Numerical control press fitting and disassembly machine for aero tires

A technology for aircraft tires and disintegrators, applied in tire installation, tire parts, transportation and packaging, etc., can solve the problems of low degree of automation, low universality, high labor intensity of workers, etc., and achieve a high degree of mechanization and automation. , The effect of improving work efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

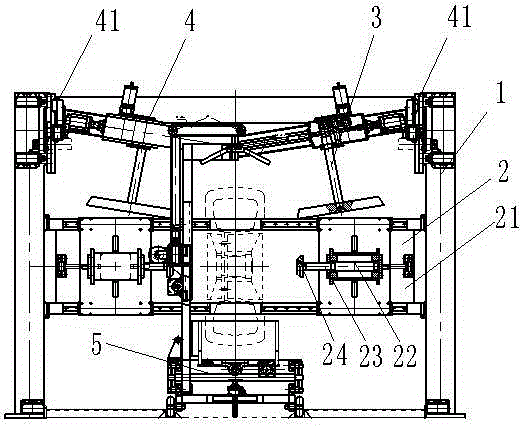

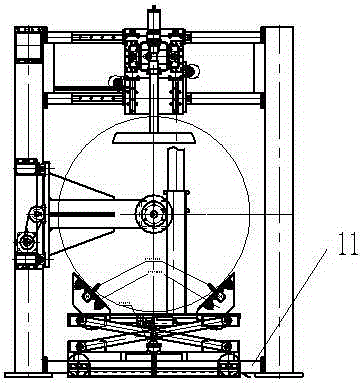

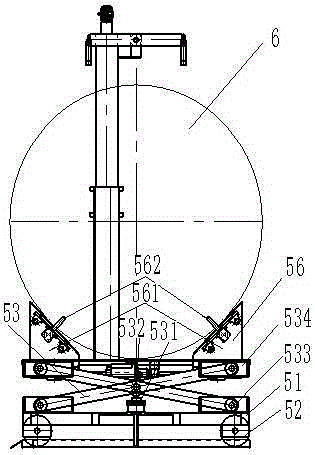

[0016] Such as Figures 1 to 4 As shown, the present invention discloses a numerical control press-fitting and decomposition machine for aircraft tires, comprising a frame 1, a wheel clamping device 2, a rolling wheel device 3, a V-shaped beam device 4, a control system, and the rolling wheel device 3 is set On the V-shaped beam 4, the rolling wheel device is made up of left and right gear boxes, rolling wheels and linear drive motor. The left and right gear boxes are installed on the slide rails of the slide table at both ends of the V-shaped beam. The two rollers run in opposite directions at a constant speed. The two gearboxes are driven by their own independent linear motors to move linearly with a 10-degree inclination to the center. It can move at the same speed in opposite directions, or in the same direction at the same speed, or independently in any directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com