H-shaped tubular mold

A tubular crystallizer and covering layer technology, which is applied in the field of H-shaped tubular molds, can solve the problems of H-shaped billet webs that cannot be cooled uniformly, cracks appear, and affect solidification quality, so as to avoid thermal resistance from being unaffected. Control the increase, eliminate cracks, and improve the effect of solidification quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

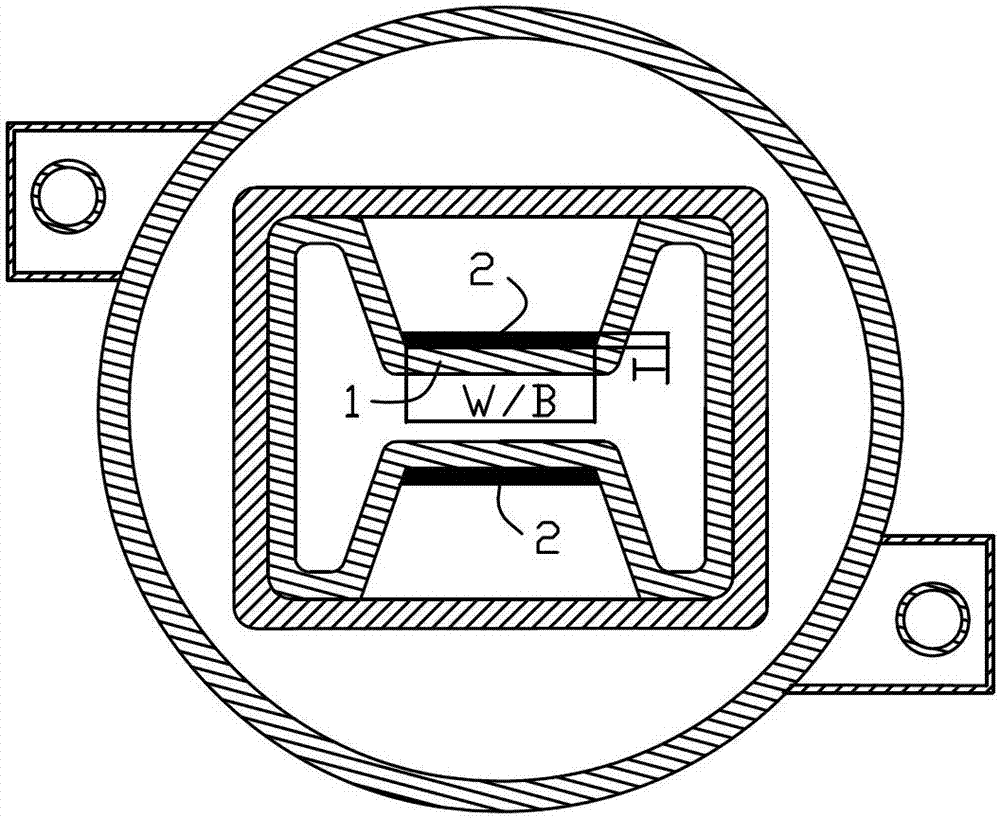

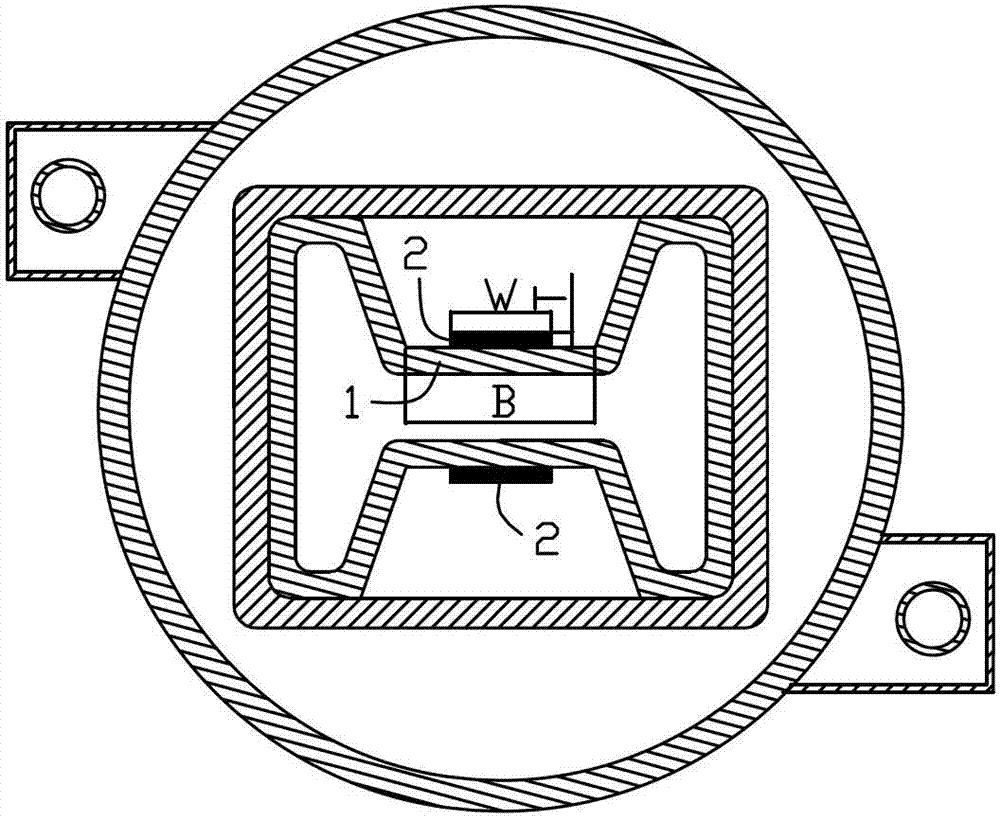

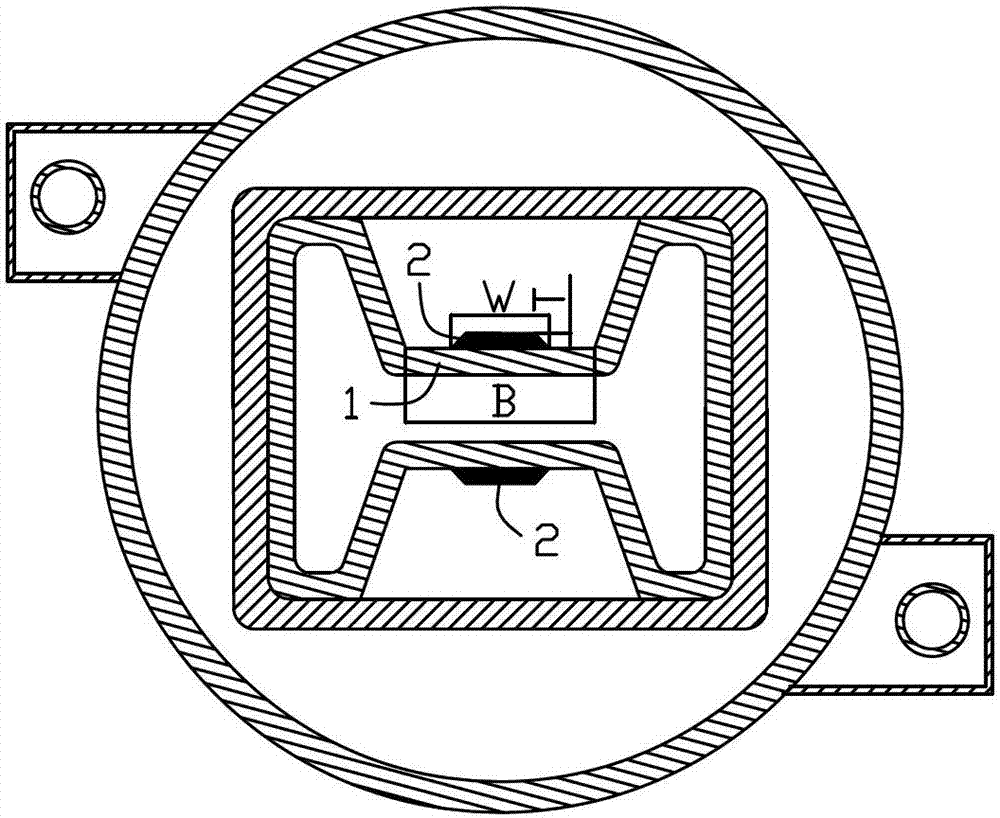

[0024] In order to improve the problem of uneven cooling of the web of the existing H-shaped tubular crystallizer, the present invention provides an H-shaped tubular mold capable of improving the condensation quality of the web of the H-shaped continuous casting slab. The outer web portion of the working wall Coating or attaching a layer of covering layer made of material with heat insulation function. Regardless of whether the inner surface of the working wall is provided with plating or coating, the covering layer for heat insulation can be coated or attached at the position of the web part of the outer layer of the working surface.

[0025] figure 1 The sectional structure of preferred embodiment one of the present invention is shown, as shown in it, this preferred embodiment one comprises web 1, and the center of web 1 of working...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com