Adjustable hanger system

An adjustable and hanging technology, applied in the connection of scaffolding, formwork/formwork/work frame, scaffolding supported by house structure, etc. Effects of reuse, improved safety, and labor liberation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

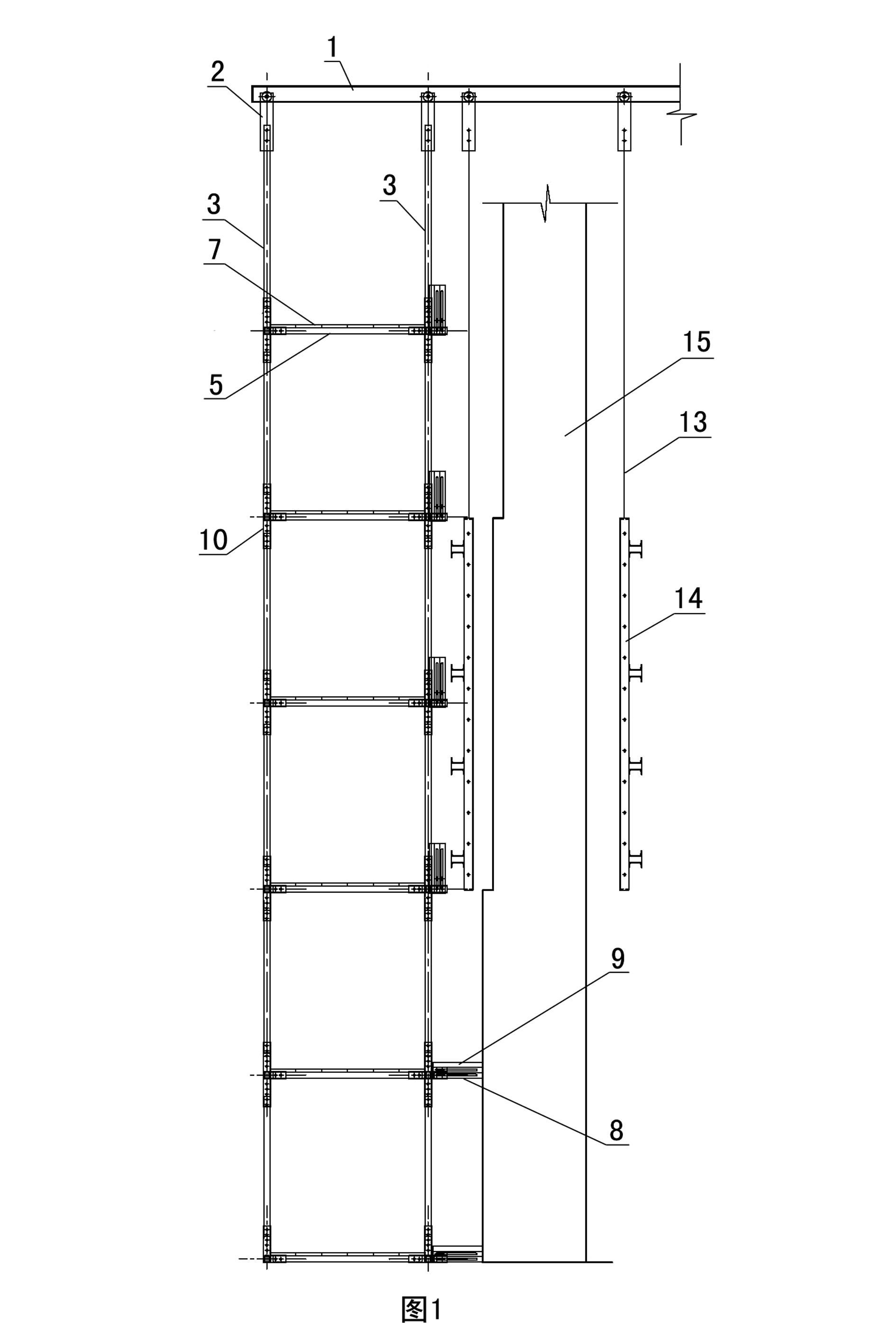

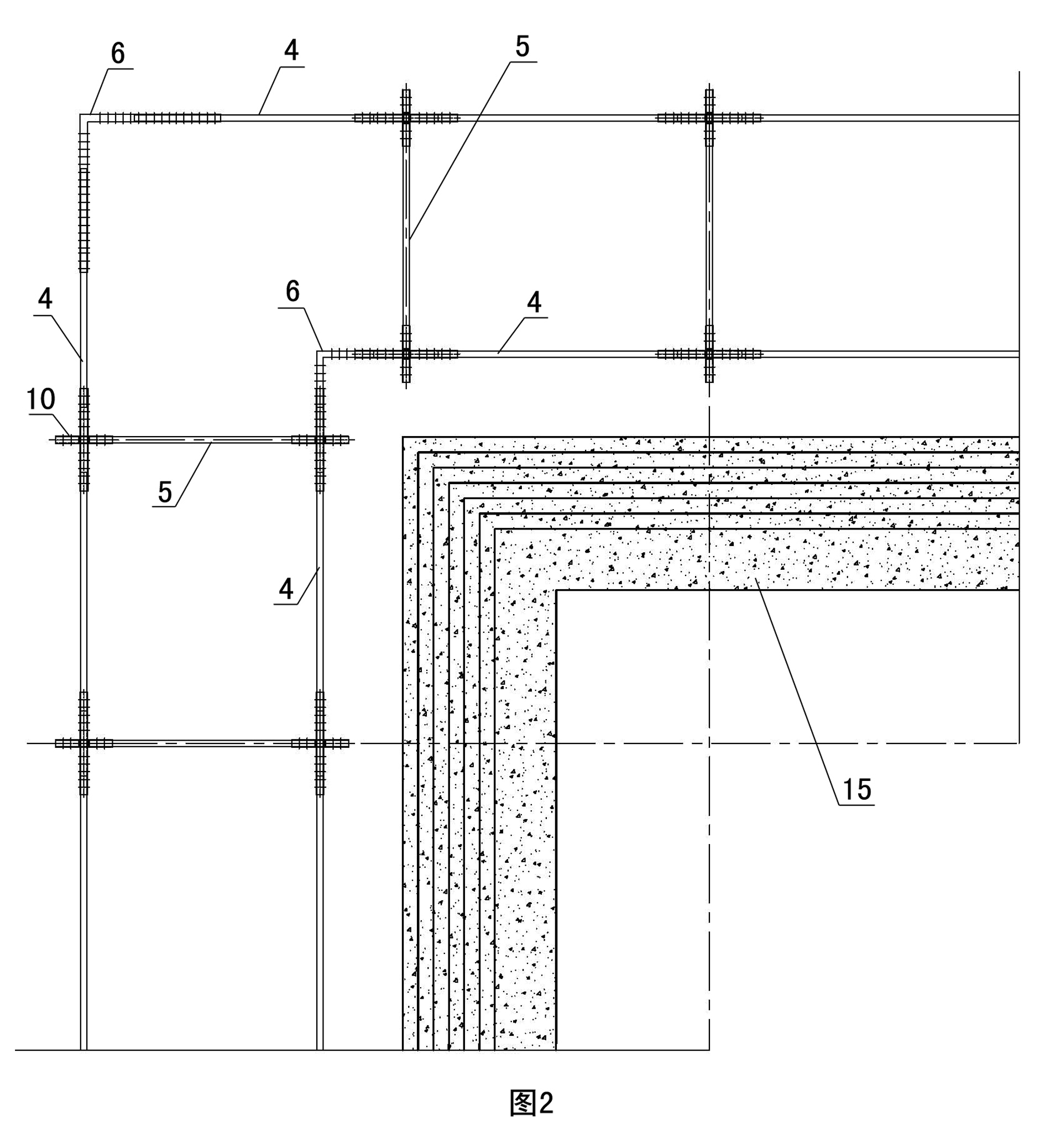

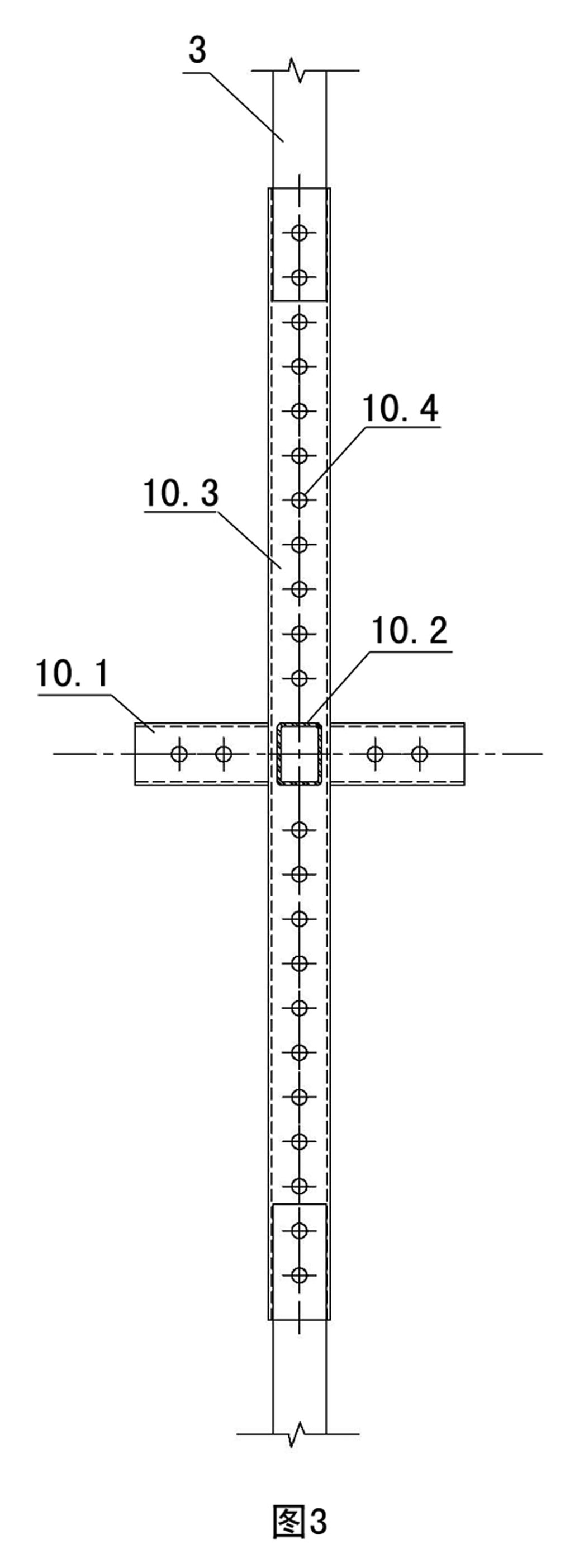

[0028] Embodiment one sees Figure 1-4 As shown, this adjustable hanger system includes a skeleton connected to the steel platform system and a steel springboard 7 fixed on the skeleton. The inner and outer sheet connecting rods 5 form a three-dimensional grid structure, and the inner sheet of the hanger and the outer sheet of the hanger all include suspenders 3, horizontal cross bars 4 and shaped joint pipes 10 at the nodes at intervals, and the suspenders 3, Horizontal bar 4 and inner and outer sheet connecting rod 5 can be square steel pipe or round steel pipe or flat steel, and the present embodiment is square steel pipe. see image 3 , Figure 4 The shaped joint pipe 10 is evenly distributed with screw holes 10.4, and is welded by a horizontal pipe joint 10.1, a vertical pipe joint 10.2 and a vertical pipe joint 10.3. The shaped joint pipe 10 can be a square steel pipe or a round steel pipe or a flat steel. This implementation For example, a square steel pipe, the vert...

Embodiment 2

[0029] Embodiment two see Figure 12 As shown, the difference from Embodiment 1 is that the push-pull platform slideway 8 is in the shape of a guide rail, and a corbel 11 is connected between the lower surface of the push-pull platform slideway 8 and the inner sheet of the hanger, and the push-pull platform slideway 8 A diagonal brace 12 is connected between the upper surface and the inner sheet of the hanger, and the push-pull turning platform 9 is directly placed on the slideway 8 of the push-pull platform and slides along the slideway 8 of the push-pull platform.

[0030] The distance between the suspender 3 and adjacent suspenders is 1m-2m, and the distance between the inner piece of the hanger and the outer piece of the hanger is also 1m-2m. The horizontal pipe joint 10.1, the vertical pipe joint 10.2 and the vertical pipe joint 10.3 of the shaped joint pipe 10 are each provided with two or more screw holes 10.4.

[0031] see figure 1 , Figure 5 , Image 6 , the shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com