Transportation method and device for optical cable bundle tube reel

The technology of a transportation device and transportation method, which is applied in the field of optical cable production, can solve problems such as hidden safety hazards and low efficiency, and achieve the effects of reducing labor intensity and rationally utilizing plant space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

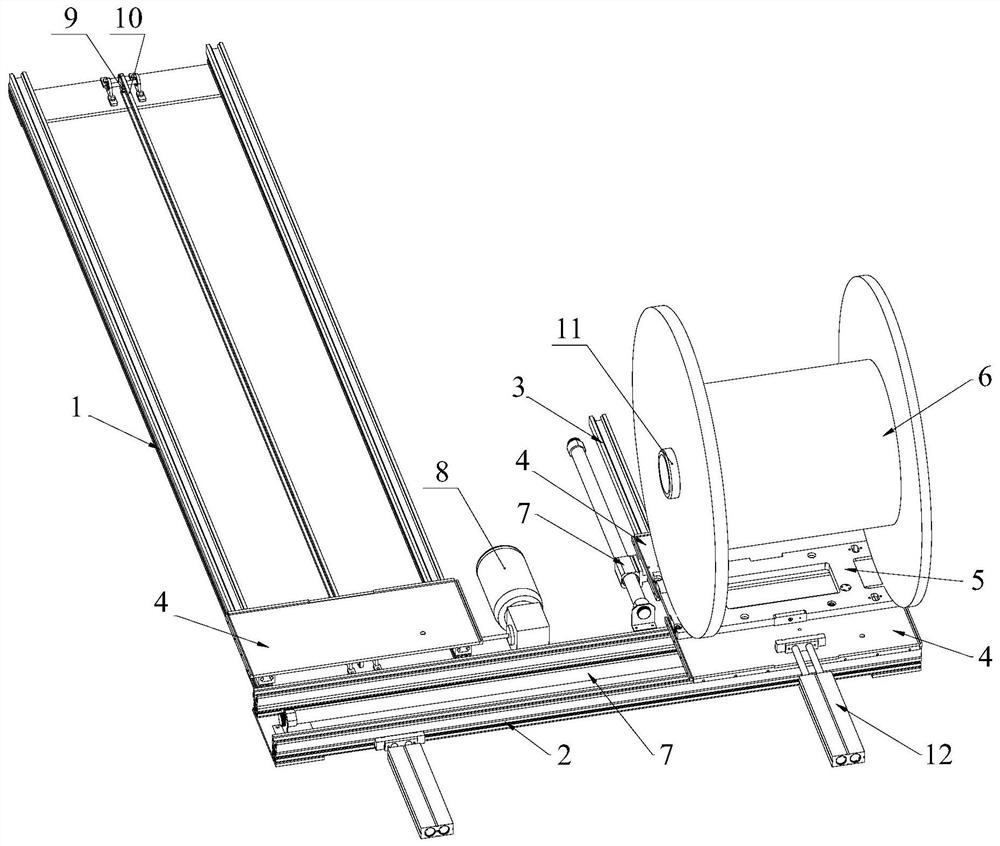

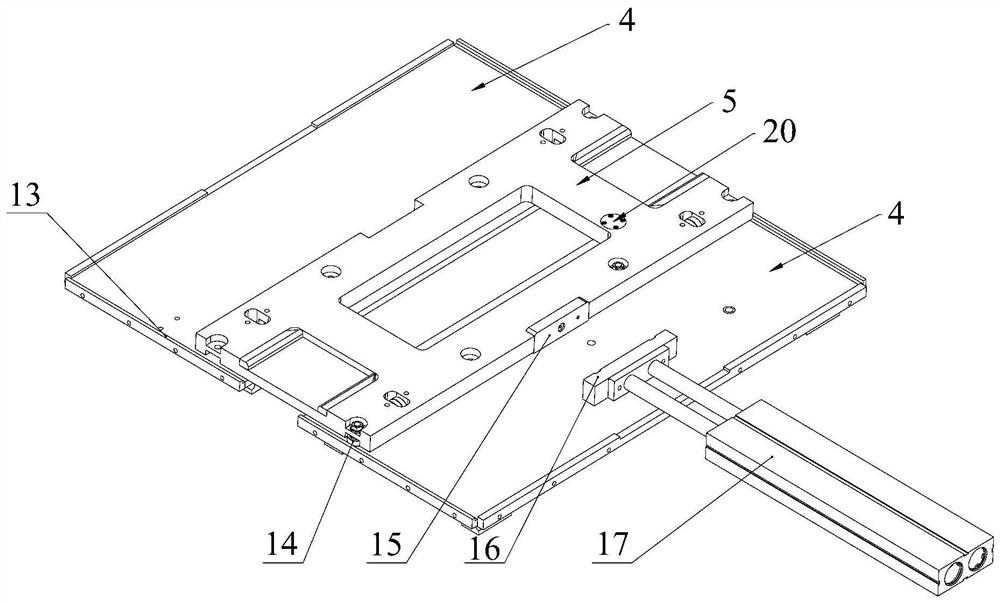

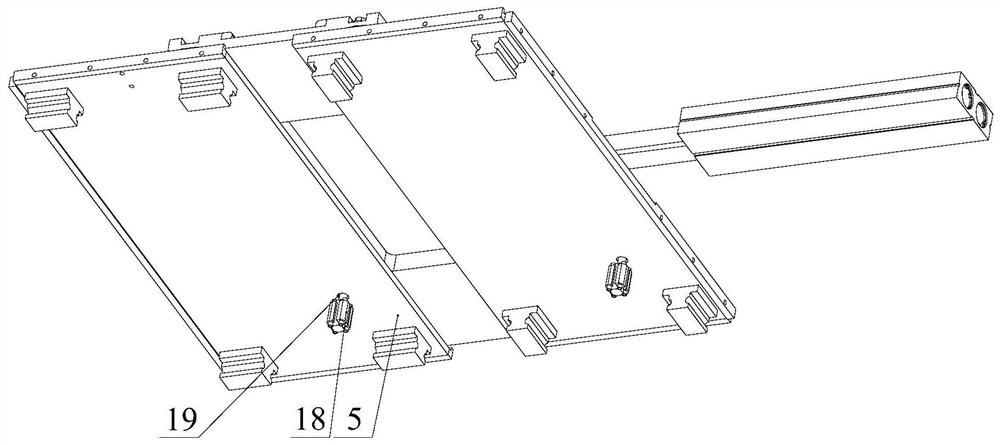

[0048] The present invention will be described in detail below with reference to the accompanying drawings.

[0049] A method for transporting an optical cable bundle tube reel, the tube bundle reel is transported to a clamping and rotating station through a movable pallet movably arranged on a guide rail, wherein the tube bundle reel is placed on a transfer platform, and the tube bundle reel is moved through a moving platform. The carrier table is fixed on the movable pallet, and after the tube bundle reel is placed on the transfer table, the height difference between the center line of the clamping part of the bundle tube reel and the center line of the top shaft on the clamping rotation station is 6-8mm.

[0050] In this embodiment, there are multiple guide rails, and each guide rail is connected in sequence, one guide rail extends to the empty area of the tube bundle, and one guide rail extends to the clamping and rotating station; each guide rail is movably provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com