An aerated concrete block wall structure

A technology for aerated concrete and wall structures, which is applied to walls, building components, building structures, etc., can solve the problems of damaging the overall rigidity of the structure, reducing the overall strength of the project, and worrying about the quality of the wall, so as to improve the firmness and improve the quality of the wall. Thermal insulation effect, effect of improving aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

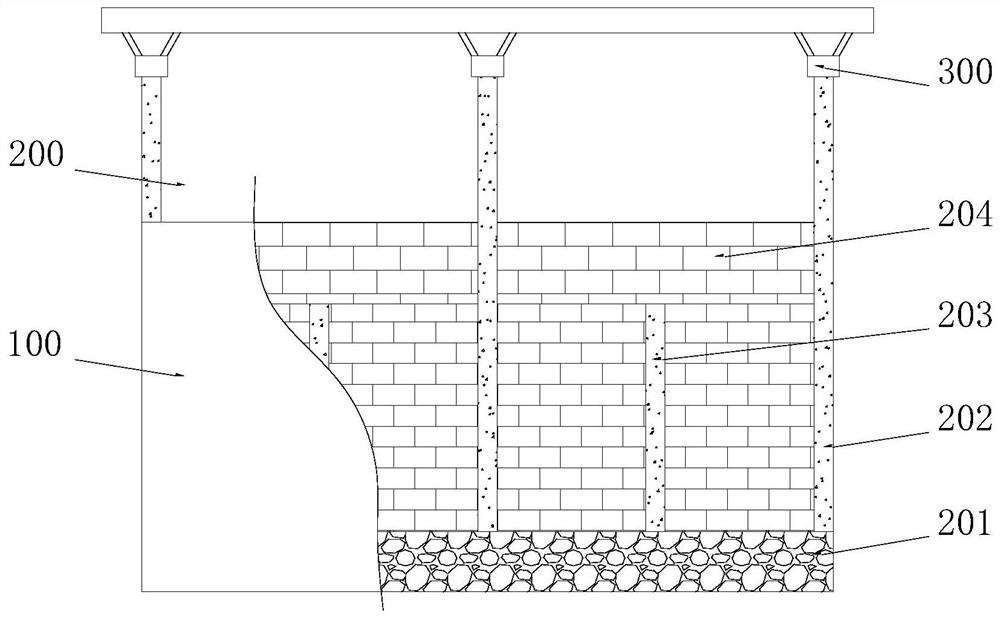

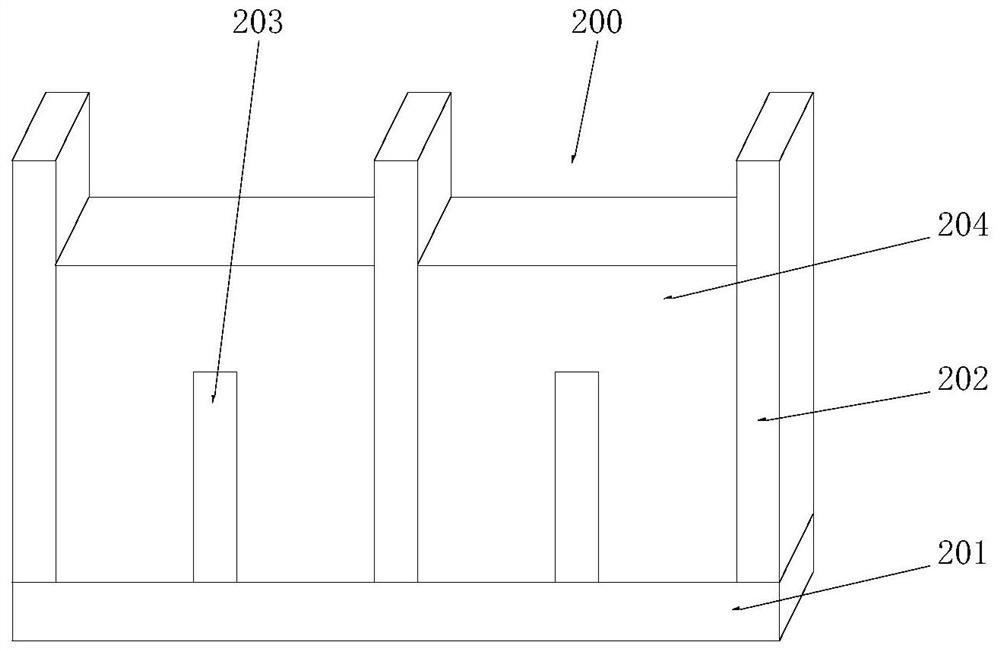

[0034] See Figure 1-2 , an aerated concrete block wall structure, comprising an inner wall 200 and two outer walls 100, the front and rear sides of the inner wall 200 are respectively provided with an outer wall 100, and the inner wall 200 includes a foundation wall 201, the foundation wall 201 is made by pouring C2O fine stone concrete, the height of the foundation wall 201 is 200 mm to 300 mm, and a steel skeleton is embedded in the foundation wall 201 to enhance the strength and stability of the foundation wall 201;

[0035] The top of the foundation wall 201 is evenly provided with several first construction columns 202 and some second construction columns 203, the height of the second construction columns 203 is less than two-thirds of the height of the second construction columns 202, the second construction The column 203 and the first structural column 202 are interlaced with each other, the second structural column 203 is made of C2O concrete, and the vertical steel ...

Embodiment 2

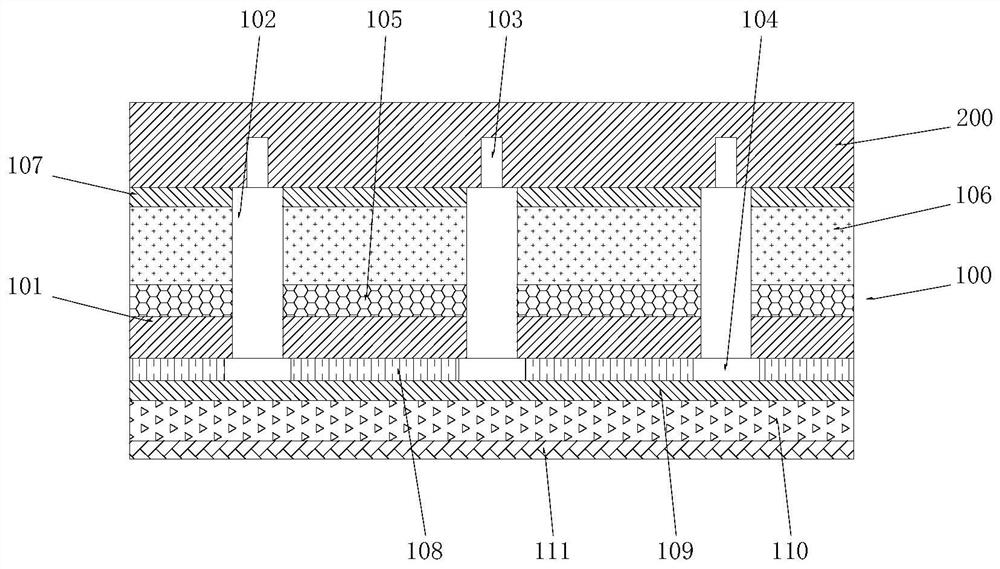

[0038] See Figure 3-4 The difference from Embodiment 1 is that the outer wall 100 includes a base plate 101, on which a number of mounting coils 102 are evenly embedded, and the front of the base plate 101 is connected to the mounting coils. 102 is flush with the positive end surface, and the mounting screw 102 is internally threaded with a fastening screw 103 that matches the inner wall 200, and the positive end of the fastening screw 103 is provided with a set that matches the base plate 101 The fastening sleeve 104, the base plate 101 can be installed on the inner wall 200 through the fastening screw 103 and the installation screw 102, and the fastening sleeve 104 can further improve the firmness of the base plate 101 installation ;The entire installation structure is very simple, which is convenient for later disassembly and maintenance;

[0039] The end of the base plate 101 close to the inner wall 200 is provided with a sound insulation layer 105 matched with the insta...

Embodiment 3

[0042] See Figure 5-6 The difference from Embodiment 1 is that the protection assembly 300 includes a protection shell 301 and several top cylinders 308 matched with the first construction column 202, the protection shell 301 is a box structure with an open bottom end, and the protection The middle part of the inner cavity of the shell 301 is provided with an inner brace 302, and the protective shell 301 and the inner brace 302 are integrally formed, and the inner brace 302 divides the inner cavity of the protective shell 301 into two working chambers 303 , all of the top tubes 308 are cylindrical structures with open bottoms, and the top of the top tubes 308 is symmetrically provided with support rods 309, and the two support rods 309 are in a figure-eight structure, and the top tubes 308 are supported by The rod 309 is fixedly connected to the bottom end of the inner support plate 302, and is set on the top of the first construction column 202 through the top tube 308, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com