Automatic welding production line for robot based on full automatic control of central computer

A central computer, automatic welding technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of wasting a long time and material resources, low welding efficiency, etc., to strengthen modern management, improve product quality, The effect of improving efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

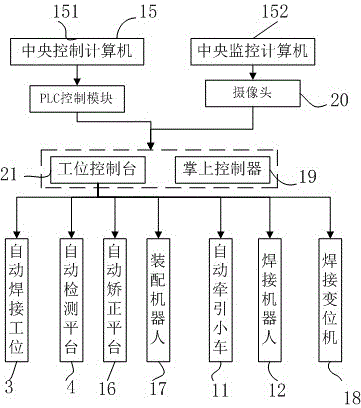

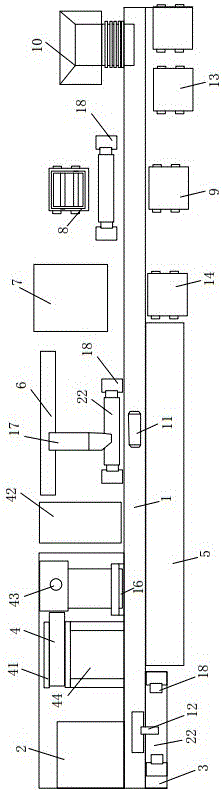

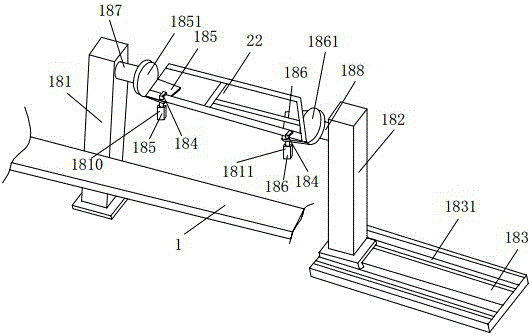

[0024] like figure 1 As shown, based on the automatic welding production line of robots fully controlled by the central computer, the PLC control modules in the station consoles 21 on each production line are connected and controlled by the central computer 15; Automatic welding station 3, automatic detection platform 4, automatic correction platform 16, assembly robot 17, automatic traction trolley 11, welding robot 12 and welding positioner 18; the consoles of the above stations are all equipped with palm controllers 19; wherein: Central computer 15 comprises central control computer 151 and central monitoring computer 152, and central monitoring computer is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com