Fermentation production system based on container and solid fermentation production method

A production system and solid fermentation technology, which is applied in the field of fermentation, can solve the problems of time-consuming and labor-consuming, and the large area occupied by the warehouse of fermentation products, and achieve the effects of good device combination, mechanized and automated fermentation production, and standardized operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

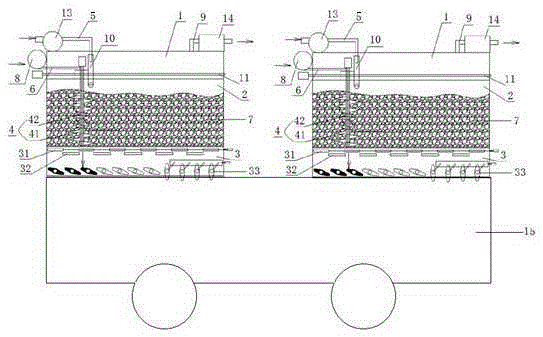

[0049] Example 1 Construction of fermentation production system

[0050] as attached figure 2 As shown, the present embodiment provides a solid fermentation production system based on a turnover box, including:

[0051] ⅰ. Fermentation chamber 2;

[0052] ⅱ. Quantitative discharge bin 3;

[0053] ⅲ. turnover box 15;

[0054] And there is no need to set up a warehouse.

[0055] The turnover box 15 includes a box body, and the top of the box body can be opened. When the turnover box 15 top is opened, it can communicate with the bottom of the quantitative discharge bin 3 . The box body of the turnover box 15 is connected with a quantitative discharge bin, and an opening at the top of the turnover box matches the size of the bottom of the quantitative discharge bin, and forms a relatively sealed discharge space after being connected.

[0056] At least one side of the turnover box 15 is provided with a sealed door to facilitate unloading. The structure of the sealed door re...

Embodiment 2

[0064] Example 2 Construction of fermentation system

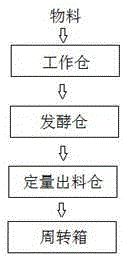

[0065] as attached figure 2 As shown, the present embodiment provides a solid-state fermentation device, including a working bin 1, a fermentation bin 2, a quantitative discharge bin 3 and a turnover box 15, and the working bin 1, the fermentation bin 2, and the quantitative discharging bin 3 are detachable ground connection to form fermentation equipment; the turnover box 15 is a container-like structure with an openable top, and is connected with the bottom of the quantitative discharge bin 3 after the top is opened.

[0066] Described working chamber is connected with intake pipe 6, exhaust pipe 9 and feed pipe 5, and it is provided with work frame, and work frame is provided with some stirring devices 4 and some distribution devices 10; One end of described air intake pipe 6 and described Several stirring devices 4 are connected respectively; the feeding pipes 5 are respectively connected with the several distribut...

Embodiment 3

[0080] Example 3 Construction of fermentation system

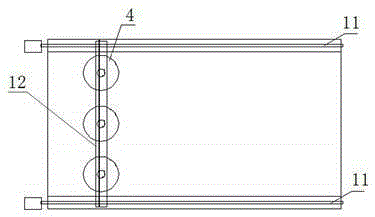

[0081] Others are the same as embodiment 1 or embodiment 2. The difference is that if attached Figure 4 As shown, the turnover box 15 can be a box connected with several quantitative discharge bins, the top of the turnover box 15 is provided with a plurality of openings, each opening is adapted to the size of the bottom of a corresponding quantitative discharge bin, connected Finally, a relatively sealed discharge space is formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com