Patents

Literature

77results about How to "Realize standardized operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

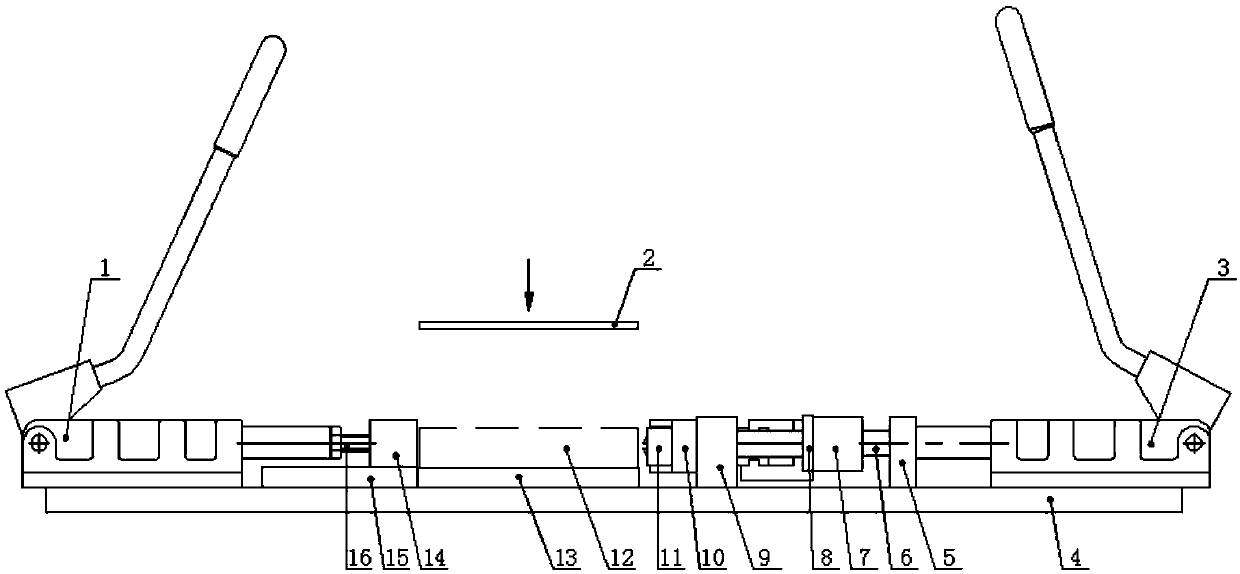

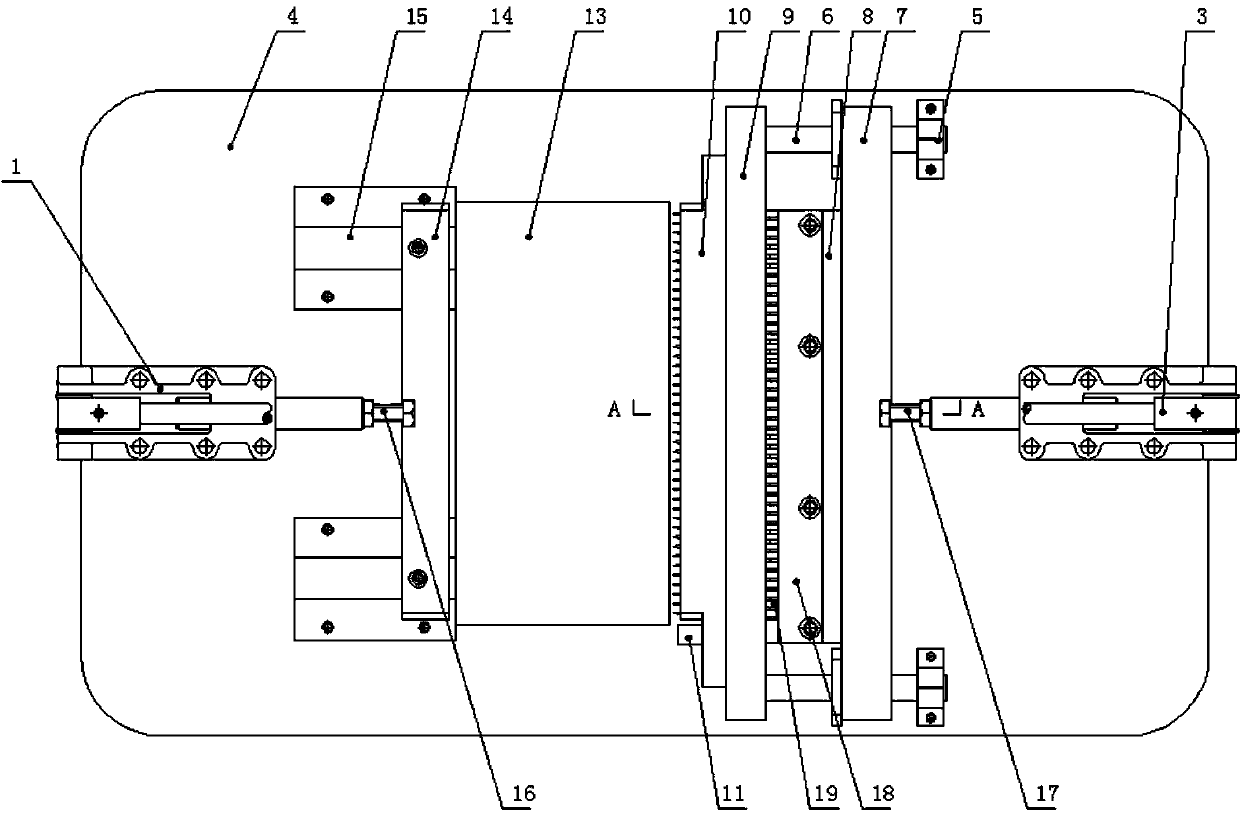

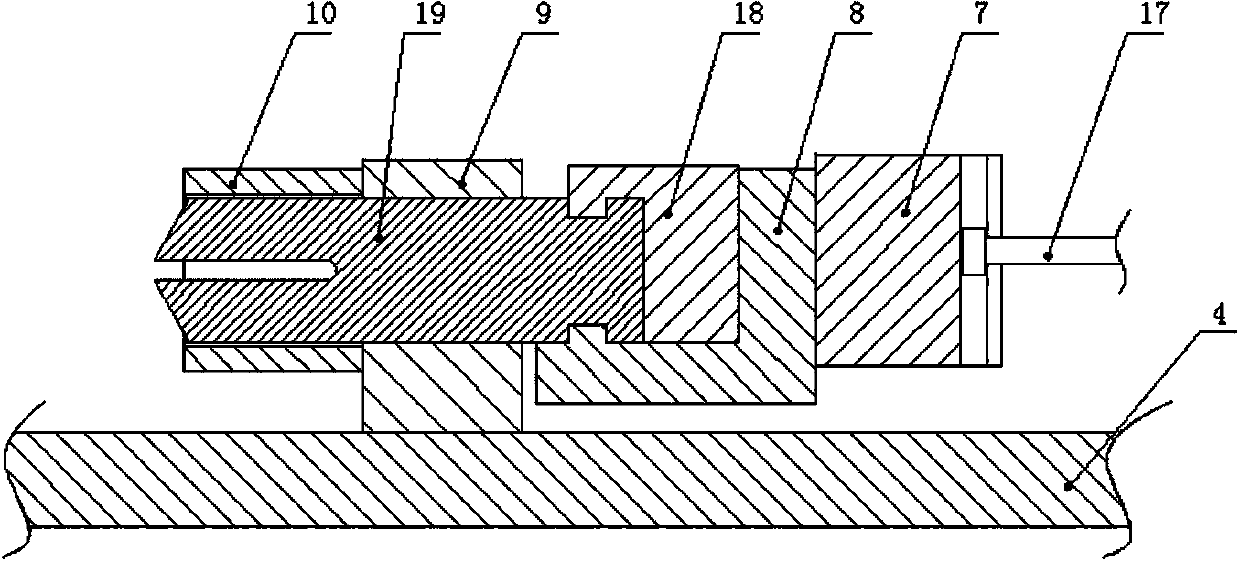

Full-automatic paper box forming machine

InactiveCN101786343ALabor savingRealize standardized operationBox making operationsPaper-makingDevice formCarton

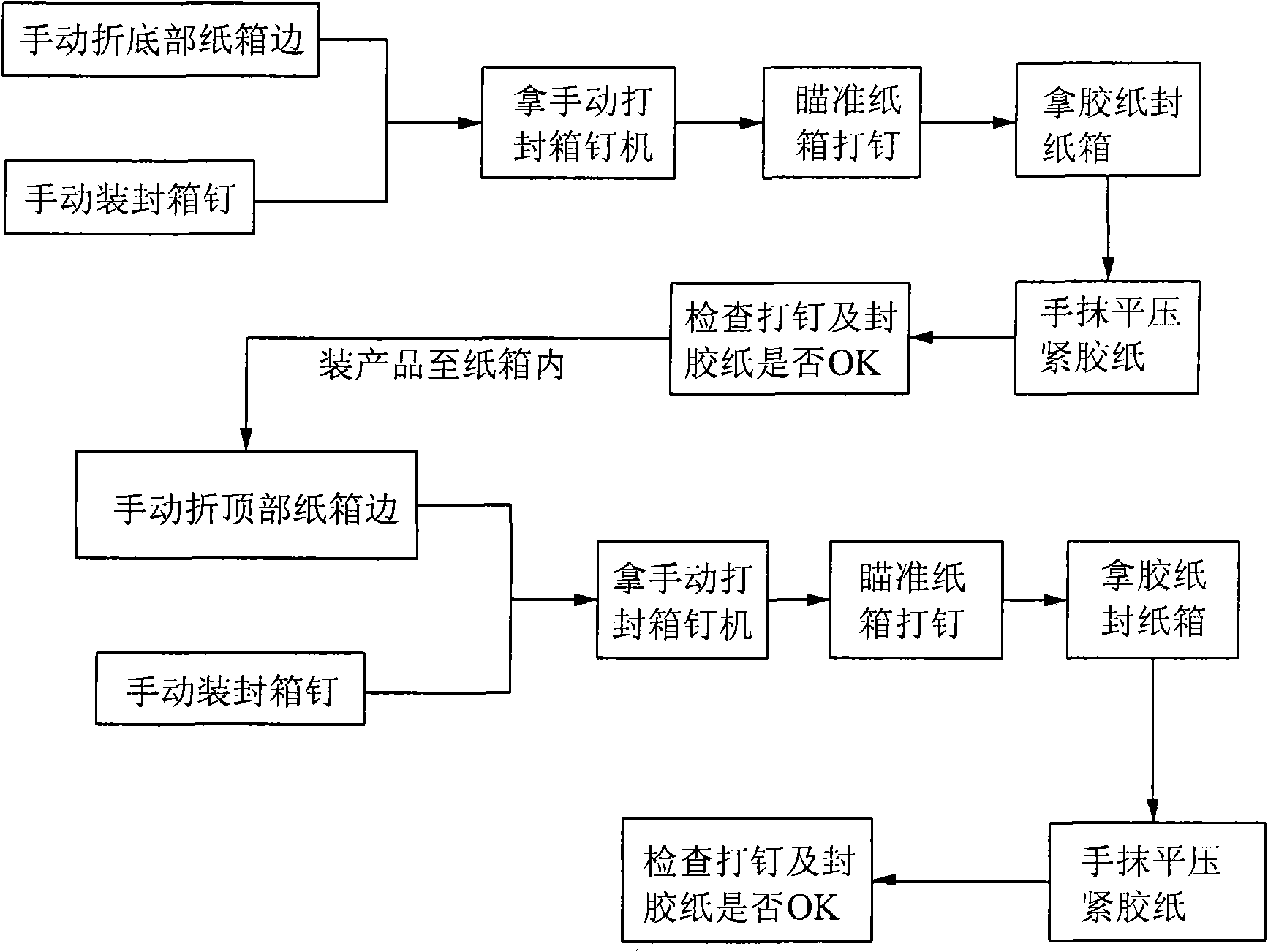

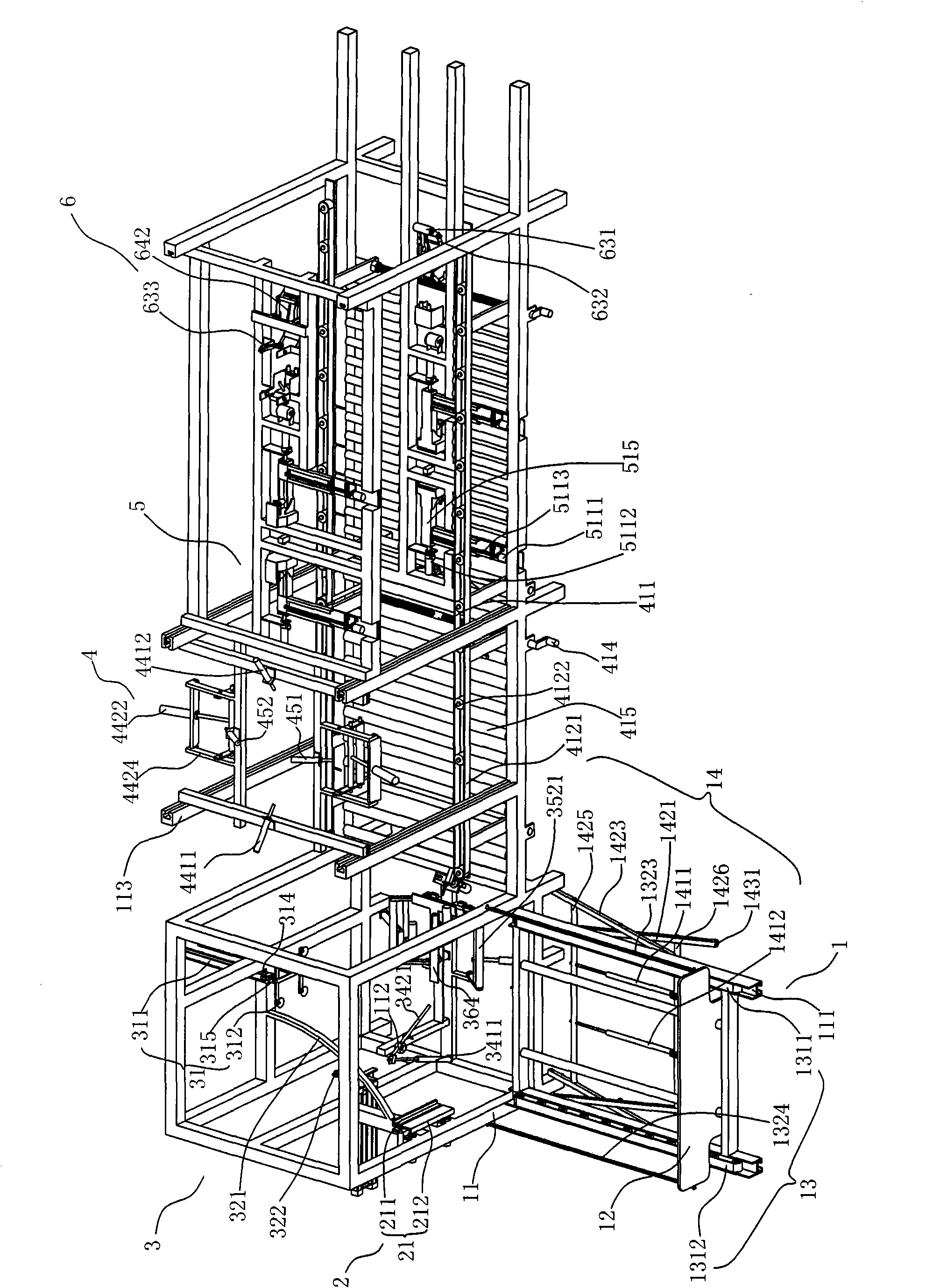

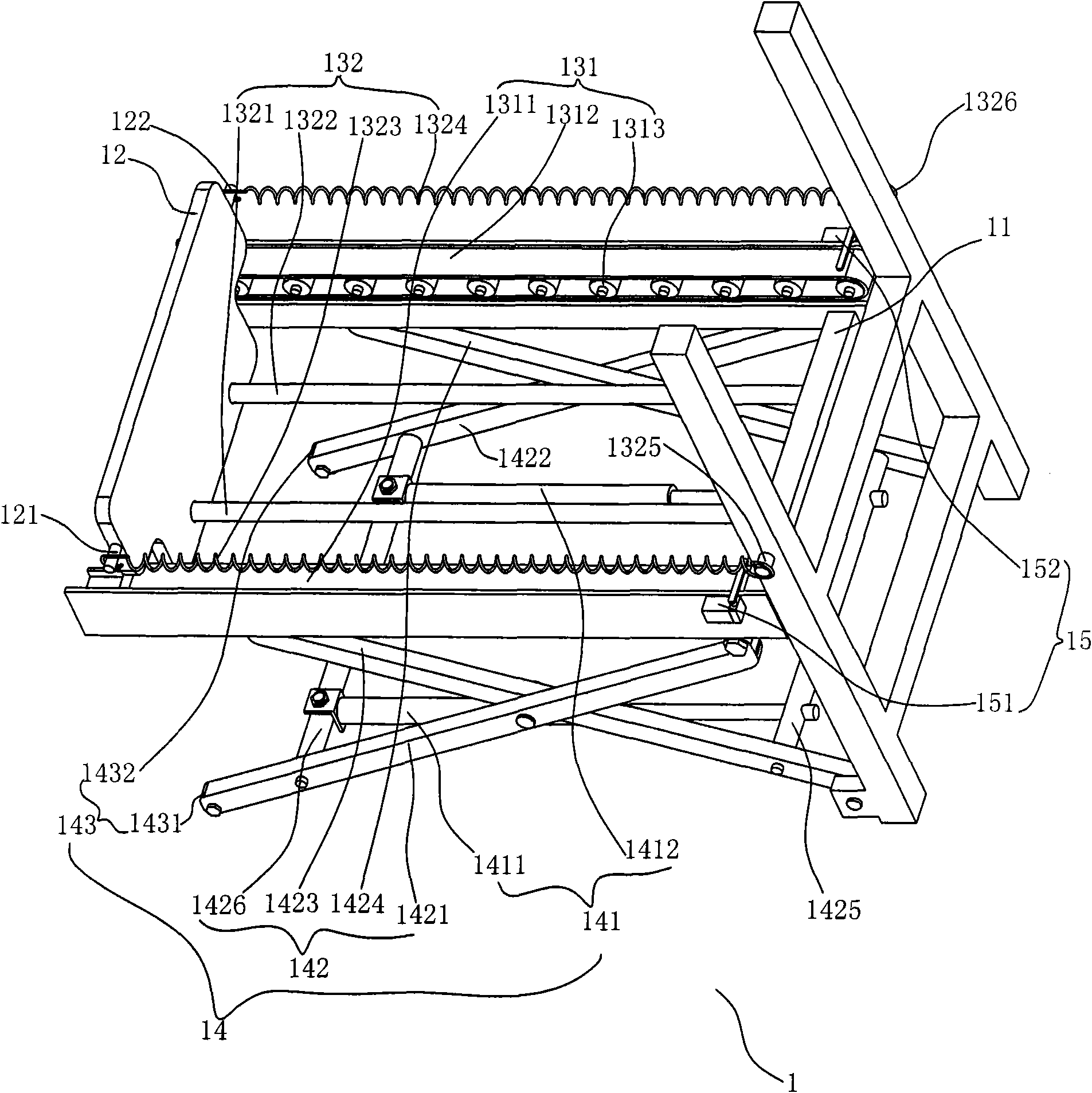

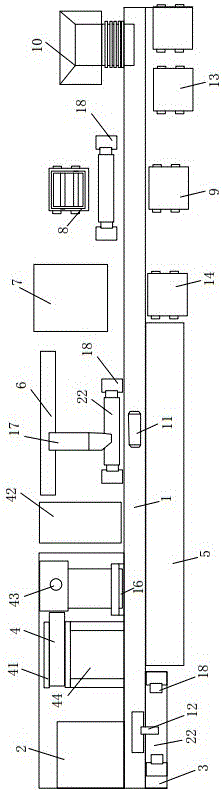

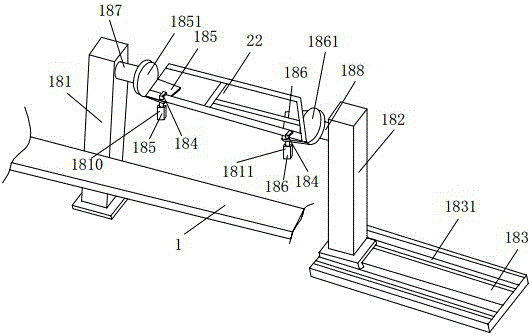

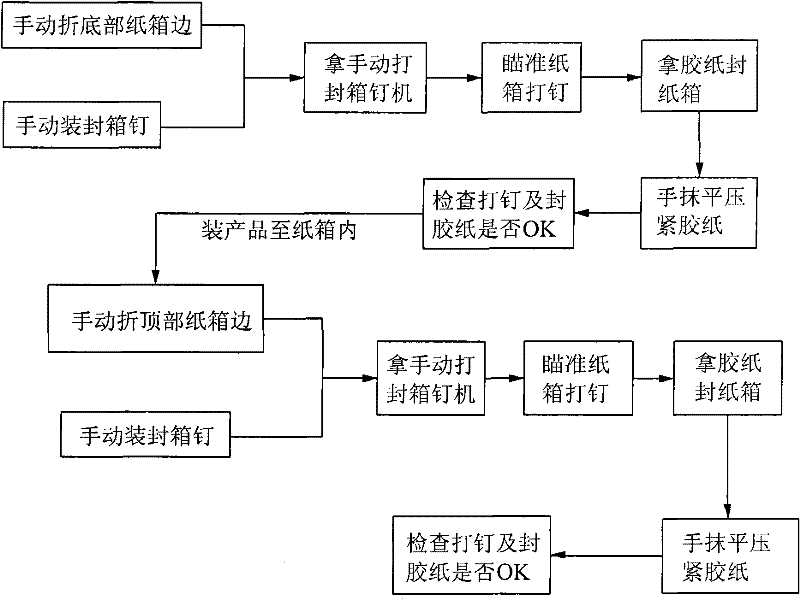

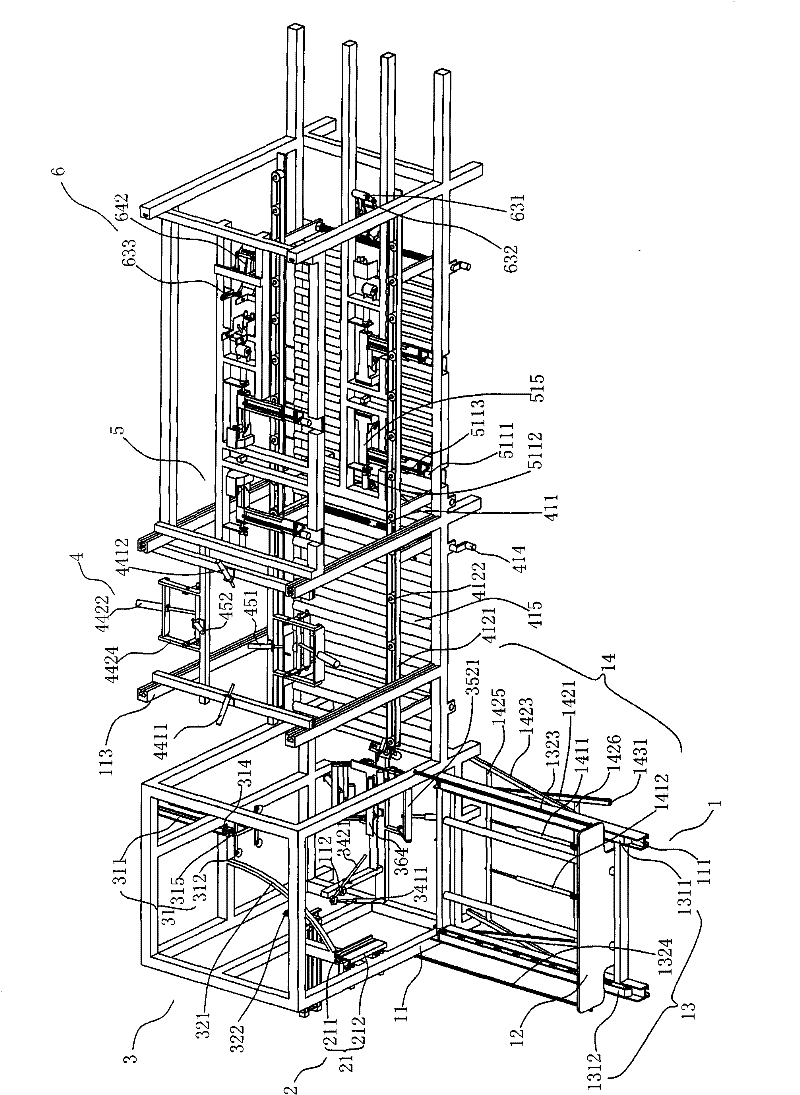

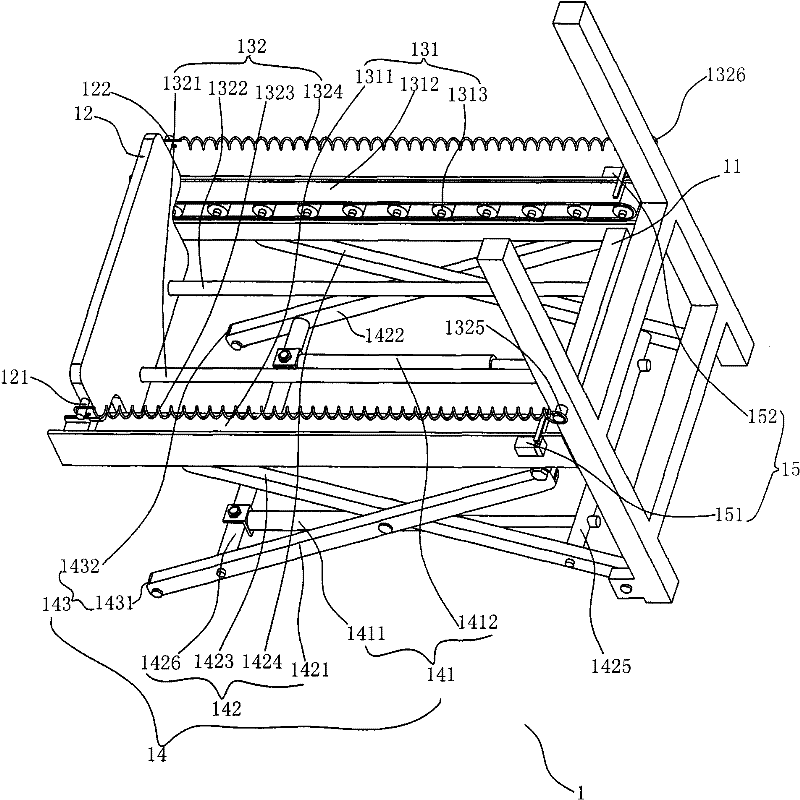

The invention provides a full-automatic paper box forming machine, which is applicable to the technical field of full atomization. The paper box forming machine comprises a machine frame, a paper box loading device, a releasing device, a paper box forming device, a top edge folding device, a feeding and nailing device, an adhesive tape sealing device and a controller, wherein the paper box loading device, the releasing device, the paper box forming device, the top edge folding device, the feeding and nailing device and the adhesive tape sealing device are sequentially arranged on the machine frame, the paper box loading device loads a paper box under the control of the controller, the release device moves the paper box into the paper box forming device, the paper box forming device forms the paper box, the feeding and nailing device binds the paper box, and the adhesive tape sealing device seals adhesive tapes on the bound paper box. Compared with the conventional paper box forming machine, the invention has the advantages that all flow processes are completed through controlling an automatic forming machine by the controller, the labor is saved, the standard operation is realized, and the invention can ensure that each product can be finished according to the technical requirements. In addition, the work efficiency is improved.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

Cultivating technology of erigeron breviscapus

A technique for cultivating fleabane as a Chinese-medicinal material for treating cardiovascular disease includes such steps as immersing seeds in the solution of carbendazim, culturing seedling, applying base fertilizer, transplanting, applying top application, preventing and eliminating diseases and pests and picking up flower and flower bud.

Owner:云南红灵生物科技有限公司

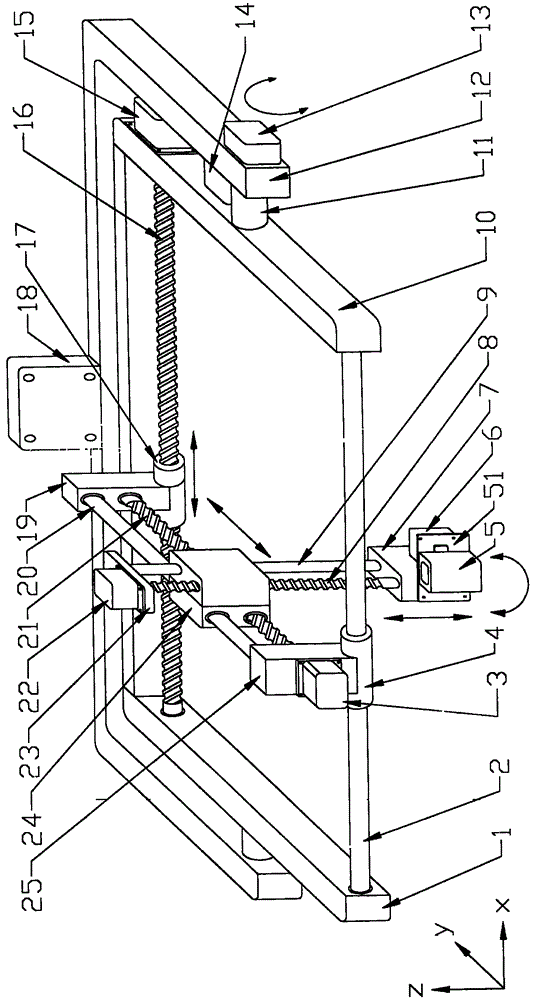

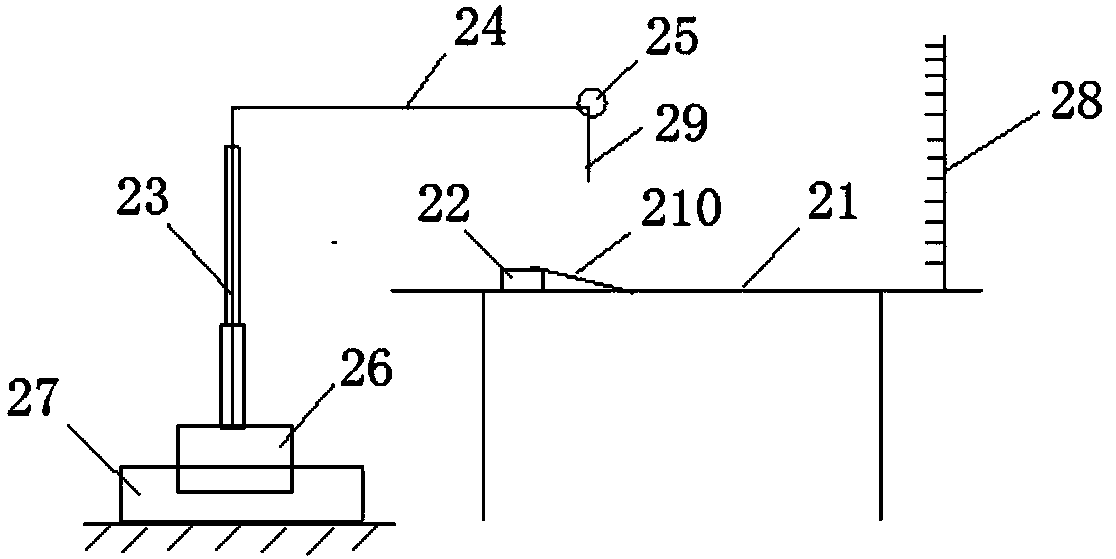

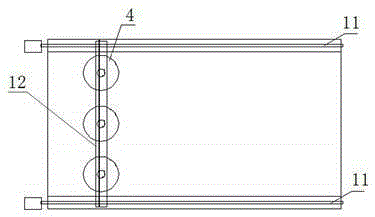

Constant-speed constant-pressure plain scanning guide rail of B ultrasound probe

InactiveCN104665931ASolve the technical defect that the B-ultrasound probe cannot be missed at a uniform speedAddressing Individual DifferencesUltrasonic/sonic/infrasonic diagnosticsGearingAcoustic waveEngineering

The invention provides a mechanical device and a method for achieving constant-speed, constant-pressure and non-missing plain canning of a B ultrasound probe. The device comprises a guide rail assembly and a guide rail assembly bracket; the guide rail assembly comprises an X axial guide rail, a Y axial guide rail, a Z axial guide rail, and a rotatable B ultrasound probe clamp which is mounted at the bottom end of the Z axial guide rail; a pressure sensor and an angle measuring sensor are arranged on a lower bracket of the Z axial guide rail; the guide rail assembly is connected with the guide rail bracket through a rotating shaft and can be rotated around the rotating shaft; the guide rail assembly rotates to drive a motor and a rotating speed reduction device; the transmission mode of the guide rail is performed through a precision lead screw or a gear belt; the B ultrasound probe is driven by a driving mechanism to axially move at constant speed in the X, Y and Z directions; meanwhile, the probe is swung under the effect of the probe clamp rotating mechanism; a track assembly is driven by the rotating mechanism to rotate to adjust the vertical relationship between the ultrasound direction and the detection surface, so as to achieve constant-pressure, constant-speed, non-missing and overlapping-free scanning of the B ultrasound probe.

Owner:BEIJING NINGHE YIFENG TECH

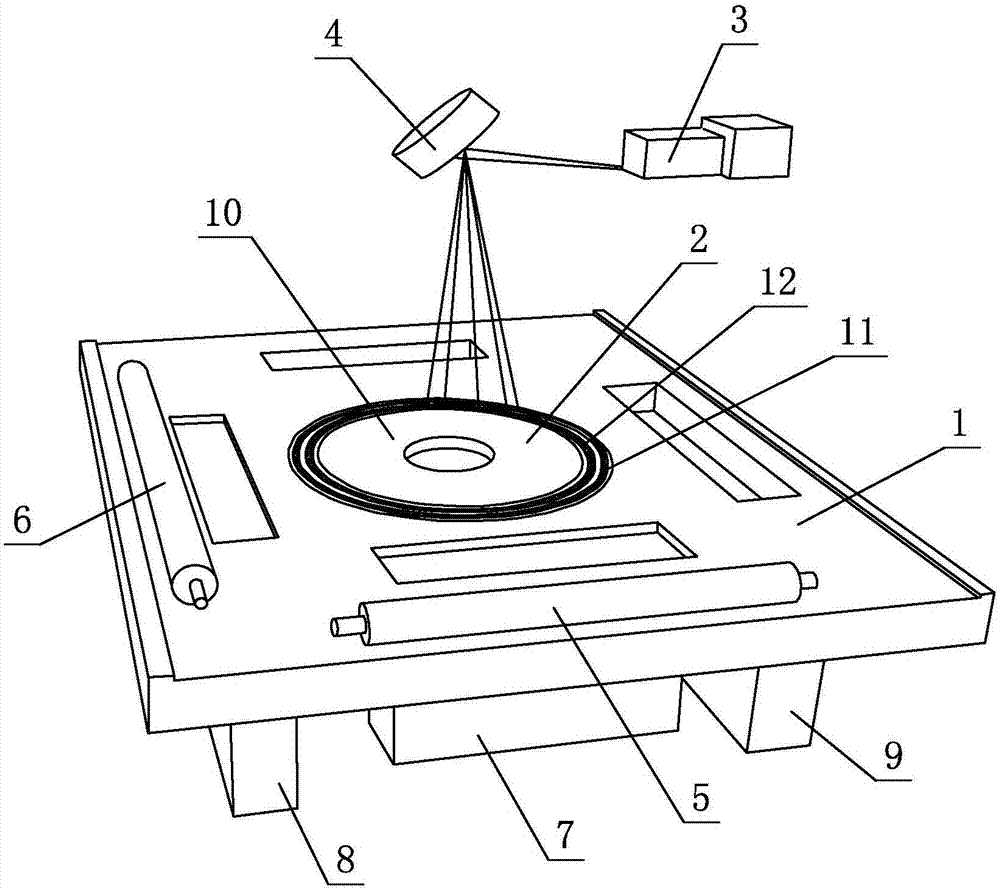

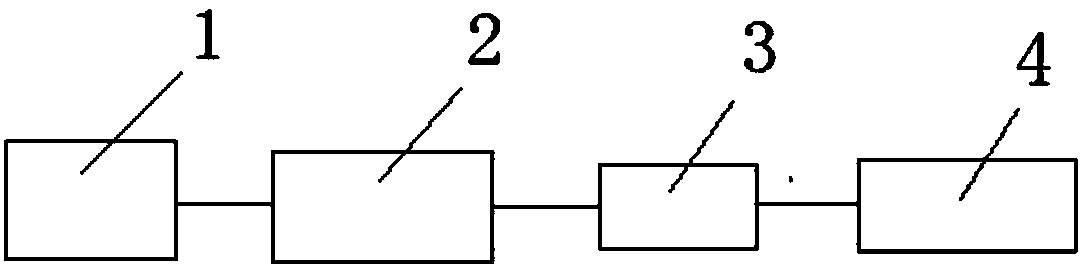

Full-automatic non-invasive micro-test technology

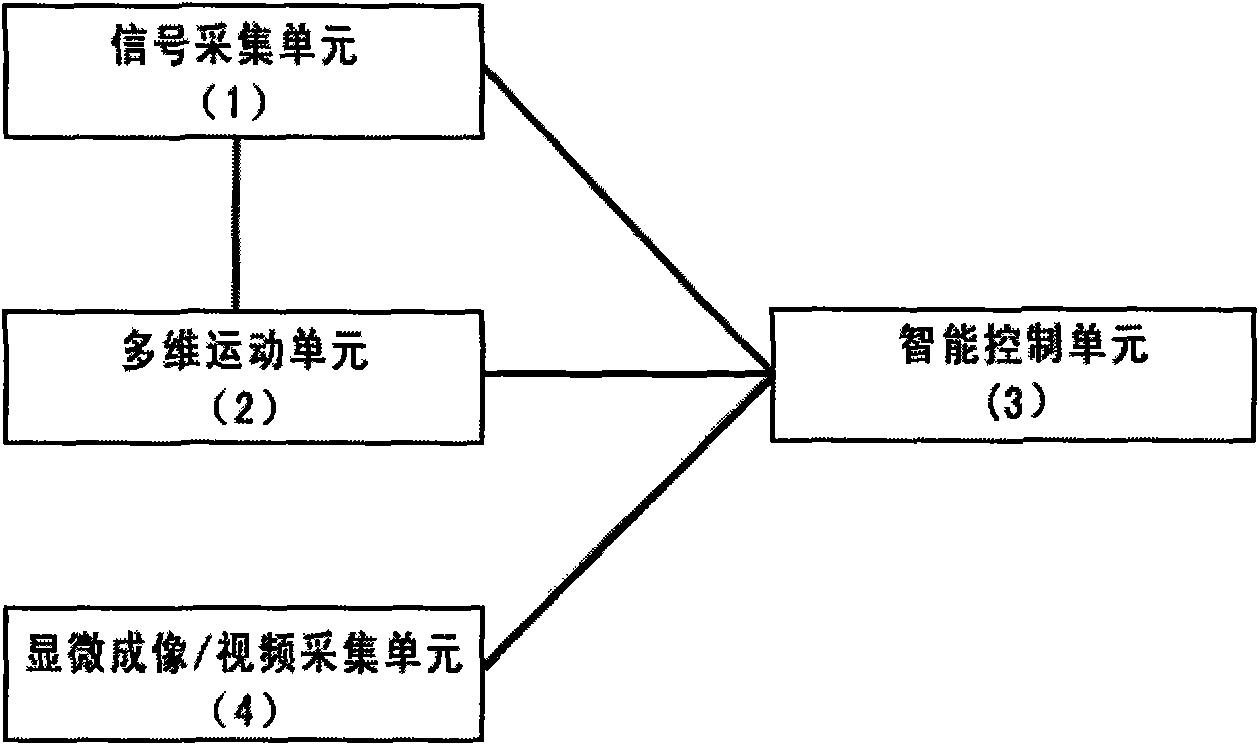

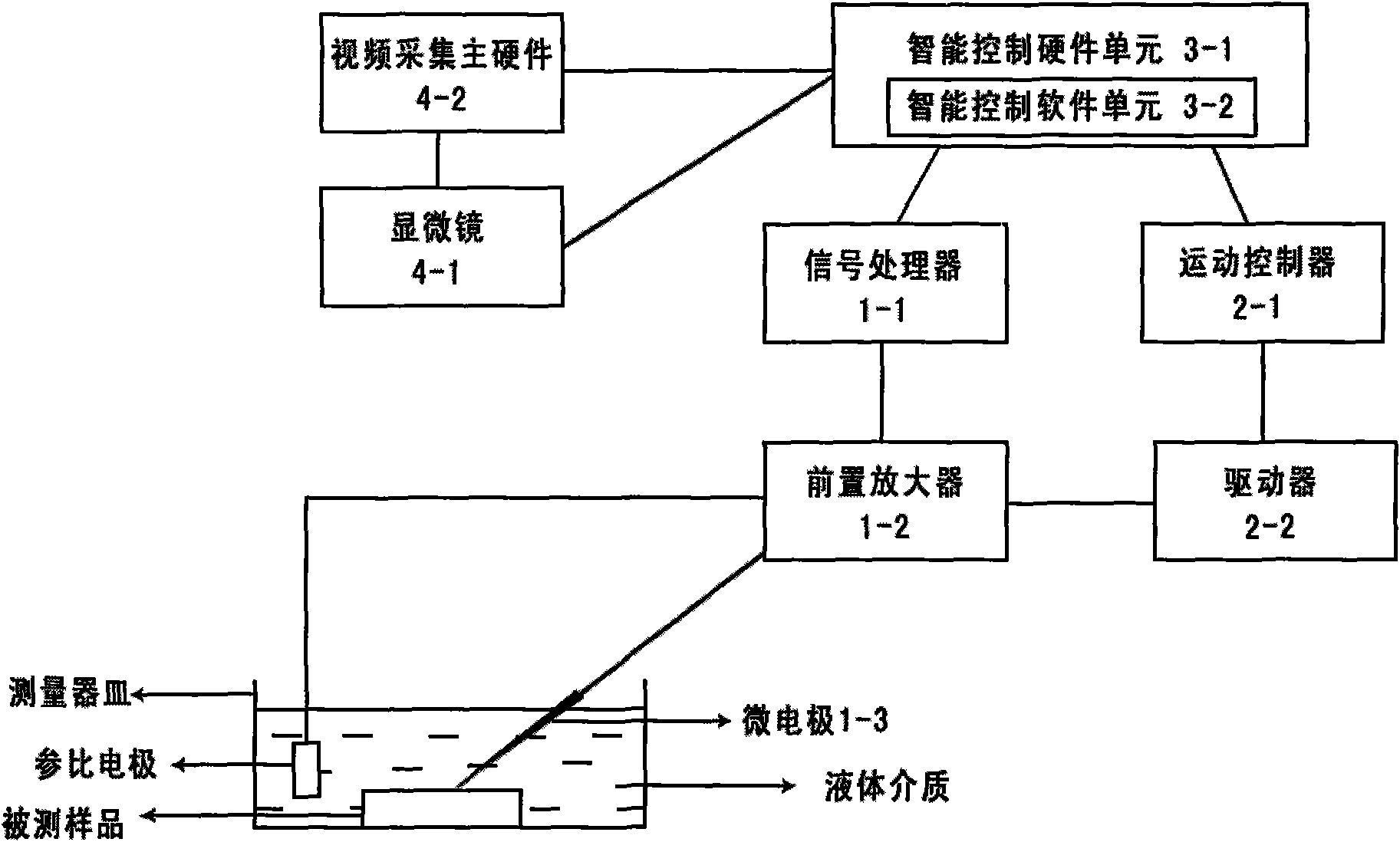

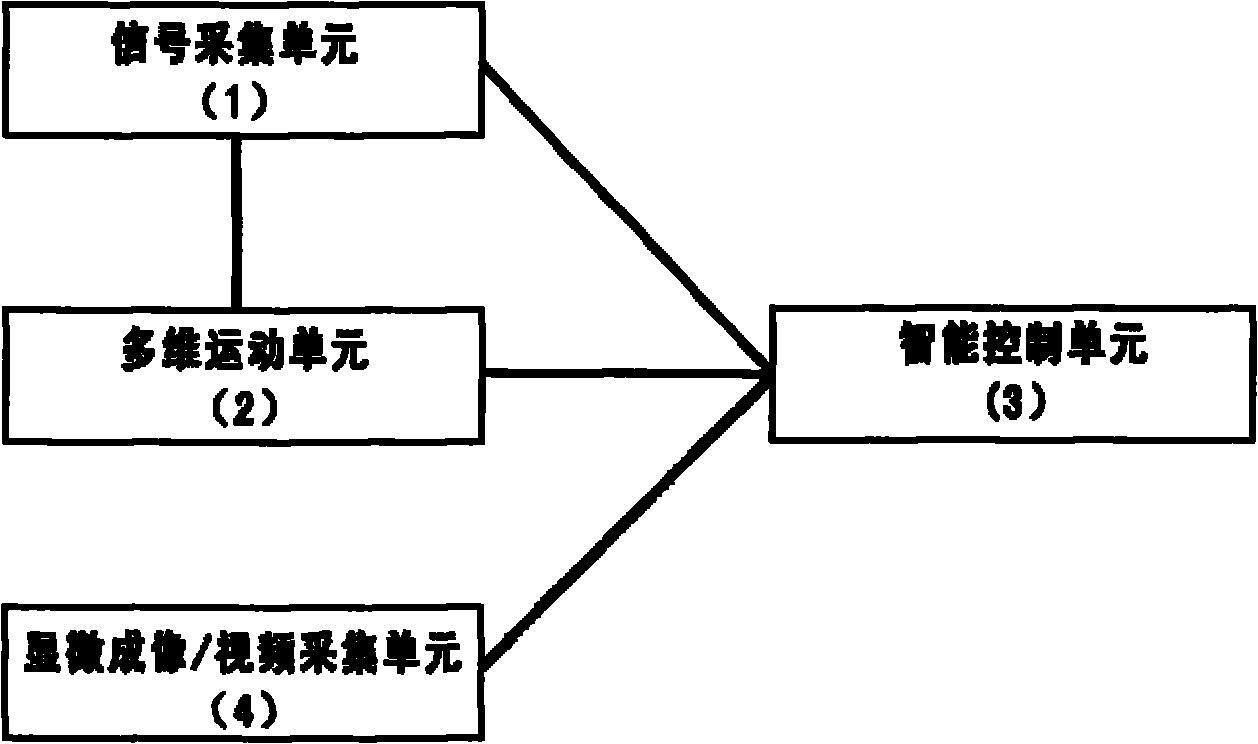

ActiveCN101988914ARealize fully automated operationGood application effectMaterial electrochemical variablesMicro imagingLocal current

The invention provides a method for fully automatically controlling a microelectrode to approach a sample for testing and non-invasively acquiring ion and molecule concentration, flow rate and flow direction of the incoming and outgoing samples, and sample microcell information such as sample surface local current information and the like. The method involves a signal acquisition unit (1), a multidimensional motion unit (2), an intelligent control unit (3) and a micro-imaging / video acquisition unit (4). The intelligent control unit (3) sends a control command to the multidimensional motion unit (2) and the micro-imaging / video acquisition unit (4) by analyzing a signal transmitted by the signal acquisition unit (1) and the micro-imaging / video acquisition unit (4), controls the motion of the microelectrode and the measured sample, and realizes full-automatic information acquisition of the measured sample by the microelectrode. The method causes no damage to the measured sample, the operating process is fully automatic and independent of man-made operating factors, and the acquired data is steady and reliable. The method can be applied to biological living body, non-organism and other samples.

Owner:XUYUE BEIJING

Automatic welding production line for robot based on full automatic control of central computer

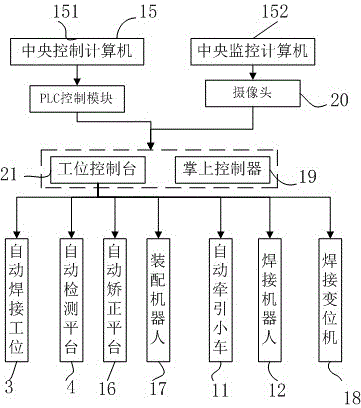

ActiveCN106736116AReal-time monitoring of working statusStrengthen modern managementWelding/cutting auxillary devicesAuxillary welding devicesInformatizationProduction line

The invention discloses an automatic welding production line for a robot based on full automatic control of a central computer, which is connected with and controls PLC (Programmable Logic Controller) control modules in station consoles on all production lines through a central computer; the station consoles each comprise an automatic welding station, an automatic detection platform, an automatic correction platform, an assembly robot, an automatic trailer wagon, a welding robot and a welding positioner which are respectively and independently connected to the central computer; the station consoles are each provided with a handheld controller; wherein the central computer comprises a central control computer and a central monitoring computer, and the central monitoring computer is connected with cameras arranged on all the station consoles, and then monitors the working condition of all the stations in real time. The production line disclosed by the invention is a production line for welding large parts with a full automatic intelligent robot, which is integrated with high informatization, intellectualization and integration, is simple in structure, reasonable in design, and safe and reliable in performance, reduces the costs effectively, and has obvious application effects.

Owner:南京臻铭信自动化装备有限公司

Full-automatic paper box forming machine

InactiveCN101786343BLabor savingRealize standardized operationBox making operationsPaper-makingDevice formCarton

The invention provides a full-automatic paper box forming machine, which is applicable to the technical field of full atomization. The paper box forming machine comprises a machine frame, a paper box loading device, a releasing device, a paper box forming device, a top edge folding device, a feeding and nailing device, an adhesive tape sealing device and a controller, wherein the paper box loading device, the releasing device, the paper box forming device, the top edge folding device, the feeding and nailing device and the adhesive tape sealing device are sequentially arranged on the machine frame, the paper box loading device loads a paper box under the control of the controller, the release device moves the paper box into the paper box forming device, the paper box forming device forms the paper box, the feeding and nailing device binds the paper box, and the adhesive tape sealing device seals adhesive tapes on the bound paper box. Compared with the conventional paper box forming machine, the invention has the advantages that all flow processes are completed through controlling an automatic forming machine by the controller, the labor is saved, the standard operation is realized, and the invention can ensure that each product can be finished according to the technical requirements. In addition, the work efficiency is improved.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

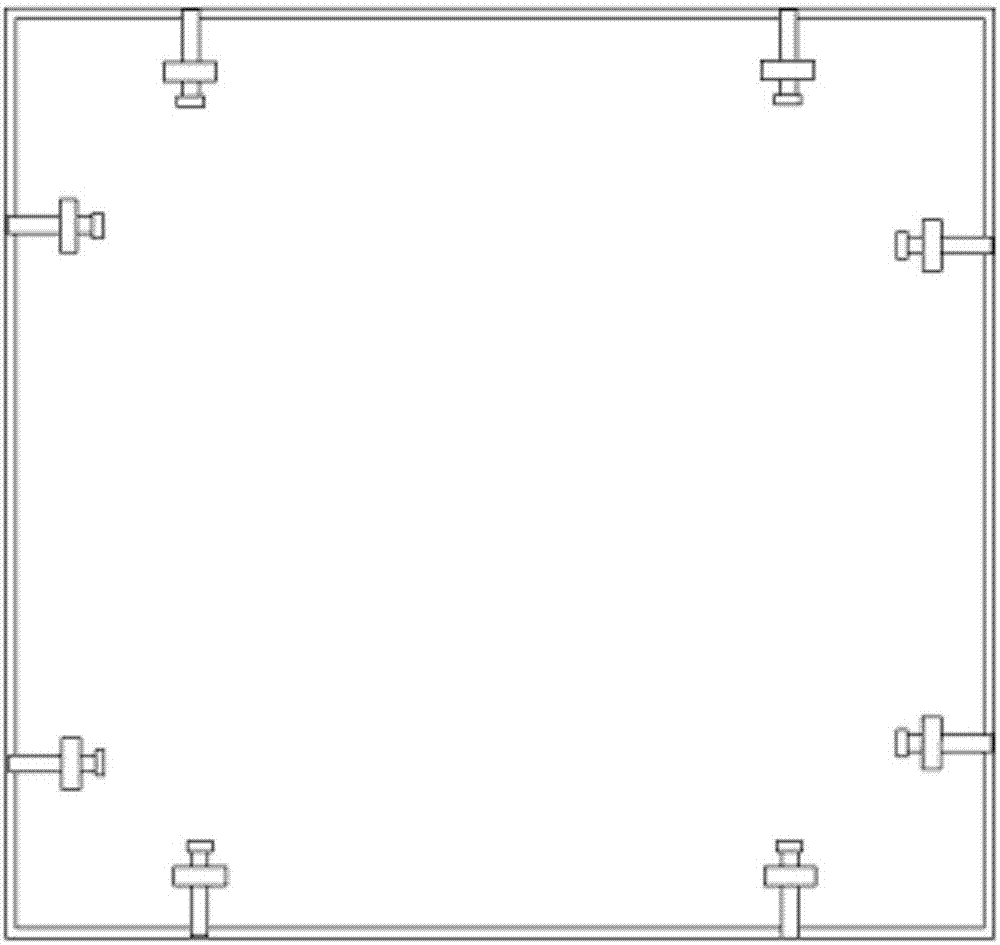

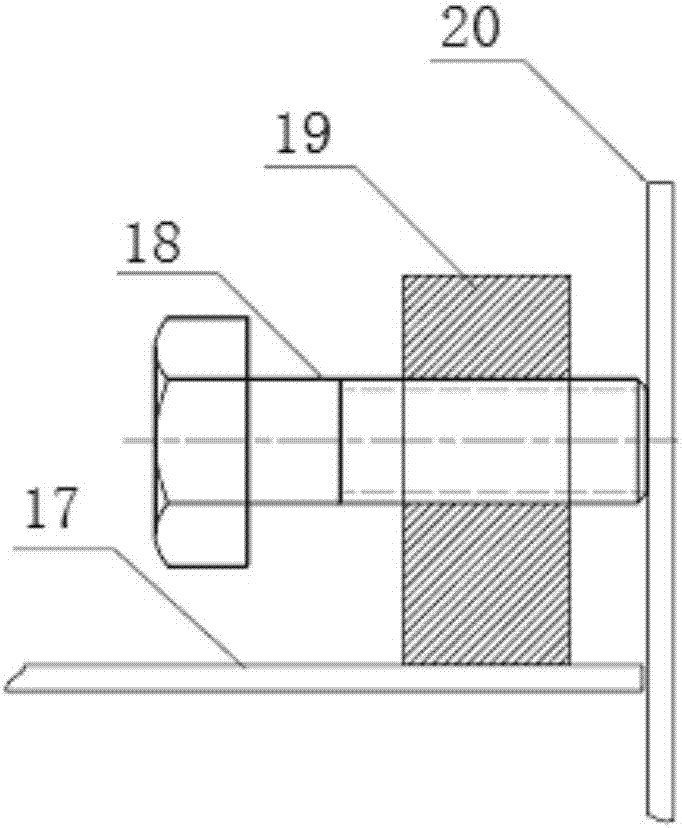

Adjustable hanger system

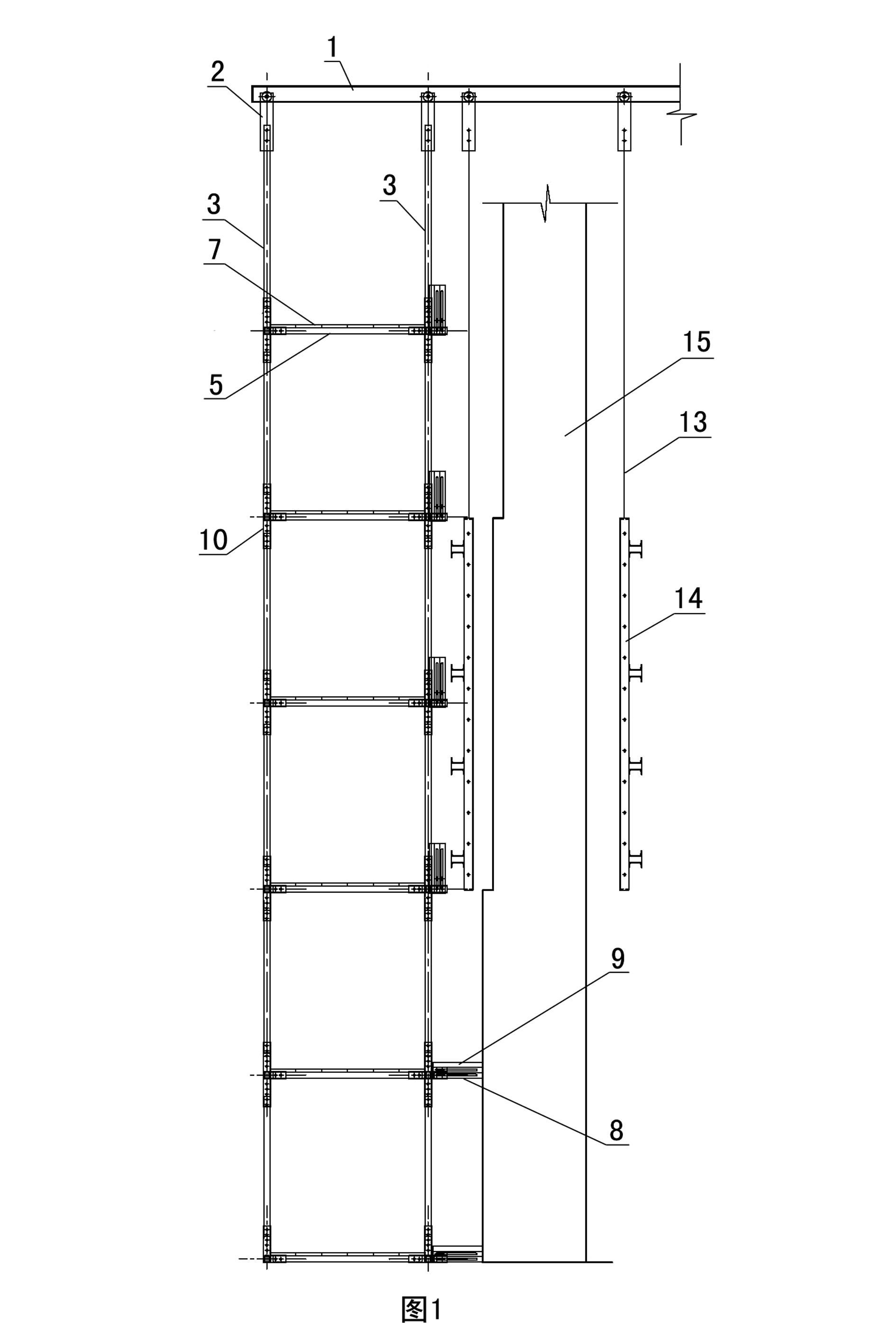

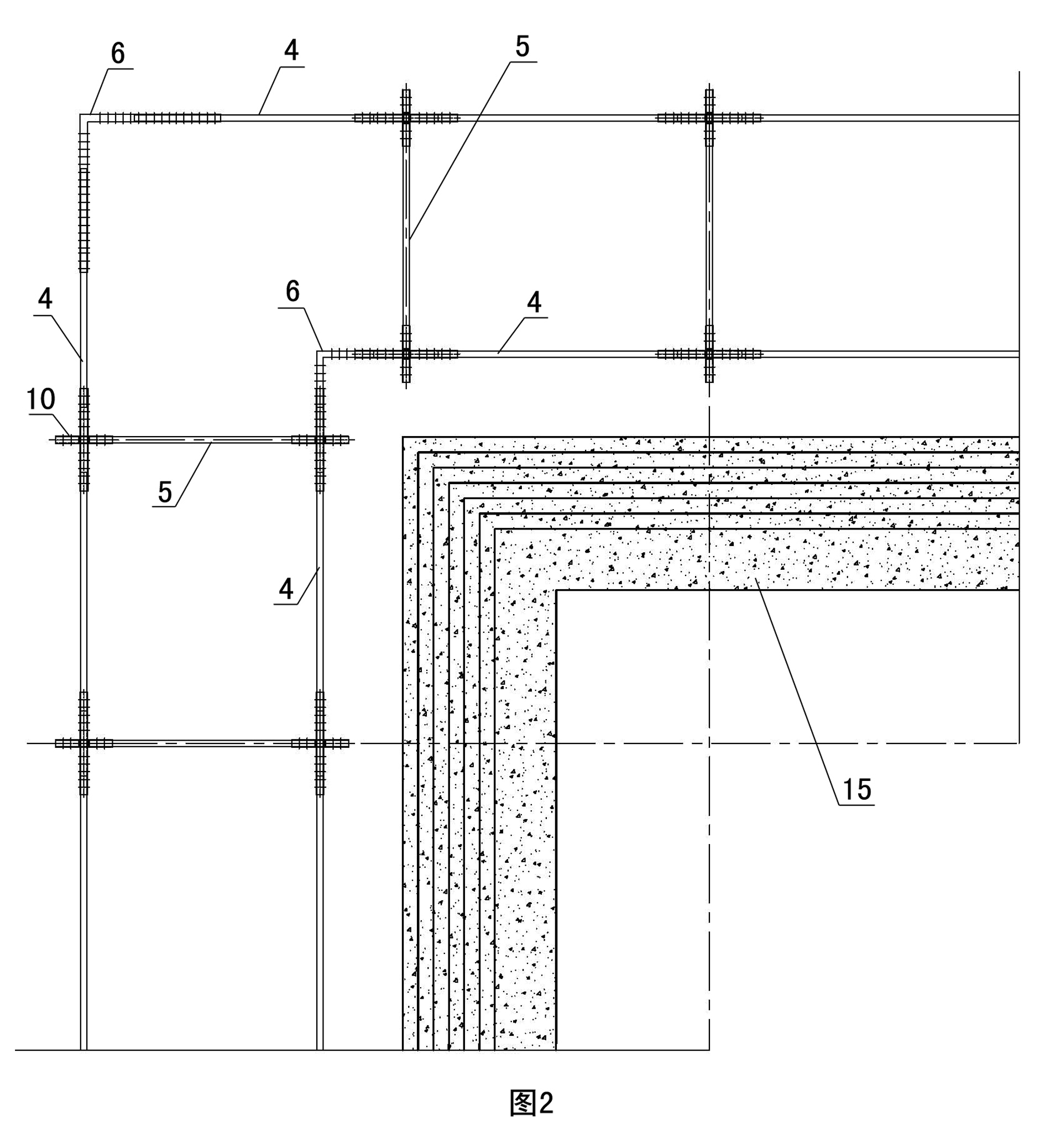

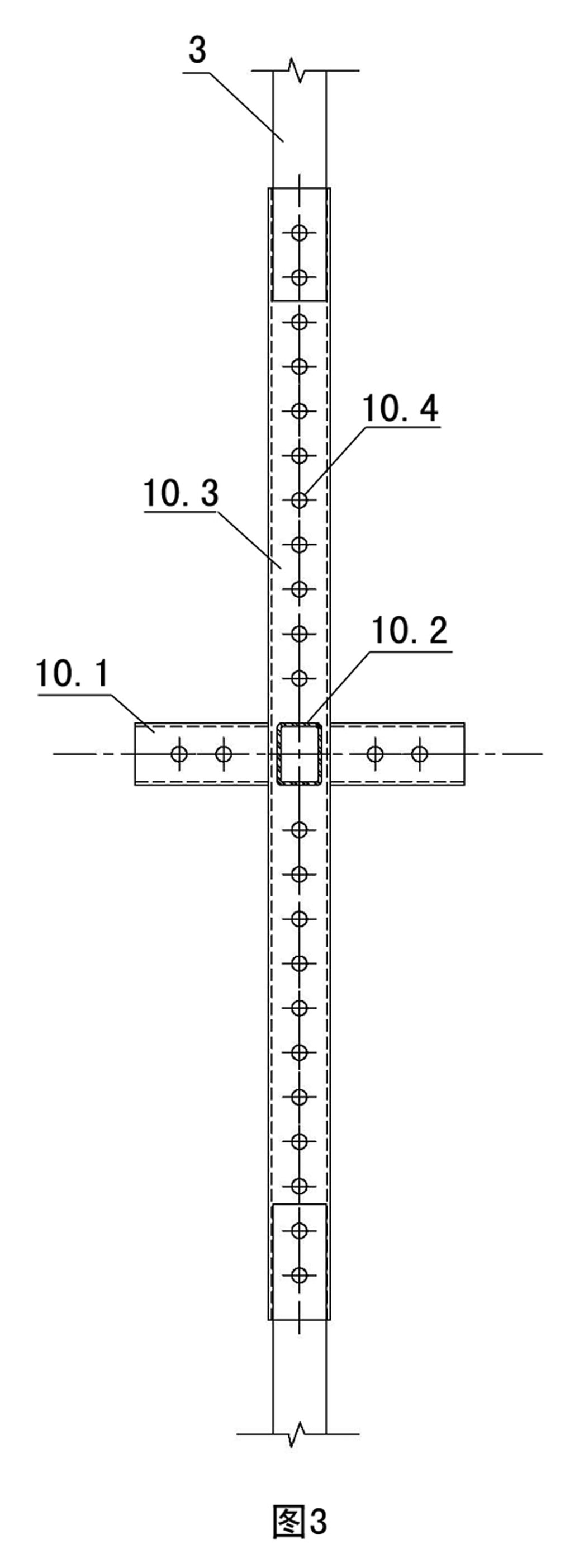

ActiveCN101818564AImprove securityRealize mechanized workScaffold connectionsForms/shuttering/falseworksVertical tubeEngineering

The invention discloses an adjustable hanger system, which comprises a framework connected with a steel platform system and a steel jump plate fixed on the framework. The framework has a three-dimensional pane structure consisting of an inner hanger sheet, an outer hanger sheet and an inner and outer sheet connecting rod connected between the inner hanger sheet and the outer hanger sheet; both the inner hanger sheet and the outer hanger sheet comprise a suspender, a horizontal cross rod and a shaped joint tube at a node, which are arranged at intervals; and screw holes are uniformly distributed on the shaped joint tube, and the shaped joint tube is welded by a transverse tube joint, a longitudinal tube joint and a vertical tube joint, wherein the vertical tube joint is detachably connected with the inner and outer sheets through bolts, the transverse tube joint is detachably connected with the horizontal cross rod through bolts, and the longitudinal tube joint is detachably connected with the inner and outer sheet connecting rod through bolts. The hanger system can be widely applied to mounting construction of a high-rise concrete core tube structure of formwork creeping or lifting system construction, a steel structure and the like. The hanger system can meet the requirements of different buildings, realizes integral standardized operation, liberates a large amount of labor force, reduces the cost, and improves the safety of a hanger.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD +1

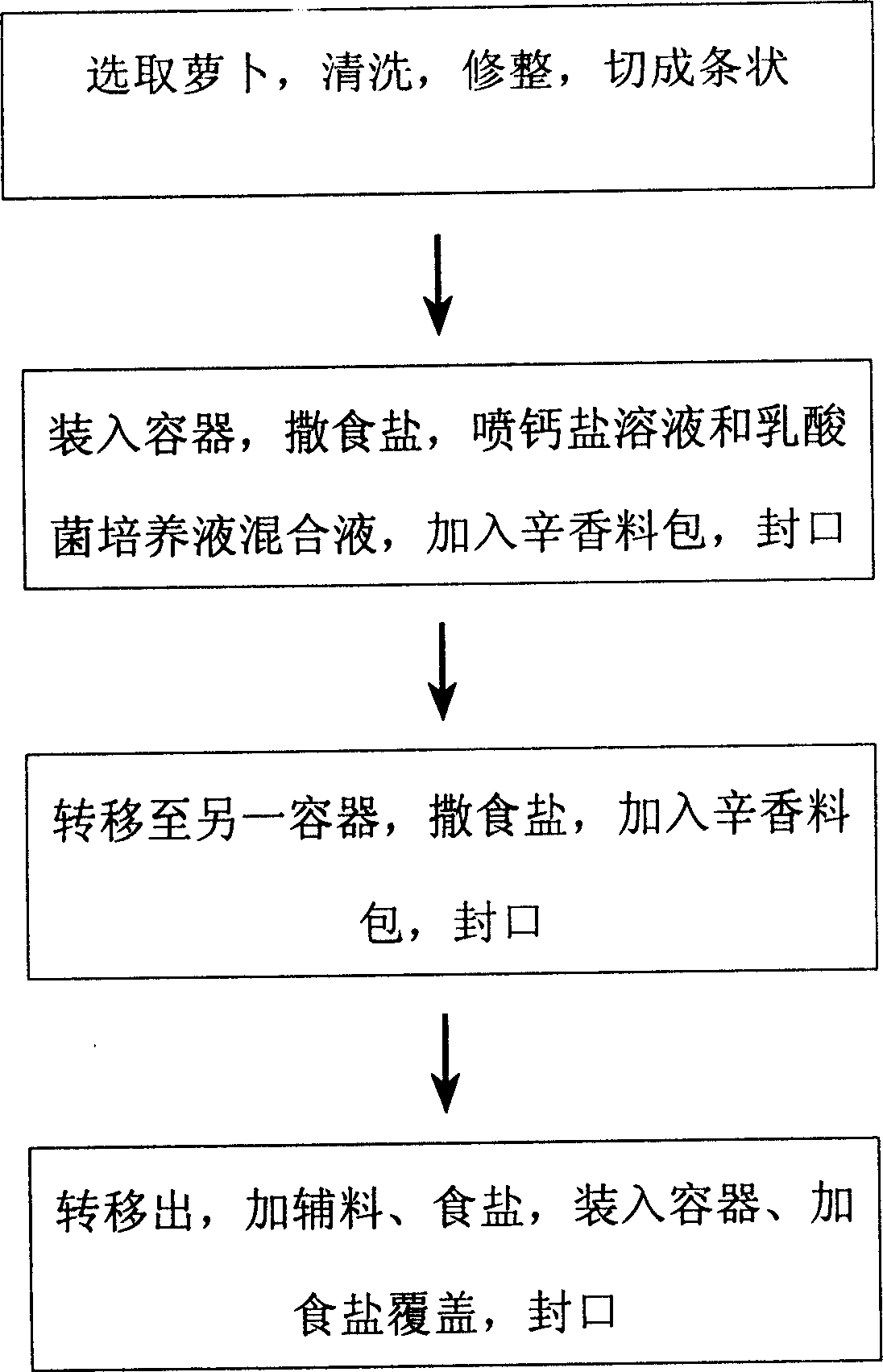

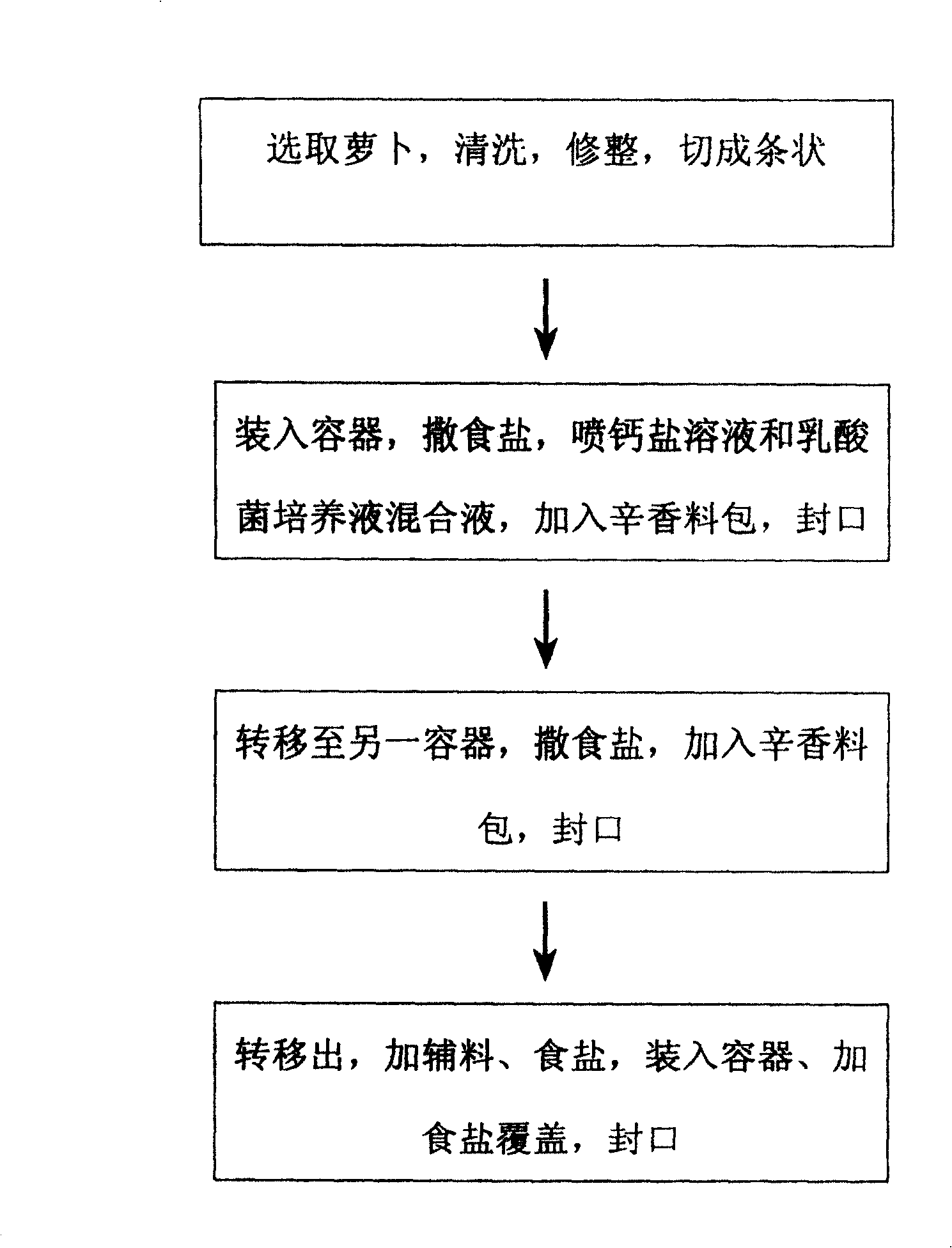

Method for producing typical flavour turnip slices

ActiveCN1860924AInhibition of reproductionPromote the formation of flavor substancesFood scienceGenus LactobacillusCalcium

A process for preparing the salted radish strips with special taste includes such steps as loading the radish strips in a container layer by layer while adding edible salt and spraying the mixture of the liquid culture of lactobacillus and the solution of Ca salt onto each layer, adding the hot spicing bag to the middle of container, sealing, salting for 36-72 hr, transferring said radish strips into another container but removing said hot spicing bag, sealing, salting for 48-72 hr, mixing the radish strips with additive and edible salt, loading the mixture in the third container, compacting, spraying edible salt, sealing and salting for 28 days.

Owner:桐庐弘武食品有限公司

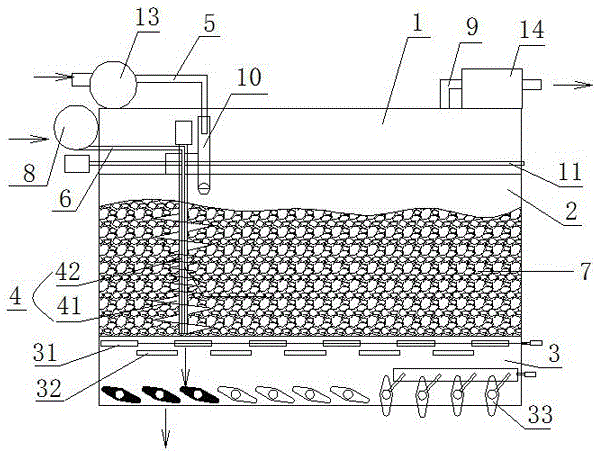

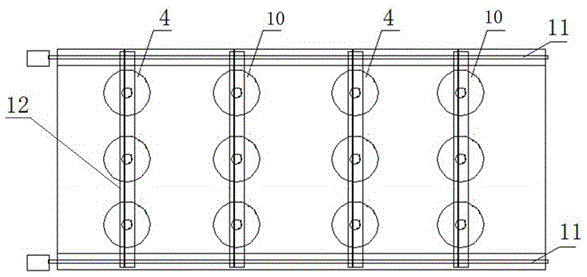

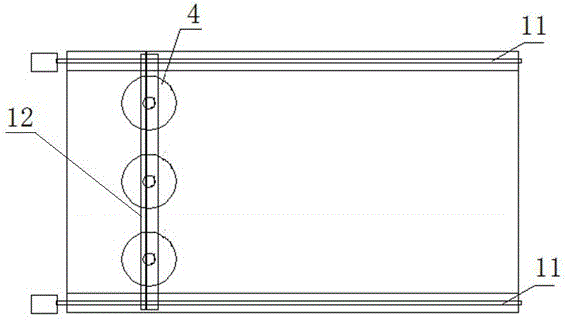

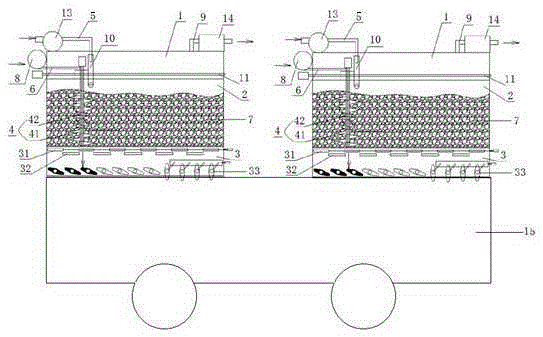

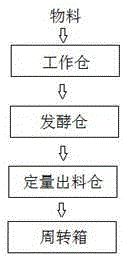

Solid-state fermentation device and system as well as fermentation method

ActiveCN105062883AAchieving standardized workClear working structureBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyBiochemical engineering

The invention discloses a solid-state fermentation device and system as well as a fermentation method. The fermentation device is divided into three parts with clear functions, namely, a working bin, a fermentation bin and a quantitative discharging bin, and the standard fermentation system is constructed. The quantitative discharging bin is controlled to discharge materials quantitatively every day, the working bin distributes the materials into the fermentation bin, quantitative material distribution is controlled, and the materials in the fermentation bin are fermented in a layered manner. Further, turnover boxes are adopted for discharging and are storage and transporters for fermented products. The components of the device are well combined, equipment maintenance and fermentation production as well as standard operation of the fermentation technology are guaranteed due to adoption of standard equipment, the automation degree is high, multiple groups of equipment can be combined for work while operators are not increased excessively, the management cost and the production cost are lower, mass production and mass operation are facilitated, and operation and control are easy, so that the fermented products as well as storage and transportation of the products are also standardized.

Owner:麦行

Converter steel ladle bottom argon blowing automatic control system

The invention relates to the improvement of a converter steel ladle bottom argon blowing automatic control system. The converter steel ladle bottom argon blowing automatic control system is characterized by comprising a system main module, a tapping stage judgment module, an argon station stage judgment module, a gas amount adjusting module, a pipeline on-off module and a manual control module. The converter steel ladle bottom argon blowing automatic control system has the advantages that standard operation of converter argon blowing is achieved, the argon blowing effect is improved, and therefore the purity degree of molten steel is increased; molten steel composition segregation and continuous casting flocculant flow caused by non-in-place or nonstandard argon blowing due to manual reasons are reduced; argon blowing is managed in a refined manner, and argon moving and manual waste are eradicated; and convenience is brought to all-procedure accident analysis, and process management dead zones are eliminated.

Owner:辽宁鸿盛冶金科技有限公司

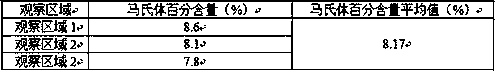

Method of measuring martensite content in dual-phase steel by using electron backscatter diffraction (EBSD) technique

ActiveCN109959670ACertaintySolve the distinctionMaterial analysis using wave/particle radiationScanning electron microscopeElectron

The invention relates to a method of measuring a martensite content in a dual-phase steel by using an electron backscatter diffraction (EBSD) technique. The method comprises the following steps: 1) ato-be-measured sample is inlaid and is ground and polished to be made to a common metallographic sample; 2) the well-polished common metallographic sample is subjected to vibration polishing in a vibration polishing machine; 3) the metallographic sample after vibration polishing is corroded, wherein a corrosion solution is a 1% to 4% nital solution, and the corrosion time is 10 to 15 s; 4) the well-made metallographic sample is placed in a field emission scanning electron microscope sample chamber; and 5) through reasonable parameter setting, EBSD data are acquired, software is used to analyzethe data, a kikuchi slope map is acquired, a new subset is formed, the M phase in the subset is extracted, and thus, the percentage content of a martensite structure in the to-be-measured sample is thus acquired. The scheme can accurately and efficiently extract the martensite phase in the dual-phase steel structure and solves the problems that the martensite structure and a ferrite structure aredifficult to distinguish and the accurate percentage content cannot be obtained.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

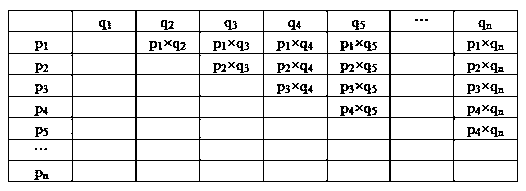

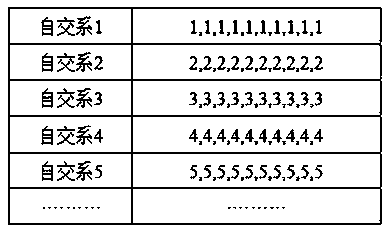

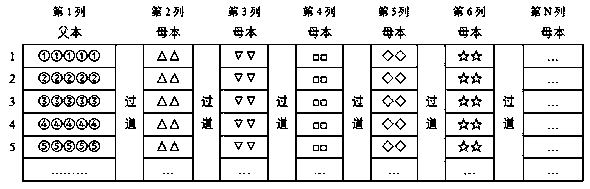

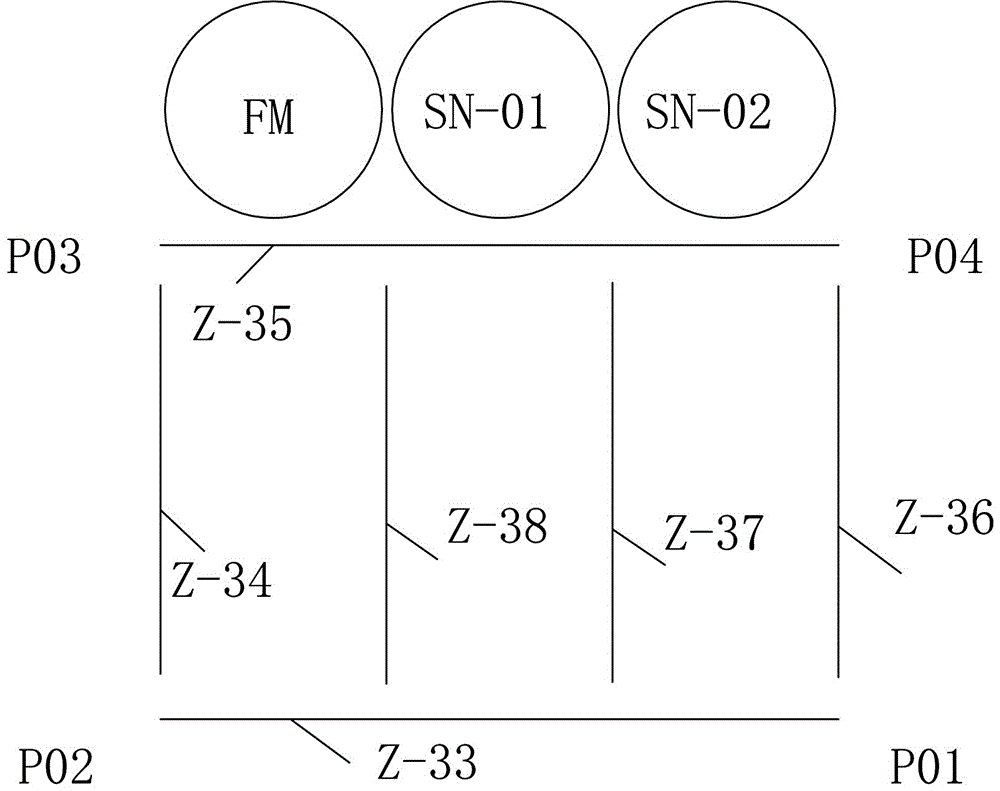

Field planting method for efficiently mating maize diallel crossing combinations

InactiveCN110235777AReduce the chance of confoundingReduce workloadPlant genotype modificationPollinationPollen

The invention discloses a field planting method for efficiently mating maize diallel crossing combinations. Male parents are planted in rows, wherein the male parents of the same row are the same male parent selfing line; female parents are planted in lines, wherein the female parents of the same line are the same female parent selfing line, the number of rows of each line of the female parents is equal to that of the types of the male parent selfing lines, the first row of the male parent selfing lines and the first row of all the lines of the female parent selfing lines are planted into one row, the second row of the male parent selfing lines and the second row of all the lines of the female parent selfing lines are planted into one row, and the rest can be done in the same manner until the last row of the male selfing lines and the last row of all the lines of the female parent selfing lines are planted into one row. During pollination, the female parent selfing lines are subjected to castration, the male parent selfing lines pollinate corresponding rows of female parent selfing lines by row in correspondence to the lines, and after the selfing lines are ripe, harvesting is sequentially conducted by row and by line. According to the field planting method, the workload and complicated degree in the preparing links of existing diallel crossing combinations are lowered, the probability of pollen mixing is lowered, the pollination and seed clearing efficiency is improved, errors caused by human negligence are reduced, and the field planting method is suitable for application and popularization of maize breeding within a large range.

Owner:CHONGQING ACAD OF AGRI SCI

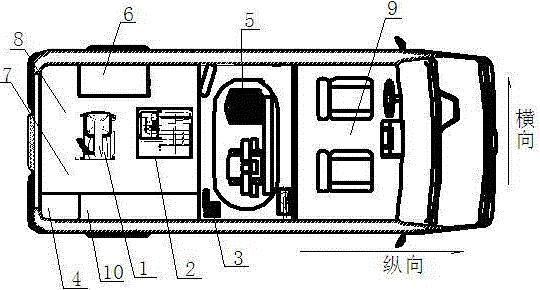

Mini movable service vehicle for tire

InactiveCN104827955AImprove space utilizationImprove service qualityItem transportation vehiclesBalancing machineDynamic balance

The invention relates to a mini movable service vehicle for a tire. The service vehicle comprises a cab and a service vehicle box body, wherein a tire changer, a dynamic balancing machine, a jack, an air compressor, a tool kit and a jack hammer are arranged in the box body, wherein a space in the box body is divided into five different sections, wherein one side, which is close to the cab, in the box body is an air compressor section which is transversely arranged along the box body; the longer direction of the machine dimension of the air compressor is transversely placed in the section along the box body; other spaces in the box body are longitudinally divided into a jack hammer section, a tire changer and dynamic balance section, a tool kit section and a tire placing area along the box body, wherein the jack hammer section, the tire changer and dynamic balance section, the tool kit section and the tire placing area are longitudinally arranged along the box body; the tire placing zone is located at the middle position of the four sections. The mini movable service vehicle has the advantages of high space utilization rate of the box body, convenience for use, complete equipment and strong mobility.

Owner:SHUANGXING GRP CO LTD QINGDAO

Method for producing fibrous protein-removed original blood from newborn calf blood

ActiveCN104546913AAchieve the purpose of mixingImprove stabilityAerosol deliveryOintment deliveryFiberFiltration

The invention discloses a method for producing fibrous protein-removed original blood from newborn calf blood. The method comprises the following steps: (1) receiving the blood of a newborn calf by a blood bottle and starting to stir the blood by a glass rod with a bulge at the stirring end at a speed of 110-140 rpm when the blood flows to 1 / 6 to 1 / 4 of the holding volume of the blood bottle; (2) stopping the stirring when the blood achieves the holding volume of the blood bottle and sealing the blood bottle; (3) stirring at a speed of 160-200 rpm for 2-4 min, stopping the stirring, standing for 3-4 min, stirring at 110-140 rpm for 5-8 min, stopping the stirring, and taking out the glass rod and the fibrous protein wound on the stirring end. The method provided by the invention has the advantages that the stability is high and the homogenization degree is high; the automatic stirring is realized so as to avoid the interferences of human factors; the standard operation and industrial production can be realized; the fibrous protein can be removed to a relatively complete extent without filtration, so that the time and the labor are saved; the bottle does not need to change and the blood bottle is a storage bottle for the non-solidified original blood; the recovery rate of the original blood is high and has an average of 93%.

Owner:内蒙古维克生生物技术股份有限公司

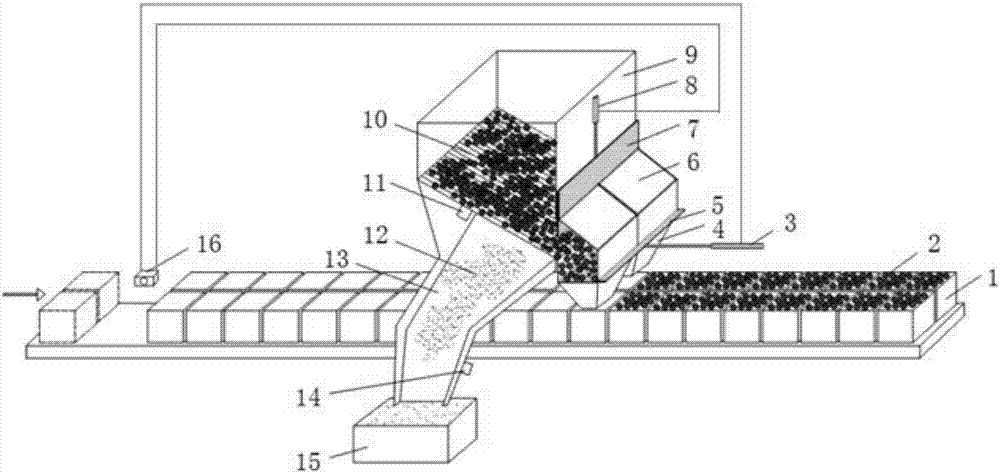

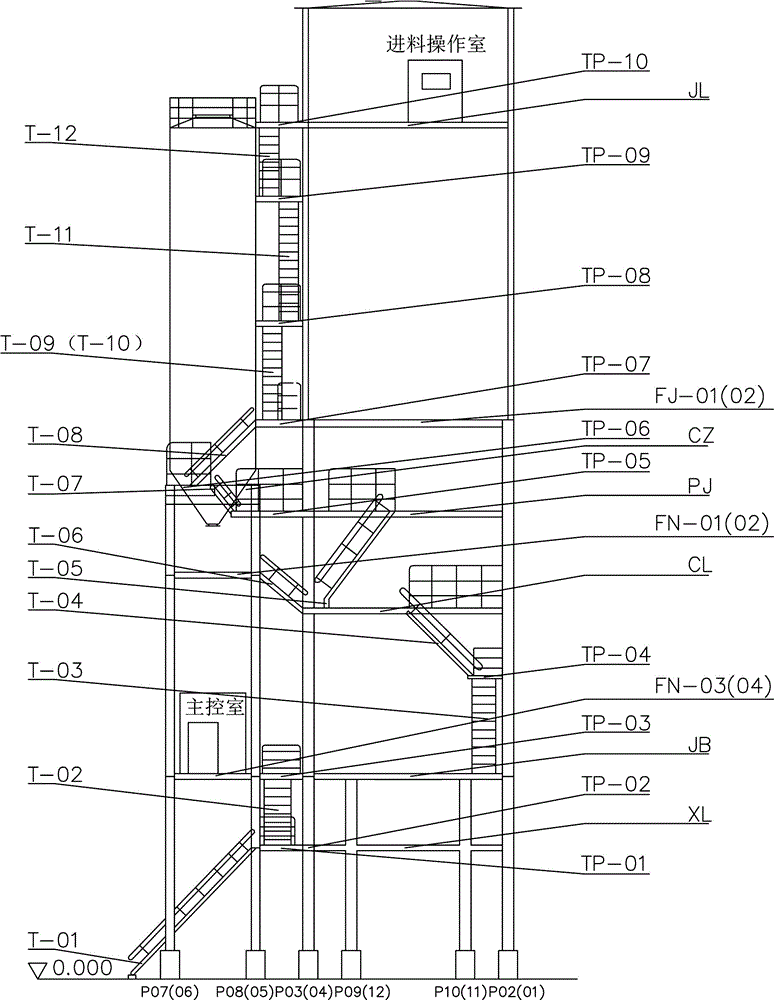

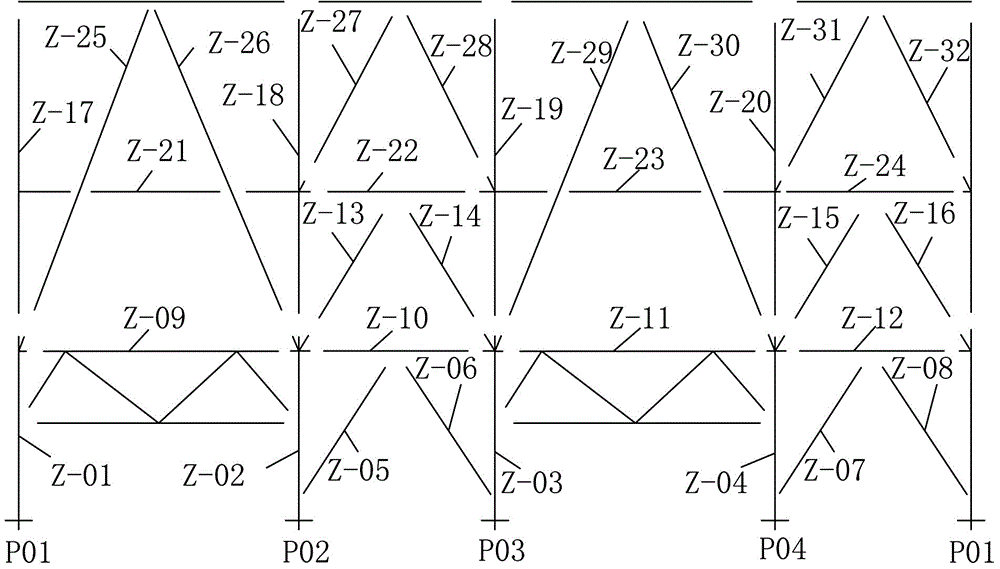

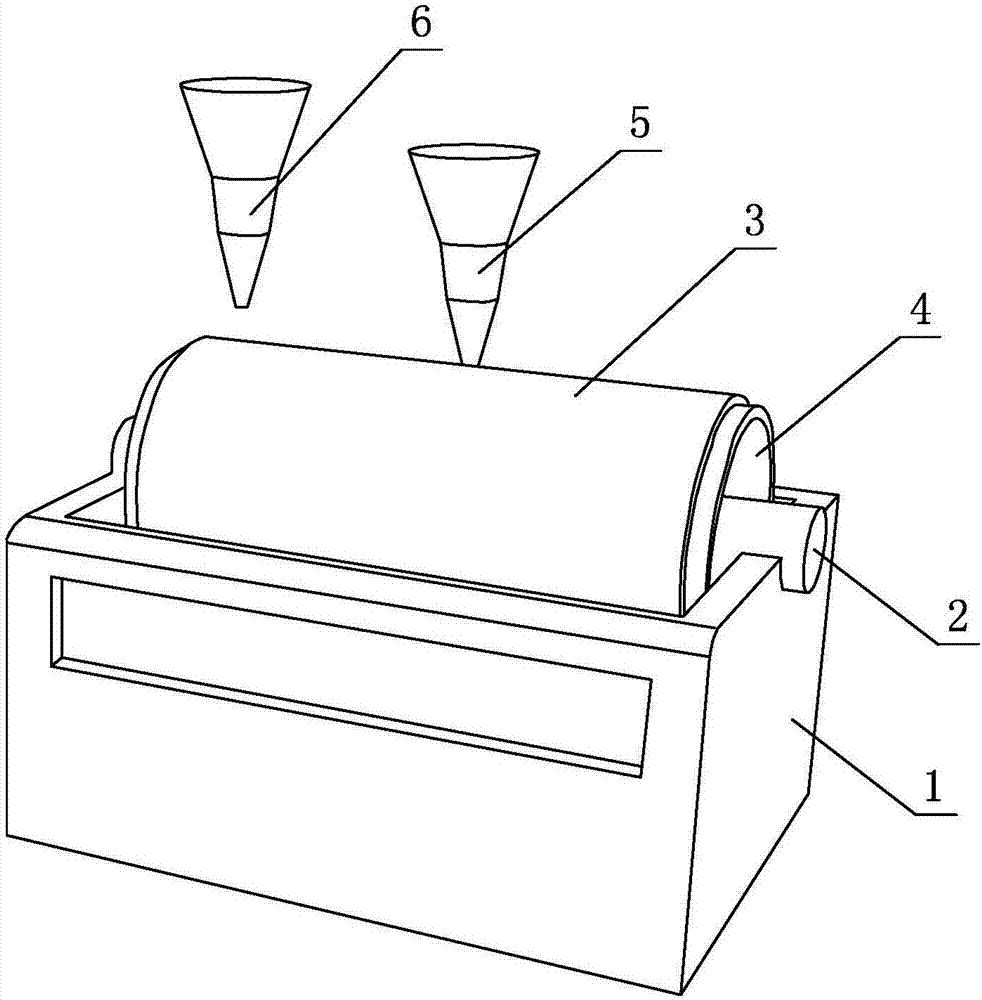

Automatic loading system for vanadium-nitrogen alloy and loading method

PendingCN107166955ARealize quantitative chargingGuaranteed uniformityCharge composition/stateCharge manipulationCrucibleStructural engineering

The invention discloses an automatic loading system for a vanadium-nitrogen alloy and a loading method. The system comprises loading equipment and a crucible circulating heating device; the loading equipment comprises a main bin, a sieve, at least one fixing bin and at least one discharging hopper; a feeding port is formed in the top of the main bin; the sieve is obliquely mounted at the bottom of the main bin; a discharging port is formed in the wall of the main bin at the lowest end of the sieve; a vertical gate is mounted on the discharging port and is controlled by a vertical gate air cylinder to be opened and closed; the at least one fixing bin is mounted on the outer side of the discharging port and communicates with the discharging port; a movably-mounted transverse gate is arranged at the bottom of the at least one fixing bin and is controlled by a transverse gate air cylinder to be opened and closed; the at least one discharging hopper is arranged at the lower end of the at least one fixing bin; the crucible circulating heating device comprises a track and at least one row of crucibles placed on the track; the crucibles run on the track in a circulating manner; the loading equipment is fixed at the upper end of the crucible circulating heating device; and the volume of each fixing bin is equal to that of each crucible.

Owner:山东济钢泰航合金有限公司

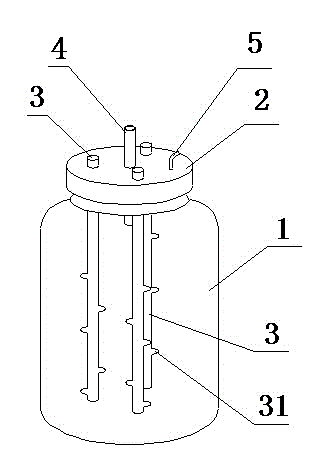

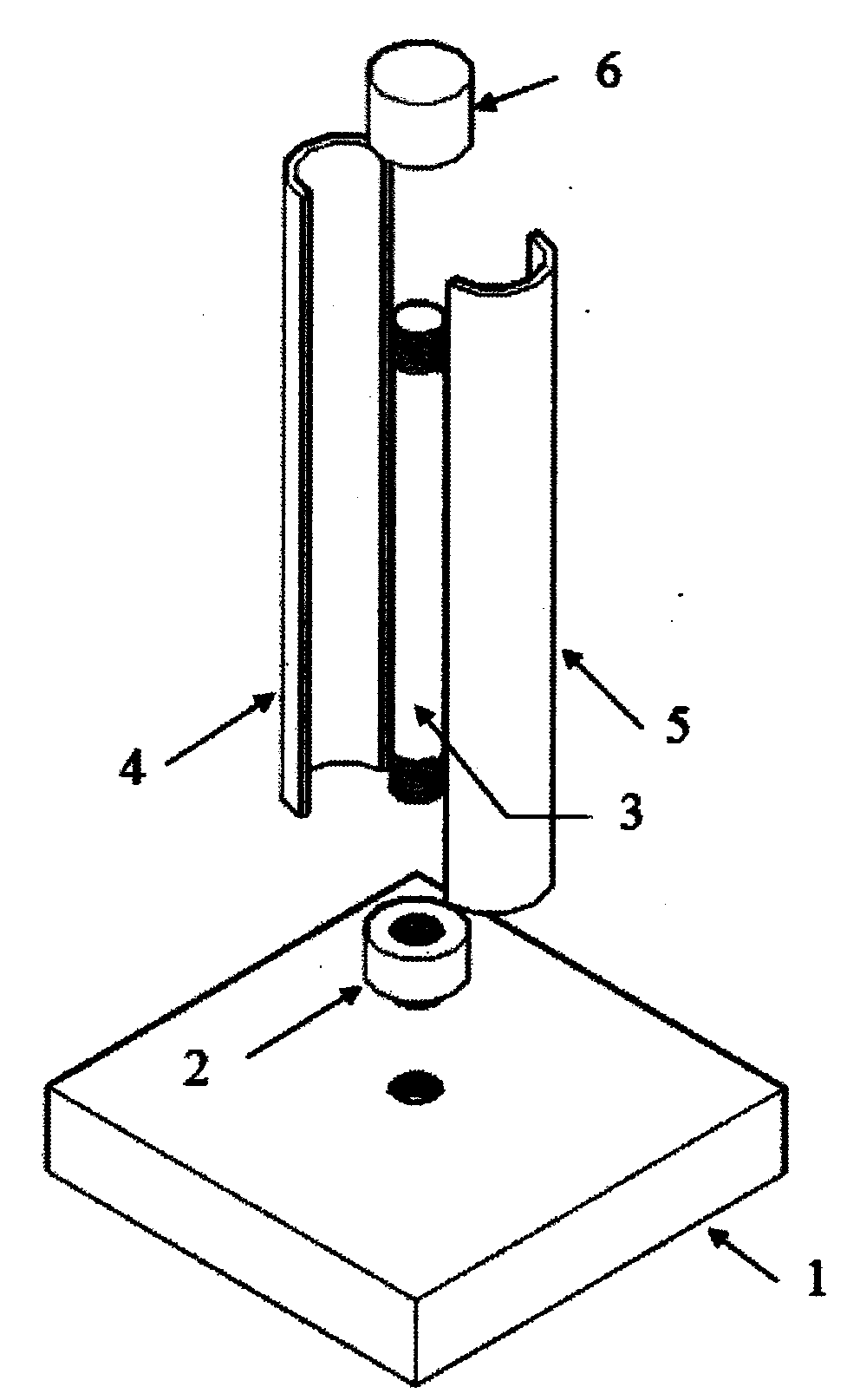

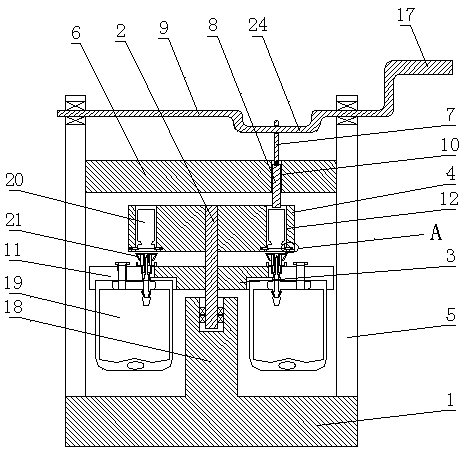

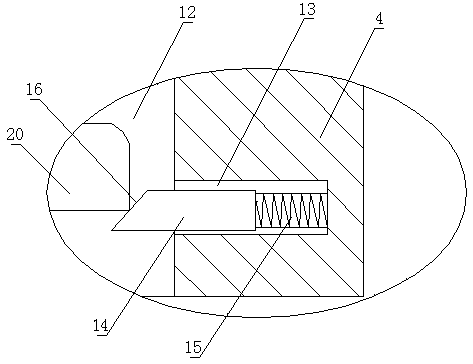

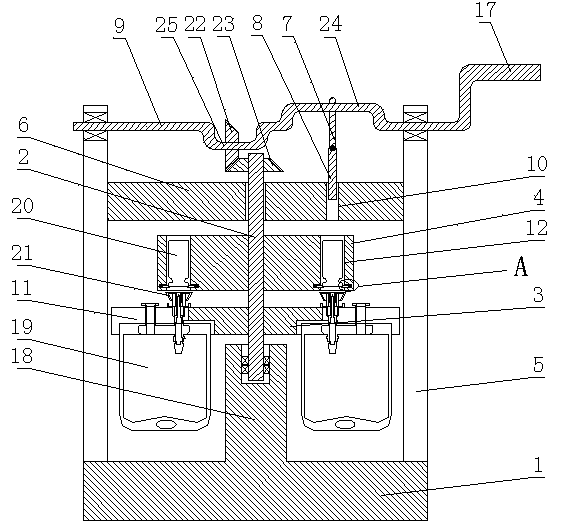

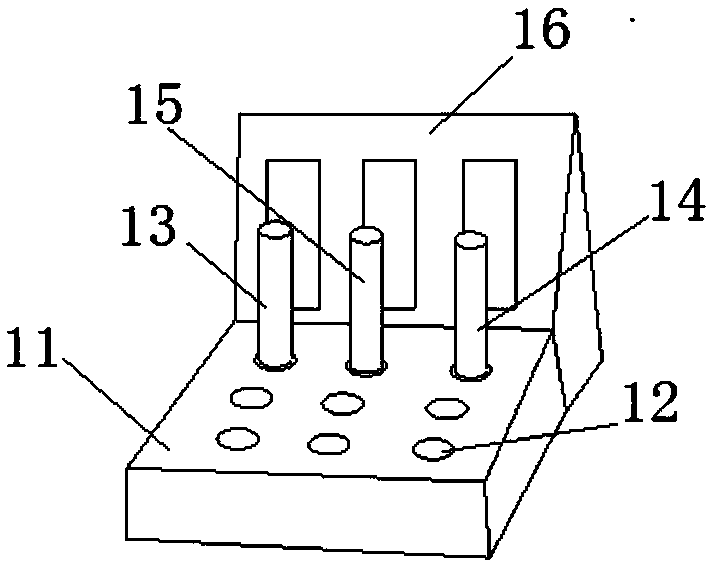

Pipeline organ cast forming device and use method thereof

InactiveCN103989537AEasy to disassembleEasy to demouldTubular organ implantsEngineeringStructural engineering

The invention provides a pipeline organ cast forming device and a use method thereof. The pipeline organ cast forming device is characterized by comprising a base, a lower fixing nut, a core column, a first shell, a second shell, an upper fixing nut and a tubular shell, the lower fixing nut is connected with the base through threads, one end of the core column is connected with the lower fixing nut through threads, the upper fixing nut is connected with the other end of the core column through threads, the tubular shell surrounds the upper fixing nut and the lower fixing nut, a cavity is formed between the tubular shell and the core column, the tubular shell is composed of the first shell and the second shell, and the lateral side of the first shell and the lateral side of the second shell are connected in a detachable mode, namely, a concave-convex matching mode. By means of the pipeline organ cast forming device, a seamless pipeline with the accurate and controllable inner diameter and the accurate and controllable outer diameter can be formed at a time; the pipeline organ cast forming device is easy to detach and assemble and can be demoulded easily. The pipeline organ cast forming device is suitable for forming pipeline organs by casting polymer solutions.

Owner:DONGHUA UNIV

Instrument for perpendicularly assembling chemical mixer and penicillin bottle

The invention discloses an instrument for perpendicularly assembling a chemical mixer and a penicillin bottle. The instrument for perpendicularly assembling the chemical mixer and the penicillin bottle comprises a base, a rotary shaft, a disk I, a disk II, a support, a guide plate, a connecting rod, a push rod and a curved bar, wherein the rotary shaft is vertically arranged on the base, the rotary shaft is fixedly sleeved with the disk I and the disk II, the guide plate is arranged above the disk II, the curved bar is arranged on the top of the support, an outwards protruding section I of the curved bar is sleeved with one end of the connecting rod, the other end of the connecting rod is hinged to one end of the push rod, the push rod penetrates through the guide plate, a plurality of clamping grooves are formed in the disk I in the circumferential direction of the disk I, the outer sides of the clamping grooves are open, round holes which correspond to the clamping grooves in a one-to-one mode are formed in the disk II, and the other end of the push rod is arranged above a rotation track of the round holes. The instrument for perpendicularly assembling the chemical mixer and the penicillin bottle is integrally designed, and is fixed in occupied space and good in stability; due to the fact that synchronous rotation is formed between the two disks, continuous operation of loading, puncture assembly and unloading can be achieved, and handling capacity is flexible and adjustable; due to the fact that puncture assembly between penicillin bottles of different specifications and infusion bags of different specifications can be achieved through switching between the disks of different specifications, and the instrument for perpendicularly assembling the chemical mixer and the penicillin bottle is wide in range of application.

Owner:重庆莱美医疗器械有限公司

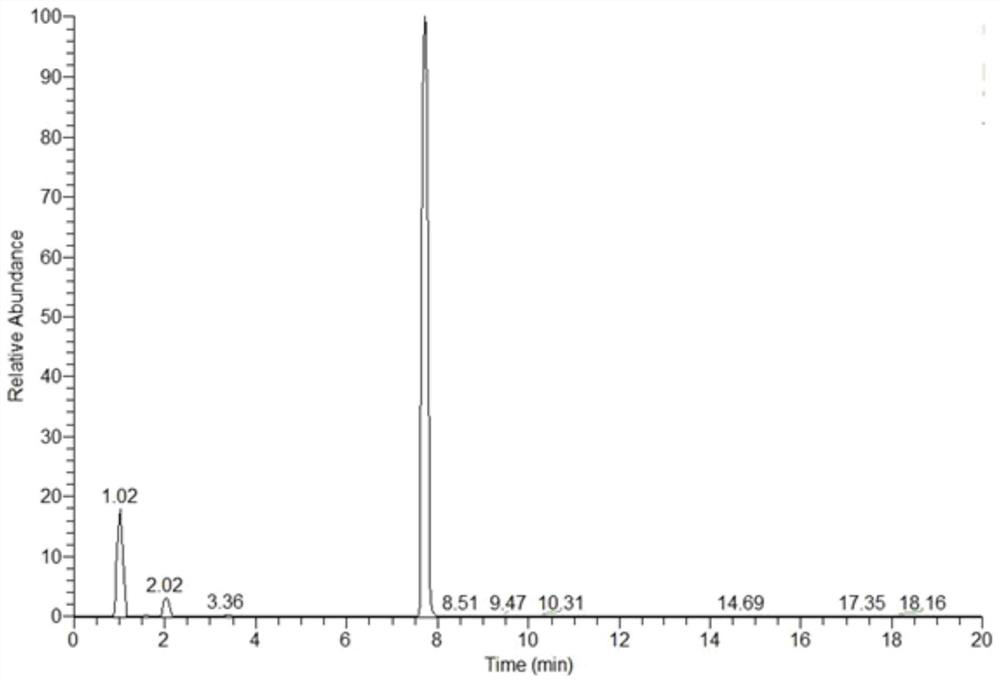

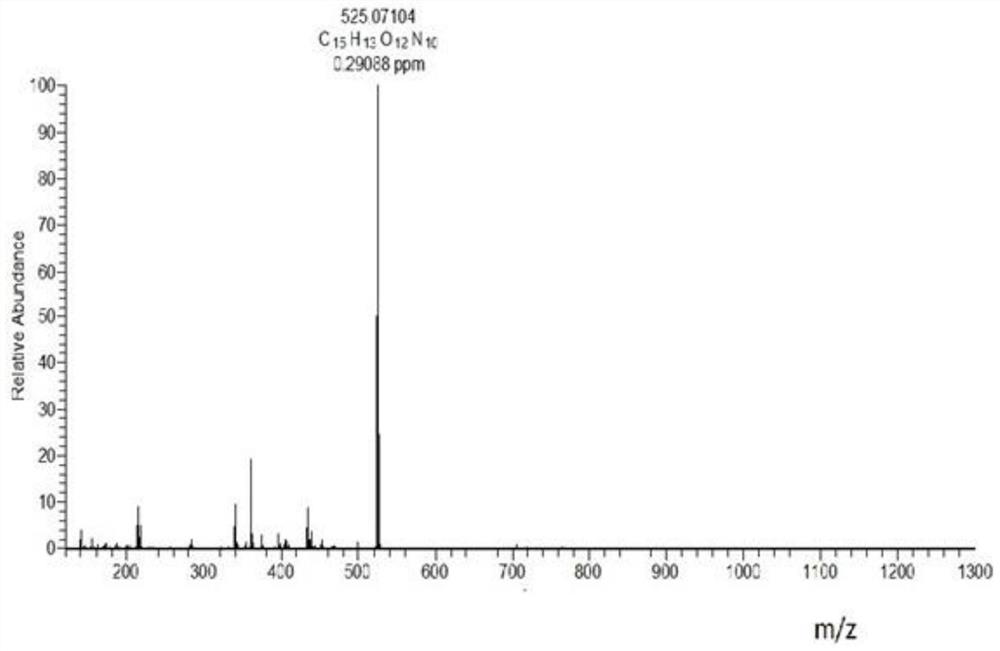

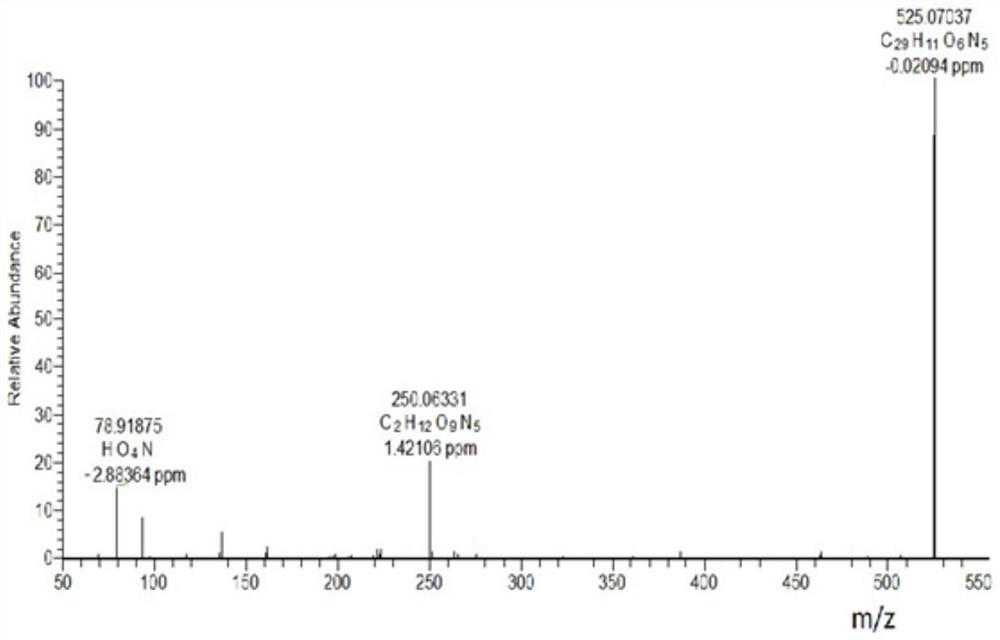

Common poison screening identification and confirmation standard, screening method and kit

PendingCN113588830AHigh screening sensitivity and accuracyImprove work efficiencyComponent separationBroad spectrumToxicant

The invention discloses a common poison screening identification and confirmation standard, a screening method and a kit, the common poison screening identification and confirmation standard comprises a precursor ion m / z used for identification, a threshold coverage greater than 5000, a signal-to-noise ratio threshold greater than 5, and a mass deviation less than 5 ppm; the retention time is used for confirmation, and the window coverage is + / -1min; the fragment ions are used for confirmation, the minimum number of the fragment ions is 1, the peak intensity threshold value is 1000, and the MS Order is set as MS2; the isotope mode is used for confirmation, the matching threshold value is larger than 70%, and the allowable mass deviation and the allowable intensity deviation are smaller than 20%. When a poisoning event occurs and a judicial poison test occurs, the database provided by the invention can realize rapid, accurate and broad-spectrum screening of organic poison at a poisoning level.

Owner:SICHUAN UNIV

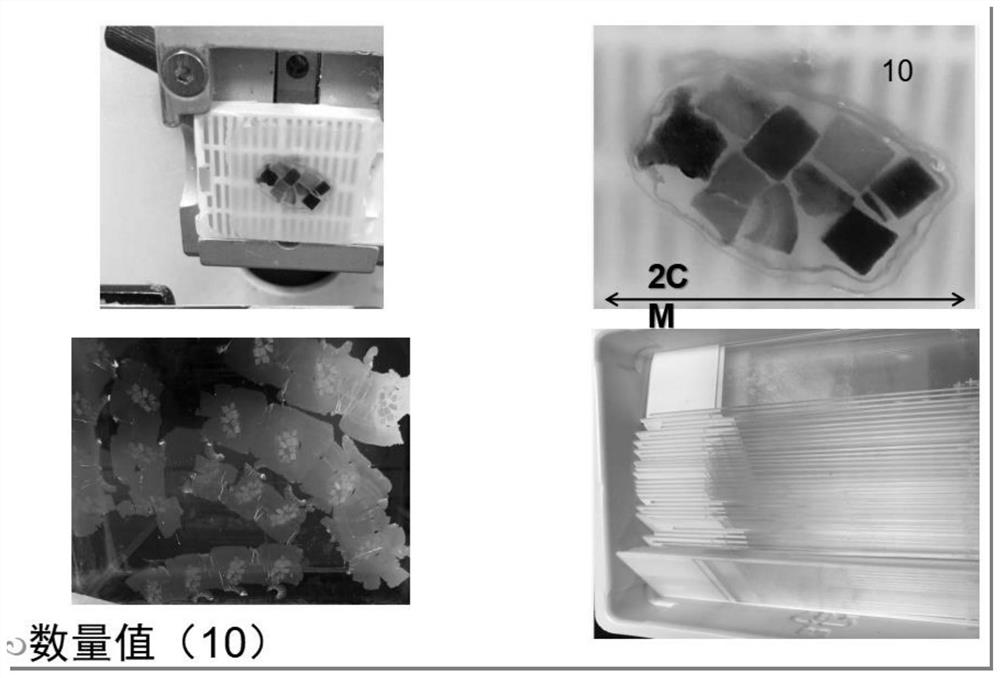

Immunohistochemical quality control product constructed based on animal organs or tissues

PendingCN113720669AGet goodRealize standardized operationPreparing sample for investigationBiological testingNeutral buffered formalinAnimal Organs

The invention relates to the field of pathological examination, in particular to an immunohistochemical quality control product constructed based on animal organs or tissues. In the scheme provided by the invention, the tissues and organs of the pig can effectively replace human organs and tissues to serve as a source of a reference substance in the aspect of partial immunohistochemical detection. The material is convenient to obtain in the market, and commercialized production of quality control products based on tissue morphology and immunohistochemical inspection in the future is facilitated. According to the basic histological manufacturing requirements, such as fixation by using 10% neutral buffer formalin, an automatic tissue dehydration treatment instrument and the like, the manufacturing of the quality control product wax block can be completed. And standardized operation can be realized. The method is simple, convenient and easy to implement without special methods and change of inspection paths.

Owner:吴鸿雁

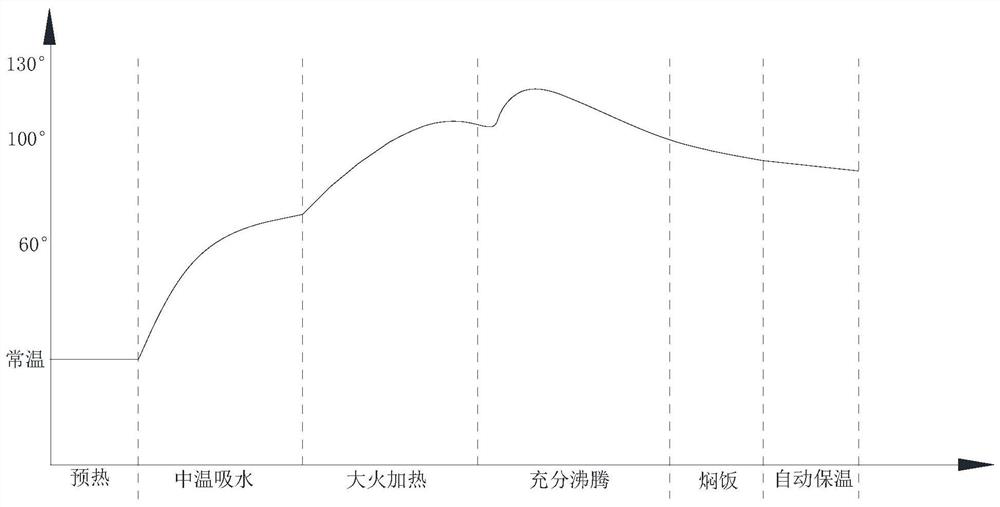

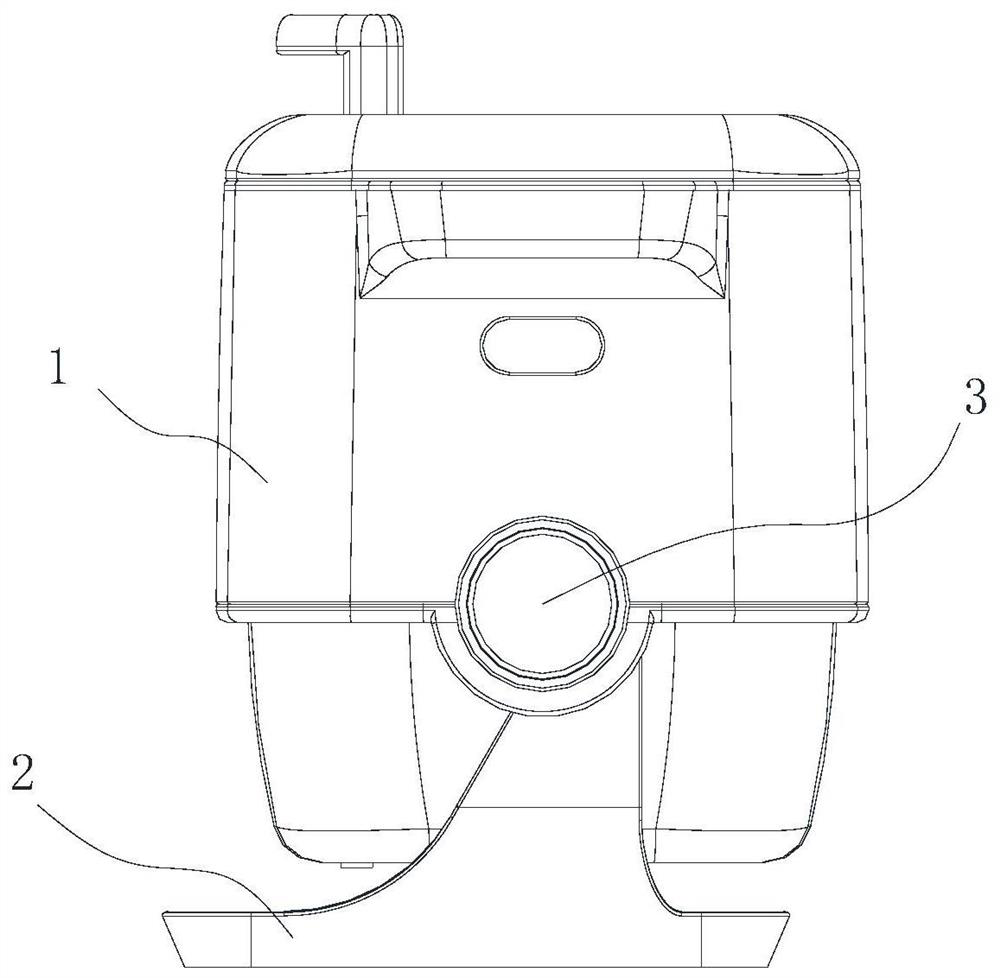

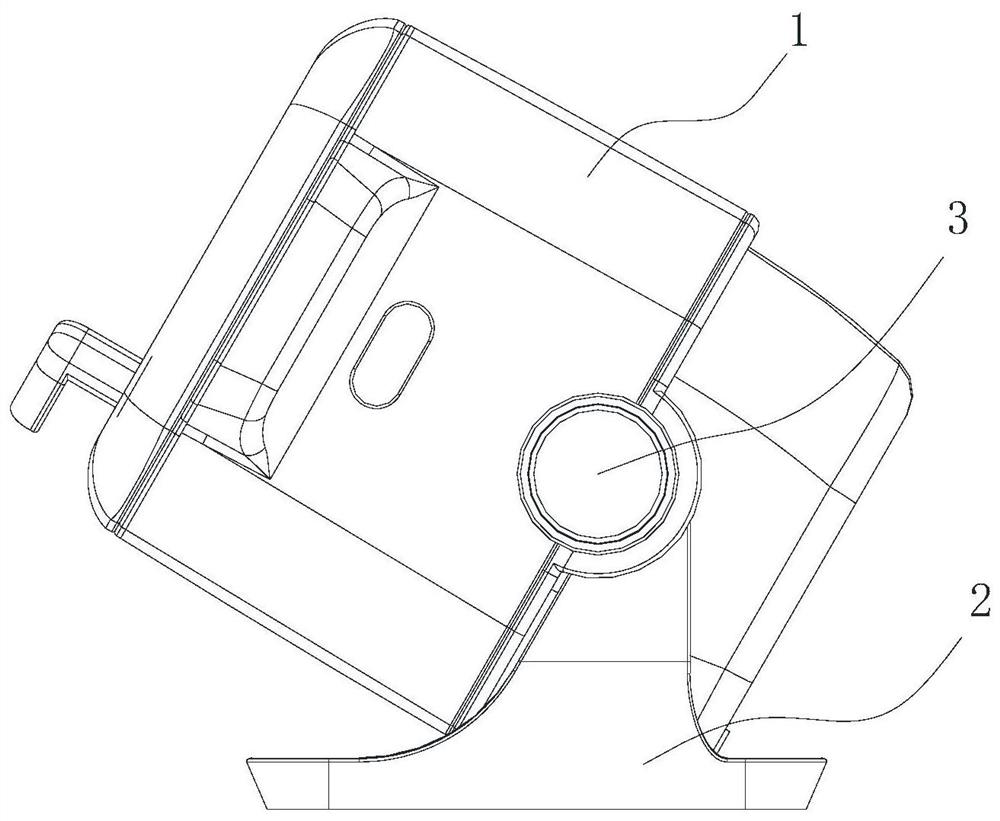

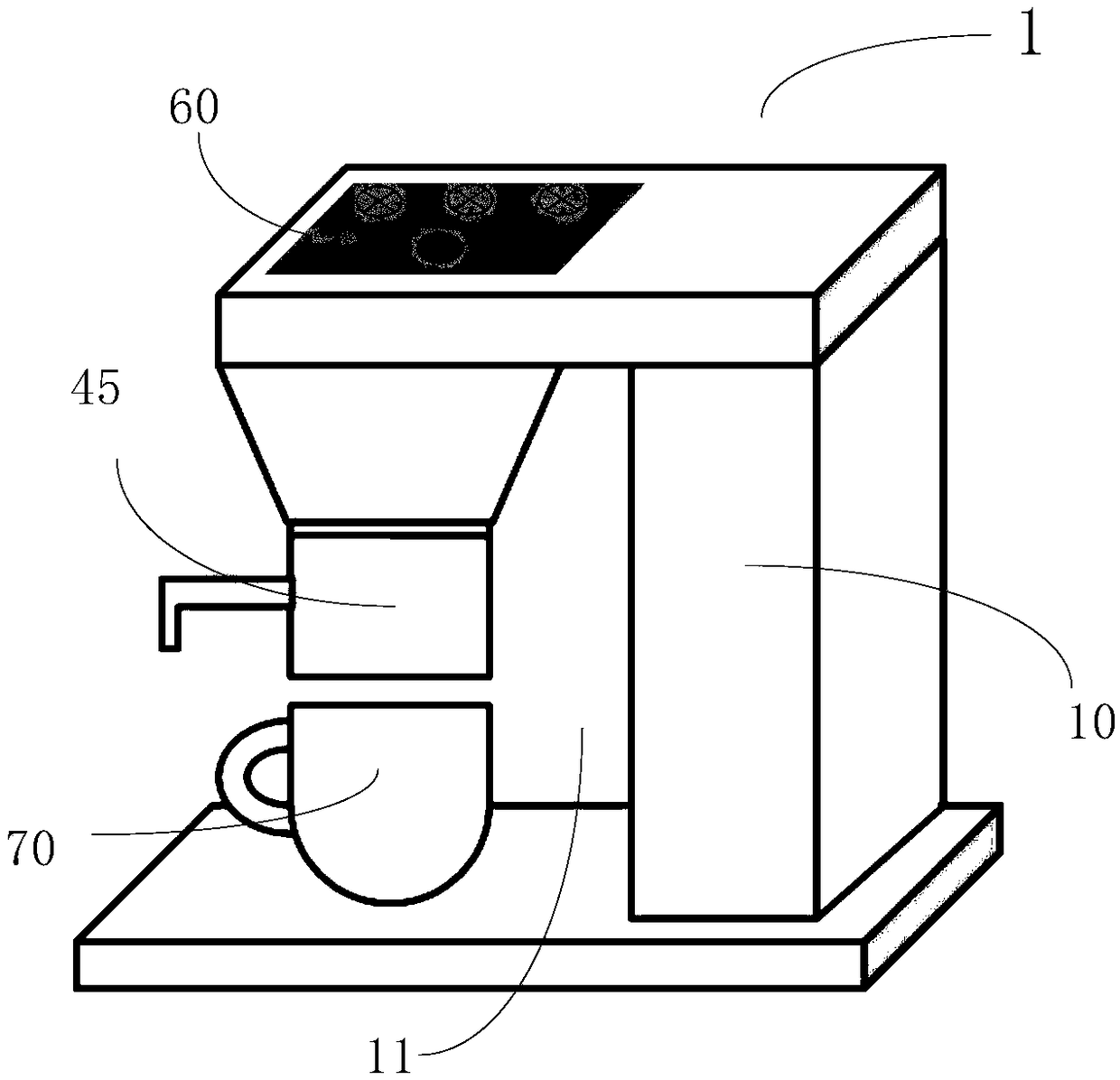

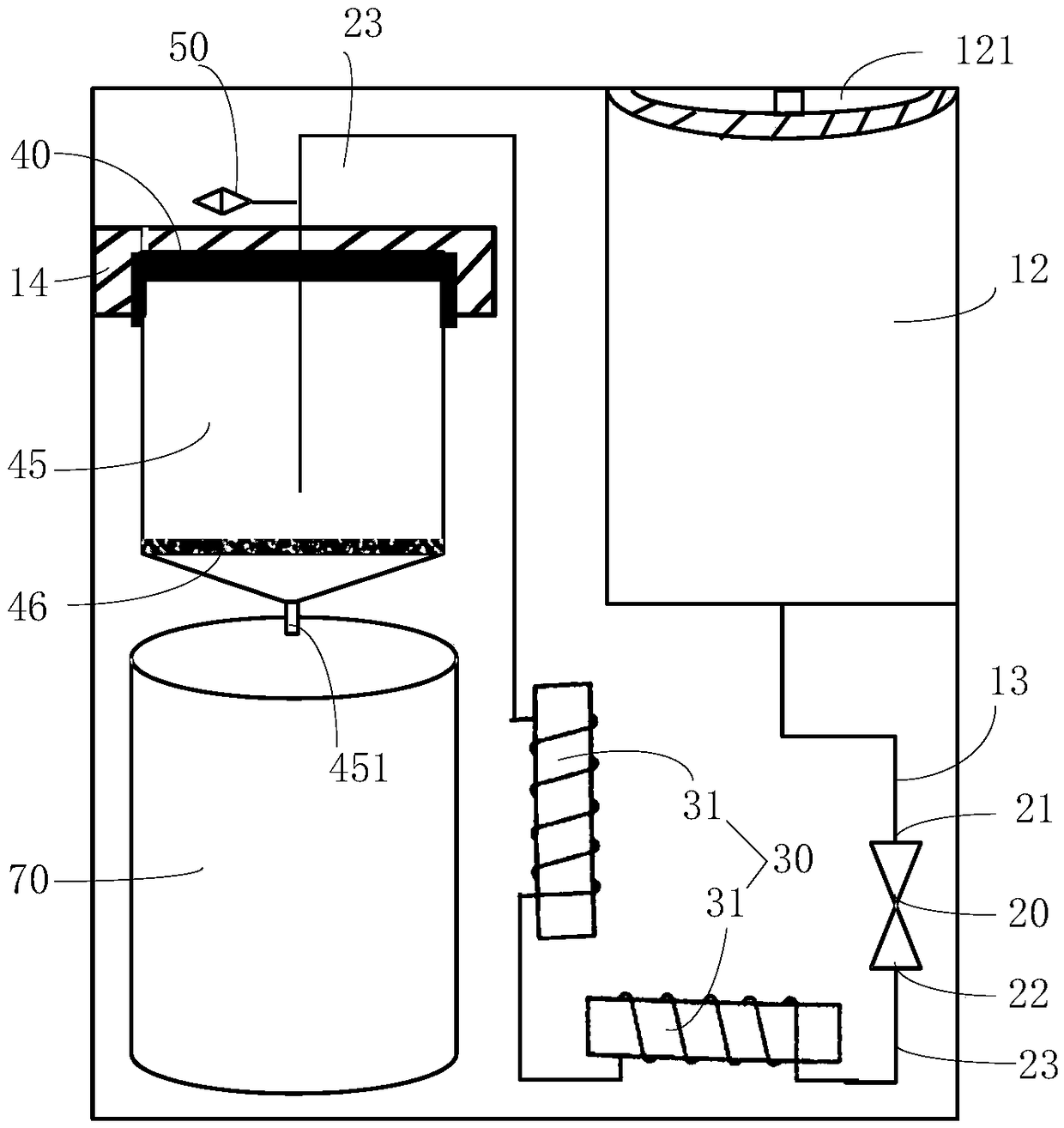

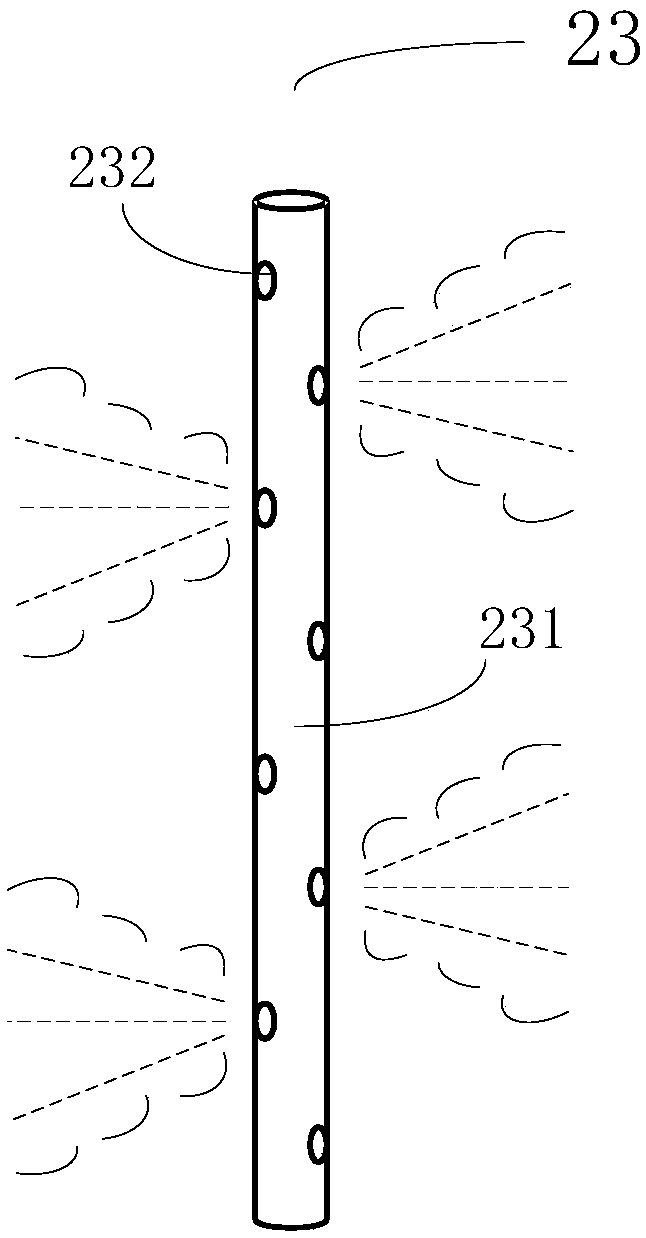

Cooking method and cooking equipment

InactiveCN112006548AImprove tasteMaintain consistencyMultiple-unit cooking vesselsVessels with intergral heatingProcess engineeringRice dishes

The invention discloses a cooking method, which comprises the steps of acquiring a cooking processing technology, and executing rice cooking operation according to the acquired cooking processing technology; according to a side dish adding instruction in the cooking process, executing midway dish adding operation in the cooking utensil; and when the side dishes are added into the cooking utensil,executing continuous cooking operation, wherein the continuous cooking operation comprises the step of driving the cooking utensil to rotate through a driving device until cooking is completed. The invention further discloses cooking equipment. The cooking equipment comprises an inner container, a heating unit, a temperature detection unit, a driving device and a control unit, wherein the controlunit comprises at least one memory and a processor connected with the at least one memory, and the memory stores instructions which can be executed by the at least one processor so as to enable the atleast one processor to execute the cooking method. According to the invention, the dish adding operation in the cooking process can be realized, and side dishes can be added into rice through the dish adding operation so as to make rice served with meat and vegetables on top or soup rice.

Owner:JOYOUNG CO LTD

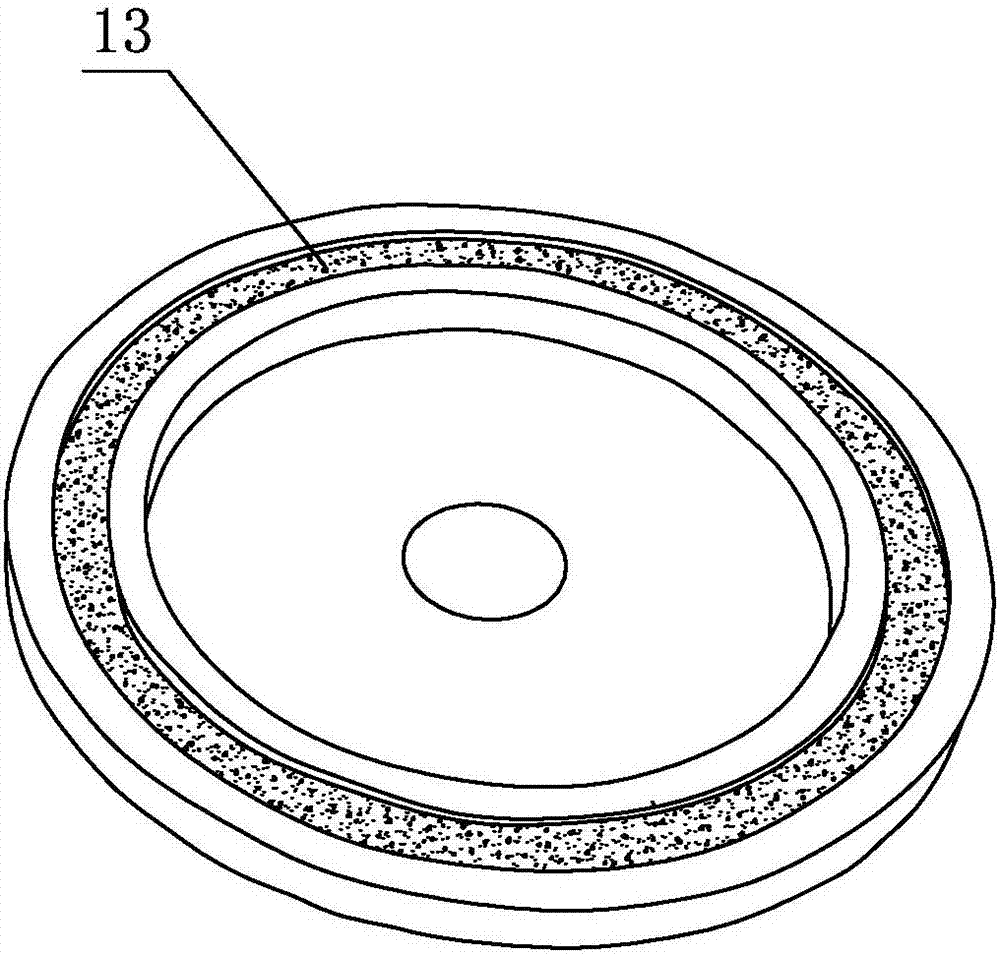

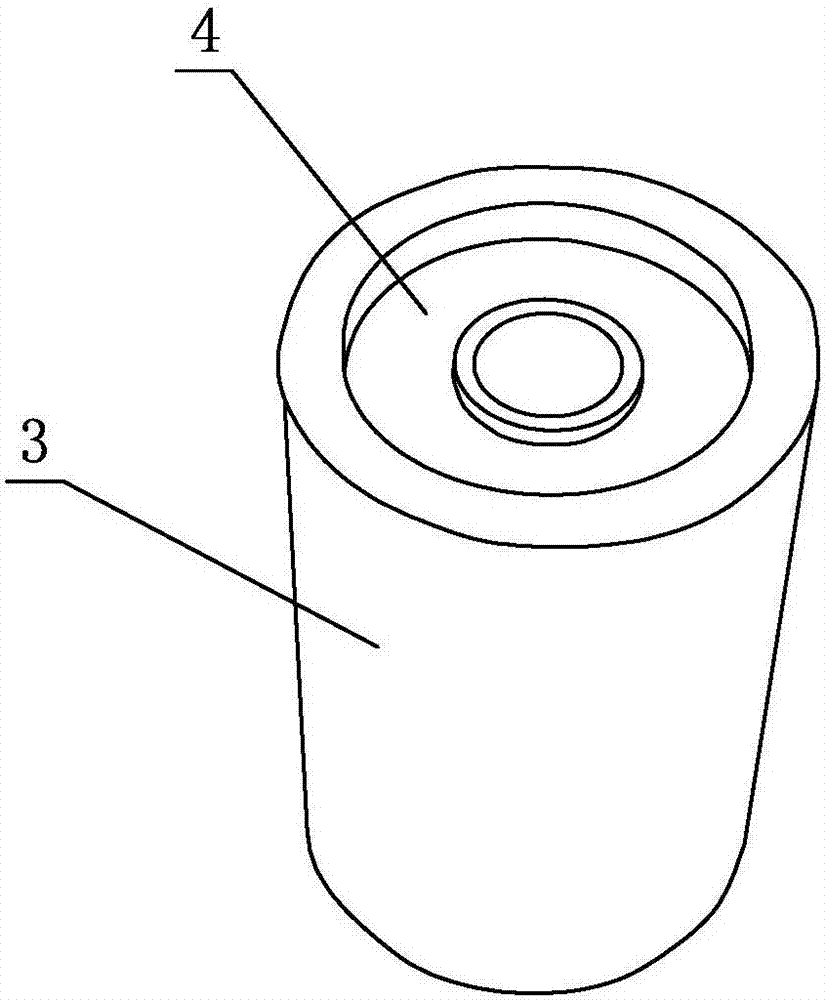

Diamond abrasive wheel mechanism based on 3D printing

ActiveCN106938335AImprove the degree of automated productionImprove quality stabilityAdditive manufacturing apparatusIncreasing energy efficiencyLayer wiseEngineering

The invention discloses a diamond abrasive wheel mechanism based on 3D printing. The diamond abrasive wheel mechanism comprises a computer three-dimensional modeling machine, a printing machine table and a laser generation assembly. A powder laying assembly, a powder sending assembly and a base work layer are arranged on the printing machine table, wherein the base work layer is of a sandwich type structure. A three-dimensional solid model of a to-be-manufactured product is designed through the computer three-dimensional modeling machine, and the work path of the laser generation assembly is calculated. The powder laying assembly is arranged on one side of the printing machine table and is used for conducting powder laying on the base work layer. The powder sending assembly is cooperatively connected with the powder laying assembly and conducts powder sending operation on the powder laying assembly. The laser generation device is arranged on the printing machine table and conducts layer-by-layer cladding on a powder laying layer of the powder laying assembly. By means of the improvement on the above structure, the diamond abrasive wheel mechanism has the beneficial effects of being simple, reasonable, good in performance, automatic in production, environment-friendly, low in consumption, safe, reliable and high in practicability.

Owner:广东奔朗新材料股份有限公司

Method for producing typical flavour turnip slices

ActiveCN100456957CInhibition of reproductionEnhanced suppression of reproductionFood preparationLiquid cultureGenus Lactobacillus

A process for preparing the salted radish strips with special taste includes such steps as loading the radish strips in a container layer by layer while adding edible salt and spraying the mixture of the liquid culture of lactobacillus and the solution of Ca salt onto each layer, adding the hot spicing bag to the middle of container, sealing, salting for 36-72 hr, transferring said radish strips into another container but removing said hot spicing bag, sealing, salting for 48-72 hr, mixing the radish strips with additive and edible salt, loading the mixture in the third container, compacting, spraying edible salt, sealing and salting for 28 days.

Owner:桐庐弘武食品有限公司

Cultivating technology of erigeron breviscapus

Owner:云南红灵生物科技有限公司

Reaming and claw fixing tool for core body of radiator and using method of reaming and claw fixing tool

ActiveCN103418699AImprove work efficiencyImprove consistencyHeat exchange apparatusEngineeringReamer

The invention relates to a reaming and claw fixing tool for a core body of a radiator and a using method of the reaming and claw fixing tool. The tool comprises a substrate, a base plate fixedly arranged on the middle part of the substrate, a clamping device and a reamer device, wherein the clamping device and the reamer device are oppositely arranged on the substrate on the two sides of the base plate respectively, and are driven by a driving device to transversely move relative to each other respectively. According to the tool, the core body is fixedly arranged through the clamping device and the reamer device, and a reamer is rapidly inserted into radiating tube orifices of the core body through the driving device, so that the working efficiency is improved, and high reaming consistency is ensured; a claw fixing block is fixedly arranged on a support plate on one side of the reamer, and has a mounting structure which is completely the same as that of the reamer, and claw fixing work is finished at the same time of reaming, so that the working efficiency is greatly improved; the tool is scientific and reasonable in design, simple in structure and convenient to manufacture, and can be effectively used for standard reaming operation, labor force is saved, and the working efficiency is effectively improved.

Owner:TIANJIN YAXING RADIATOR

Building installation unit identification system and method

PendingCN106845576AQuick identificationHigh degree of informatizationCo-operative working arrangementsRecord carriers used with machinesSoftware engineeringComputer terminal

The invention provides a building installation unit identification system and method. The system comprises electronic tags fixed to installation units, a unit router corresponding to the electronic tags, and a terminal used for reading the electronic tags and communicating with the unit router, wherein an electronic tag reader and a network component are arranged in the unit router; and an electronic tag reader, a calculation unit and a network component are arranged in the terminal. The method comprises the steps of dividing a building into the installation units, wherein each installation unit generates an independent code; inputting the independent codes to the electronic tags, and fixing the electronic tags to the installation units; forming a group by the installation units to correspond to the unit router; and reading the electronic tags and communication information of the terminal and the unit router through the terminal to guide uninstallation, transport and installation of the building. Through different schemes for grouping different data, intelligent installation and uninstallation can be realized, so that the construction efficiency is greatly improved. The building installation unit identification system and method can be used for detecting installation quality.

Owner:CHINA GEZHOUBA GRP THREE GORGES CONSTR ENG CO LTD

Porous alumina porcelain sand microspheres, preparation method thereof and application of porous alumina porcelain sand microspheres in injecting tackifying device

ActiveCN106396720AImprove crushing efficiencyEasily brokenCeramicwareLocomotivesMicrosphereMicrometer

The invention provides porous alumina porcelain sand microspheres, a preparation method thereof and an application of the porous alumina porcelain sand microspheres in an injecting tackifying device, and belongs to the technical field of porcelain materials. The alumina porcelain sand microspheres with high strength and high breaking efficiency can be prepared, so that the adhesiveness between a wheel and a steel rail can be improved effectively. The preparation method comprises the following steps: micrometer alumina powder and ammonia water are added to deionized water, and alumina slurry is prepared, oscillated, subjected to ball milling and stirred continuously for standby application; alumina porcelain sand microsphere blanks are obtained by performing spray drying on the standby alumina slurry; the alumina porcelain sand microsphere blanks are rolled in a sugarcoating machine, and semi-finished alumina porcelain sand microsphere blanks are prepared; the semi-finished alumina porcelain sand microsphere blanks are calcined in a high-temperature rotary kiln and cooled to the room temperature with the kiln, and the porous alumina porcelain sand microspheres with the diameters being 0.25-1.65 mm are obtained. The invention can be used in a preparation process of the porous alumina porcelain sand microspheres for the injecting tackifying device.

Owner:青岛宏达赛耐尔科技股份有限公司

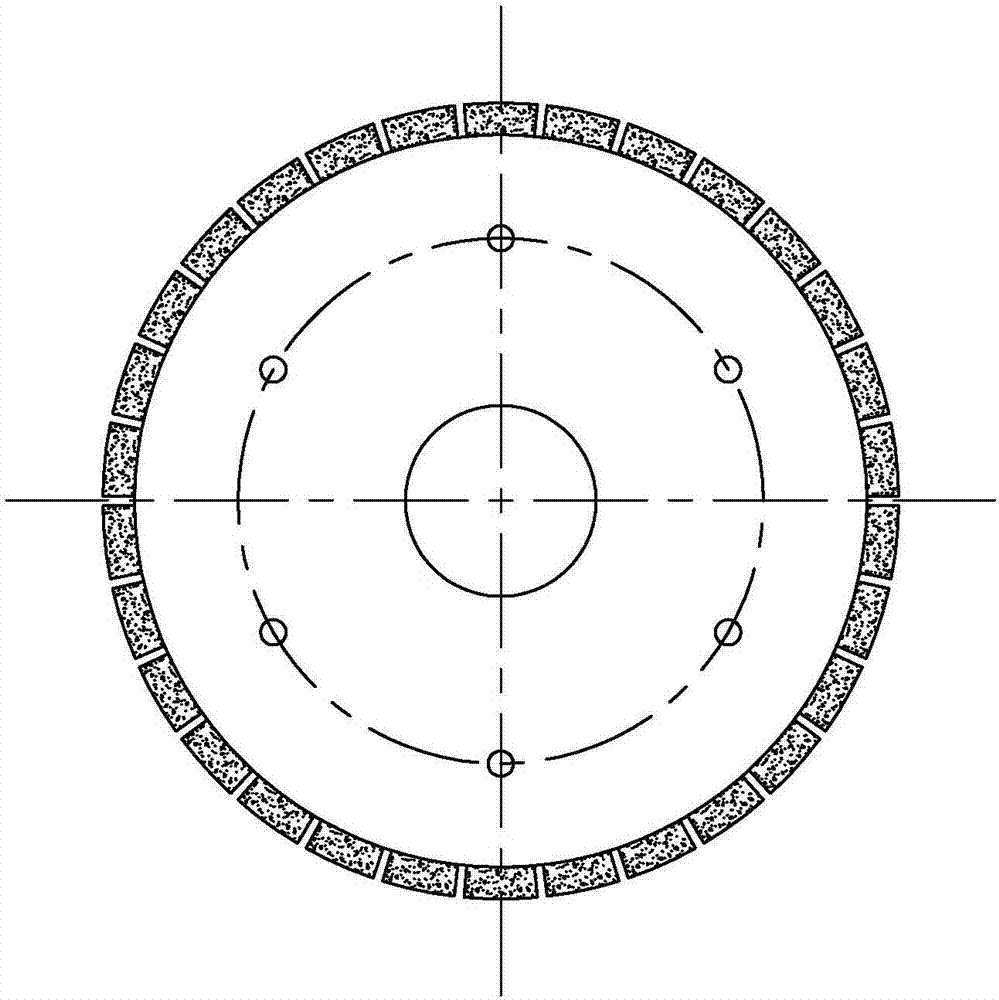

Resin roller grinding wheel based on 3D printing forming

PendingCN106926446AAvoid consumptionSolve consumptionAdditive manufacturing apparatus3D object support structures3d printRotational axis

A resin roller grinding wheel based on 3D printing forming comprises a computer three-dimensional modeling machine, a printer platform, a base body and a material extruding opening working layer. The base body is an elastic roller and arranged on the printer platform in a rolling mode. The computer three-dimensional modeling machine designs a three-dimensional solid model of a product to be made and calculates a working path of the material extruding opening working layer. The material extruding opening working layer is arranged on the outer round face of the elastic roller and extrudes materials on the outer round face of the elastic roller layer by layer according to the working path. By improving the structure, the roller made of an elastic material serves as the base body, the part between the base body and a rotating shaft on the printer platform is made of abrasion resistant steel, the material extruding opening working layer is arranged on the outer round face of the elastic roller, and the setting mode of the working layer can be independently designed according to practical requirements. The resin roller grinding wheel has the characteristics of simple and reasonable structure, excellent performance, automatic and environmental-friendly production, low consumption, safety, reliability and the like, practicability is high.

Owner:广东奔朗新材料股份有限公司

Dropping device for making bone marrow chromosome G-band

ActiveCN108318313AQuality improvementPrevent bulkMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationBurn unitsBone marrow cell

The invention discloses a dropping sheet device for making a bone marrow chromosome G-band. The dropping device comprises a specific turbid unit, a dropping unit, a heating burning unit and a normal-temperature cooling unit. For the dropping device provided by the invention, by arranging the specific turbid unit, the turbidity of cell suspension of a bone marrow cell culture is regulated and is controlled at 2-3 Macfarland turbidity, so that a division phase of chromosome can be prevented from becoming scattered, the phenomenon that insufficient burning is prevented, and the mass of a preparedbone marrow chromosome specimen is improved; and by arranging the burning unit, a glass slide can be uniformly burnt, and staff is prevented from being burnt during burning operation. The dropping device provided by the invention can realize standard operation of bone marrow chromosome dropping and lower the fatigue and damage of the staff caused by dropping.

Owner:济南金域医学检验中心有限公司

Fermentation production system based on container and solid fermentation production method

ActiveCN105254361AGuaranteed standard operationRealize standardized operationBio-organic fraction processingClimate change adaptationProcess engineeringManufacturing engineering

The invention discloses a fermentation production system based on a container and a solid fermentation production method. A warehouse is designed to be a standard part of a container structure, meanwhile, a fermentation device is divided into a working bin, a fermentation bin and a quantified discharging bin, the working bin, the fermentation bin and the quantified discharging bin have clear functions, the completely standardized fermentation production system is constructed, and a traditional warehouse management facility and method are completely omitted. After fermentation, material storage and transportation are correspondingly standardized, a new breakthrough improvement is generated in establishment of fermentation production equipment, equipment maintenance and fermented product storage and transportation are greatly influenced, and breakthrough revolution is brought to construction, management and a business model of a traditional fermentation production enterprise.

Owner:麦行

Traditional Chinese medicine extracting method and device

PendingCN109432818AFast extractionImprove extraction efficiencySeparation devicesSolid solvent extractionTemperature controlAdditive ingredient

The invention provides a traditional Chinese medicine extracting method and device. According to the traditional Chinese medicine extracting method, traditional Chinese medicine ingredients are efficiently extracted in a low intensity and high frequency extracting manner by controlling the temperature and pressure of extraction. The invention further provides the traditional Chinese medicine extracting device capable of realizing the extracting method. The traditional Chinese medicine extracting device comprises a connecting base, a high pressure adjustable metering pump and an instantaneous heater, wherein a detachable extraction cup is arranged at the bottom of the connecting base; a filtering part and at least one liquid outlet pipe are arranged at the bottom of the extraction cup; oneend of the high pressure adjustable metering pump is connected to a water source by a pipeline, and the other end of the high pressure adjustable metering pump is arranged on the connecting base by apipeline and is communicated with the extraction cup; the instantaneous heater acts on the pipeline between the high pressure adjustable metering pump and the connecting base. The device is simple tooperate, convenient in metering, timing and temperature control and small in size, so that the device can meet household requirements.

Owner:陈静怡

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com