Numerical control plasma cutting machine trepanning modular system

A module system and intersecting line technology, which is applied in the field of CNC intersecting wire cutting machine nesting module system, can solve the problem of inability to meet the nesting requirements of CNC intersecting wire cutting machine, etc., so as to improve the competitiveness of enterprises and improve the pipe arrangement. The effect of high efficiency and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

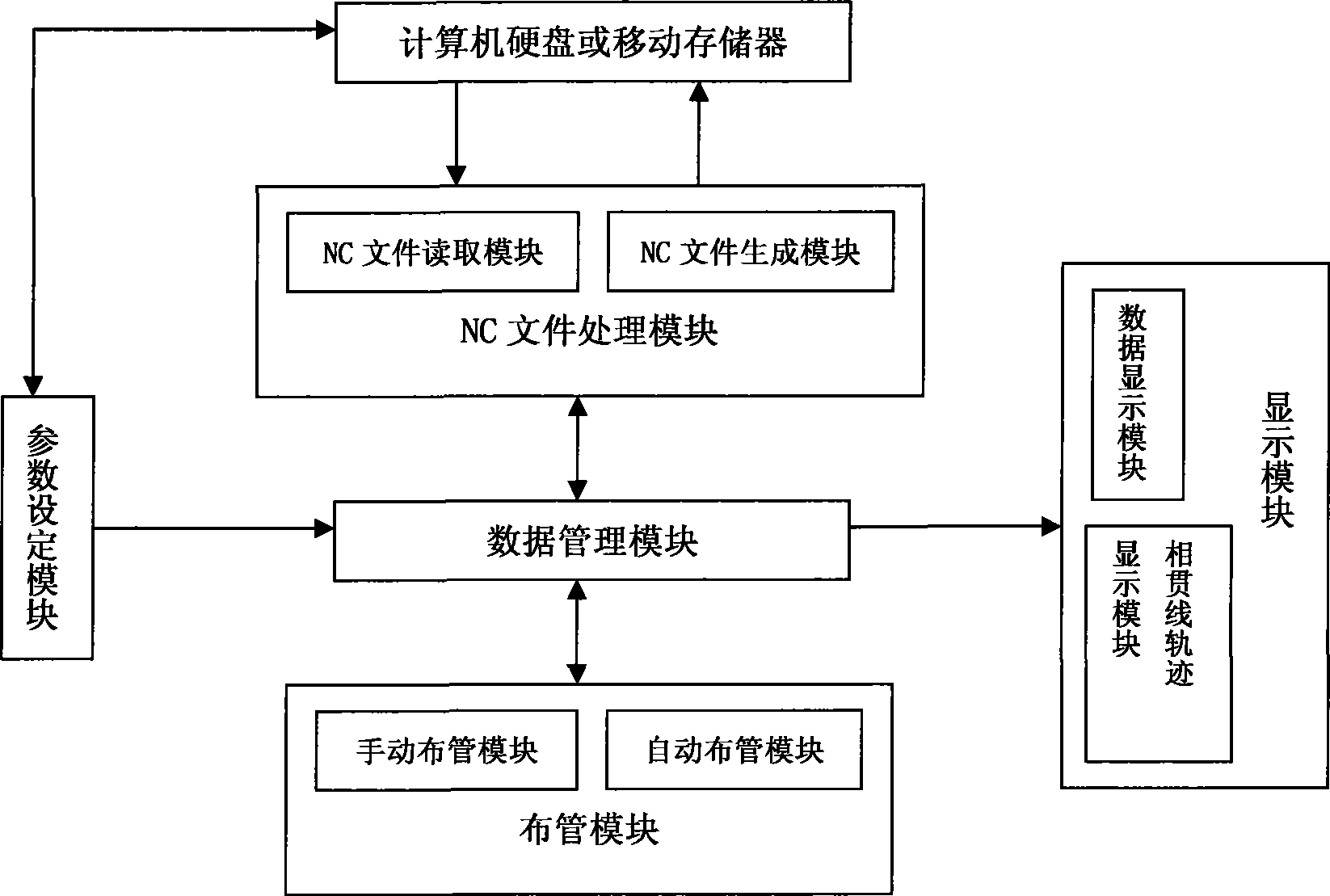

[0040] Such as figure 1 As shown, the system of the present invention includes: NC file processing module, parameter setting module, pipe layout module, data management module and display module, wherein:

[0041] The NC file processing module reads the NC file to be processed from the computer hard disk or mobile memory, reads the original steel pipe processing data from the file, and stores these data together with the NC file path into the data management module. The module takes out the steel pipe processing data after the pipe layout operation is completed, gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com