Automatic arranging machine

A discharger and automatic technology, which is applied to conveyor objects, stacking, transportation and packaging of objects, etc., can solve the problems of small size of workpieces, large manual operation workload, waste of time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

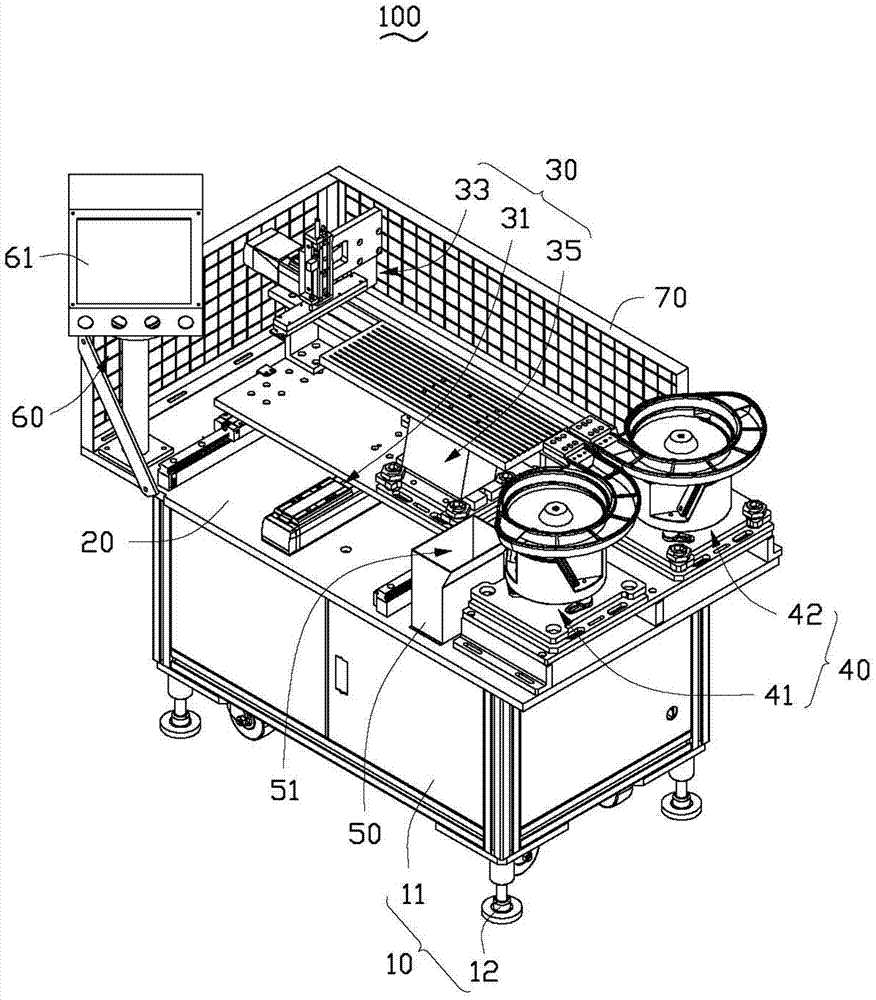

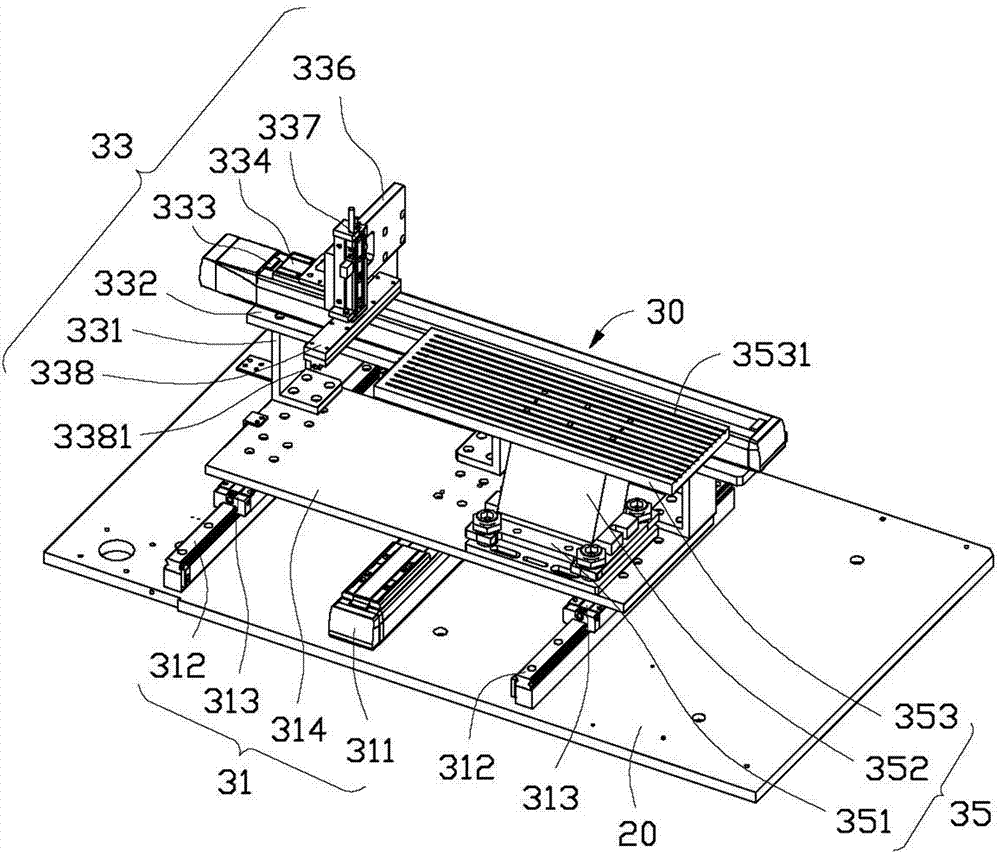

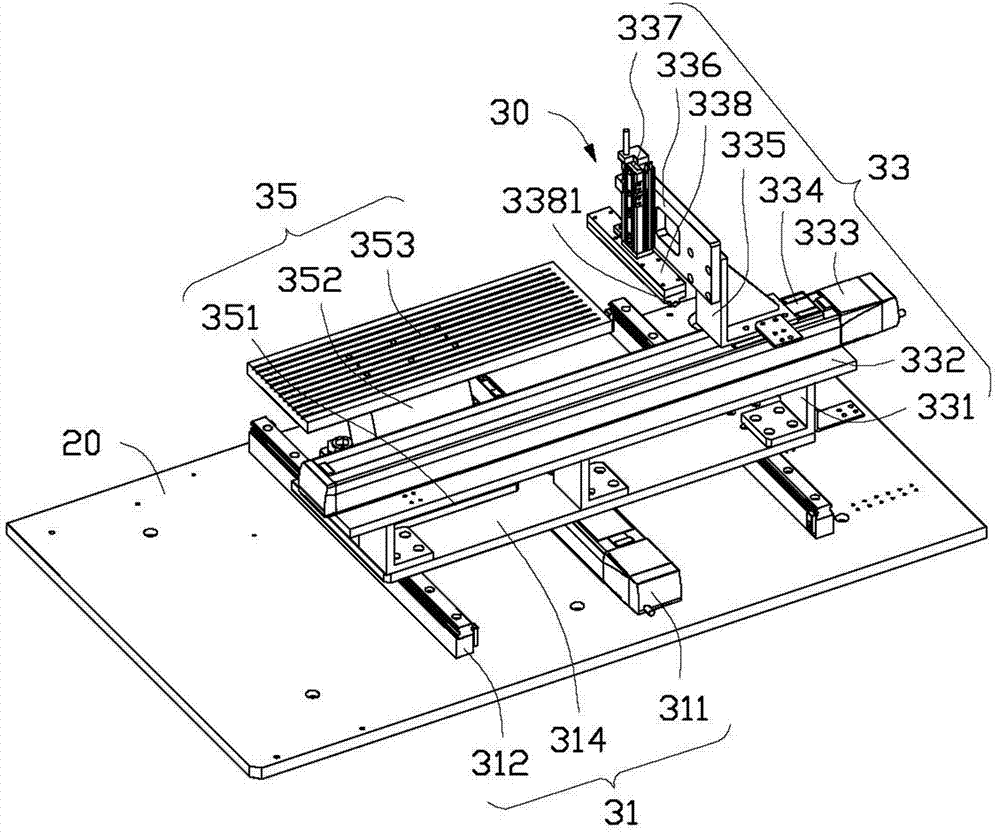

[0015] see figure 1 , an automatic discharger 100 according to a preferred embodiment of the present invention, which is used to evenly arrange several workpieces on a jig plate. The automatic discharge machine 100 includes a machine body 10 , a workbench 20 , a moving assembly 30 , a vibrating assembly 40 , a receiving box 50 and a control assembly 60 . The workbench 20 is fixed on the machine body 10, the moving assembly 30, the vibrating assembly 40, the receiving box 50 and the control assembly 60 are installed on the workbench 20, and several workpieces (not shown) are placed on the vibrating Component 40 inside. The moving assembly 30 includes a jig 35, the vibrating assembly 40 vibrates to move the workpieces into the jig 35, the moving assembly 30 arranges the workpieces on the jig 35 evenly, and the redundant workpieces flow into the receiving jig 35. In the material box 50. Both the moving assembly 30 and the vibrating assembly 40 are electrically connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com