Pipeline organ cast forming device and use method thereof

A technology of pouring molding and organs, which is applied in the field of biomedicine, can solve the problems of few patents, achieve the effect of simple disassembly and assembly, overcome the limitations of raw materials and the control of pipeline shape and structure, and the effect of easy demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

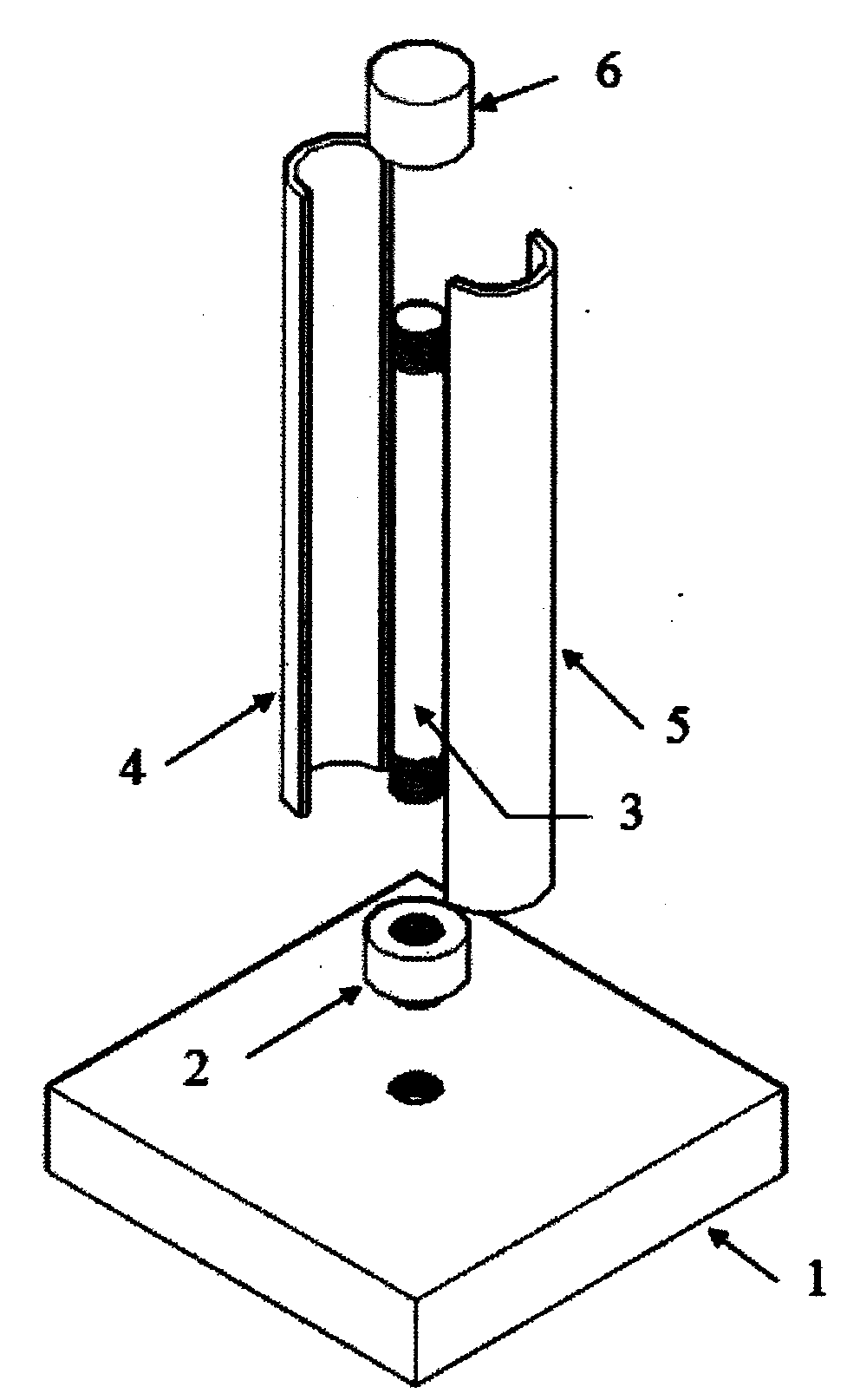

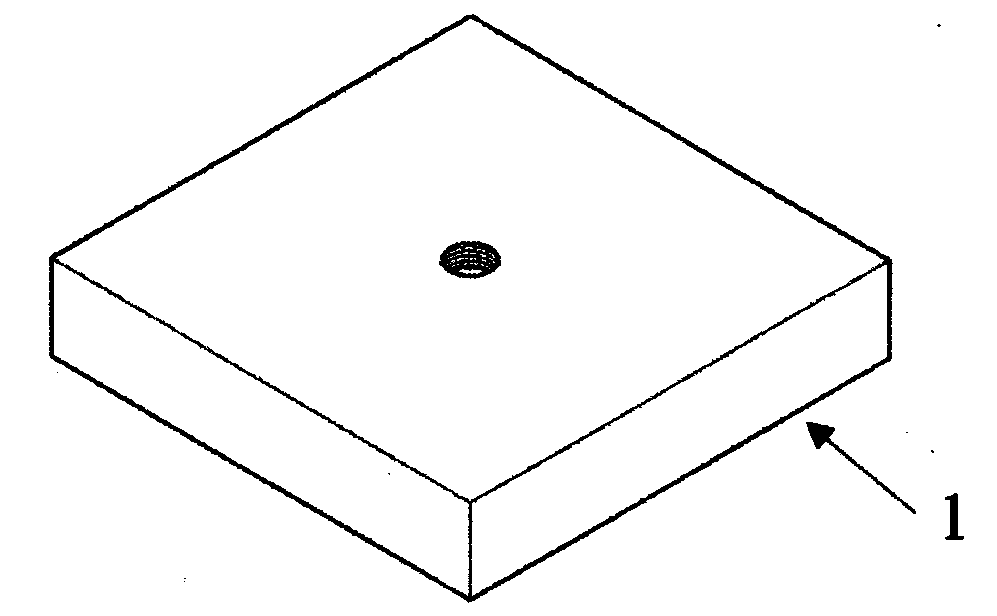

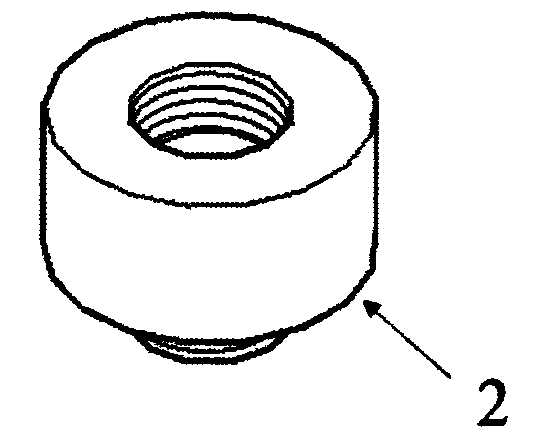

[0028] Such as figure 1 As shown, it is a schematic structural diagram of the pouring and molding device for pipe organs of the present invention. The device for pouring and molding pipe organs includes a base 1, a lower fixing cap 2, a stem 3, a casing one 4, a casing two 5, an upper fixing cap 6 and a tubular Shell, the lower fixing cap 2 is connected with the base 1 through threads, one end of the stem 3 is connected with the lower fixing cap 2 through threads, the upper fixing cap 6 is connected with the other end of the stem 3 through threads, and the tubular shell is surrounded by the upper fixing cap 6 and the lower On the outside of the fixed cap 2, a cavity is formed between the tubular shell and the stem 3. The tubular shell is composed of a shell one 4 and a shell two 5. The sides of the shell one 4 and the shell two 5 are connected in a detachable manner. The detachable method described above is a concave-convex matching method.

[0029] Such as figure 2 As show...

Embodiment 2

[0035] Such as figure 1 As shown, it is a schematic structural diagram of the pouring and molding device for pipe organs of the present invention. The device for pouring and molding pipe organs includes a base 1, a lower fixing cap 2, a stem 3, a casing one 4, a casing two 5, an upper fixing cap 6 and a tubular Shell, the lower fixing cap 2 is connected with the base 1 through threads, one end of the stem 3 is connected with the lower fixing cap 2 through threads, the upper fixing cap 6 is connected with the other end of the stem 3 through threads, and the tubular shell is surrounded by the upper fixing cap 6 and the lower On the outside of the fixed cap 2, a cavity is formed between the tubular shell and the stem 3. The tubular shell is composed of a shell one 4 and a shell two 5. The sides of the shell one 4 and the shell two 5 are connected in a detachable manner. The detachable method described above is a concave-convex matching method.

[0036] Such as figure 2 As show...

Embodiment 3

[0042] Such as figure 1 As shown, it is a schematic structural diagram of the pouring and molding device for pipe organs of the present invention. The device for pouring and molding pipe organs includes a base 1, a lower fixing cap 2, a stem 3, a casing one 4, a casing two 5, an upper fixing cap 6 and a tubular Shell, the lower fixing cap 2 is connected with the base 1 through threads, one end of the stem 3 is connected with the lower fixing cap 2 through threads, the upper fixing cap 6 is connected with the other end of the stem 3 through threads, and the tubular shell is surrounded by the upper fixing cap 6 and the lower On the outside of the fixed cap 2, a cavity is formed between the tubular shell and the stem 3. The tubular shell is composed of a shell one 4 and a shell two 5. The sides of the shell one 4 and the shell two 5 are connected in a detachable manner. The detachable method described above is a concave-convex matching method.

[0043] Such as figure 2 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com