High-strength low-hydration-heat low-density cement paste system for well cementation, and preparation method thereof

A low-heat of hydration, high-strength technology, applied in chemical instruments and methods, drilling compositions, etc., to achieve the effects of improving technical water, delaying thickening time, and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] 3. On the basis of above research results, the present invention further provides a kind of preparation method of cement slurry system with high strength, low heat of hydration and low density for well cementing, comprising the following steps:

[0057] S1. Weigh the raw materials according to the following parts by weight: 25-35 parts of Portland cement with low heat of hydration, 20-25 parts of vitrified microspheres, 25-30 parts of slag powder, 8-10 parts of micro-silica fume, cooked 3-5 parts of gypsum, 1-2 parts of sodium sulfate, 1-2 parts of quicklime, 2-3 parts of slaked lime, 2-3 parts of sodium metasilicate, 0.5-1.5 parts of sodium carbonate, 2-3 parts of fluid loss reducer, 0.1-0.25 parts of drag reducer; 0-0.4 parts of retarder;

[0058] S2. Under normal temperature conditions, mix the raw materials weighed in S1 evenly to obtain mixed dry ash;

[0059] S3. Put 65-75 parts of water into the mixing cup of the constant-speed agitator, turn on the constant-spe...

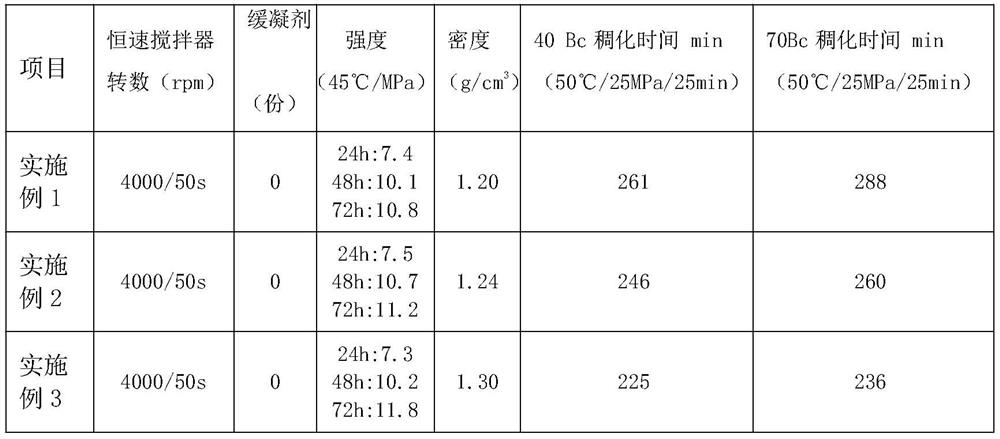

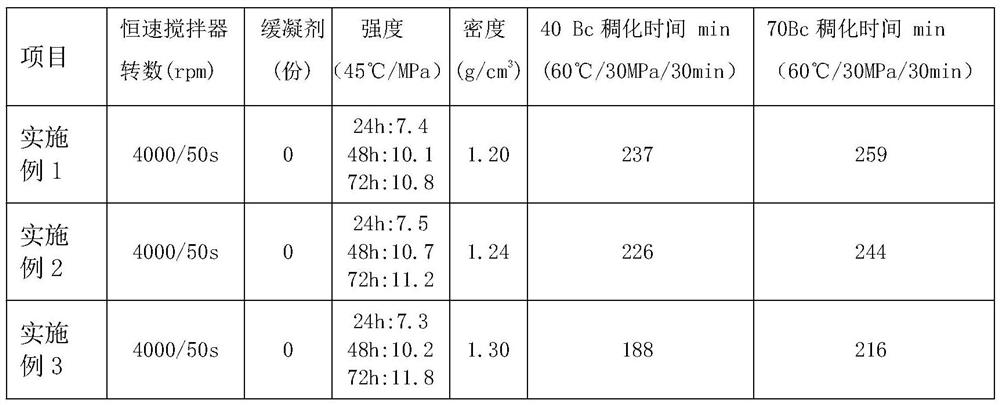

Embodiment 1

[0064] This embodiment provides a high-strength, low-heat-of-hydration, low-density cement slurry system for well cementing. Its formula is: 25 parts of low-heat of hydration cement+30 parts of 60-mesh closed-mouth vitrified perlite (vitrified microspheres)+ 25 parts of S105 slag powder + 10 parts of silica fume + 3.5 parts of plaster of paris + 3.0 parts of sodium metasilicate + 0.75 parts of sodium carbonate + 1.5 parts of sodium sulfate + 1.0 parts of quicklime + 1.0 parts of slaked lime + 2.2 parts of fluid loss reducer + 0.15 Parts of drag reducer + 75 parts of tap water.

[0065] The preparation method of the high-strength low-heat-of-hydration low-density cement slurry system for well cementing described in this embodiment comprises the following steps:

[0066] S1. Under normal temperature conditions, mix 25 parts of low heat of hydration cement, 30 parts of 60 mesh closed vitrified perlite, 25 parts of S105 slag powder, 10 parts of silica fume, 3.5 parts of plaster of...

Embodiment 2

[0069] This example provides a high-strength, low-heat-of-hydration, low-density cement slurry system for well cementing, the formula of which is: 25 parts of low-heat of hydration cement + 30 parts of 60-mesh closed vitrified perlite + 25 parts of S105 slag powder + 10 parts of silica fume + 3.5 parts of plaster of Paris + 2.5 parts of sodium metasilicate + 0.5 parts of sodium carbonate + 1.5 parts of sodium sulfate + 1.0 parts of quicklime + 1.0 parts of slaked lime + 2.2 parts of fluid loss reducer + 0.15 parts of drag reducer + 65 servings of tap water.

[0070] The preparation method of the high-strength low-heat-of-hydration low-density cement slurry system for well cementing described in this embodiment comprises the following steps:

[0071] S1. Under normal temperature conditions, mix 25 parts of low heat of hydration cement, 30 parts of 60 mesh closed vitrified perlite, 25 parts of S105 slag powder, 10 parts of silica fume, 3.5 parts of plaster, 2.5 parts of sodium m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com