Feeding and discharging mechanism

A technology of pushing mechanism and feeding mechanism, which is applied to conveyors, vibrating conveyors, conveyor objects, etc., can solve the problems of low degree of automation, low work efficiency, and manpower consumption, so as to improve the degree of automation, improve efficiency, The effect of liberating manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

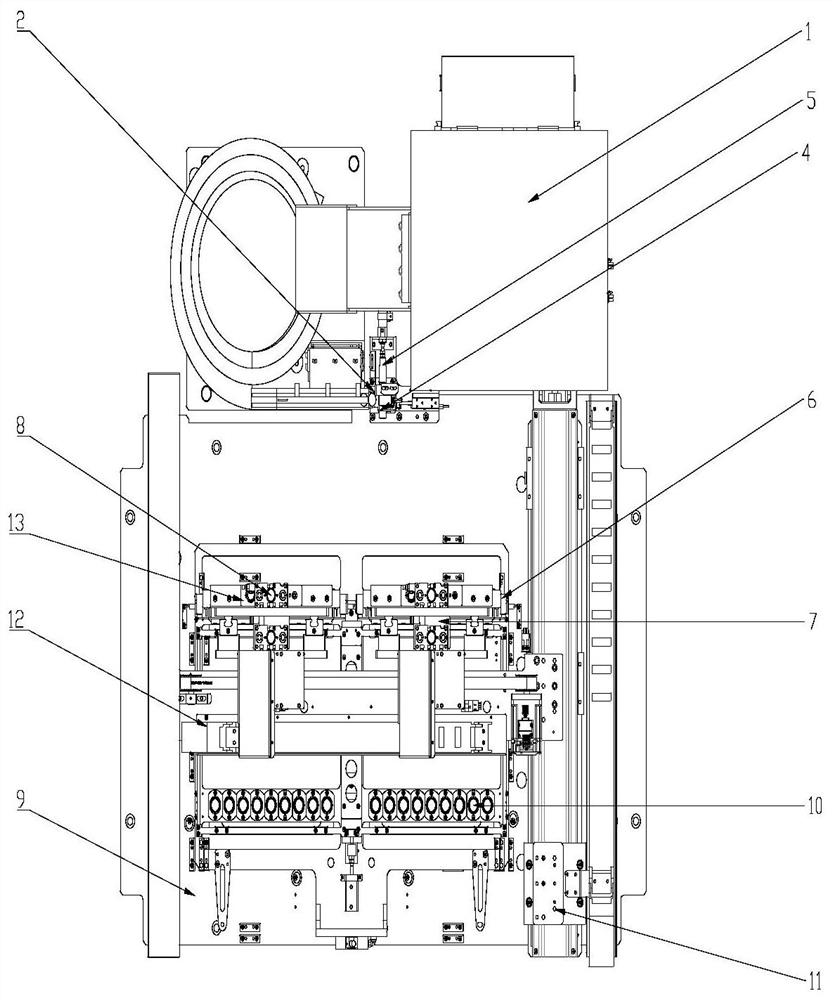

[0037]The present invention provides a loading and unloading mechanism, including a fixing mechanism, a feeding mechanism and a material receiving mechanism; the fixing mechanism includes a fixed large plate 9 and a cake rack 10, and the vibrating plate mechanism includes a feeding bin, a direct vibration guide rail and Circular silo, the setting of the feed silo needs to have a certain radian, which can effectively help the mechanism to transmit smoothly during transmission, and effectively reduce the possibility of material jamming. In this embodiment, circular feed is used The bin is only used as a preferred embodiment. This mechanism can also be provided with a plurality of feeding bins, and other feeding bins are arranged above the circular feeding bin. The bottom of the feeding bin and the circular feeding bin is connected with a vibration body. The discharge port of the circular silo is connected with a direct vibration guide rail, one side of the end of the direct vibra...

Embodiment 2

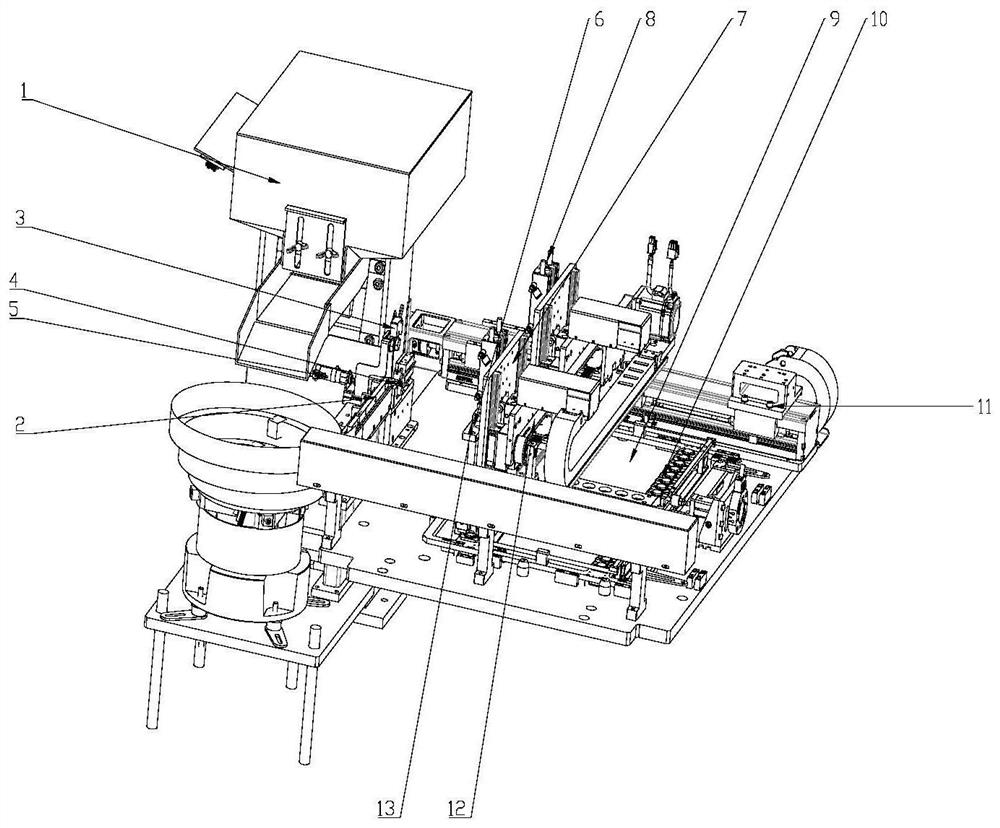

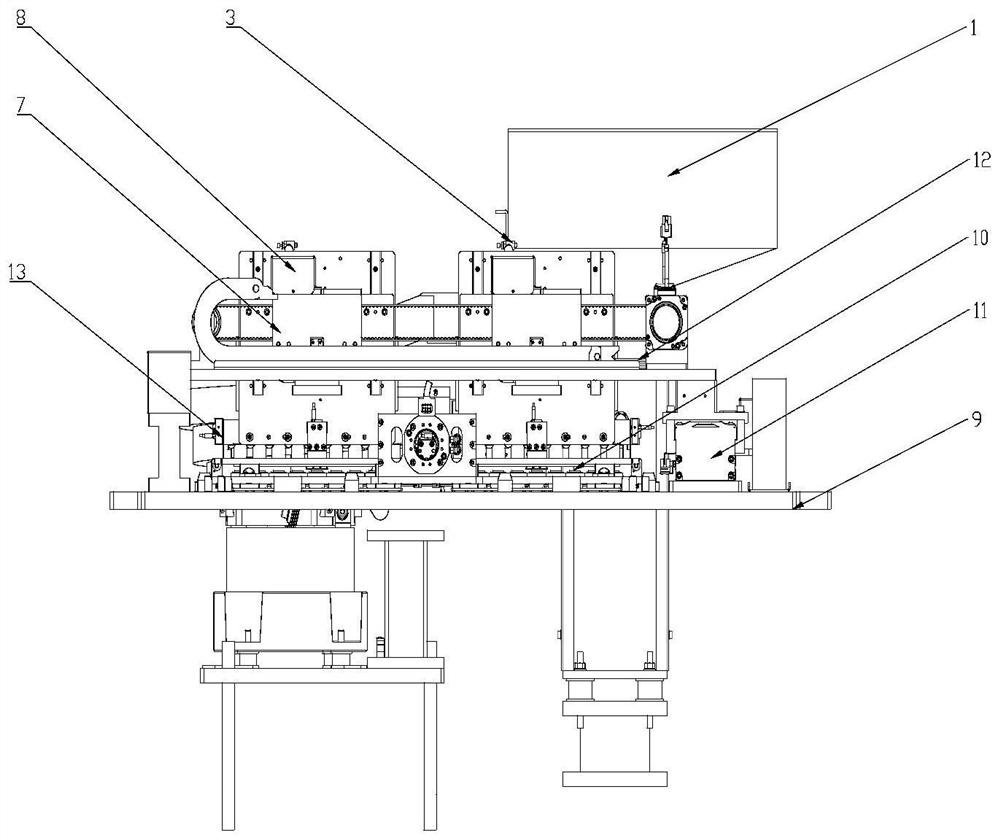

[0039] Such as figure 1 As shown, an automatic upper and lower plastic sealing material mechanism provided by the present invention includes a vibrating plate mechanism, a material receiving mechanism, a material pushing mechanism, a material receiving and transferring mechanism, a material unloading mechanism, a fixed large plate, and a material cake rack. Set at least one, one of which is a circular feeding bin; the circular feeding bin is located directly below the outlet of the other feeding bins, and the direct vibration guide rail is connected with the circular feeding bin; the material receiving mechanism 2 is connected with the direct vibration The guide rail is connected and adjacent to the pushing mechanism 5, and the in-position detection sensor 3 is connected with the pushing mechanism 5 and placed directly above the material receiving mechanism 2; The feeding mechanism 2 is connected; the fixed large plate 9 is fixed and installed on the frame of the box body by s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com