Environmental protective flint optical glass with heavy lanthanum, production method and equipment

A technology of optical glass and production method, which is applied in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of affecting glass transmission performance, long production cycle, high production cost, etc., so as to improve optical transmission performance and production The effect of short cycle and less process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

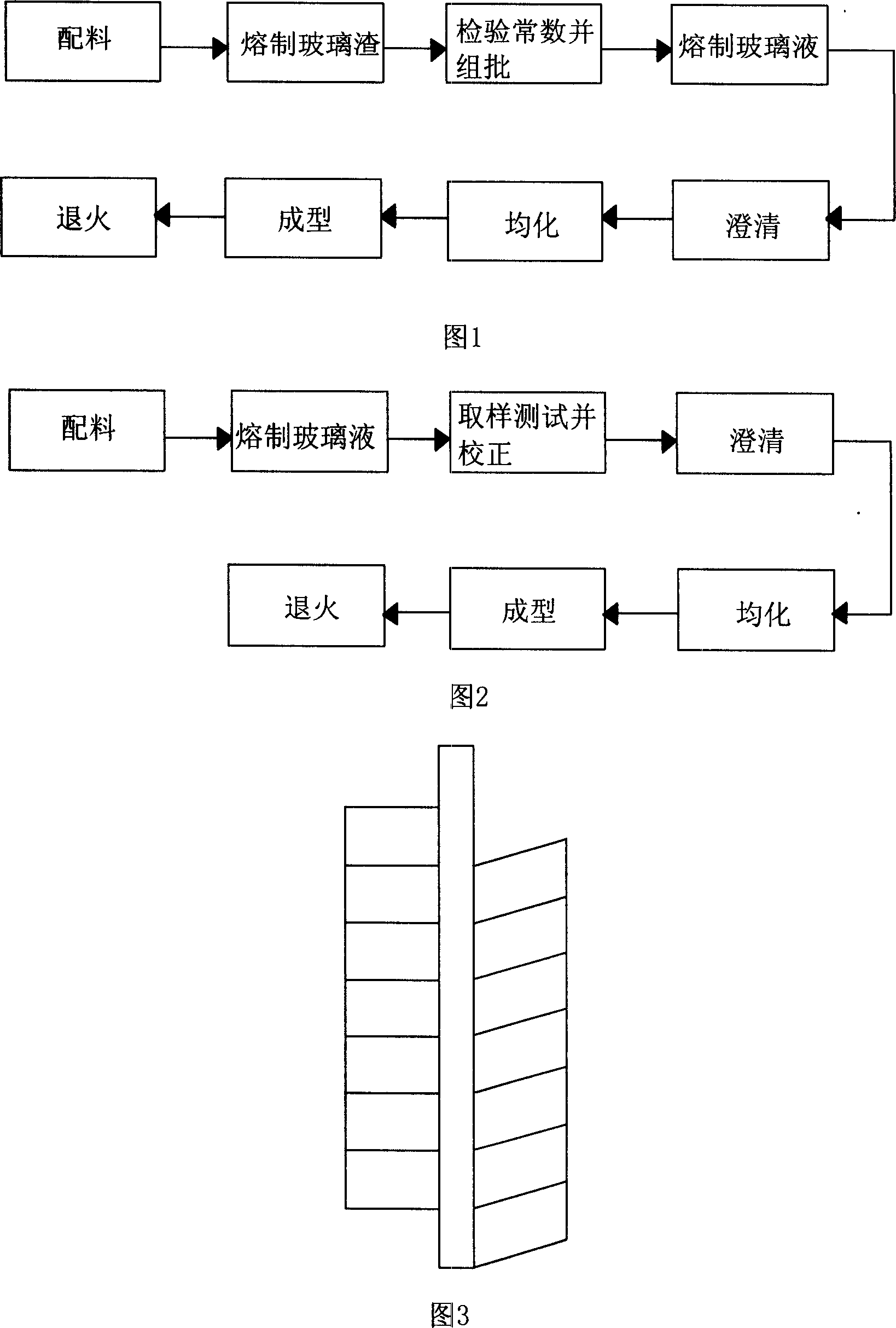

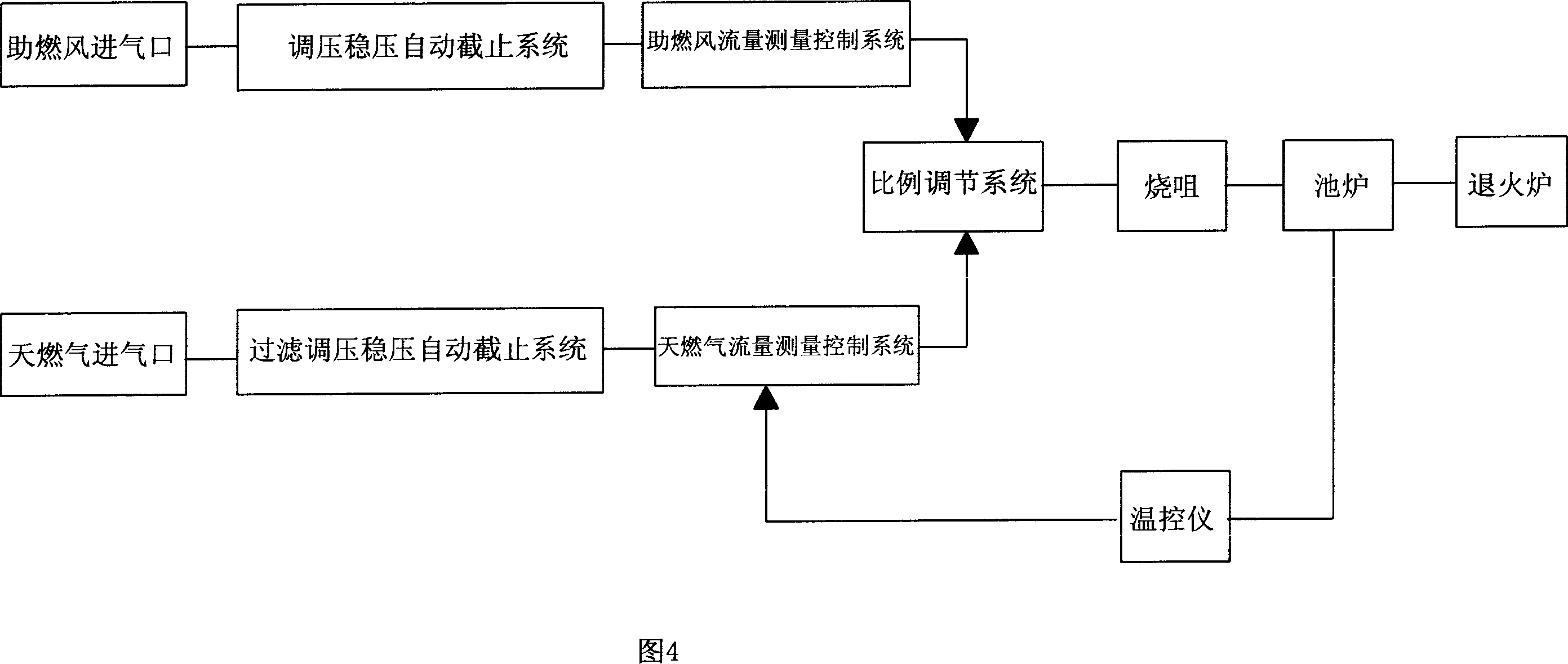

Method used

Image

Examples

Embodiment Construction

[0013] The optical glass of the present invention contains 20-40% (weight percent content, hereinafter the same) glass former SiO 2 , if SiO in the glass 2 If the content is too high, the refractive index of the glass will not meet the requirements, and the melting temperature will be high, making it difficult to melt; if the content is too low, the ability to form glass and chemical stability will be reduced. The preferred SiO 2 The content is 20-35%, and the particularly preferred content is 20-28%.

[0014] Another glass former of the present invention is B 2 o 3 , B 2 o 3 It has a melting function, and its content is 5-20%, preferably 6-17%, particularly preferably 7-14%.

[0015] In order to make the glass have a high refractive index, it needs to contain an appropriate high refractive index component, and the present invention selects TiO 2 , Nb 2 o 5 , ZrO 2 and La 2 o 3 .

[0016] TiO 2 The content is 5-20%, which can significantly improve the refractive i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com