Volume reduction method and device aiming at fly ash stabilization substance

A stabilized and fly ash technology, which is applied in the field of volume reduction for fly ash stabilized products, can solve the problems of increasing the density of fly ash stabilized products, and achieve the effects of improving transportation efficiency, flexible layout, and environmentally friendly operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

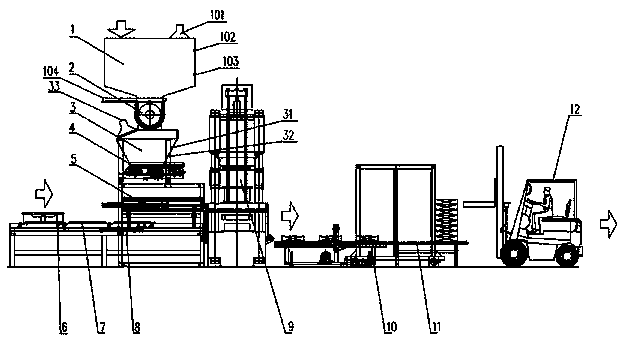

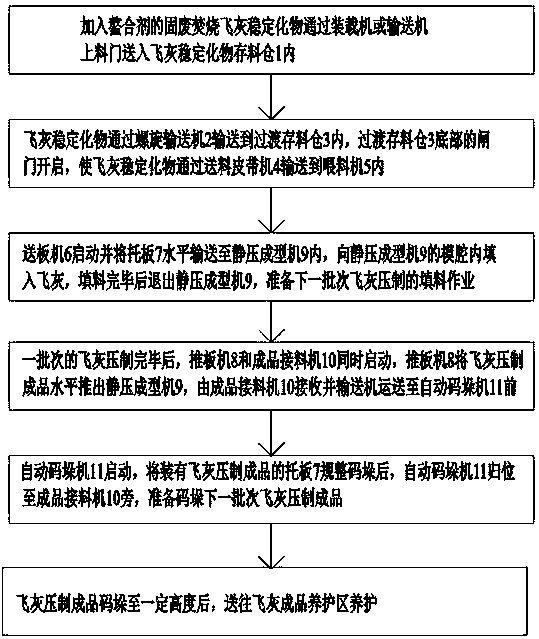

[0031] Please see attached figure 1 , a volume reduction device for stabilized fly ash, including a fly ash stabilized storage bin 1, a screw conveyor 2, a transition storage bin 3, a feeding belt conveyor 4, a feeder 5, a plate feeder 6, a tray Plate 7, push plate machine 8, static pressure forming machine 9, finished product receiving machine 10 and automatic palletizer 11; the solid waste incineration fly ash stabilized product added with chelating agent is stored from the fly ash stabilized product through a loader or conveying equipment The top of bin 1 is fed in, the feed port of screw conveyor 2 is connected to the bottom discharge port of fly ash stabilized storage bin 1, and the feed port of transition storage bin 3 is set at the bottom discharge of screw conveyor 2 Below the mouth; the feeding belt conveyor 4 is arranged at the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com