System and method for evaluating reliability of machine tool

A technology for evaluating systems and reliability, applied in biological neural network models, instruments, data processing applications, etc., can solve problems such as reducing the accuracy of processing objects and reducing the efficiency of processing processes, and achieve the effect of ensuring operational reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit this invention.

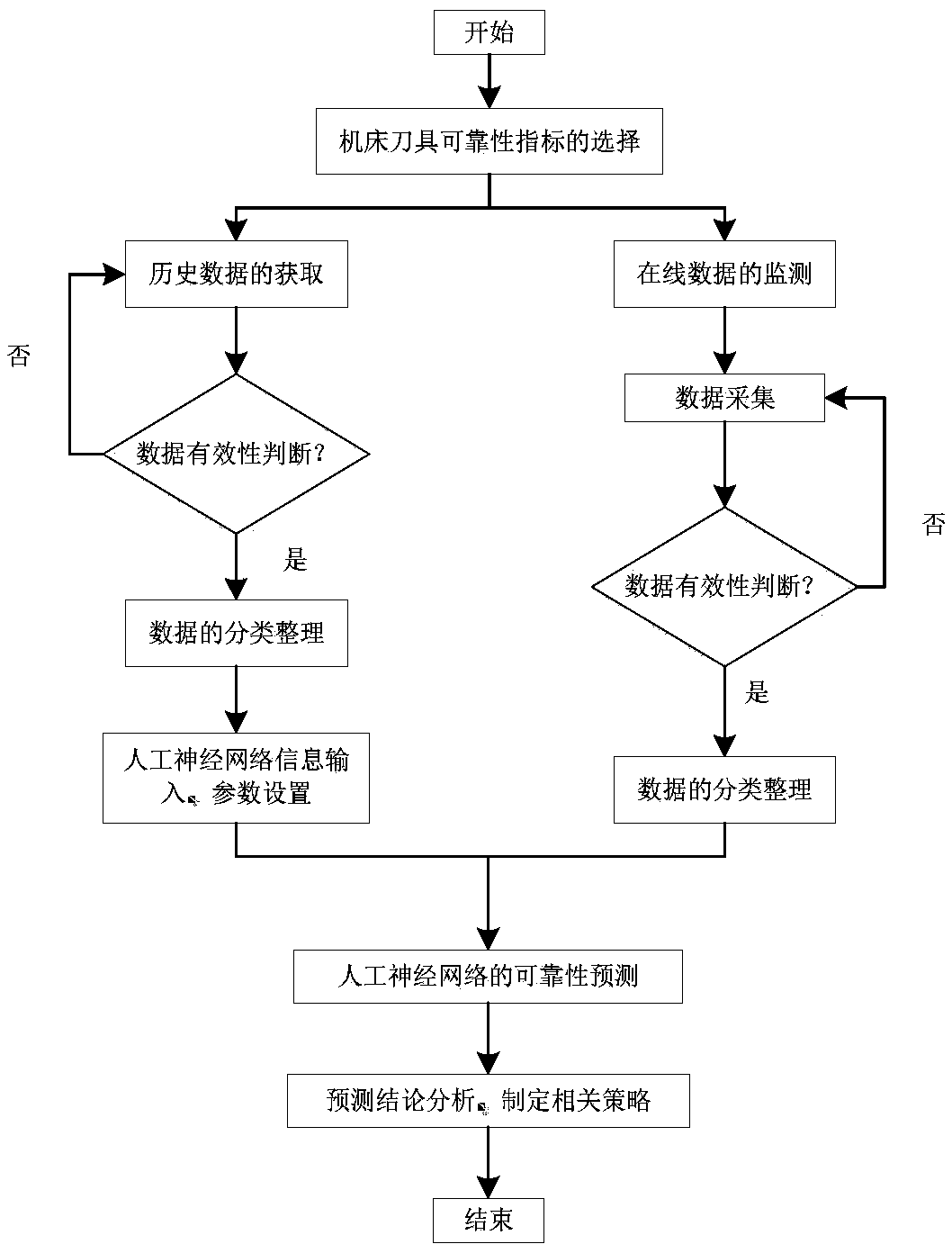

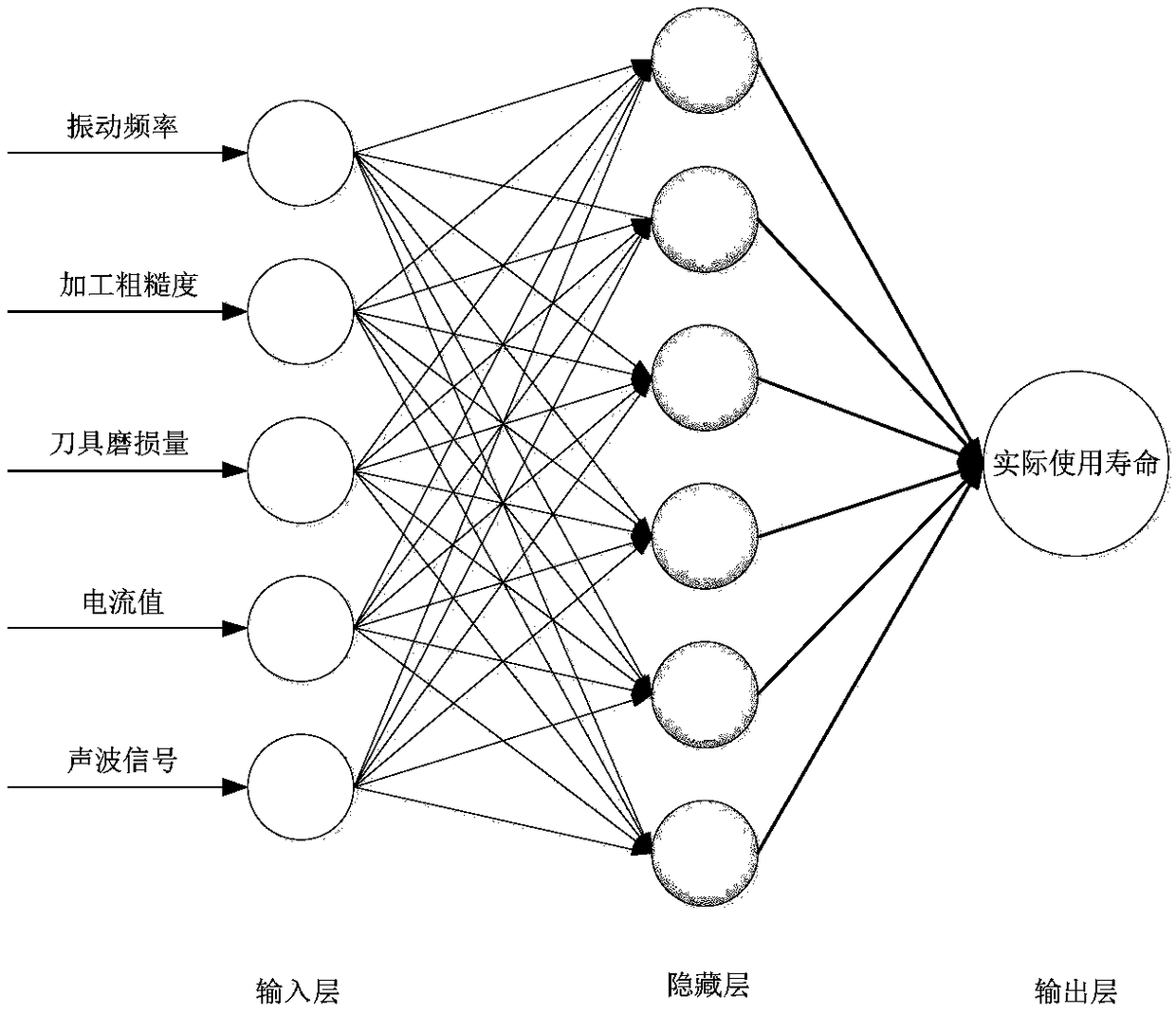

[0023] A machine tool tool reliability evaluation system provided by the present invention includes a terminal information processing module, a data acquisition module, a vibration monitoring module, a micro-optical module, and an image processing module; and a terminal information processing module, which is used to collect statistics on historical wear information of machine tool tools , input historical data into the set artificial neural network, and carry out self-adaptive learning of the artificial neural network, pave the way for subsequent real-time pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com