Device for stabilizing mechanical arm in in-and-out movement process of electrolytic manganese cathode plate from tank

A movement process and stabilizing device technology, applied in the direction of electrolysis process, electrolysis components, photography technology, etc., can solve the problems of diaphragm bag rupture, uneven force on the cathode plate, and influence on normal production, so as to improve work efficiency and avoid stress Unevenness, the effect of reducing personnel costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

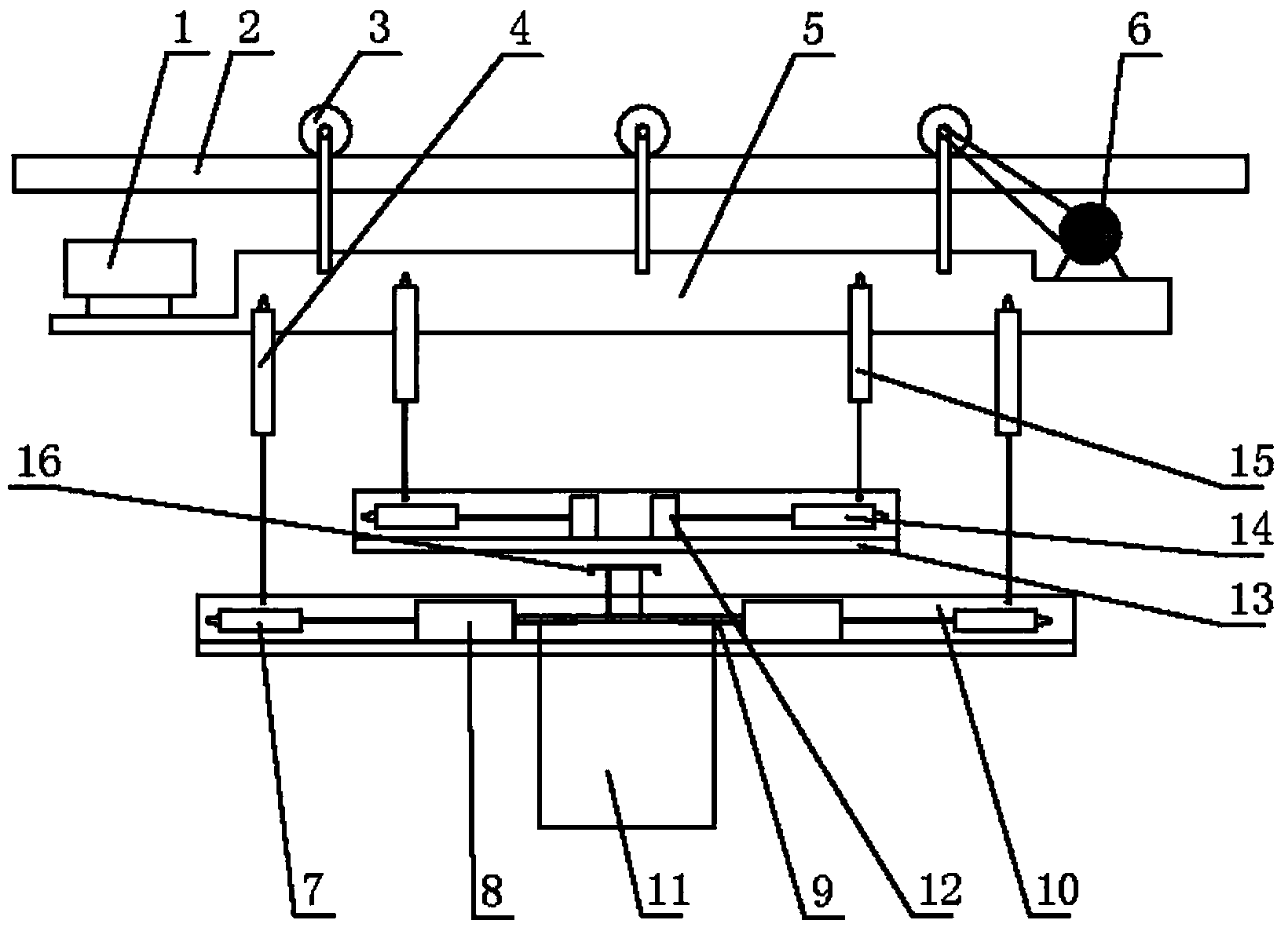

[0022] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

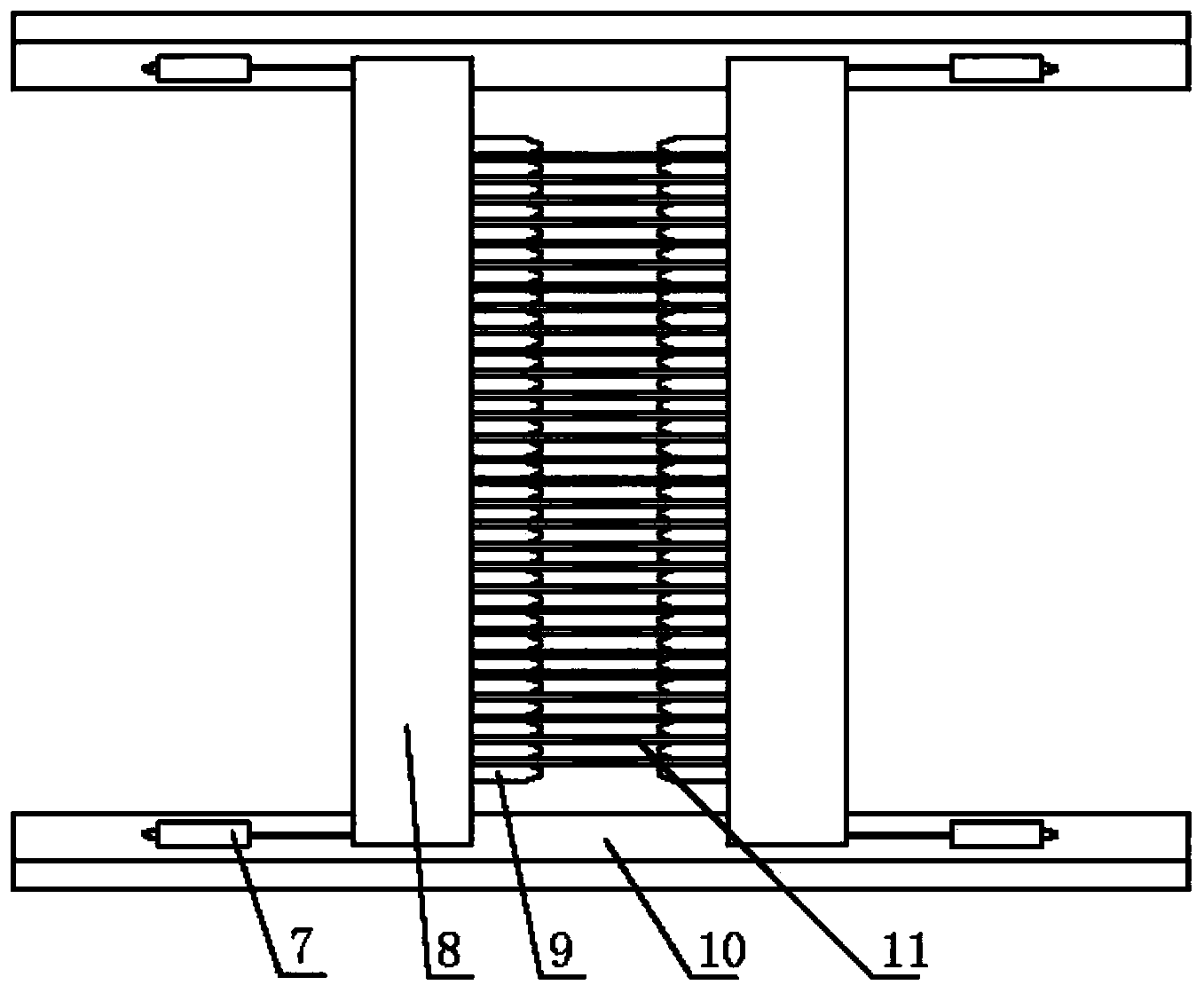

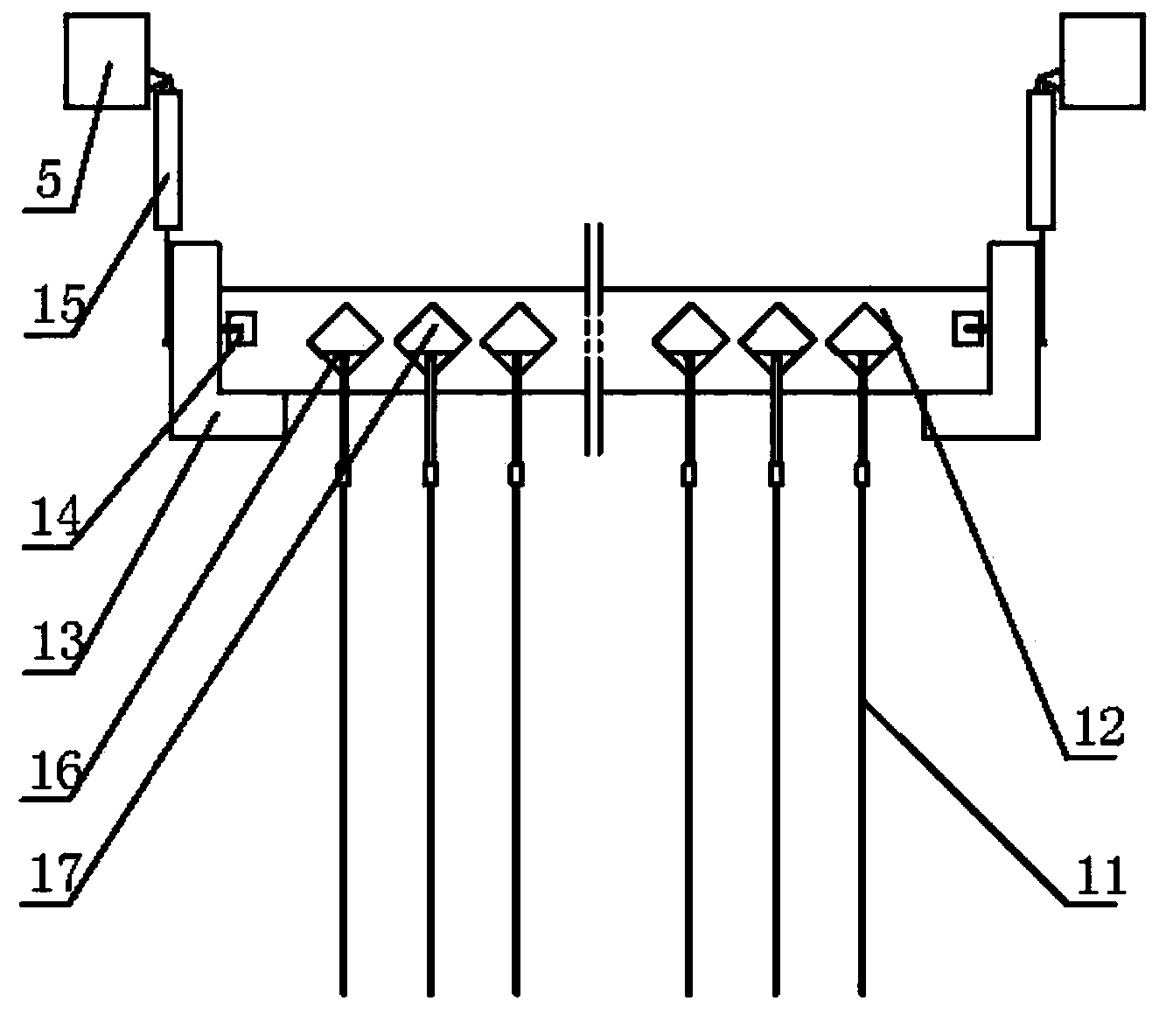

[0023] Such as figure 1 As shown, a stabilizing device for a manipulator during the movement of an electrolytic manganese cathode plate in and out of the tank is characterized in that it includes a guide rail 2, a walking wheel 3, a support beam 5, a part in and out of the tank, and a moving part. The walking wheel 3 has at least Two, placed on the guide rail 2, and can slide on the guide rail 2, the support beam 5 is suspended on the guide rail 2 by being connected with the road wheels 3, and can move synchronously with the road wheels 3 sliding on the guide rail 2, so The moving part is suspended below the support beam 5 through two moving lifting cylinders 15 on both sides, and the moving lifting cylinder 15 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com