Autoloader

A tray loading machine and automatic technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of low tray loading efficiency and low degree of mechanization, and achieve the effect of improving tray loading efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

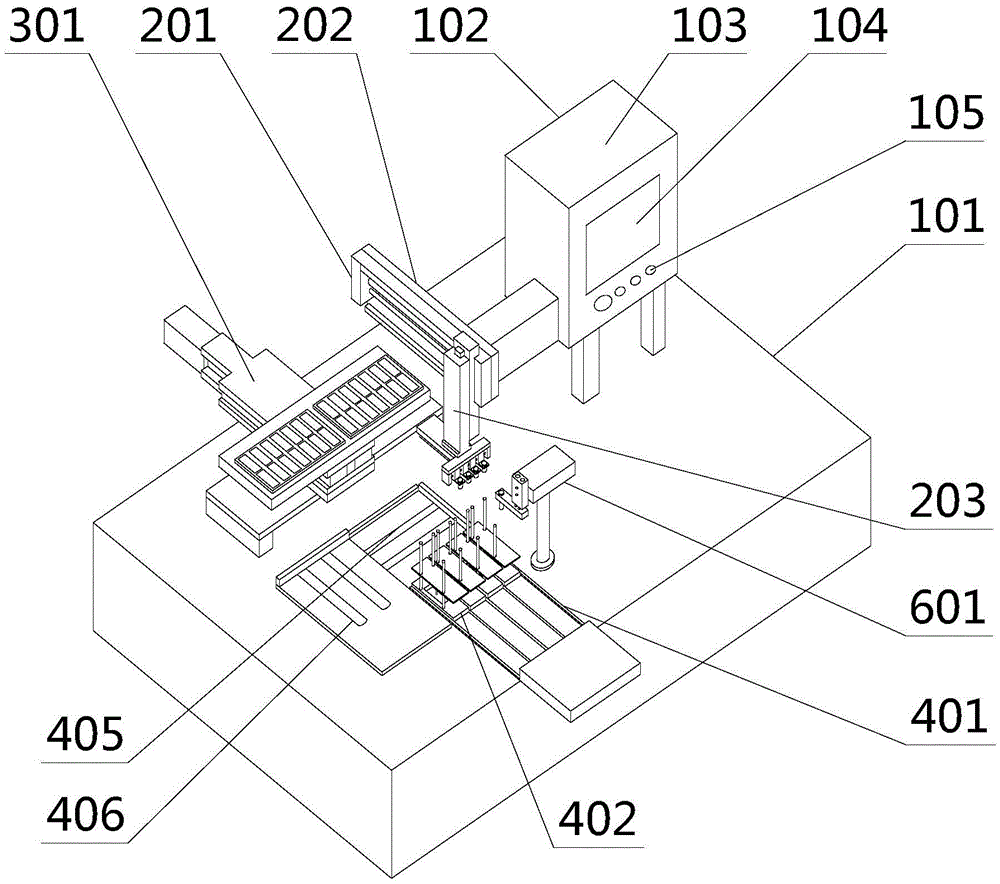

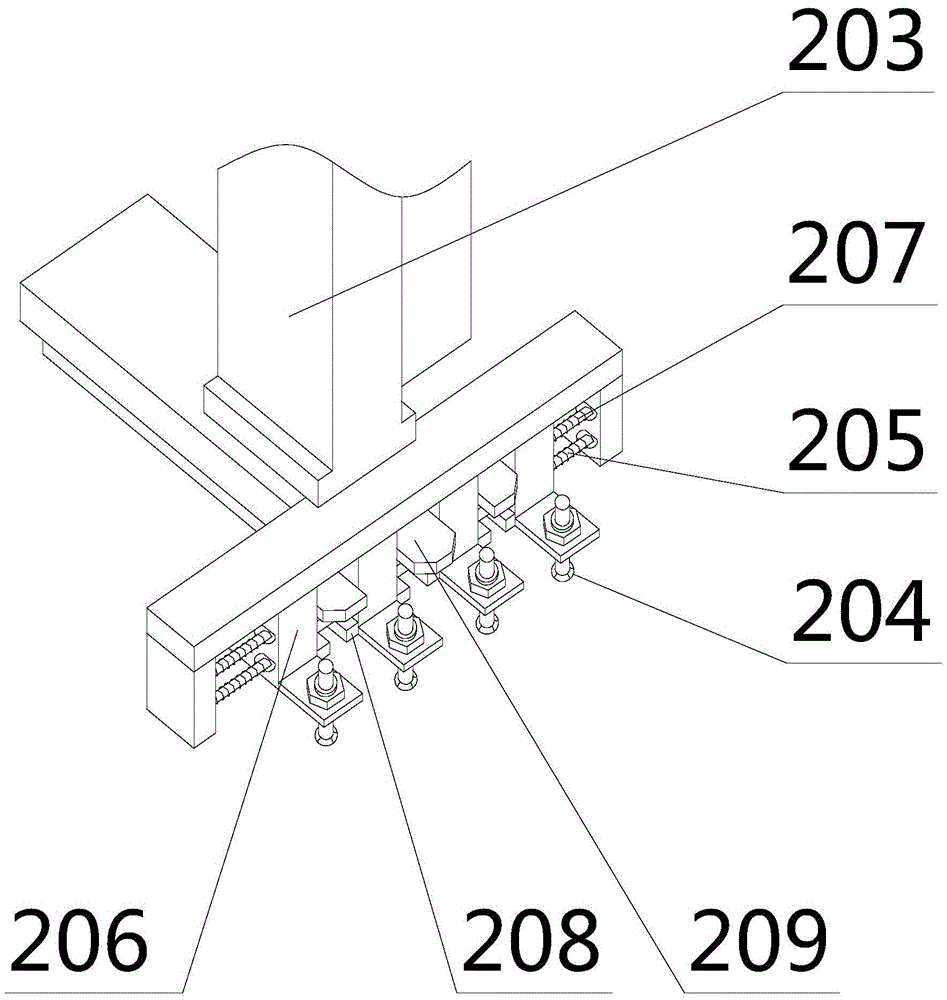

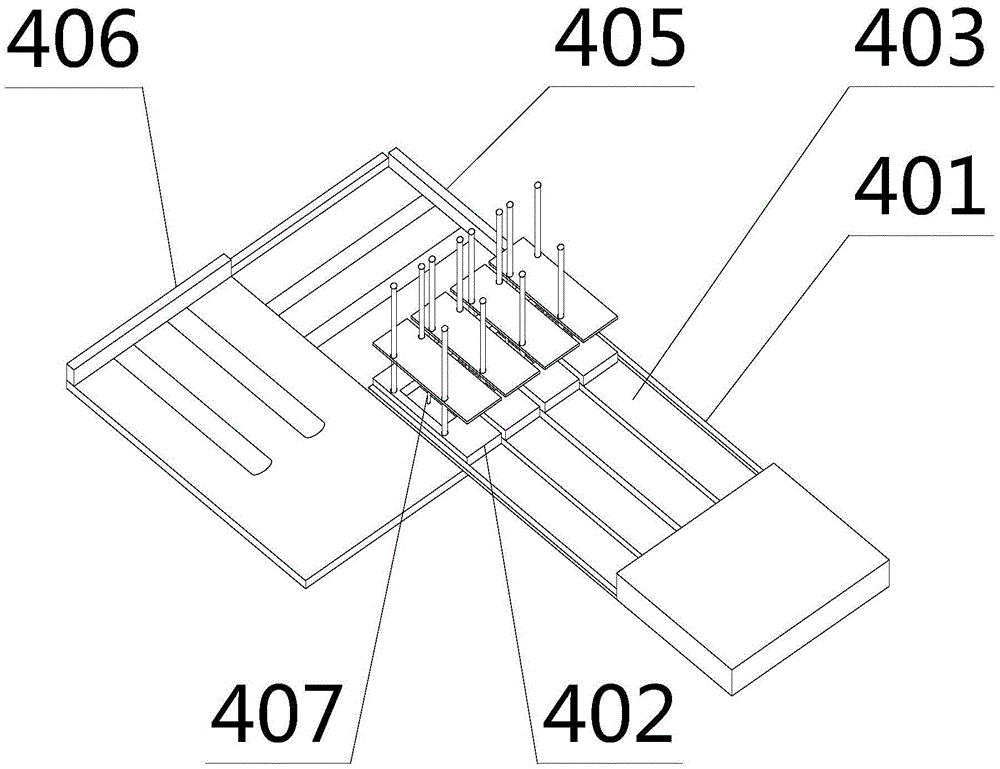

[0048] figure 1 It shows the overall structure of the automatic disk loading machine provided by the embodiment of the present invention; figure 2 It shows the structure of the grasping part of the manipulator 201 of the automatic disk loading machine provided by the embodiment of the present invention; Figure 11 shows the construction of an existing shield; see figure 1 , figure 2 and Figure 11 , the present invention provides an automatic disk loading machine, the automatic disk loading machine is used to place the shielding cover on the corresponding part of the tray 305, the shielding cover is formed by punching a metal sheet, and the first cover hole 701 is arranged on the shielding cover and the second mask hole 702 . The automatic disk loading machine includes a machine body 101 , a mobile platform device 301 for placing a tray 305 , a manipulator 201 for transferring a shield to the tray 305 , a feeding device 401 and a control system 102 .

[0049] The manipu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com