Full-automatic machine for sewing trouser buttons

A trousers buttoning machine, fully automatic technology, applied in the direction of sewing tools and other directions, can solve the problems of easily hurting operators, complicated operation of trousers buttoning, improving product qualification rate, etc., to reduce labor intensity and facilitate large-scale production. Batch buttoning, high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with accompanying drawing description and specific embodiment:

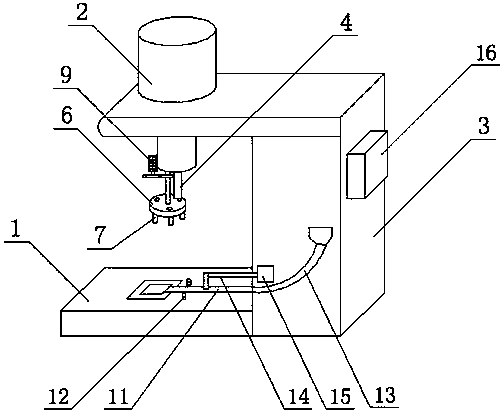

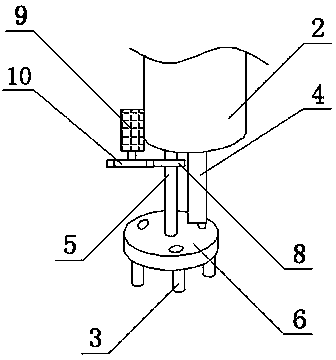

[0020] see figure 1 , figure 2 , a kind of fully automatic trousers buttoning machine of the present invention, comprises base 1, and column 3 is fixed on base 1, and machine head 2 is installed on the upper end of column 3, and striking driving device is installed in described machine head 2, and striking drive The lower end of the shaft center at the bottom of the device is vertically fixed with a beating rod 4, and the bottom of the beating drive device is located on the outside of the beating rod 4, and a rotating disc 6 is installed through a rotating shaft 5, and more than one is fixed on the circumference of the bottom surface of the rotating disc 6. Rotating die head 7, a plurality of rotating die heads 7 are distributed in a ring with the rotating shaft 5 as the center of the circle, a rotating drive device is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com