Intelligent temperature and water control yeast mixing device

An intelligent, central computer technology, applied in the field of winemaking, can solve the problems of reduced labor efficiency, large labor volume and labor, consumption, etc., and achieve the effects of improving production efficiency, ensuring automation, and improving operational efficiency.

Pending Publication Date: 2022-06-21

山东景芝白酒有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In order to make up for the deficiencies of the prior art and solve the problem of consuming a large amount of labor and labor and greatly reducing labor efficiency in the process of transferring pit mud, the present invention proposes a Intelligent temperature control and water control koji mixing device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

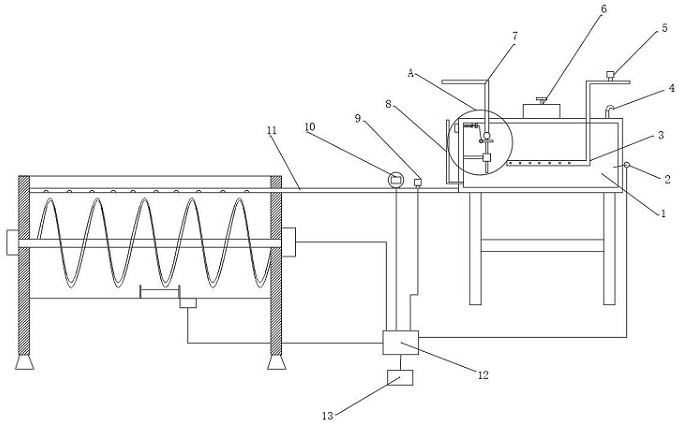

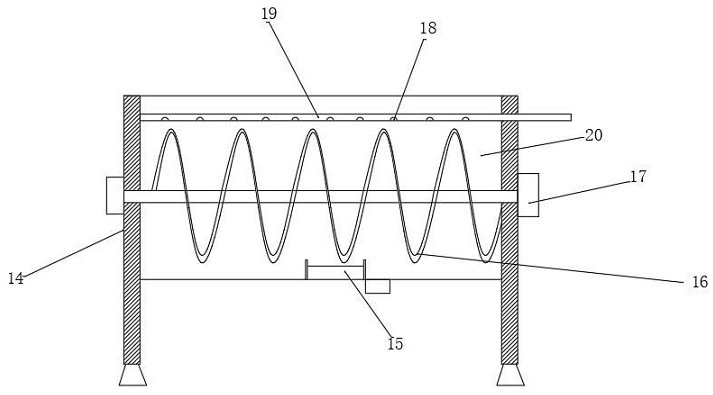

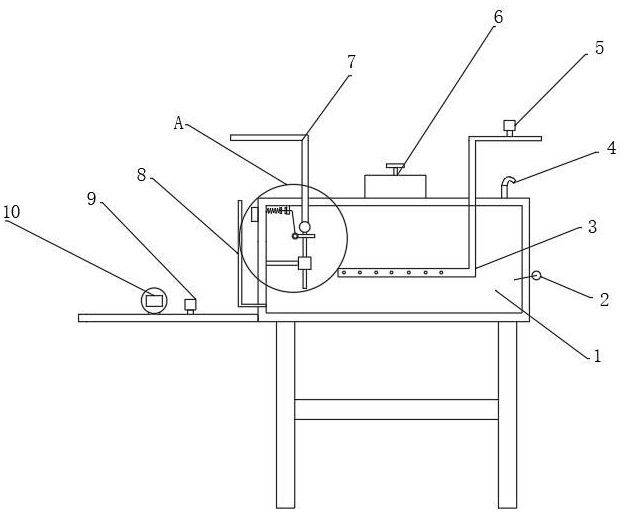

The invention belongs to the technical field of wine brewing, and particularly relates to an intelligent temperature and water control yeast mixing device which comprises a cylindrical tank body, a temperature sensor, a steam pipe, a steam outlet pipe, a steam electromagnetic valve, an observation hole, a water inlet pipe, a liquid level meter, a water outlet electromagnetic valve, a flow meter, a water outlet pipe, a parallel water pipe and a yeast mixing chamber. The yeast mixing machine completely replaces manual turning and mixing operation of workers, the labor amount of the workers is greatly reduced, the production efficiency is improved, clean production, perfect combination of the water storage tank and the controller and quantitative control and standardized operation of the yeast mixing procedure are achieved, and the production efficiency is improved. A solid foundation is laid for subsequent stacking and heating, fermentation in a pool, generation of aroma-producing and taste-producing substances in a wine body and formation of a sesame aroma style, mechanical and automatic operation is achieved, manual operation is perfectly replaced, and standardized operation and clean production are achieved while the labor amount of workers is reduced and the production efficiency is improved.

Description

technical field [0001] The invention belongs to the technical field of brewing, in particular to an intelligent temperature-controlling water-controlling koji mixing device. Background technique [0002] In the brewing of sesame-flavored liquor, the koji mixing process is particularly important. It is to add water to Hanoi white koji, aromatic yeast, bacterial koji, sauce-flavored koji, and Baobao koji according to different proportions, and then add them after mixing. The inoculated grains are mixed for the second time. The process plays a pivotal role in the subsequent heating up of accumulation, fermentation in the tank, formation of aroma and taste substances in the wine body and the formation of the sesame flavor style. After the technical staff's painstaking study and After many years of research, we finally successfully broke through the technical problem of the optimal ratio of "five tunes and one bad" that affects Zhixiang's style. The next step will be to solve the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C12G3/02B01F27/72

CPCC12G3/02

Inventor 赵德义赵百里张东跃刘建波孙伟李明刘林林齐士鹏

Owner 山东景芝白酒有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com