Method of measuring martensite content in dual-phase steel by using electron backscatter diffraction (EBSD) technique

A technology of electron backscattering and technical measurement, which is applied in the direction of material analysis, measuring devices, and instruments using wave/particle radiation, and can solve the problem of difficult distinction between martensitic and ferrite structures, and the inability to obtain accurate percentages, etc. problem, to achieve the effect of good sample repeatability, easy promotion and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

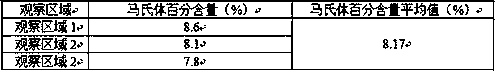

Examples

Embodiment 1

[0024] Embodiment 1: a kind of method adopting electron backscatter diffraction technique to measure the content of martensite in dual-phase steel, described method comprises the following steps:

[0025] 1) Grind and polish the sample to be tested after inlaying to make a common metallographic sample;

[0026] 2) Perform vibration polishing on the polished ordinary metallographic sample in a vibration polishing machine;

[0027] 3) Corrode the metallographic sample after vibration polishing, the corrosion solution is 1-4% nitric acid alcohol solution, and the corrosion time is 10-15s;

[0028] 4) Put the prepared metallographic sample into the field emission scanning electron microscope sample chamber. After the vacuum reaches the requirements, set reasonable acceleration voltage, beam current, tilt correction and other electron microscope conditions, and select a suitable area to obtain the sample image;

[0029] 5) Through reasonable parameter setting, collect EBSD data, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com