Electromagnetic soft contact continuous casting crystallizer

A continuous casting mold and soft contact technology, applied in the field of electromagnetic soft contact continuous casting mold, can solve the problems of uncertainty, doubts, implementation difficulties, design and manufacturing difficulties of internal water cooling structure, etc., to ensure service life and insulation. performance, improve the safety protection level, and ensure the effect of electromagnetic permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

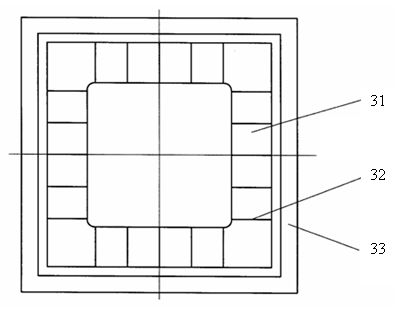

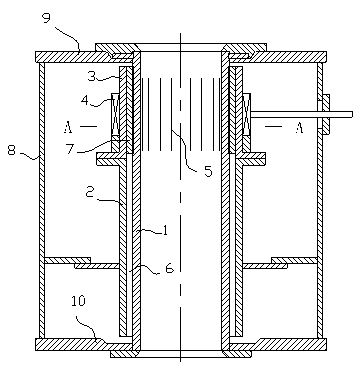

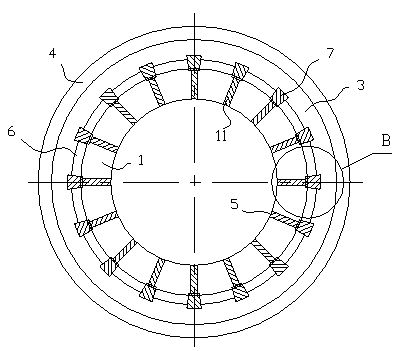

[0027] see figure 2 , image 3 , Figure 4 , an electromagnetic soft contact continuous casting crystallizer, adopts the copper tube of the traditional continuous casting crystallizer used in industry at present, and cuts on the copper tube to form a middle slotted copper tube, hereinafter referred to as the slotted copper tube 1, that is, the slotted copper tube 50-150 mm below the top of the tube 1, preferably 50-100 mm is the starting point of the slit 5, the length of the slit 5 is between 50-250 mm, preferably 100-200 mm, and the number of slits 5 is 8-40. The preferred number is 16-32, the width of the slit 5 is 0.1-3 mm, and the preferred width of the slit is 0.5-1.5 mm. The slotted copper pipe 1 of the present invention has sufficient structural strength and rigidity.

[0028] Such as figure 2As shown, an electromagnetic soft con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com