H-shaped combined crystallizer

A crystallizer and combined technology, which is applied in the field of H-type combined molds, can solve the problems of slab web cooling and uneven cooling of slab webs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

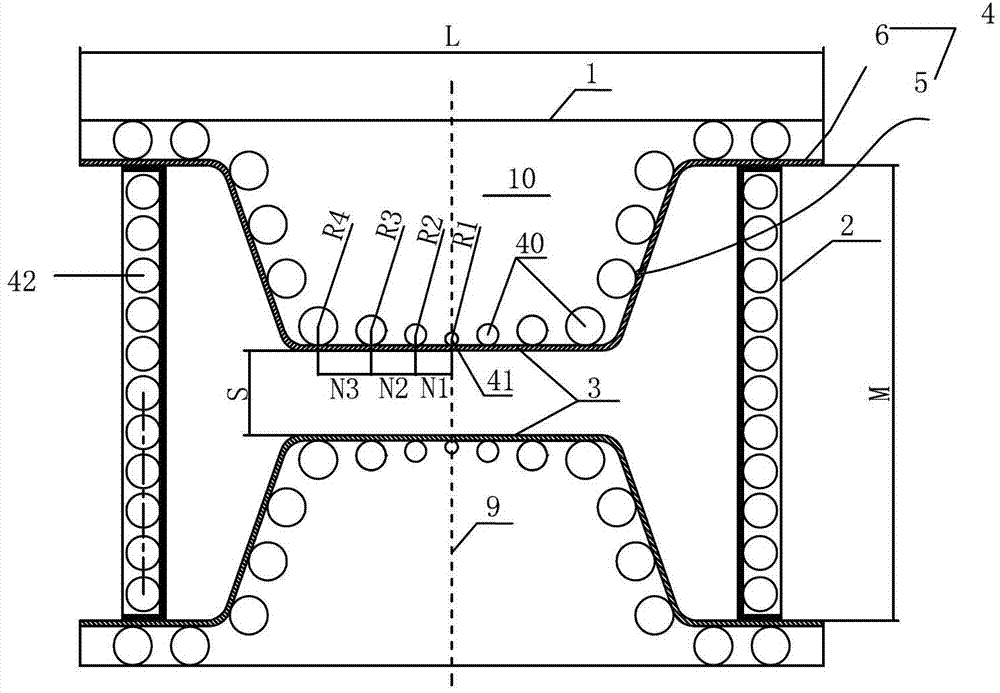

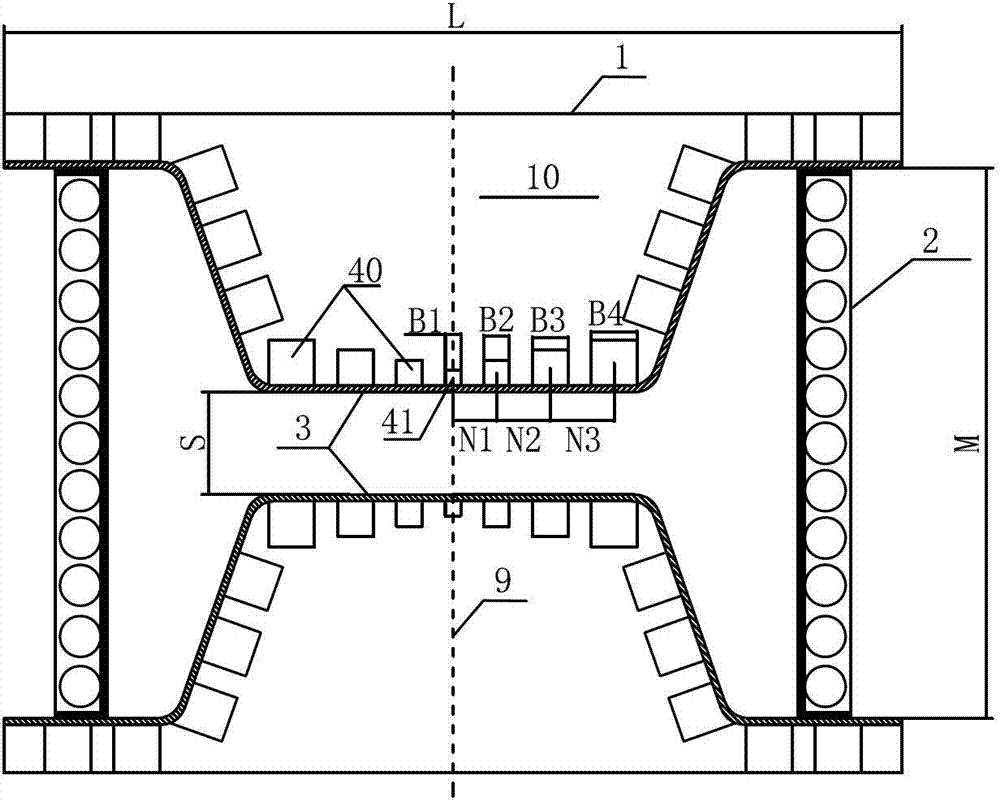

[0023] The present application will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] In order to improve the problem of non-uniform cooling of the web existing in the existing H-type combined crystallizer, the present application provides an H-type combined mold capable of improving the condensation quality of the web of the H-type continuous casting slab.

[0025] In this application, water pipes of different sizes are provided on the outside of the working wall of the flange wide plate. Under the premise of ensuring the quality control level of the existing crystallizer on the surface and core of the slab and realizing the normal application of technologies such as online width adjustment, the weakened cast The heat dissipation strength of the blank shell web and the central part of the blank shell web slows down the cooling speed of the web and the central part of the web, which not only avoids the influenc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com