Bass water entry regulator based on wet method synthetic leather production line

A technology of water regulation and synthetic leather, applied in textiles and papermaking, etc., can solve the problems of undesigned bass entering water time and angle, etc., and achieve the effect of simple structure, convenient operation and high coagulation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

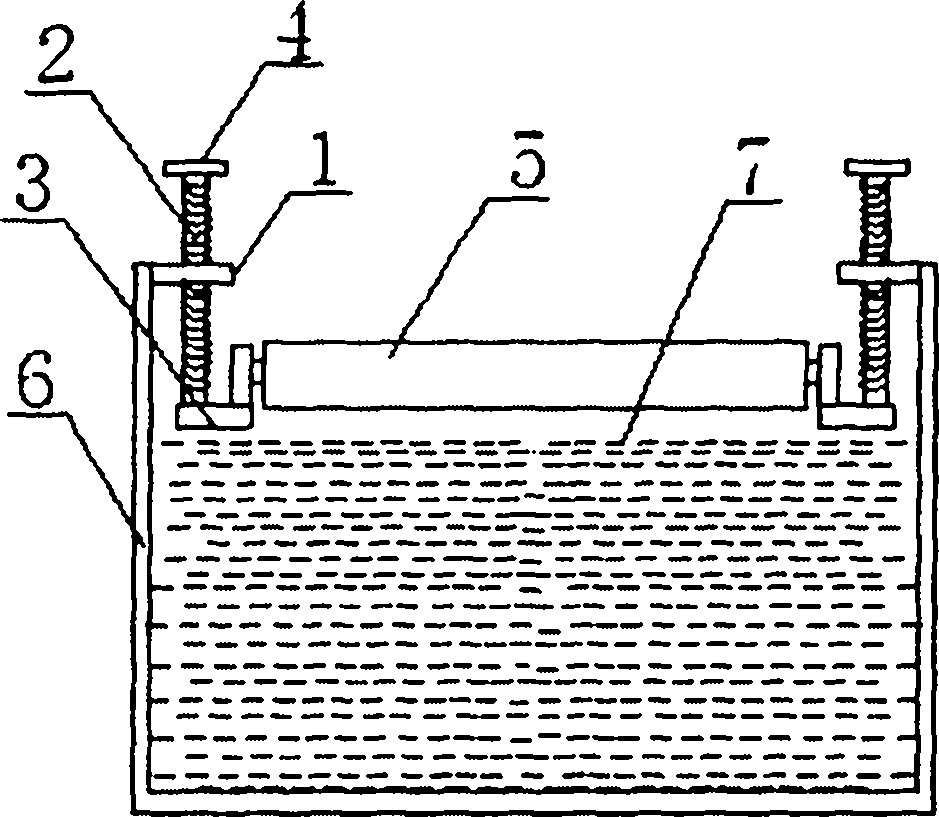

[0013] Such as figure 1 As shown, the bass water inlet adjustment device includes a support arm 1, a lifting rod 2, and a bearing assembly 3. The support arm 1 is correspondingly fixed on the upper edge of the solidification tank 6, and the support arm 1 is provided with a threaded hole with an internal thread The lifting rod 2 has an external thread corresponding to the internal thread, the lifting rod 2 passes through the threaded hole and is connected with the bearing assembly 3, the bearing assembly 3 is connected with the guide roller 4, and the upper end of the lifting rod 2 is provided with a handle 4.

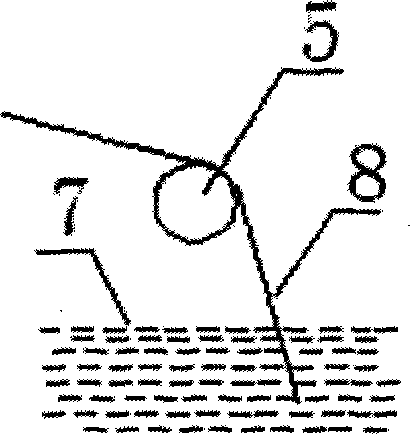

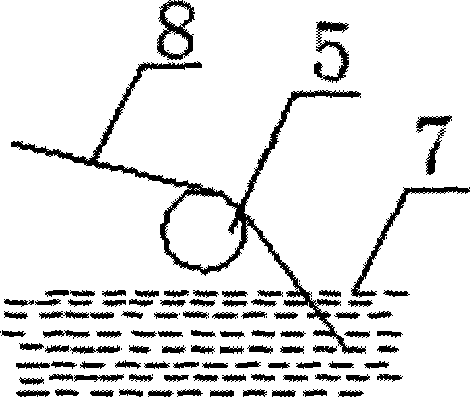

[0014] Such as figure 2 As shown, when it is necessary to prolong the water entry time of Bass 8 and reduce the water entry angle, the lifting rod 2 is rotated by the handle 4, and the lifting rod 2 drives the guide roller 5 to rise, so that the distance between the guide roller 5 and the water surface 7 in the coagulation tank is lengthened, thereby extending the Bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com