Slurry injection anchoring capsule

A bladder and grouting technology, applied in construction, sheet pile wall, infrastructure engineering, etc., can solve problems such as reducing the anchor pullout resistance, affecting the quality of the project, and preventing the external grouting pipe from being re-injected into the bottom of the bladder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

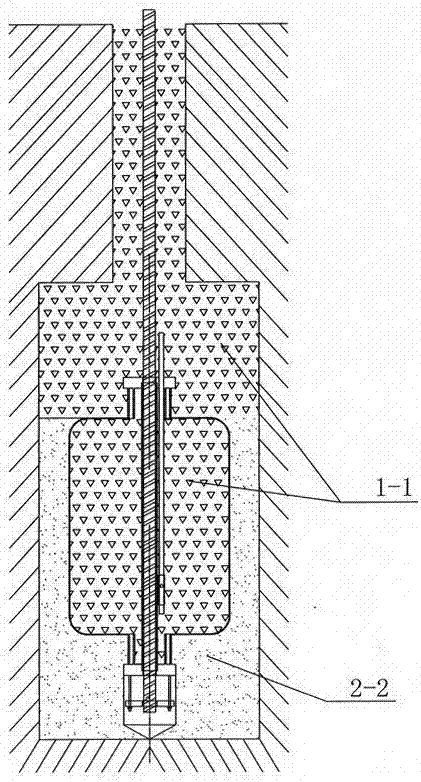

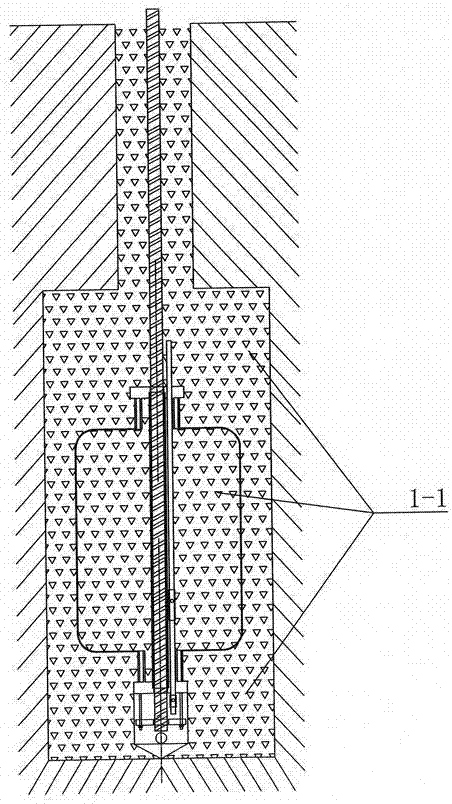

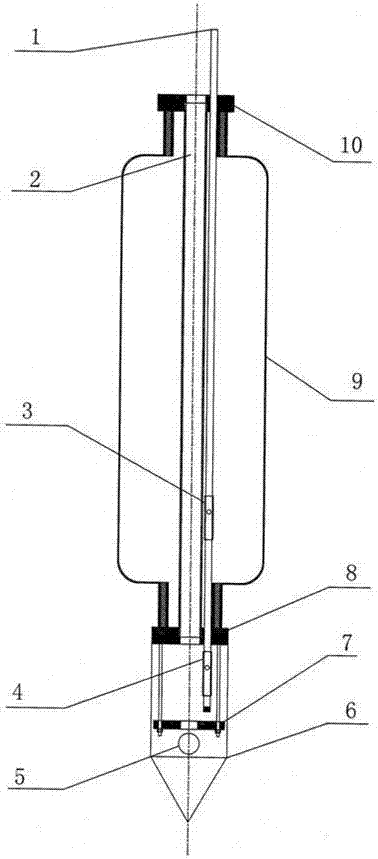

[0007] Describe embodiment in detail in conjunction with accompanying drawing, as image 3 As shown, it includes an upper chuck 10, a lower chuck 8, a positioning head guard 6 and a capsule body 9, and one or more guide tubes 2 are connected between the upper and lower chucks through the direction of the central axis of the capsule body. The outer wall of the upper positioning head guard is provided with at least one slurry discharge hole 5, and a round supporting plate 7 is installed with a suspender in the cavity of the positioning head guard, and passes through the upper chuck through the capsule body and the lower chuck to reach the positioning A grouting pipe 1 is installed in the head guard, a low-pressure grouting check valve 3 is installed in the capsule body on the grouting pipe, and a high-pressure check valve 4 is installed in the positioning head guard on the grouting pipe. The capsule body is made of reverse osmosis anti-corrosion cloth. A one-way valve is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com