Electroslag remelting device for producing composite roll by preheating consumable electrode and method of electroslag remelting device

A technology of consumable electrodes and composite rolls, which is applied in the field of electroslag remelting, can solve the problems of inability to efficiently produce high-quality bimetal composite rolls, accelerate the melting of metal consumable electrodes, and reduce the residence time of the roll core. Avoids mass melting, promotes uniformity, reduces residence time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

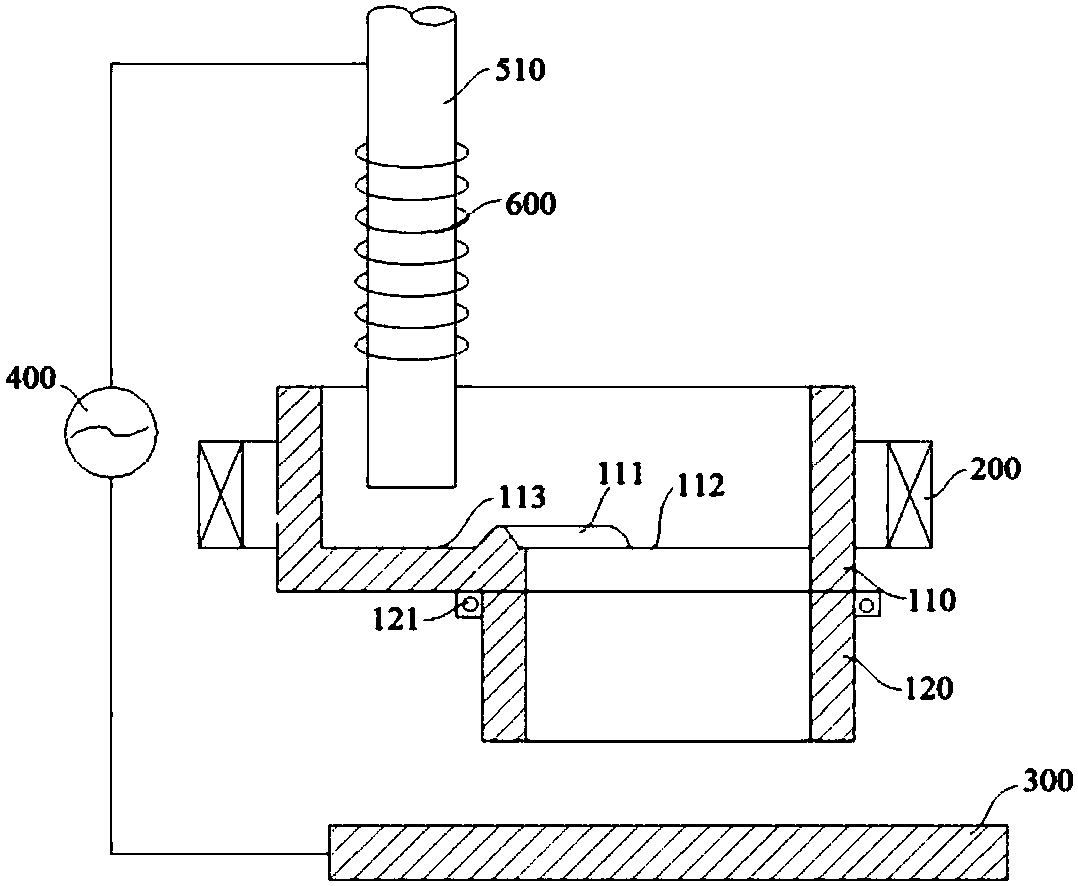

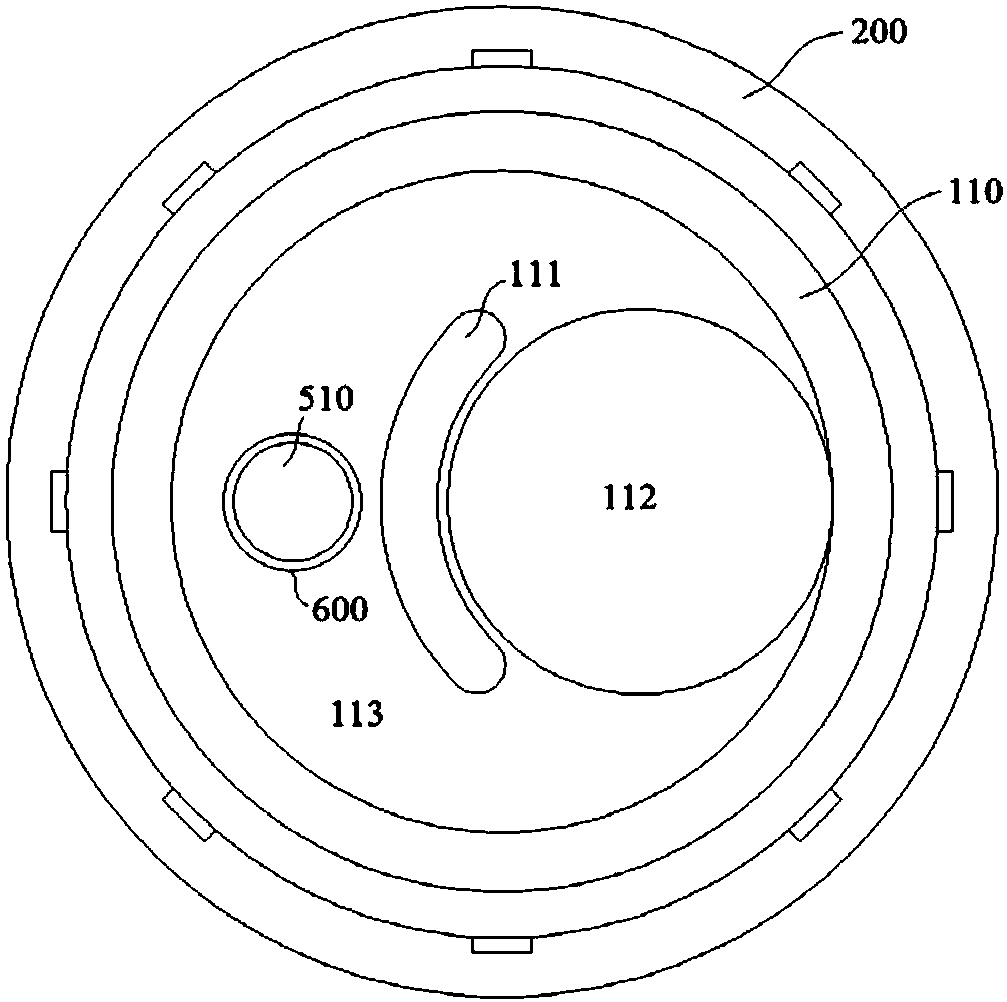

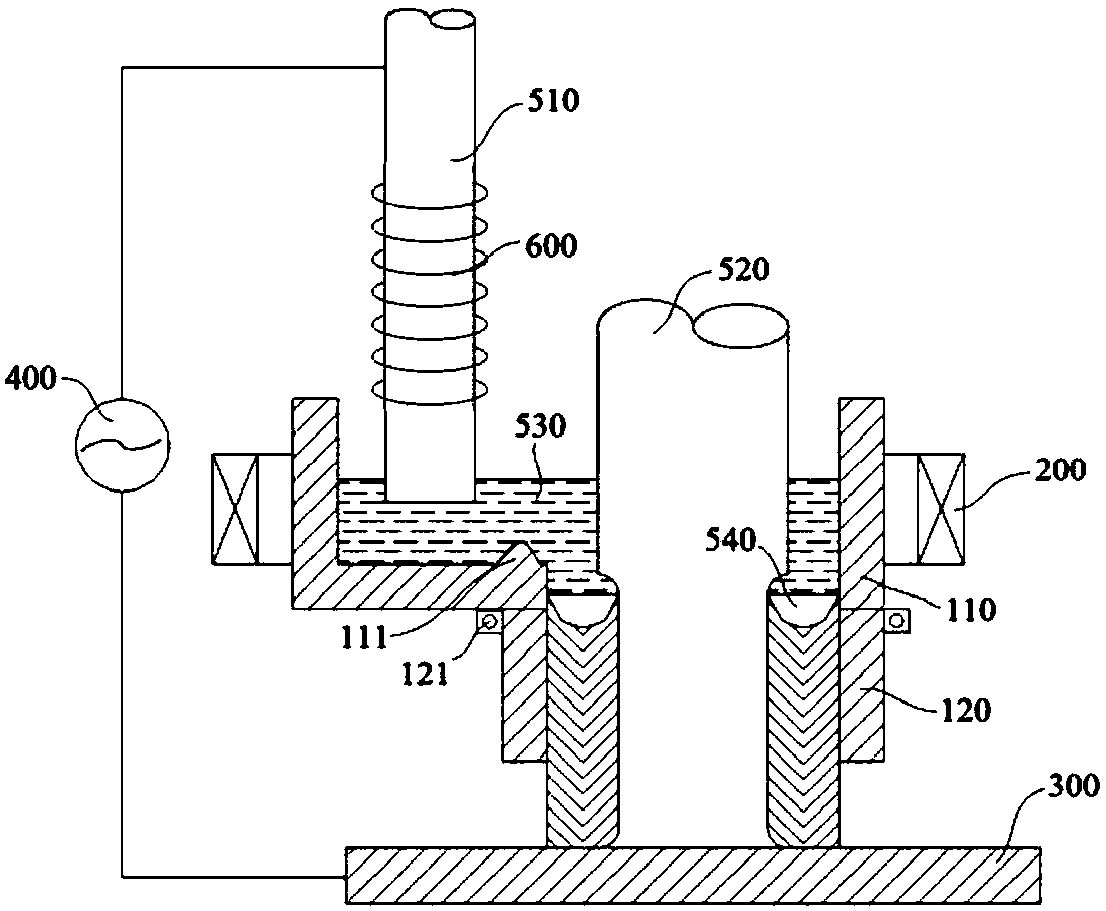

[0047] refer to figure 1 , figure 2 , image 3 and Figure 4 As shown, an electroslag remelting device for preheating consumable electrodes to produce composite rolls in this embodiment includes an eccentric mold, a bottom water tank 300 and a metal consumable electrode 510; the eccentric mold includes an upper crystallizer Mold 110 and lower crystallizer 120, upper crystallizer 110 and lower crystallizer 120 axis centers are not on the same straight line, and lower crystallizer 120 is arranged on the bottom of upper crystallizer 110; The bottom of upper crystallizer 110 includes opening side 112 and smelting Side 113, the bottom of the opening side 112 is connected to the lower crystallizer 120, and the shape of the opening side 112 matches the upper port surface of the lower crystallizer 120; the bottom surface of the upper crystallizer 110 except the opening side 112, other areas are the melting side 113, and the upper part of the melting side 113 A metal consumable elect...

Embodiment 2

[0056] Such as Figure 5 As shown, the present embodiment is basically the same as Embodiment 1, the difference is that in the present embodiment, the included angle α=45° between the upstream surface 111A of the diversion dam 111 and the bottom end surface, and the angle between the back flow surface 111B of the diversion dam 111 and the bottom surface The angle between the end surfaces is β=70°, and the height of the diversion dam 111 is 1 / 4 of the distance from the bottom surface of the upper crystallizer 110 to the bottom surface of the metal consumable electrode 510. When the molten metal hits the diversion dam 111, it is not drained A part of the molten metal directly crosses the top of the diversion dam 111, and the top of the cross-section direction of the diversion dam 111 is arc-shaped, and the molten metal is easier to cross the top of the diversion dam 111; The angle α is smaller than the angle β between the backflow surface 111B and the bottom end surface of the d...

Embodiment 3

[0058] Such as Figure 6 As shown, this embodiment is basically the same as Embodiment 1, the difference is: this embodiment is provided with a lower stirring coil 210 below the electromagnetic stirring coil 200, and the stirring range of the lower stirring coil 210 includes the molten pool 540 and its upper vicinity , the temperature in the area near the top of the molten pool 540 is relatively low, and the temperature of the molten metal in this area is difficult to control, and it is easy to solidify and cause the smelting process to be interrupted. The alternating flow in this area relieves the decrease of the temperature in this region; under the agitation of the lower stirring coil 210, the molten pool 540 flows, which breaks the columnar crystals being produced and produces more nucleation cores, thus promoting the transformation of columnar crystals to equiaxed crystals. transformation. Improve the quality of the roll face.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com