Reagent storage device

A technology for storage devices and reagents, applied in household refrigeration devices, packaging, transportation and packaging, etc., can solve the problems of high-pressure pipeline safety hazards, easily affecting experimental results, and low degree of automation, achieving a high degree of automation and facilitating later maintenance. , Compatible with a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 (the first reagent storage device):

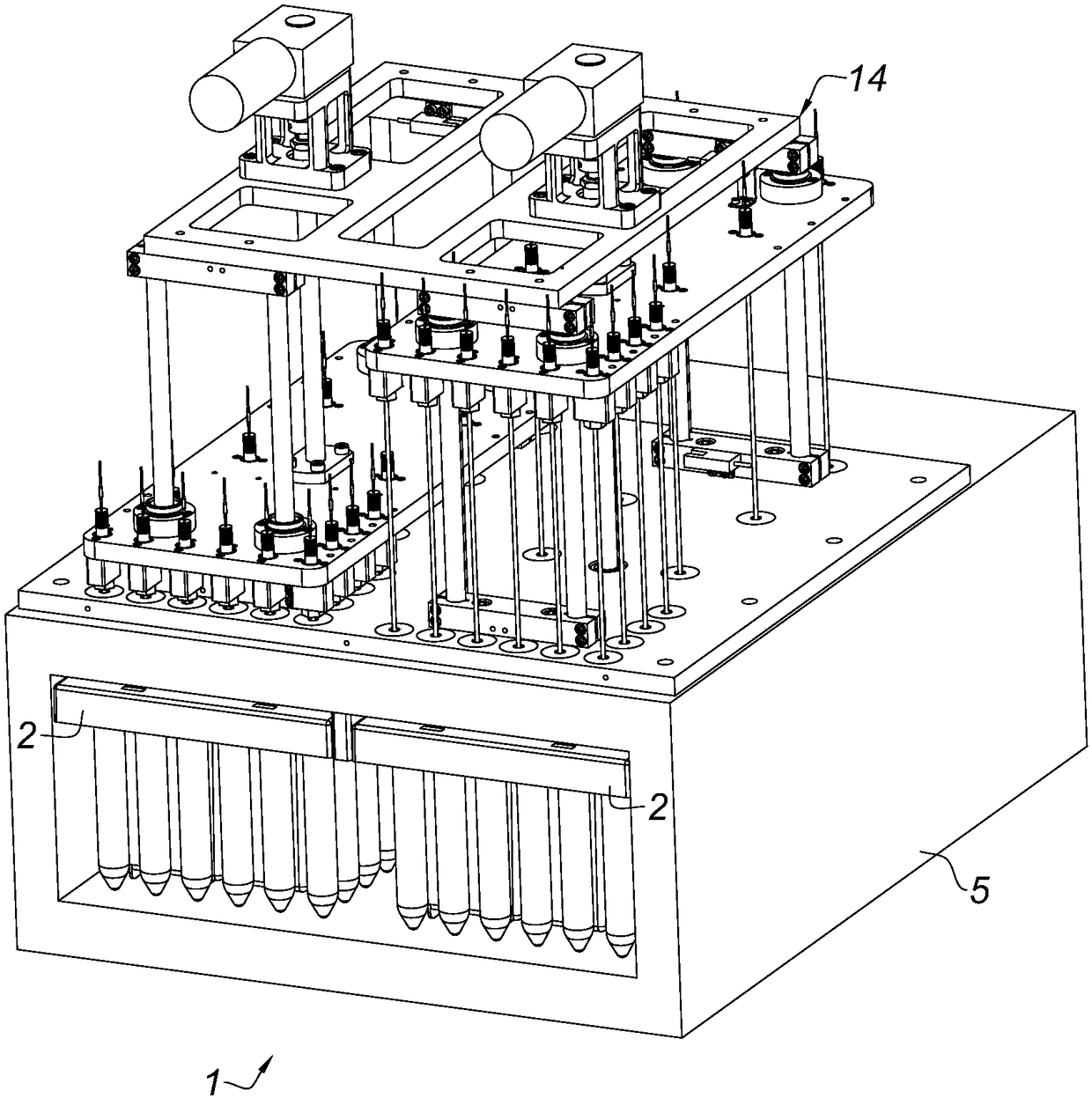

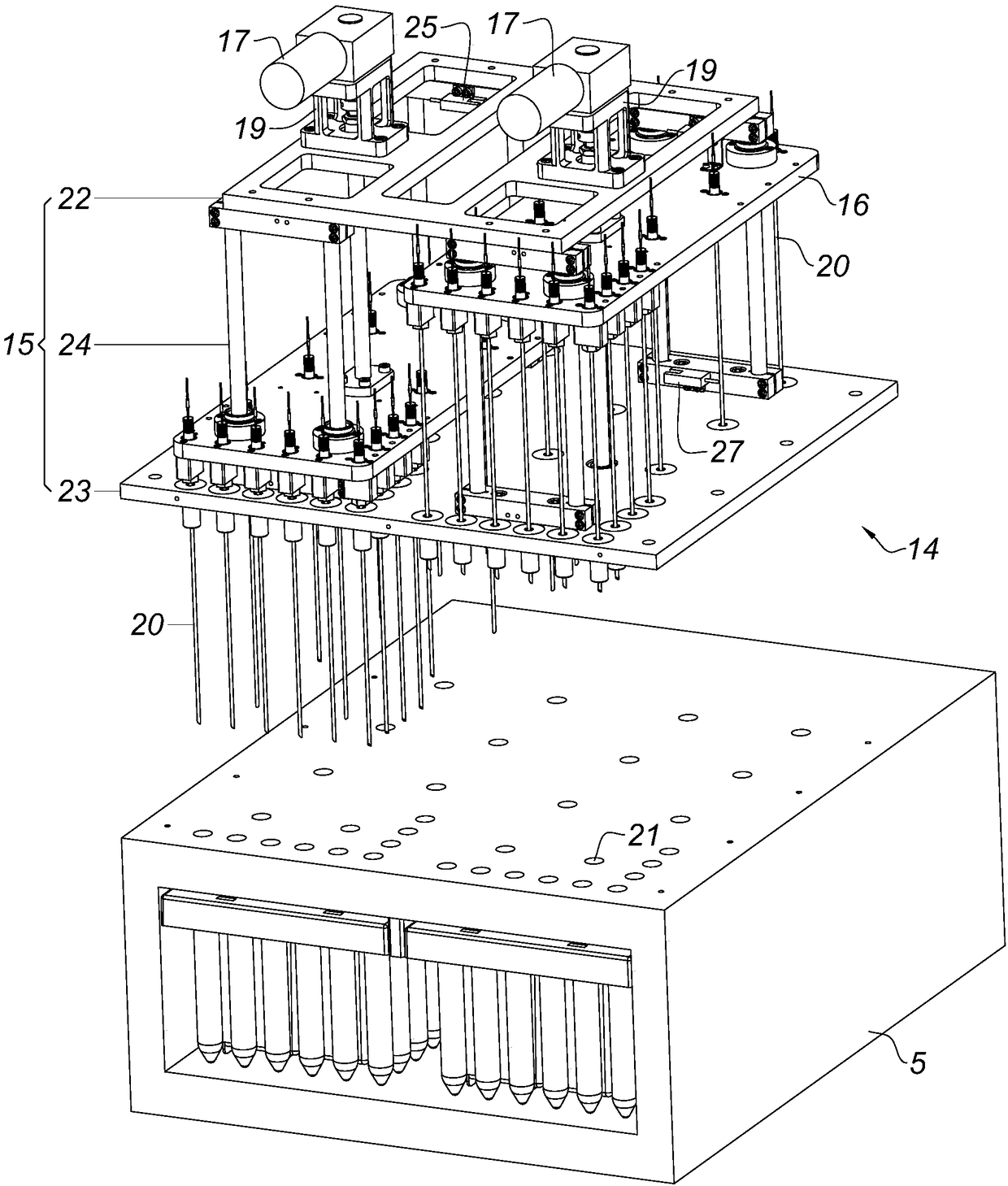

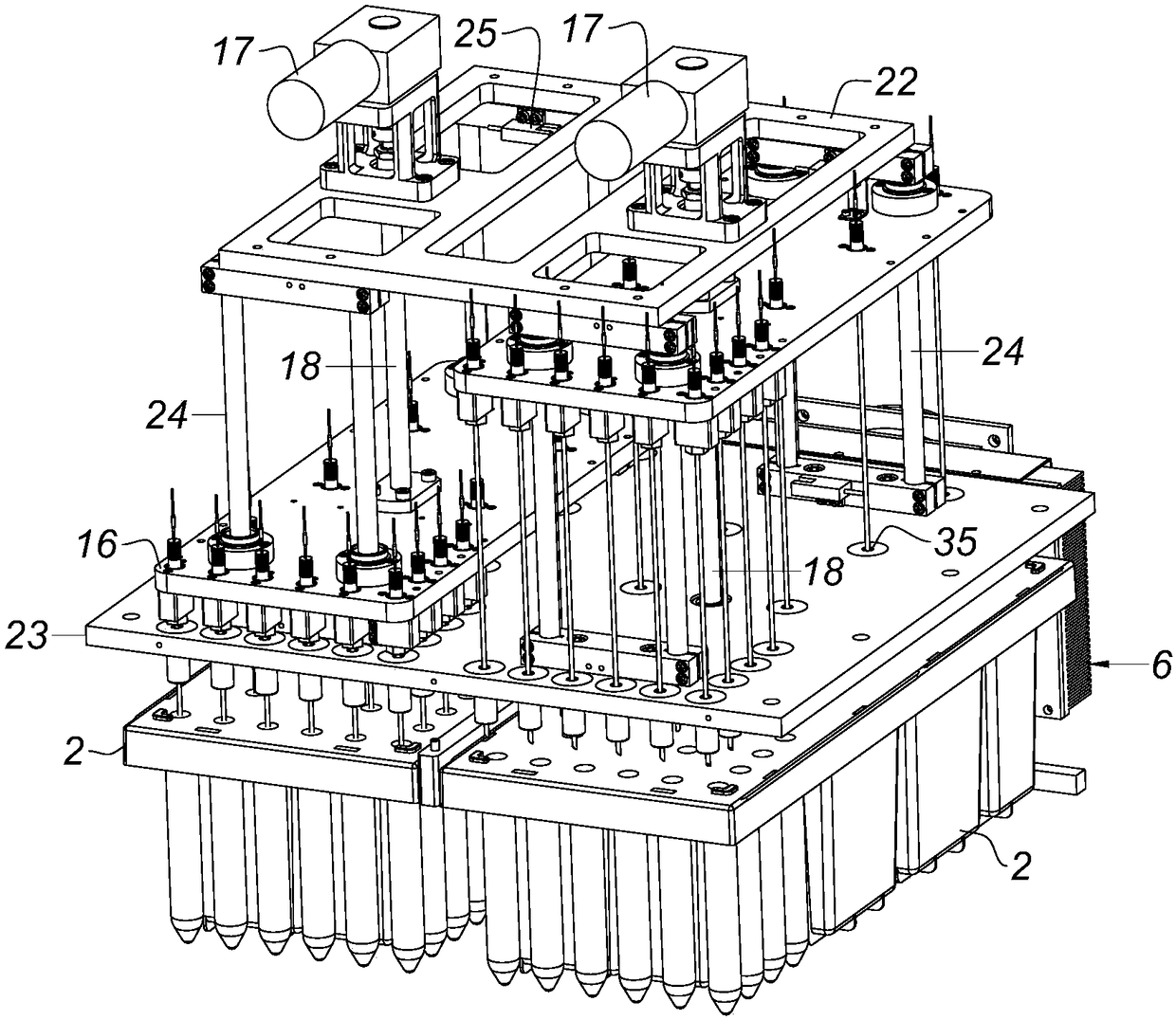

[0046] see Figure 1-Figure 11 , the present embodiment provides a reagent storage device 1, which includes:

[0047] Reagent box 2, it is provided with several reagent accommodating cavities 3, see specifically Figure 10 and Figure 11 , the reagent box 2 contains reagent chambers 3 of different shapes, which are mainly tubular and cuboid in the figure, and these reagent chambers 3 have an opening at the upper end; the upper surface 4 of the kit 2 is provided with a sealing film, The sealing film seals each reagent containing cavity, that is, the sealing film seals each opening, Figure 10 hides the seal;

[0048] Heat-insulating box 5, the wall of which is filled with heat-insulating and heat-preserving materials, the test kit 2 is placed in the heat-insulating box 5, and a temperature sensor is arranged in the heat-insulating box 5 for monitoring the temperature in the box;

[0049] The temperature control modu...

Embodiment 2

[0060] Embodiment 2 (the second reagent storage device):

[0061] see Figure 12-Figure 19 , the present embodiment provides a reagent storage device 1', which includes:

[0062] Reagent box 2', which is provided with several reagent accommodating cavities, the upper surface of the reagent box 2' is provided with a sealing film, and the sealing film seals each reagent accommodating cavity;

[0063] Insulated box 5' is provided with a door 36', and the test kit 2' is placed in the insulated box 5', which is provided with a temperature sensor in the insulated box 5';

[0064] The temperature control module 6' is located on the heat insulation box 5', and the temperature control module 6' includes built-in heat transfer fins, external heat transfer fins, Peltier refrigeration heaters, heat insulation cotton, built-in fans and External fan, heat insulation cotton is sandwiched between the built-in heat transfer fins and external heat transfer fins, the heat insulation cotton has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com