Automatic electronic connector capping machine

A technology of electronic connectors and connectors, which is applied in the direction of vibrating conveyors, conveyors, conveyor objects, etc., can solve the problems of high labor costs, waste of resources, missing manual installation of end caps, etc., to improve efficiency and effect, Increased yield and reduced labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below through specific examples.

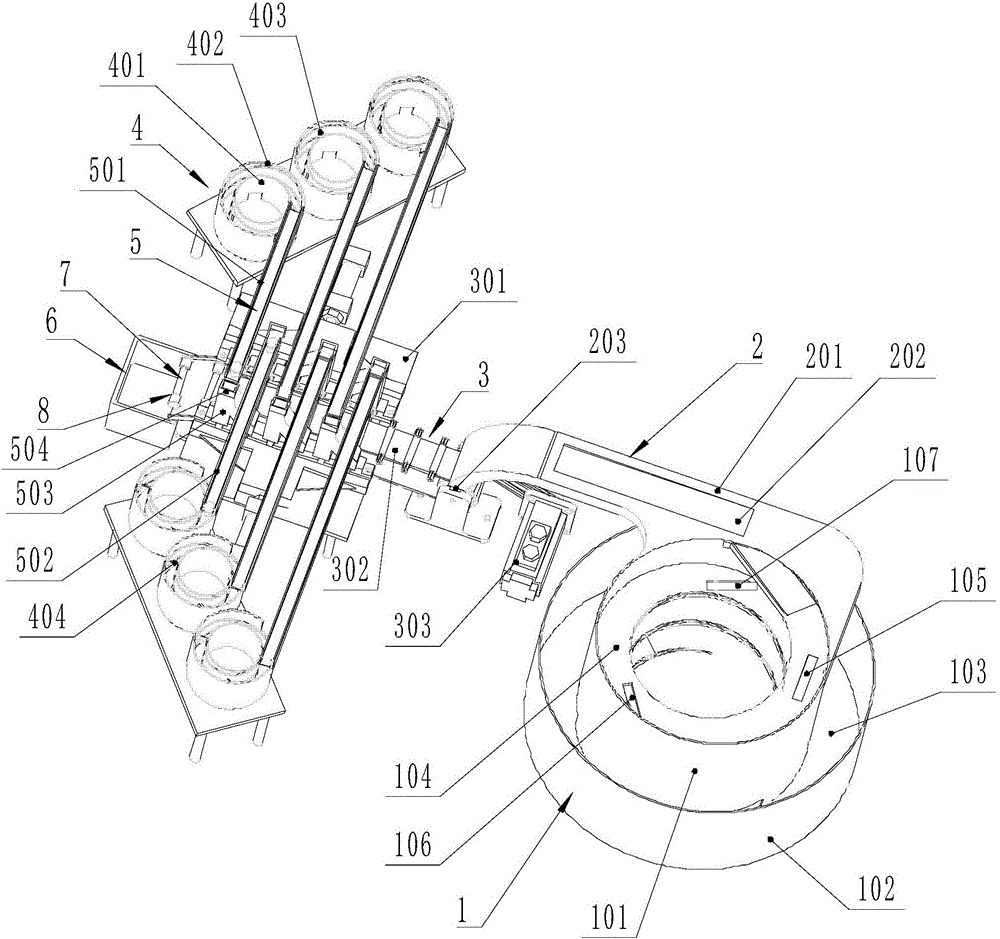

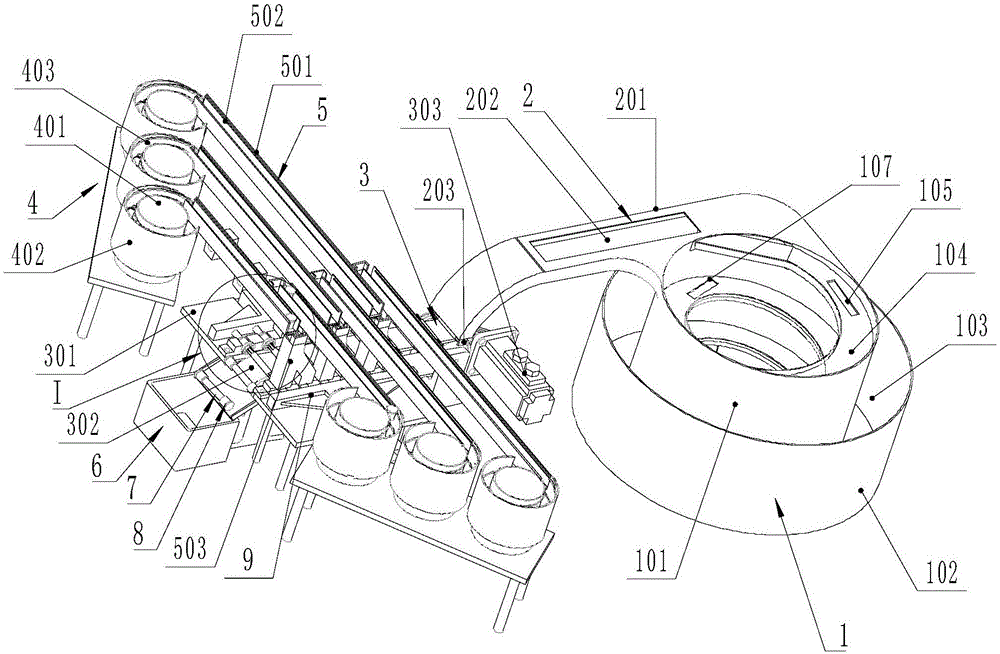

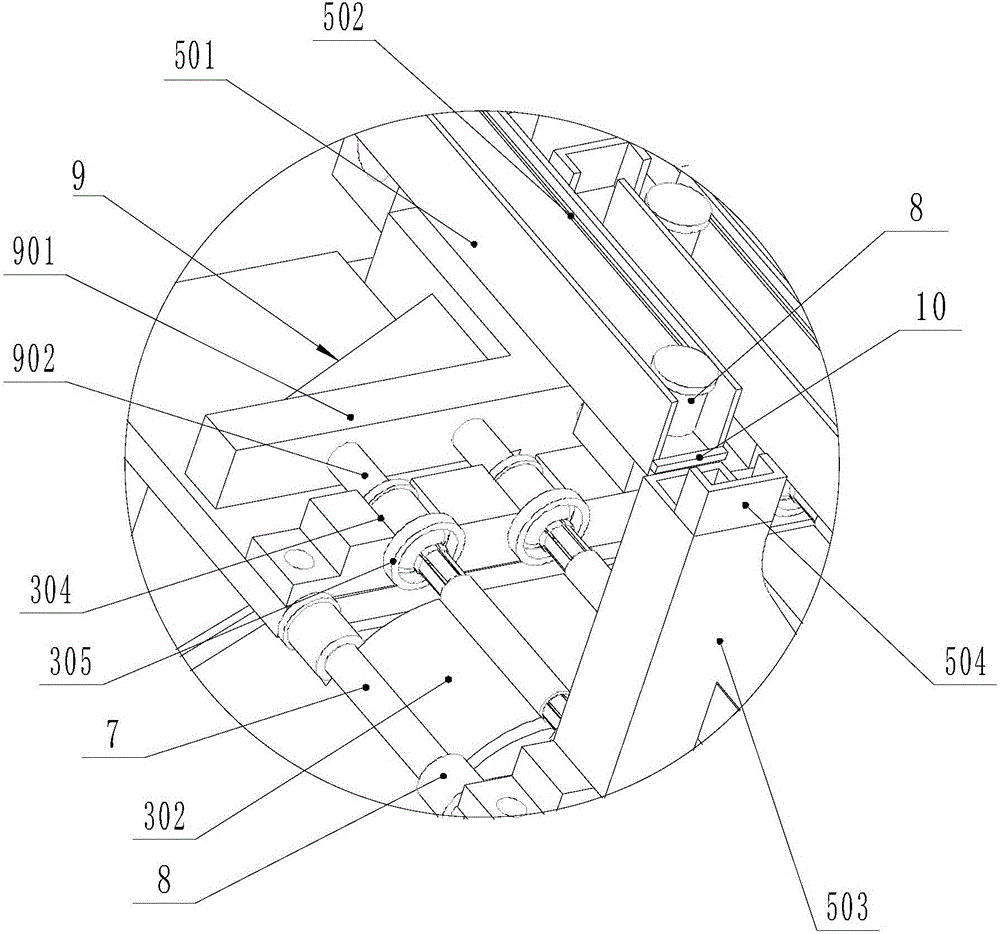

[0031] Such as Figure 1 to Figure 6 As shown, an automatic capping machine for electronic connector 7 includes an automatic feeding device for electronic connector 7, an automatic end cap feeding device 4 and an automatic capping mechanism 3; the two ends of the electronic connector 7 have axial groove. And the end cap 8 among the present embodiment comprises end cap body 801 and the flange 802 that is positioned at one end of end cap body 801, and the center of the other end of end cap body 801 is provided with axial bushing 803, and this bushing 803 is connected with electronics. The ends of the connector 7 are fitted.

[0032] The electronic connector 7 automatic feeding device includes a connector vibrating plate 1, which is provided with a spiral connector conveying track 104 for horizontally arranging and transporting the connectors, and the connector conveying track 104 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com