Gun insertion type stopper rod device and method using same for absorbing inclusions at gate

A technology of inclusions and stopper rods, which is applied in the manufacture and application of stopper rods for continuous casting, to achieve the effects of optimizing the continuous casting operation process, reducing economic costs and facilitating adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

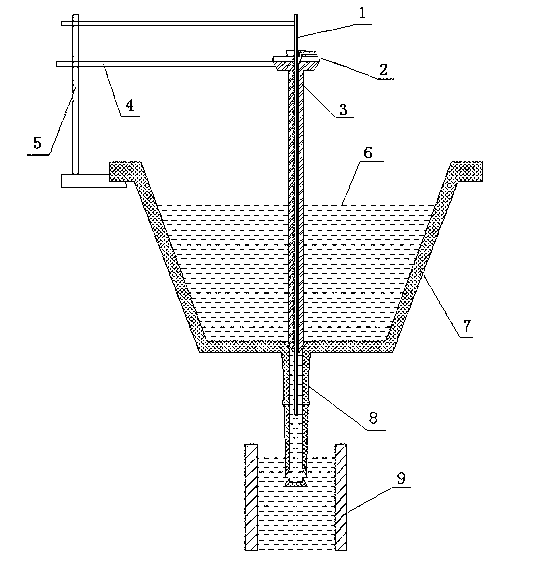

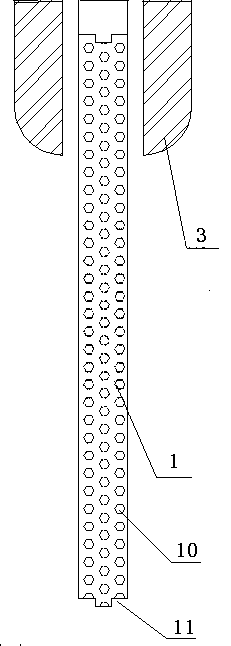

[0050] Embodiment 1 Single-section gun-type stopper device

[0051] The gun-type stopper device of this embodiment sees image 3 , this gun-type stopper device is suitable for the situation where there are few inclusions in molten steel and no need to change the gun. The adsorption gun 1 is a single-section type, the length of the gun body is 1900mm, and the diameter is 25mm. The length of the gun head is 250mm. There are a large number of concave holes 10 on the surface, and the function of the concave holes 10 is to absorb a large number of inclusions. The gun body is made of ordinary aluminum-carbon refractory material, the gun head is made of special refractory material, and the matrix is aluminum-carbon, and the outer surface of the gun head is provided with a coating layer of special refractory material. The material is calcium oxide.

[0052] Method of Adsorbing Inclusions at the Water Outlet Using a Single-section Gun Type Stopper Device

[0053] Before pouring th...

Embodiment 3

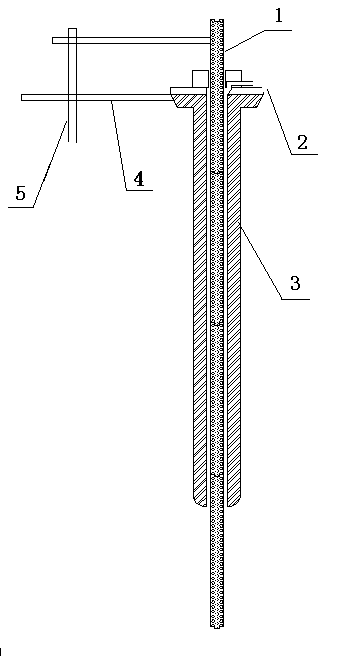

[0054] Example 3 Multi-section gun-type stopper device

[0055] See figure 2 In this embodiment, a gun-type stopper is produced, which is suitable for the situation where there are many inclusions in molten steel and the gun needs to be changed. The adsorption gun 1 is a multi-section structure with a length of 2000 mm and a diameter of 25 mm. The section length is 400mm, each section head has thread 11, and the outer surface of the adsorption gun is provided with a large number of concave holes 10, which are used to absorb a large number of inclusions. The substrate of the adsorption gun 1 is aluminum-carbon, and the outer surface is coated with a special refractory material, the thickness is 4mm, and the material is calcium oxide and magnesium oxide.

[0056] Method of Adsorbing Inclusions at the Water Outlet Using the Multi-Segment Gun Type Stopper Device

[0057] Before the tundish located above the crystallizer 9 is poured, connect the multi-section adsorption gun 1 th...

Embodiment 5

[0058] Example 5 Convex single-section gun-type stopper device

[0059] A single-section gun-type stopper was produced, which is suitable for the situation where there are few inclusions in molten steel and no need to change the gun. The adsorption gun 1 is a single-section type, with a length of 1900mm and a diameter of 25mm, of which the length of the gun head is 250mm. The tip of the gun has a large number of ribs, which can absorb a large number of inclusions. The refractory material of the gun body is ordinary aluminum-carbon, and the gun head is a special refractory material, in which the substrate is aluminum-zirconium-carbon, and the outer surface is coated with a special refractory material, the thickness is 4mm, and the material is calcium oxide.

[0060] Method of Adsorbing Inclusions at the Water Outlet Using a Convex Single-section Gun-type Stopper Rod

[0061] Before pouring the tundish 7 located above the crystallizer 9, fix the adsorption gun 1 on the horizont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com