Steel bent pipe facade transmission hot winding 3PE molding method

A forming method and tube facade technology, applied to tubular objects, other household appliances, household appliances, etc., can solve the problems of uneven coating thickness, low degree of mechanization, and low coating production efficiency, so as to ensure complete adhesion The effect of connecting and preventing changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below, the technical scheme of the present invention will be further described in conjunction with the accompanying drawings:

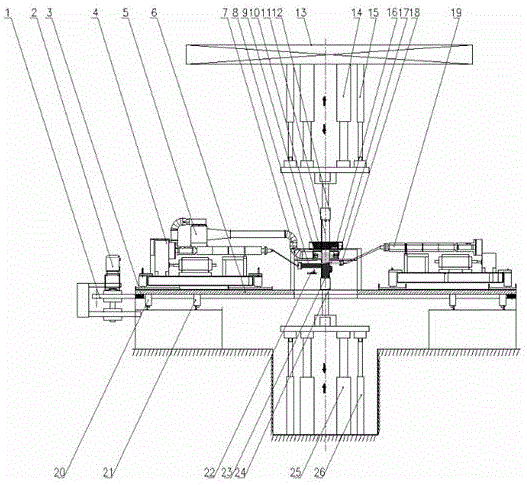

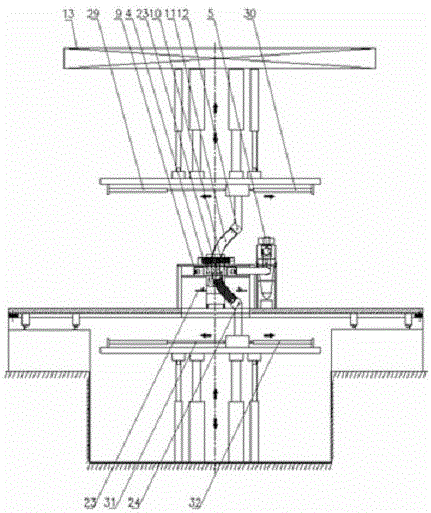

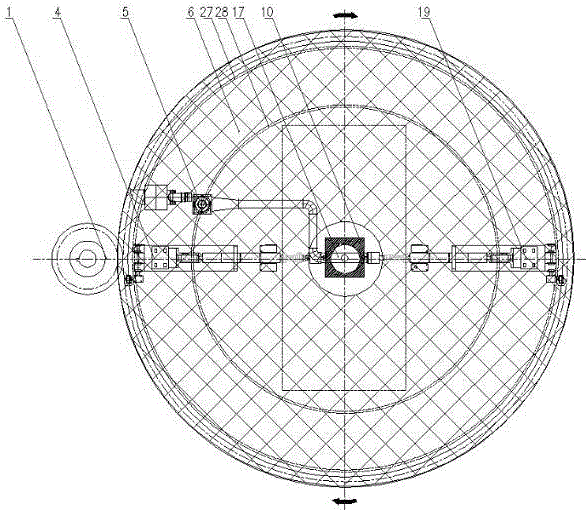

[0016] 1. If figure 1 As shown in Fig. 1, a method for forming a steel curved pipe with thermal winding 3PE on the façade, the process route is: the steel curved pipe 11 with the surface cleaned is hoisted to the upper hydraulic pipe delivery mechanism 14 installed on the top fixing device 13 and installed In the middle of the lower hydraulic connection mechanism 25 at the bottom, the upper hydraulic cylinder 15 is lifted downward and the lower hydraulic cylinder 26 is lifted upward, and the upper tube inner support mechanism 12 and the lower tube inner support mechanism 24 are sent into the upper and lower tubes of the elbow. In the mouth, use the hydraulic inner support block installed on the inner support mechanism 12 of the upper tube and the inner support mechanism 24 of the lower tube to open and fix the elbow and position it, and ensure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com