Automatic assembling machine of rotors and bearings of motors

An automatic assembly machine and rotor technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of uneven rotor and bearing assembly, easy offset between rotor and bearing, etc., to achieve stable feeding, smooth assembly, Assemble accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

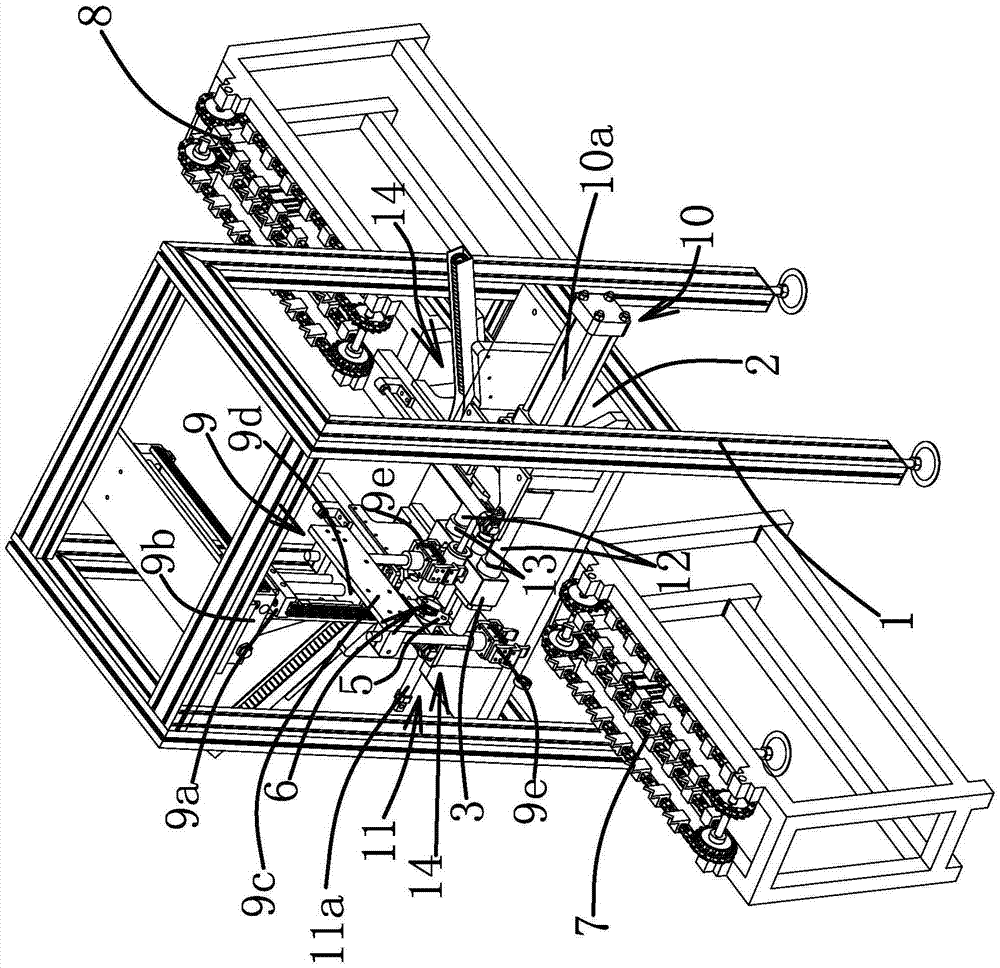

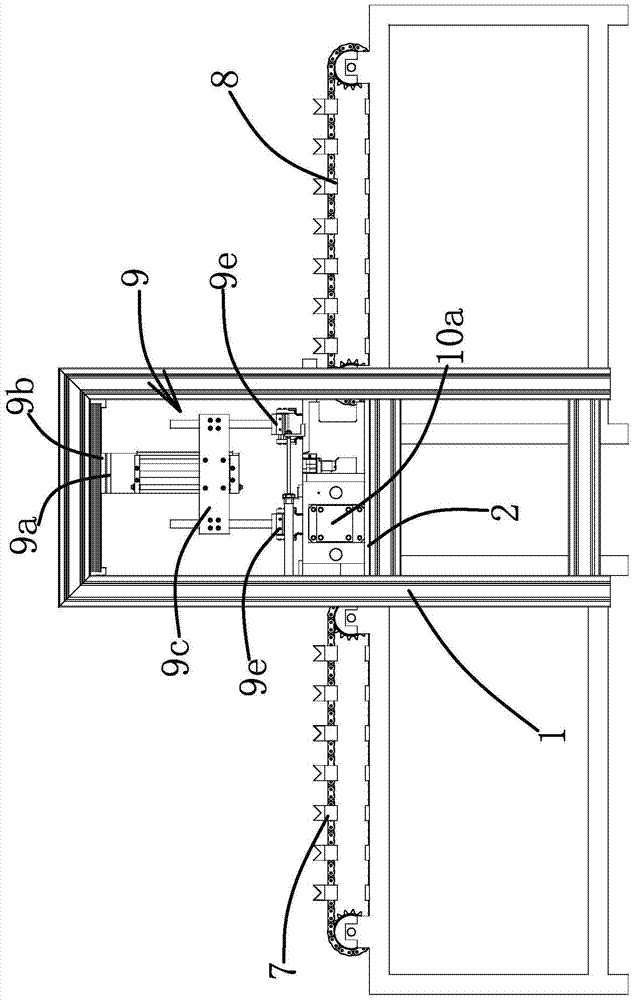

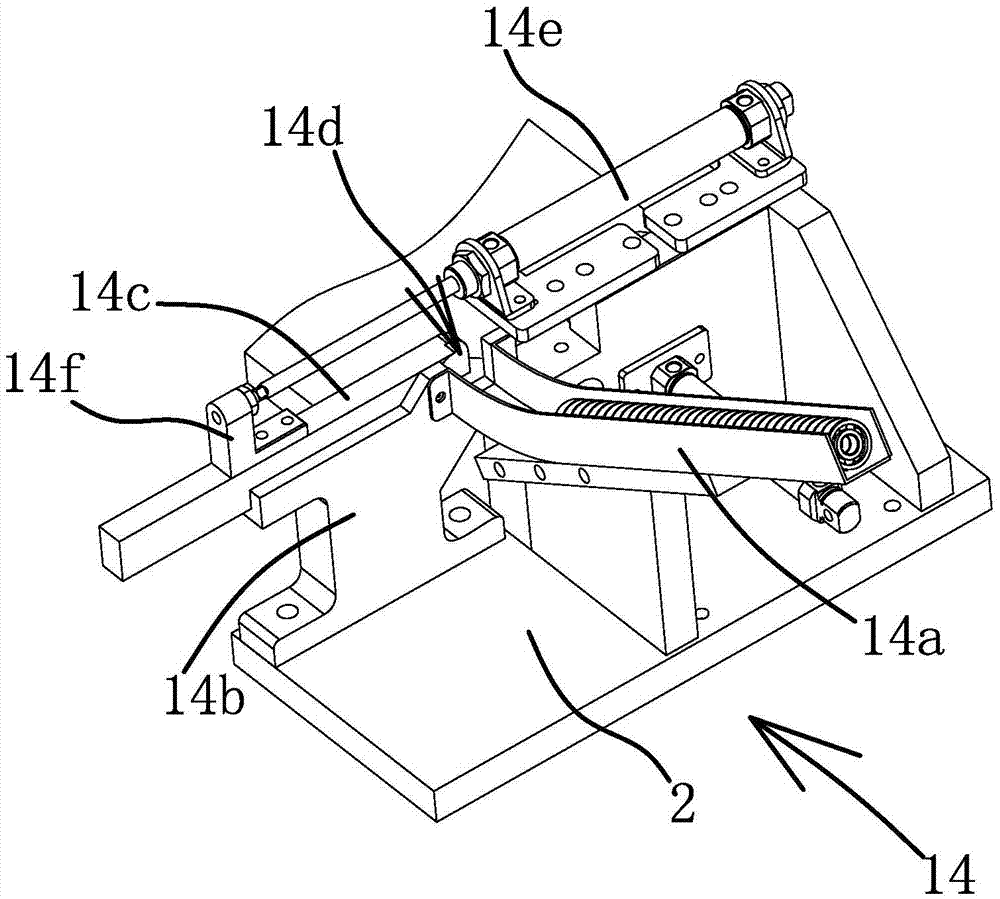

[0026] Such as Figures 1 to 3 As shown, the automatic assembly machine for the rotor and bearing of the motor includes a frame 1 and a workbench 2 arranged on the frame 1. The workbench 2 is provided with a positioning seat 3 that can be used to place the rotor. The longitudinal direction of the positioning seat 3 is The two sides are provided with material receiving block 1 4 and material receiving block 2 5, and the side of material receiving block 1 4 and material receiving block 2 facing the positioning seat 3 is provided with a receiving groove 6 for placing the bearing, and the positioning seat 3 Conveyor chain 1 7 and conveyer chain 2 8 capable of conveying the rotor are respectively provided on both lateral sides,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com