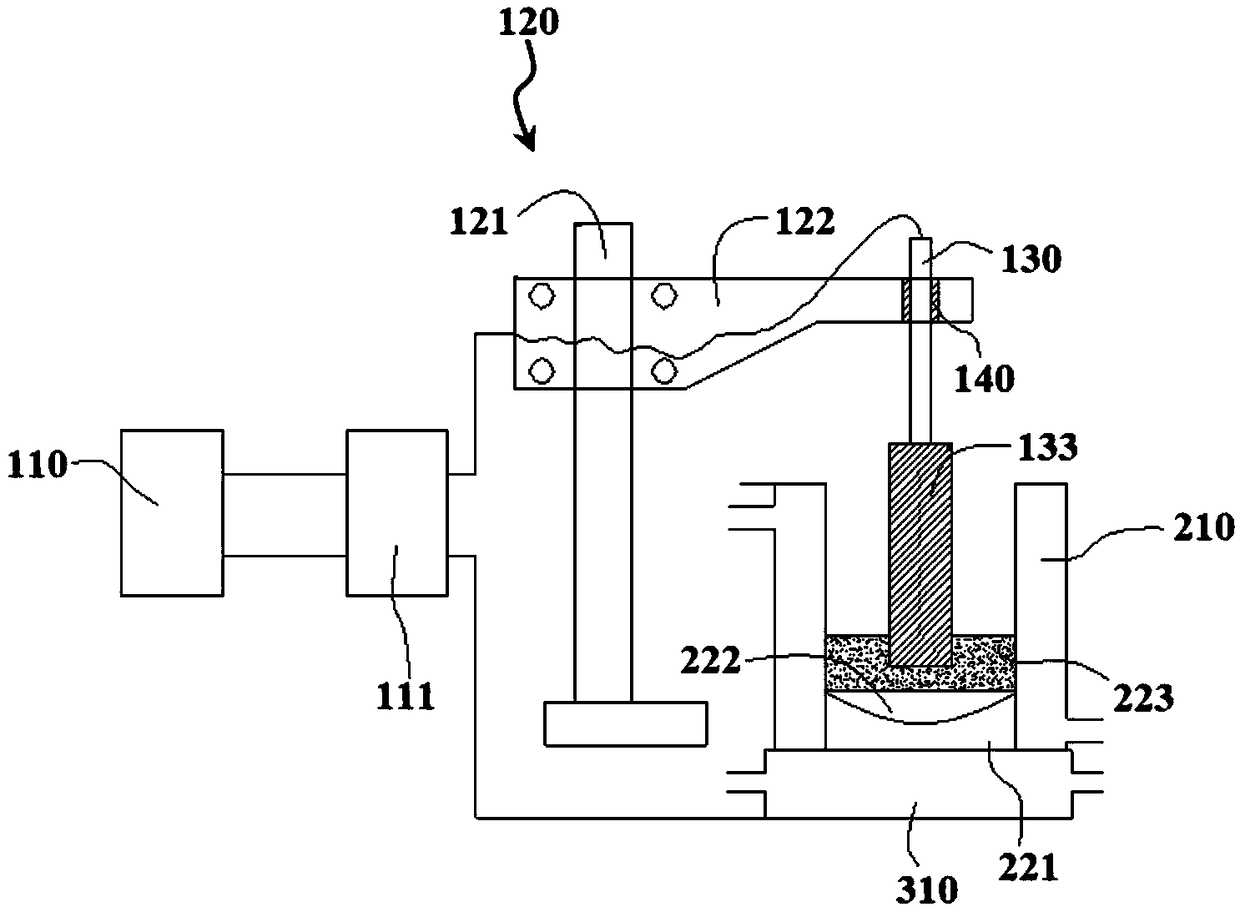

Electroslag remelting device and method for preventing segregation of remelted alloy

The invention discloses an electroslag remelting device and method for preventing segregation of a remelted alloy, and belongs to the technical field of electroslag remelting. The electroslag remelting device comprises a crystallizer, a power supply and a magnetic field unit; the crystallizer sequentially comprises a first crystallizer, a transition crystallizer and a second crystallizer from top to bottom; the first crystallizer is connected with the transition crystallizer in an insulating manner, and the transition crystallizer is connected with the second crystallizer in an insulating manner; in a slag bath, a first slag bath layer is arranged at the position corresponding to the bottom of the first crystallizer, a second slag bath layer is arranged at the position corresponding to the top of the second crystallizer, and a third slag bath layer is arranged at the bottom layer; the power supply comprises a first power supply and a second power supply; a consumable electrode is connected with the first slag bath layer through the first power supply; and the second slag bath layer is connected with the third slag bath layer through the second power supply. According to the electroslag remelting device and method for preventing the segregation of the remelted alloy, the problem that molten metal is bonded with the crystallizer can be effectively avoided, meanwhile, the remelting efficiency is improved, and the solidification quality of an electroslag ingot is improved.

Owner:ANHUI FUKAI STAINLESS STEEL

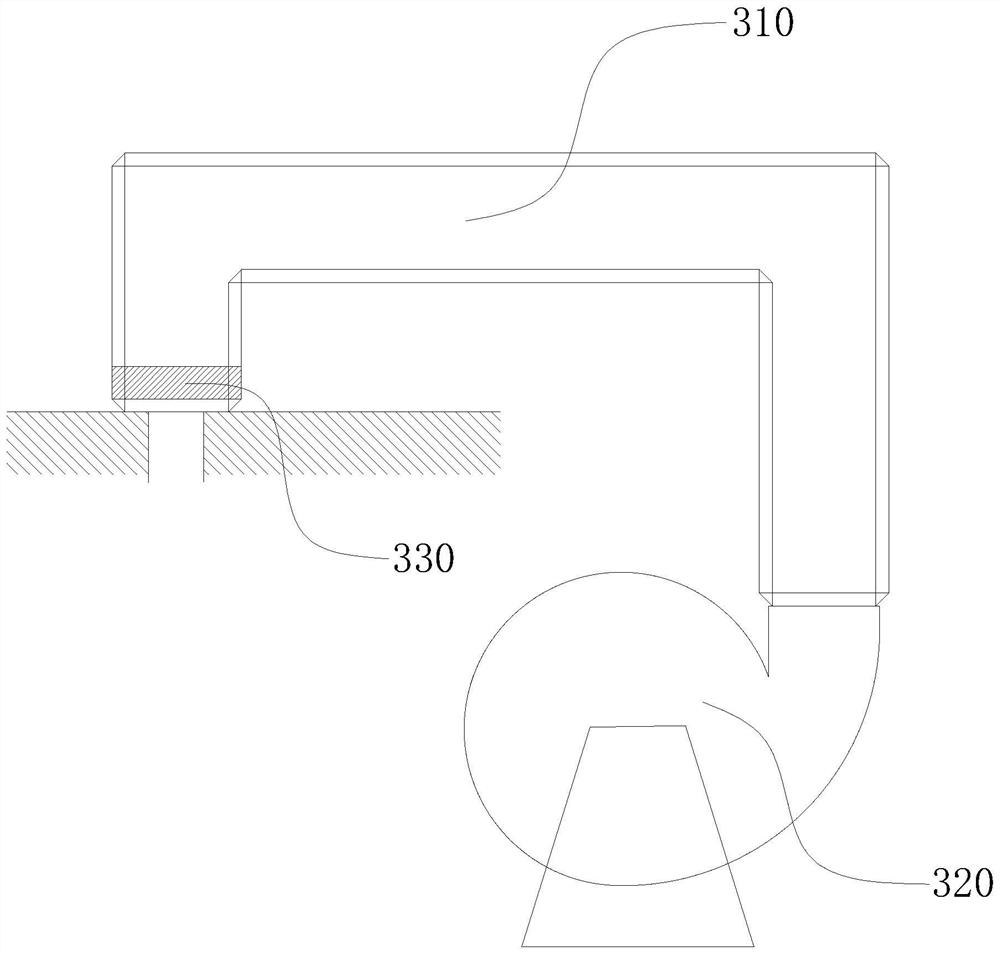

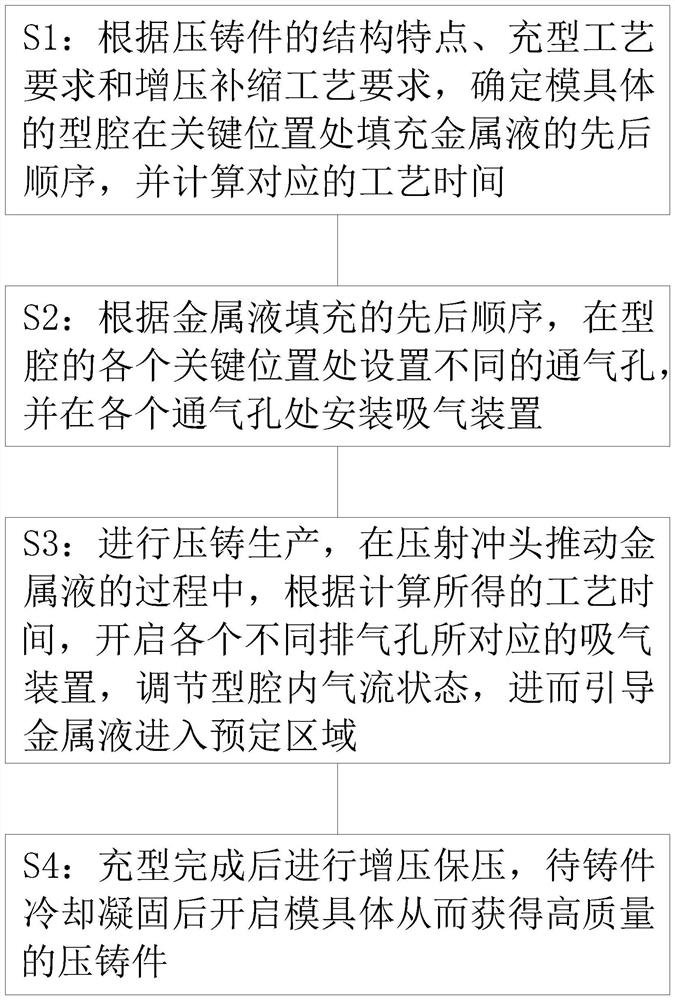

Die-casting die capable of adjusting flow field state in die cavity and die-casting process

The invention provides a die-casting die capable of adjusting the flow field state in a die cavity, and belongs to the technical field of die-casting dies, the die-casting die comprises a die body provided with a cavity and a pouring gate, and the pouring gate is communicated with the cavity; and the exhaust hole group is arranged on the mold body and communicated with the cavity, and the exhaust hole group can exhaust gas in the cavity to the outside. The invention further provides a die-casting process, and belongs to the technical field of die-casting processes. The method has the beneficial effects that the exhaust holes are formed in the important areas of the cavity, the air suction devices are installed at the exhaust holes, in the die-casting and mold-filling process, according to the specific requirements of the technology, rapid air exhaust is conducted on the different exhaust holes, the air flow state in the cavity is adjusted, and therefore molten metal is guided to enter the designated areas in sequence; molten metal mold filling sequences and mold filling states of different areas are regulated and controlled, the state of the die-casting mold filling process is improved, and therefore high-quality die castings compact in structure and excellent in performance are obtained.

Owner:DALIAN UNIV OF TECH +2

Slurry injection anchoring capsule

PendingCN107460874AImprove solidification qualityEfficient replacementBulkheads/pilesReverse osmosisEngineering

The invention discloses a slurry injection anchoring capsule. A slurry injection pipe sequentially penetrates an upper clamping head, a capsule body and a lower clamping head from top to bottom and then extends into a positioning protection head. The part, inside the capsule body, of the slurry injection pipe is provided with a low-pressure slurry injection check valve, and the part, inside the positioning protection head, of the slurry injection pipe is provided with a high-pressure slurry injection check valve. The outer wall of the positioning protection head is provided with at least one slurry draining hole, and one-way valves are arranged on portions of the slurry draining holes. A cavity of the positioning protection head is internally provided with a round supporting plate through a suspender. One or more guiding pipes are connected in the center axis direction of the upper clamping head and the lower clamping head through the capsule body. The capsule body is made of reverse osmosis anticorrosion cloth. By means of the improvement, cement slurry can be smoothly injected into the capsule body, clay grout around the capsule body can be effectively replaced, the solidification quality of the capsule body is effectively improved, and the anti-drawing strength is improved.

Owner:XINXIANG JIAHUI TECH

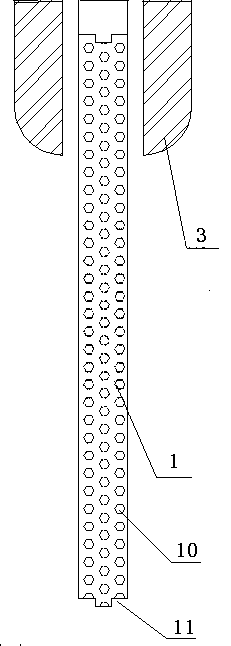

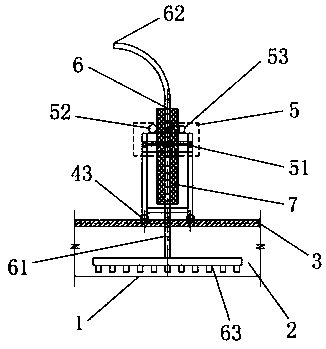

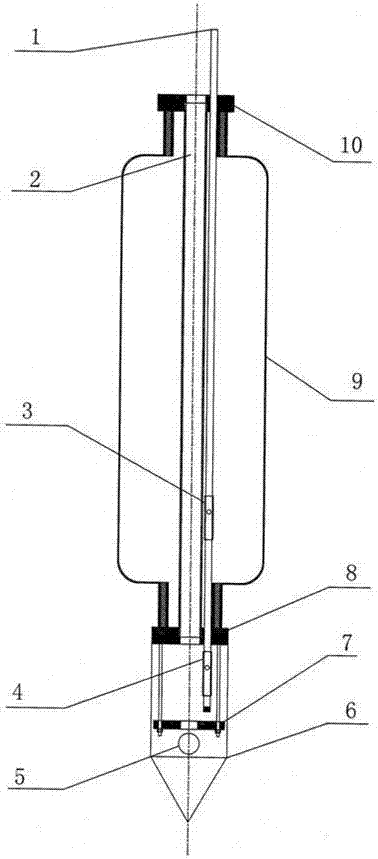

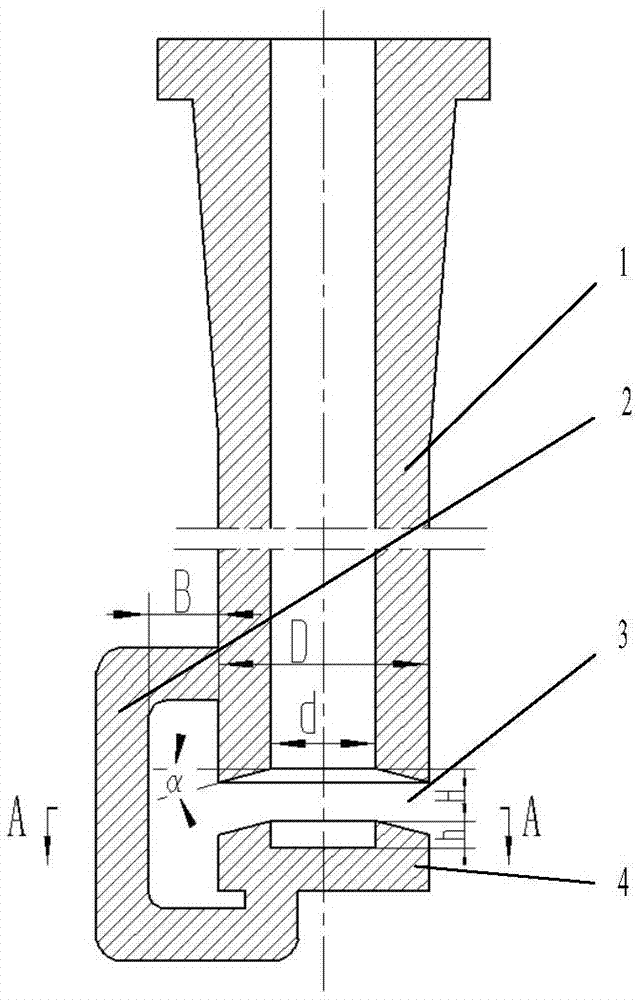

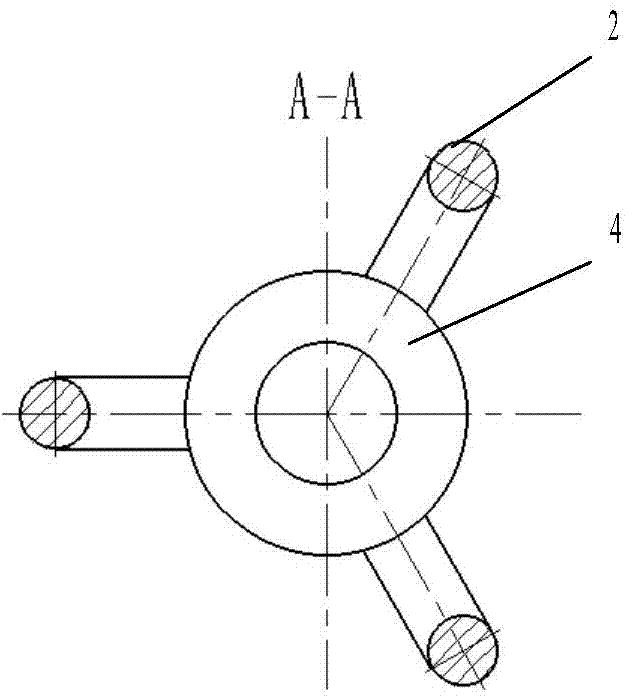

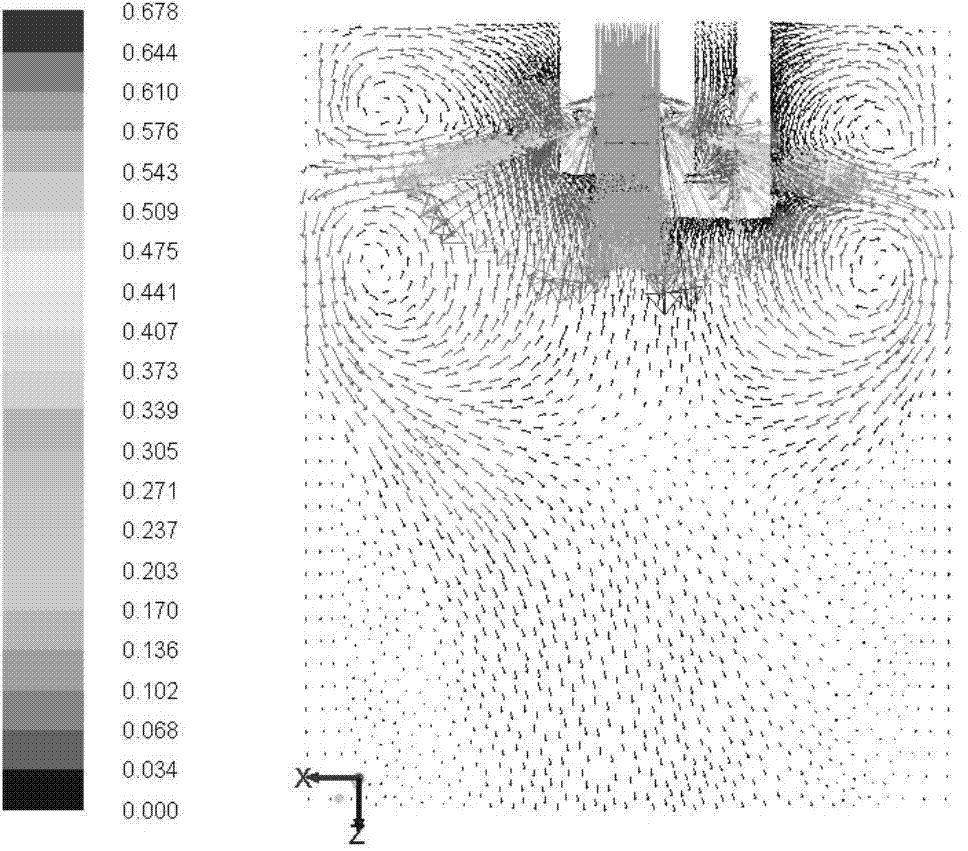

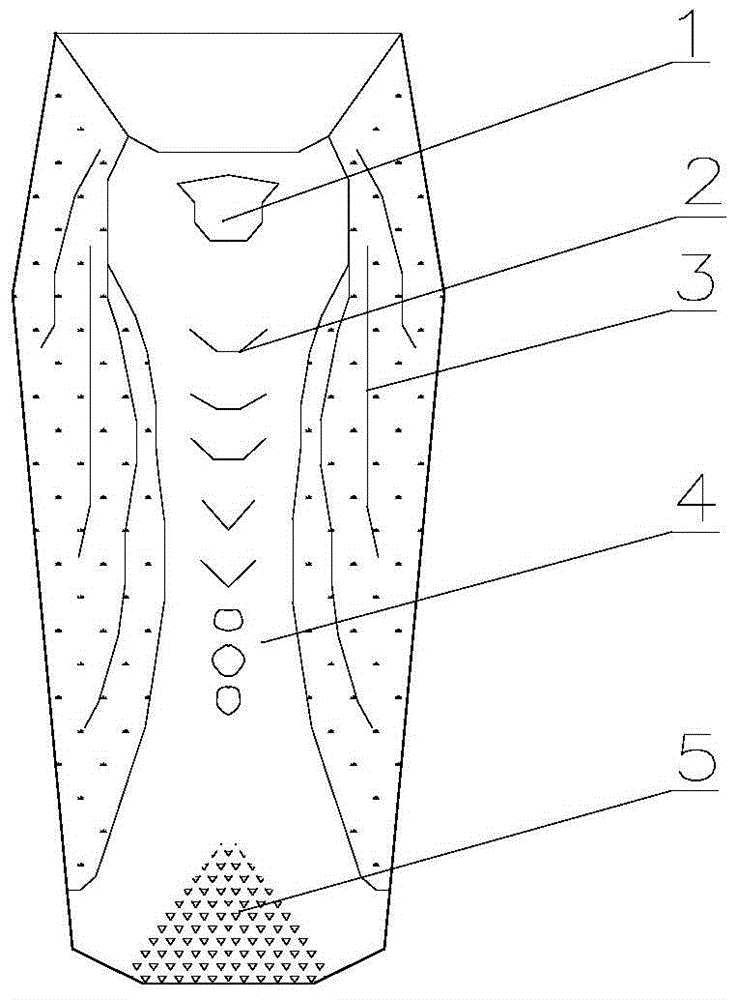

Umbrella-type submersed nozzle of crystallizer for continuous-cast round billets

ActiveCN103769570ADisadvantages affecting uniform solidificationReduce impact depthMelt-holding vesselsEngineeringMolten steel

The invention discloses an umbrella-type submersed nozzle of a crystallizer for continuous-cast round billets. The umbrella-type submersed nozzle comprises a nozzle side wall with an inner hole formed in the upper portion, a concave bottom plate with the lower portion closed, at least one side support hanging column for connecting the nozzle side wall and the concave bottom plate into a whole, and a lateral outlet arranged on the lower portion of the nozzle side wall. The lateral outlet is an annular outlet penetrating through the circumferential side wall of the whole nozzle, and the annular outlet inclines downward by an angle of alpha and is shaped like an umbrella. Molten steel can be injected in through the inner hole of the nozzle side wall and evenly flows out of the lateral outlet in the circumferential direction. Compared with the prior art, the umbrella-type submersed nozzle has the advantages that green billet shells will not be scoured or damaged, and thus the thickness of the billet shells is uniform in the circumferential direction; the flow field of the molten steel in the crystallizer is reasonable in distribution, an upper ring flow and a lower ring flow are formed in the upper flow field of the crystallizer, and thus casting powder can be molten easily; the impact depth of the molten steel is small, and thus gas and inclusions can float up easily. The superiority of the umbrella-type submersed nozzle can be better played for continuous cast of round billets with the diameter of the fracture surfaces of the cast billets larger than 400 mm.

Owner:YANSHAN UNIV

A kind of high-strength and high-toughness cast qt700-10 and its production method

ActiveCN106811676BIncrease the number ofReduce oxidation burnProcess efficiency improvementHigh intensityDuctile iron

The invention belongs to the field of casting technologies and new materials and particularly relates to a high-strength high-tenacity cast-state QT700-10 and a production method thereof. Compared with ductile iron produced in the prior art, the high-strength high-tenacity cast-state QT700-10 has high strength and a high elongation rate, heat treatment is not needed, heavy metal, such as, Ni and Mo are not added in production, the tensile strength Rm in the cast state is larger than or equal to 700 MPa, the elongation rate A is larger than or equal to 10%, compared with the standard brand QT 450-10, the lowest tensile strength is improved by 55% under the same elongation rate; and compared with the standard brand QT 700-2, the lowest elongation rate is improved by four times under the same tensile strength. The high-strength high-tenacity cast-state QT700-10 can meet requirements of automobile ductile iron castings with high requirements for safety and comprehensive mechanical properties.

Owner:山东汇金股份有限公司

Gun insertion type stopper rod device and method using same for absorbing inclusions at gate

ActiveCN103008636BStructural Design ScienceEasy to adjustMelt-holding vesselsEngineeringMolten steel

The invention provides a gun insertion type stopper rod device and a method using the same for absorbing inclusions at a gate. The device mainly comprises an absorption gun, a hollow stopper rod, a hot argon blowing device, horizontal clamps and a vertical lifting frame, the absorption gun is of a hollow bamboo-shaped structure and inserted into the hollow stopper rod of a long cylindrical structure, the upper end of the hollow stopper rod is fixed by the corresponding horizontal clamp, one end of the hot argon blowing device is connected on an external hot argon pipeline while the other end of the hot argon blowing device is inserted into a hollow pipe at the top of the hollow stopper rod, one end of the stopper rod horizontal clamp is connected with the vertical lifting frame while the other end thereof is mutually clamped with the hollow stopper rod, and one end of the absorption gun horizontal clamp is connected with the vertical lifting frame while the other end thereof is mutually clamped with the absorption gun. The method using the device for absorbing the inclusions at the gate includes the steps of gun insertion, argon sealing, gun descending, absorption and gun replacement. The device is scientific in structural design, part of time for gate changing is saved, smooth pouring of continuous casting is benefitted by using the device for absorbing sundries, molten steel cleanliness is improved, and gate nodulation probability is decreased.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

A kind of electroslag remelting device and method for preventing segregation of remelting alloy

Owner:ANHUI FUKAI STAINLESS STEEL

Method for casting large steel ingot with built-in cold core and overhead electromagnetic field

The invention discloses a method for casting a large-scale steel ingot with a built-in cold core and an overhead electromagnetic field, which can cast a large-scale steel ingot with high yield and few central defects. The steps of the invention include: cold core preparation; cold core preheating; built-in cold core; air exhaust; steel ingot filling; top electromagnetic field; demoulding and cooling. The built-in cold core of the invention can effectively control the center defects of steel ingots, such as coarse crystal structure, center segregation, looseness, etc.; the top electromagnetic field can heat and stir the cap mouth liquid steel, which can effectively reduce the cap volume ratio of steel ingots and the cutting rate of pressure processing , promote solidification feeding and disperse element segregation of steel ingots, reduce thermal processing of steel ingots and improve the qualified rate of ultrasonic flaw detection of products. The invention is applicable to the casting of solid steel ingots and solid composite steel ingots of various specifications, materials and shapes.

Owner:UNIV OF SCI & TECH LIAONING

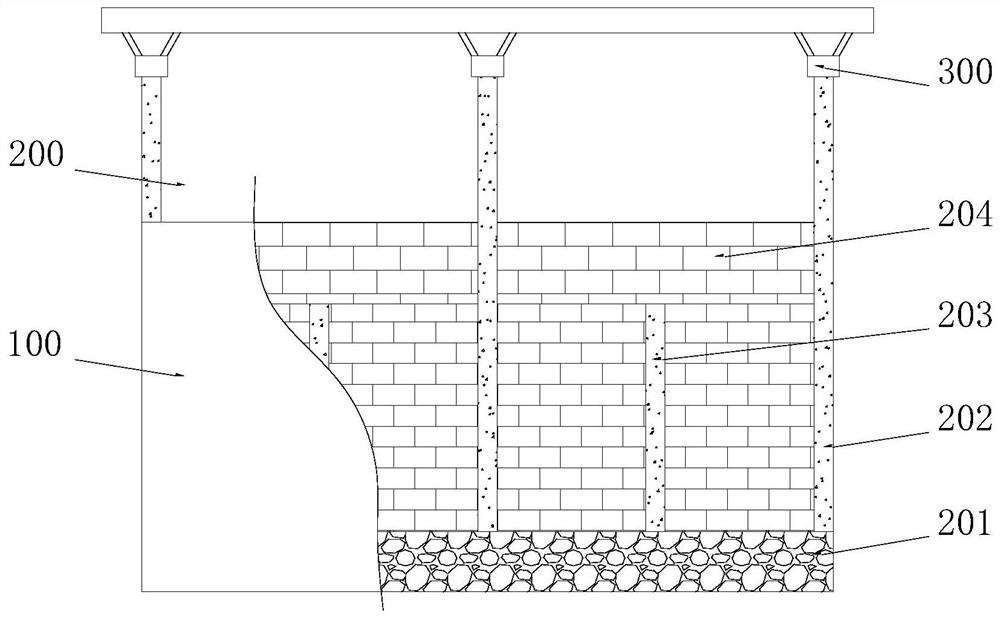

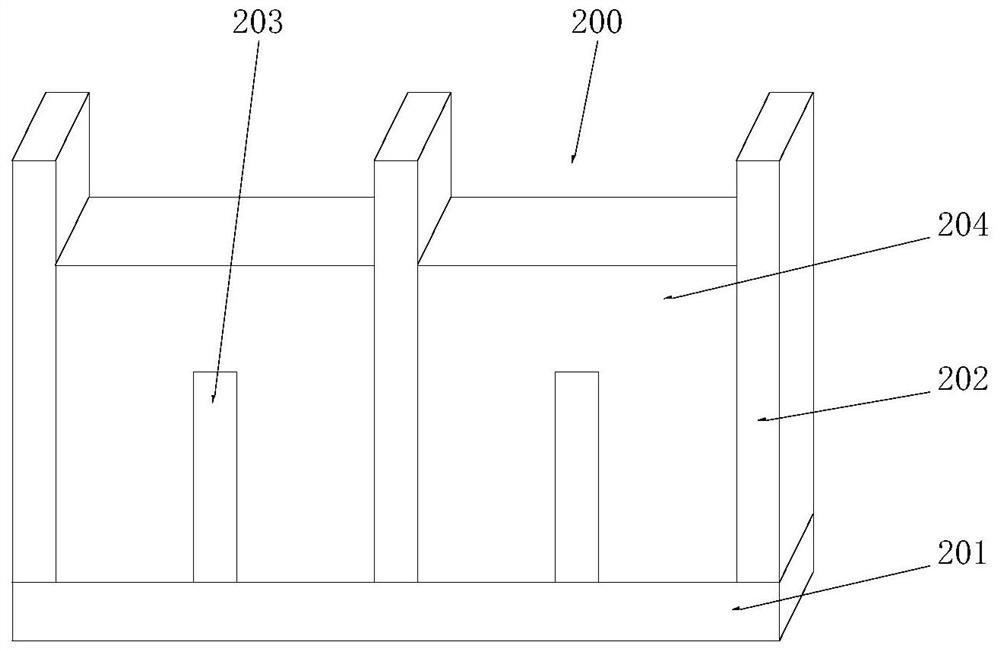

An aerated concrete block wall structure

ActiveCN112627390BImprove firm performanceSimple installation structureWallsHeat proofingArchitectural engineeringRebar

Owner:山东省建筑设计研究院有限公司

Electrode rotating speed control-based constant-smelting pool shaped electroslag remelting method

ActiveCN113249585AImprove melting efficiencyEnhanced convective heat transferSlagElectro-slag remelting

According to an electrode rotating speed control-based constant-smelting pool shaped electroslag remelting method, a consumable electrode is rotated in an electroslag remelting process, a rotating speed of the consumable electrode is dynamically adjusted, and under the action of a centrifugal force applied by rotation of the electrode, molten metal is not gathered centripetally any more but is separated from an outer side of an end part of the electrode earlier, convective heat exchange between a slag bath and a solid electrode is enhanced through electrode stirring and molten drop dispersion and dripping, the electrode melting efficiency is remarkably improved, and compared with a method adopting a fixed electrode, the melting speed or the production efficiency of the method can be improved by 25% at most. By the rotating effect of the electrode, the slag bath and the metal smelting pool can get a more uniform temperature; meanwhile, convective heat exchange from the slag bath to a crystallizer is enhanced, so that the temperature of the slag bath is lowered, a metal smelting pool which is more shallow and flatter is easily formed, macroscopic defects such as segregation and looseness in a electroslag steel ingot are restrained, and the solidification quality of the electroslag steel ingot is improved.

Owner:NORTHEASTERN UNIV

H-shaped tubular mold

The invention provides an H-shaped tubular mold, which comprises a web, wherein the center of the web of the working wall of the H-shaped tubular mold is provided with a covering layer, and the covering layer is formed by cermet material or metal material, which can resist high temperature and corrosion and the thermal conductivity of which is less than the thermal conductivity of the a material formed into the H-shaped tubular mold. The H-shaped tubular mold not only can prevent the web of a solidified shell from being affected and damaged by the stress produced by rapid chilling, but also can prevent the defect that thermal resistance is uncontrollably increased as the result of ununiform nonuniform air gaps formed by the earlier shrinkage of the initial solidified shell to affect the uniform growth of the solidified shell, so that the heat of the web of the solidified shell can be uniformly dissipated, and thereby therefore the H-shaped tubular mold increases the quality of solidification and prevents severe quality problems, such as cracks.

Owner:LAIWU IRON & STEEL GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com