Method for producing typical flavour turnip slices

A processing method and technology of radish strips, which are applied in the field of processing flavored radish strips by using lactic acid bacteria, can solve the problems of monotonous variety, impact on health, unstable quality, etc., and achieve the improvement of food safety, improvement of product flavor, and reduction of salt content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

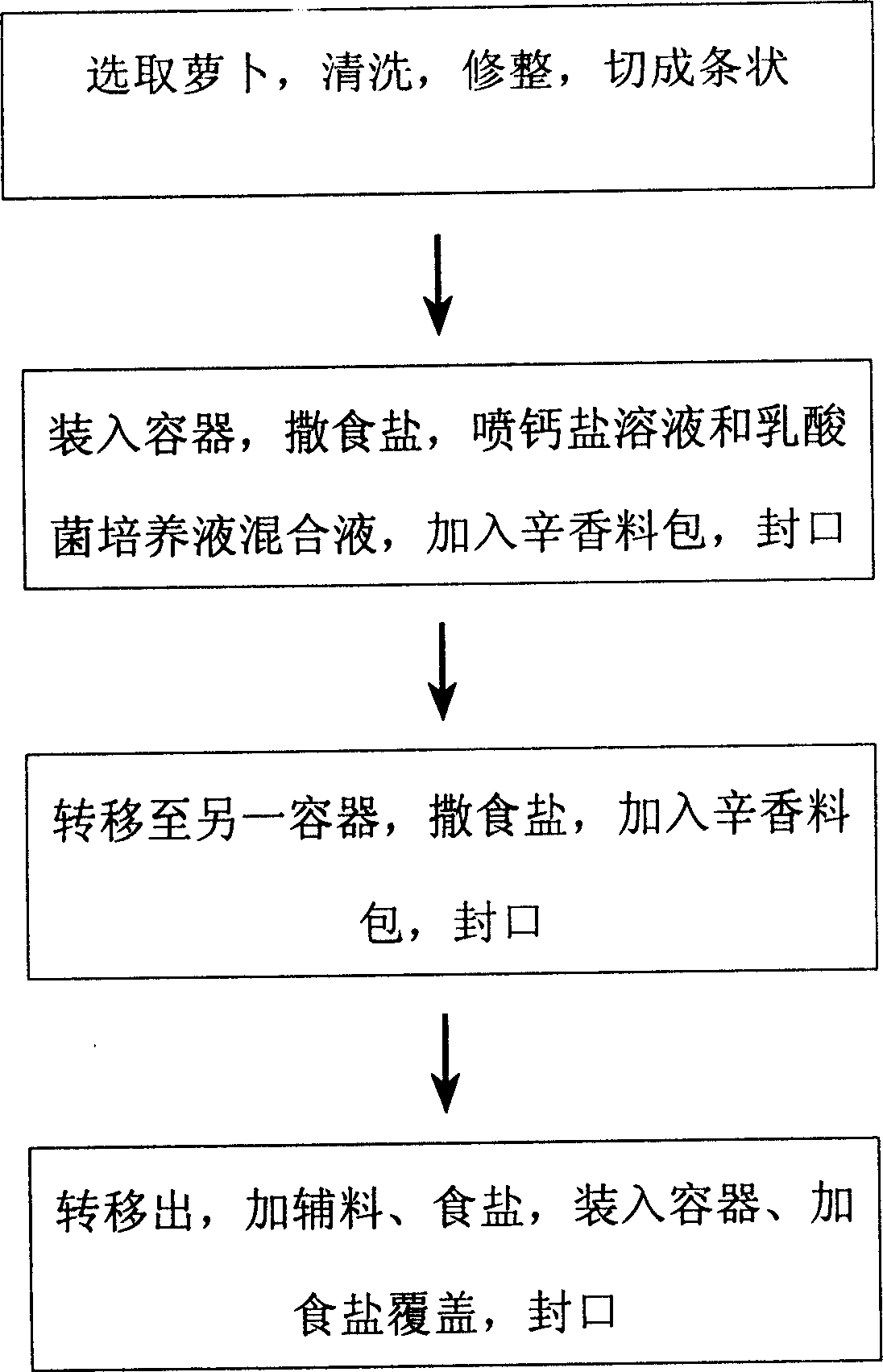

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: processing sweet and spicy radish strips

[0025] Prepare calcium lactate solution: weigh 100 grams of calcium lactate into 400 mL of water, boil to dissolve, and set aside;

[0026] Prepare lactic acid bacteria culture solution: prepare 400mL of lactic acid bacteria culture solution and set aside;

[0027] Then the above two solutions were mixed and stirred well for later use.

[0028] Spice packs: prepare 2 pieces, according to the following ratio: 10g bay leaf, 12.5g papaya, 13.7g cinnamon, 10g star anise, 15g grass fruit, 5g cumin, 5g peppercorns, 10g white fungus, 10g three Nye, 7.5 dried ginger g, black pepper 5g, cardamom 7.5g, clove 5g, coriander 8.8g, set aside.

[0029] Ratio of auxiliary materials: 40 grams of monosodium glutamate, 4 grams of I+G flavor agent, 10 grams of acesulfame potassium, 25 grams of cyclamate, 30 grams of fresh chili sauce, 30 grams of chili powder, 800 grams of white wine above 56 degrees, 1000 grams of rice wine, star ...

Embodiment 2

[0034] Embodiment 2: processing spiced radish strips

[0035] Prepare calcium lactate solution: weigh 100 grams of calcium lactate into 400 mL of water, boil to dissolve, and set aside;

[0036] Prepare lactic acid bacteria culture solution: prepare 400mL of lactic acid bacteria culture solution and set aside;

[0037] Then the above two solutions were mixed and stirred well for later use.

[0038] Spice packs: prepare 2 pieces, according to the following ratio: 10g bay leaf, 12.5g papaya, 13.7g cinnamon, 10g star anise, 15g grass fruit, 5g cumin, 5g peppercorns, 10g white fungus, 10g three Nye, 7.5 dried ginger g, black pepper 5g, cardamom 7.5g, clove 5g, coriander 8.8g, set aside.

[0039] Five-spice powder: 14 grams of cinnamon powder, 5 grams of tangerine peel powder, 6 grams of cumin powder, 8.5 grams of pepper powder, 9 grams of star anise powder, 2 grams of dried ginger powder, and 6.5 grams of licorice powder. Mix well and set aside.

[0040] Spreading ratio: 50 gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com