Electroslag remelting device and method for preventing segregation of remelted alloy

An electroslag remelting and remelting technology, applied in the field of electroslag remelting, can solve the problems of poor solidification quality of electroslag ingots and low electroslag remelting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

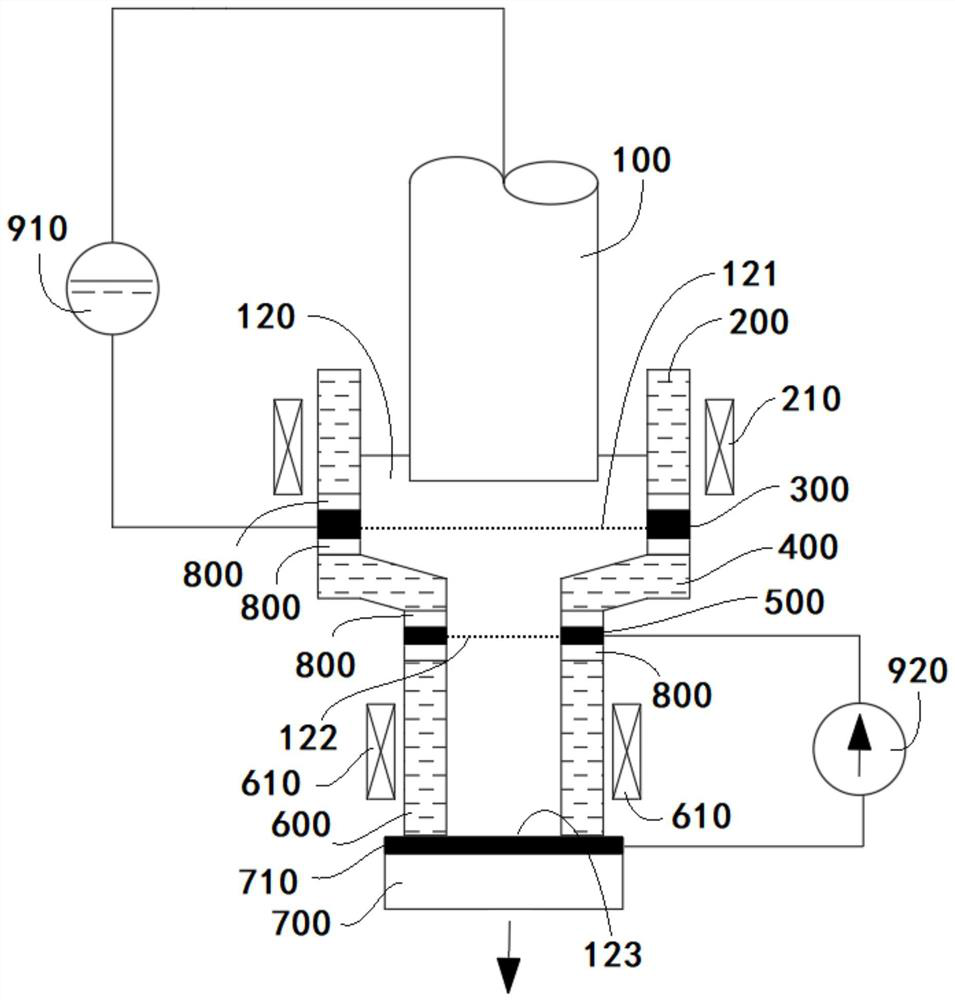

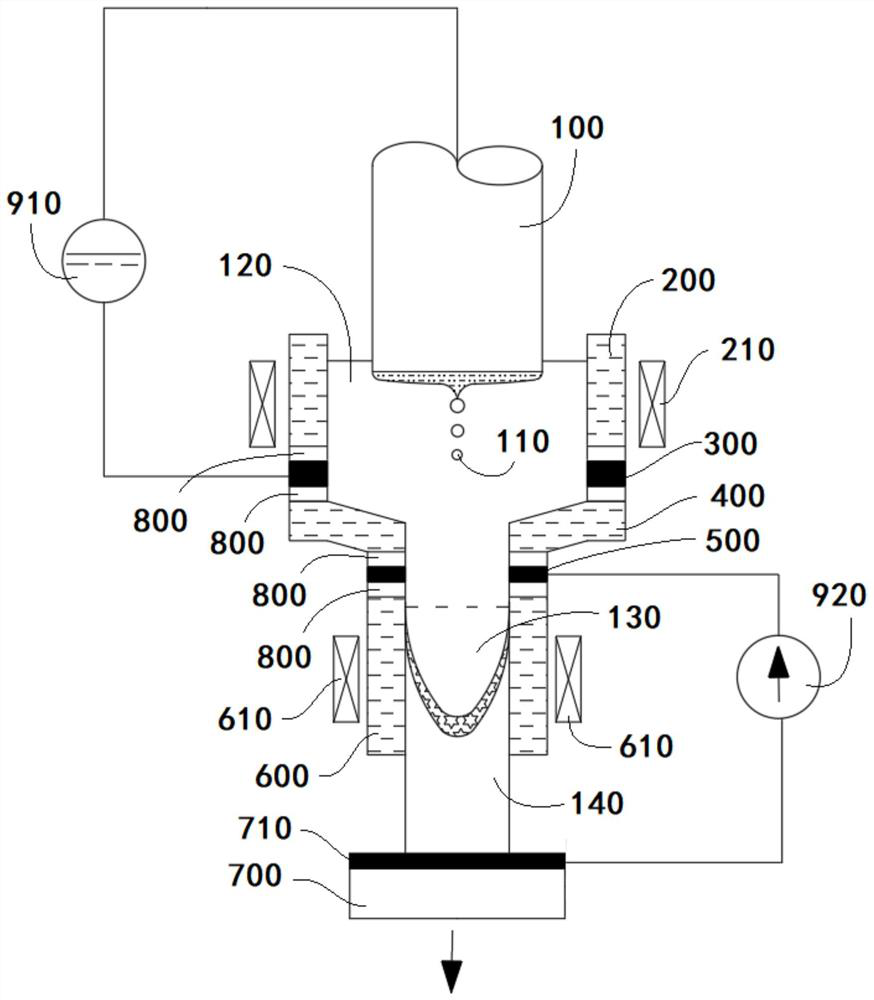

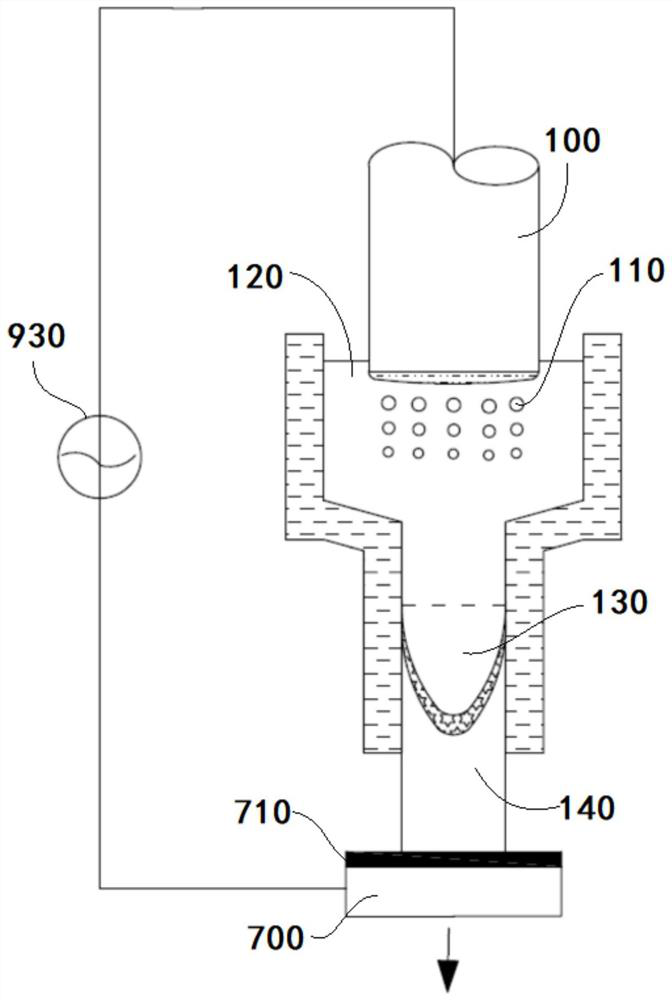

[0054] This embodiment provides an electroslag remelting device for preventing segregation of remelted alloys, such as figure 1 and figure 2 As shown, it includes a crystallizer, a power supply, a magnetic field unit and a sump tank 700 . The crystallizer is arranged on the bottom water tank 700, which is used to provide cold energy to the crystallizer to solidify the metal to form an electroslag ingot; the top of the bottom water tank 700 is provided with a conductive layer 710.

[0055] The crystallizer comprises a first crystallizer 200, a transition crystallizer 400 and a second crystallizer 600 from top to bottom. The first crystallizer 200 in this embodiment is cylindrical, and its diameter is D1=600mm. The second crystallizer 200 is cylindrical, its diameter is D2=200mm, and the D1 / D2=3.5:1; as other embodiments of the present invention, the D1 / D2 can be 3:1 or 4:1; because The diameter of the first crystallizer 200 is larger, so the diameter of the consumable electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com