Method for improving solidification quality of electroslag remelting steel ingot

A technology of electroslag remelting steel, high quality, applied in the field of electroslag remelting, can solve the problems of poor solidification quality of electroslag remelting steel ingots, achieve the effect of improving solidification quality, promoting transformation, and improving the solidification quality of steel ingots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

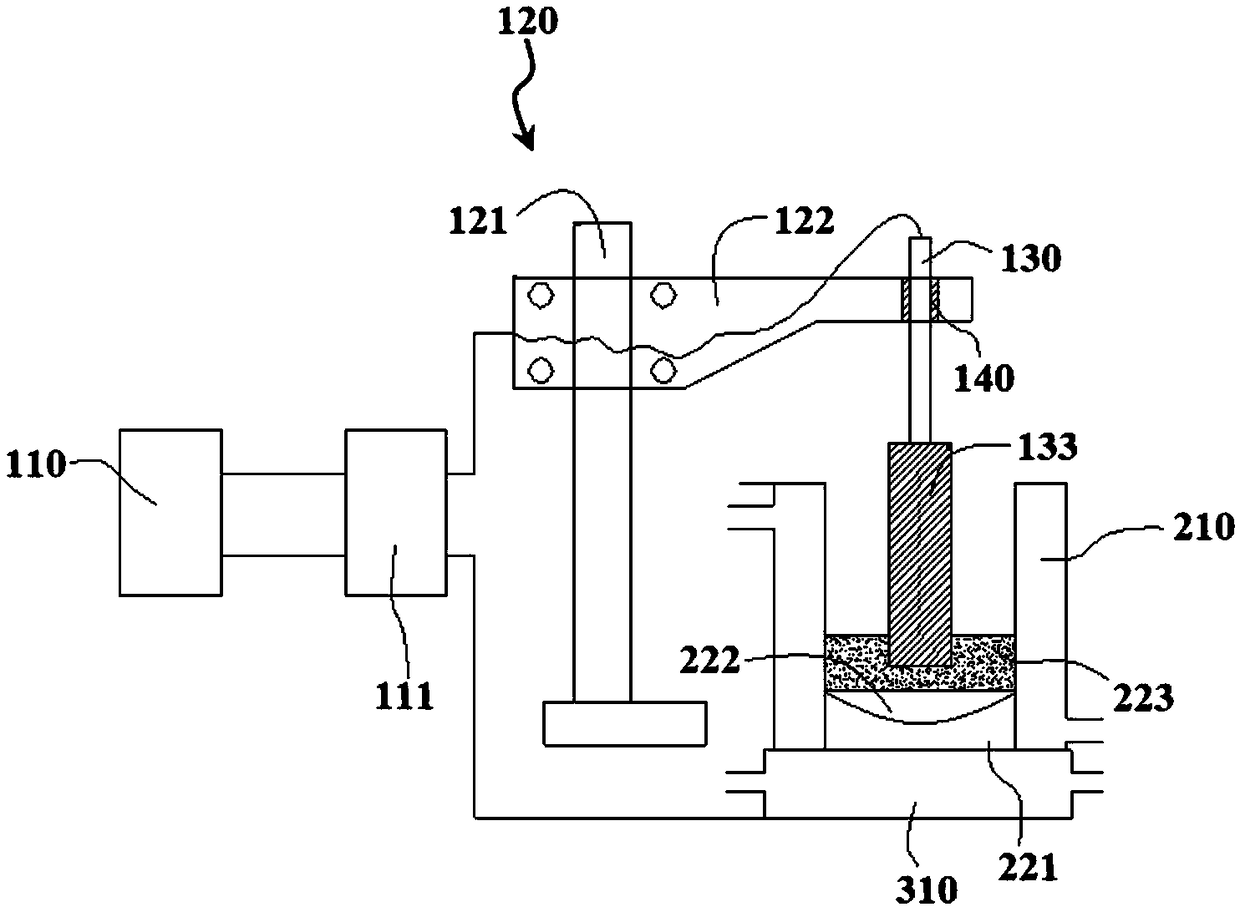

[0037] Such as Figure 7 As shown, a method for improving the solidification quality of an electroslag remelted steel ingot in this embodiment, the metal electrode 130 introduces the pulse current of the pulse power supply 111 into the smelting process, and the pulse power supply 111 is energized to form an electrical circuit. The self-consumption of the metal electrode 130 Metal 133 is remelted and re-solidified to obtain steel ingots. The details are:

[0038] Step 1. When the smelting device is used for smelting, before the metal electrode 130 is remelted, the graphite electrode is firstly used for slag removal;

[0039] Step 1. After the slag removal is completed, insert the consumable metal 133 of the metal electrode 130 into the liquid slag of the smelting crystallizer 210. The positive pole of the pulse power supply 111 is connected to the metal electrode 130, and the negative pole of the pulse power supply 111 is connected to the bottom water tank 310. The pulse power...

Embodiment 2

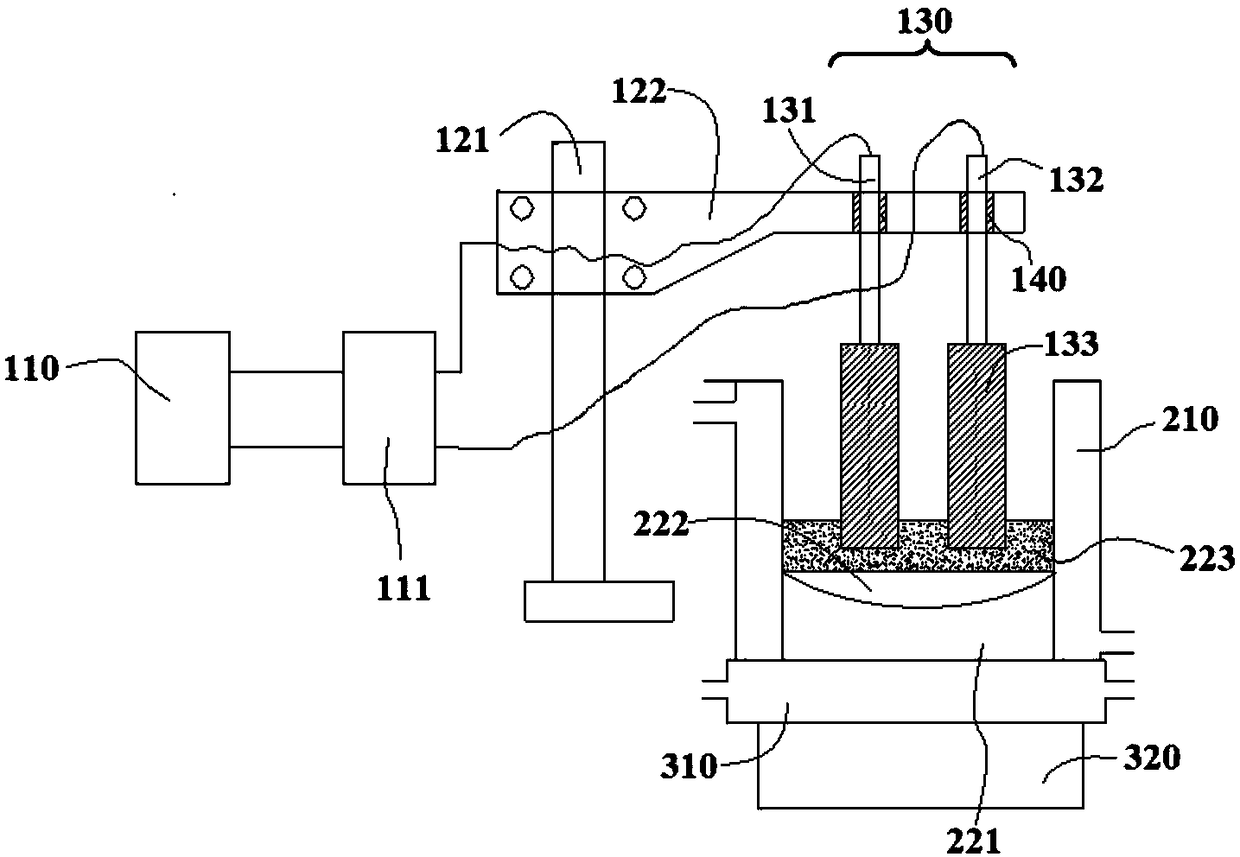

[0045] The basic content of this embodiment is the same as that of Embodiment 1, the difference is that, as figure 2 As shown, a device for improving the solidification quality of electroslag remelted steel ingots using double electrodes in this embodiment includes a pulse power supply 111, a smelting crystallizer 210, a metal electrode 130 and a bottom water tank 310, and the bottom water tank 310 is arranged on the smelting crystallizer 210 The bottom of the smelting crystallizer 210 is used to accommodate the molten metal pool 222 and the electroslag layer 223, the metal electrode 130 is inserted into the smelting crystallizer 210, the consumable metal 133 at the bottom of the metal electrode 130 is inserted into the electroslag layer 223, and the metal electrode 130 is inserted into the electroslag layer 223. The electrodes 130 include a first electrode 131 and a second electrode 132 , and the first electrode 131 and the second electrode 132 are respectively connected to t...

Embodiment 3

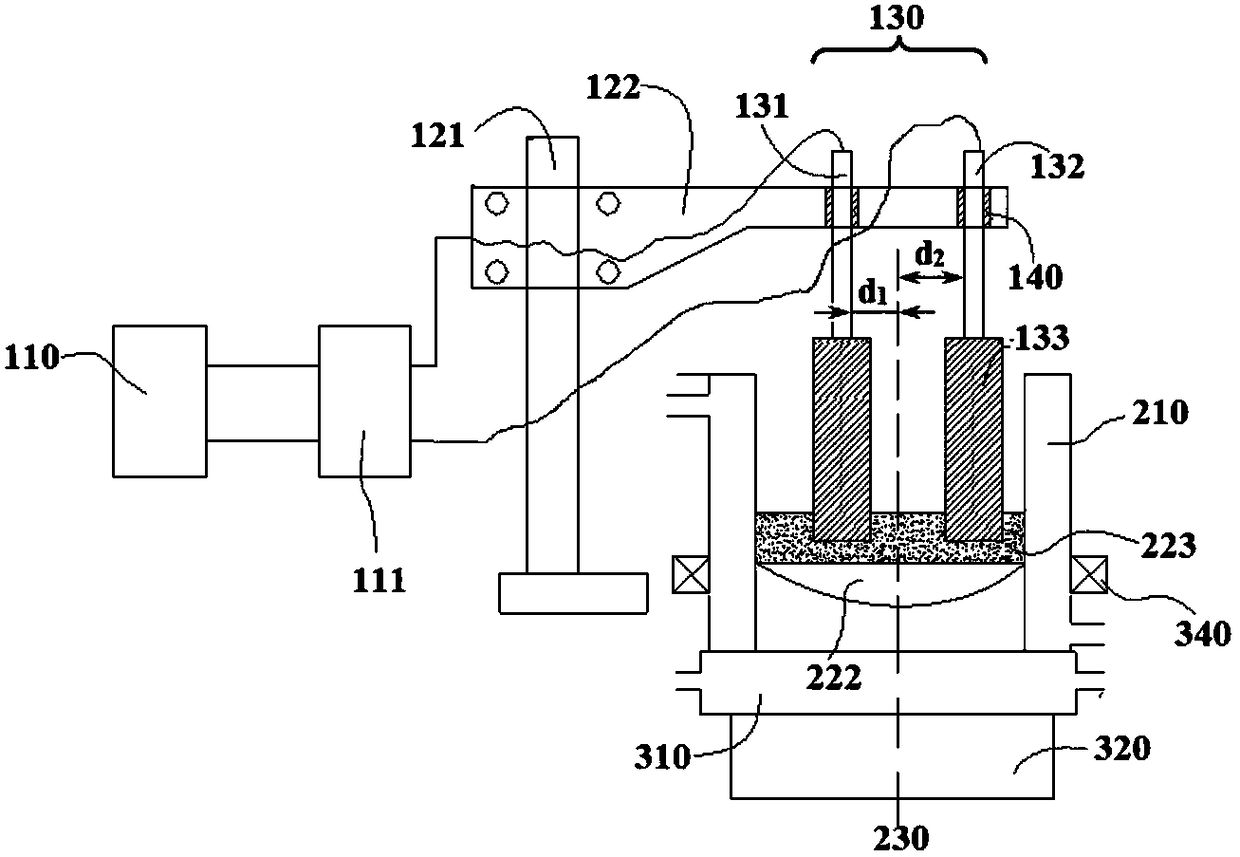

[0048] The basic content of this embodiment is the same as that of Embodiment 2, the difference is that, as image 3 As shown, the distance between the first electrode 131 and the crystallizer axis 230 is d 1 , the distance between the second electrode 132 and the crystallizer axis 230 is d 2 , and d 1 ≠ d 2 . And the first electrode 131 and the second electrode 132 are the same and are R, then d 2 >d 1 +R, so that during the rotation of the bottom tank 310, the first electrode 131 and the second electrode 132 move relative to the liquid electroslag layer 223, and the trajectory of the first electrode 131 and the second electrode 132 are different. They also do not overlap, thereby promoting the uniform distribution of the molten inner layer metal in the electroslag layer 223, which not only improves the uniformity of the distribution of the inner layer metal, but also makes the molten liquid metal and the electroslag layer 223 fully react. The outside of smelting crysta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com