Pinch valve working state detecting device and detecting method

A technology of working state and detection device, which is applied in the direction of valve device, measuring device, measuring fluid pressure, etc., can solve the problem that the working and fault state of the pinch valve cannot be monitored, and achieve the effect of all-round monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

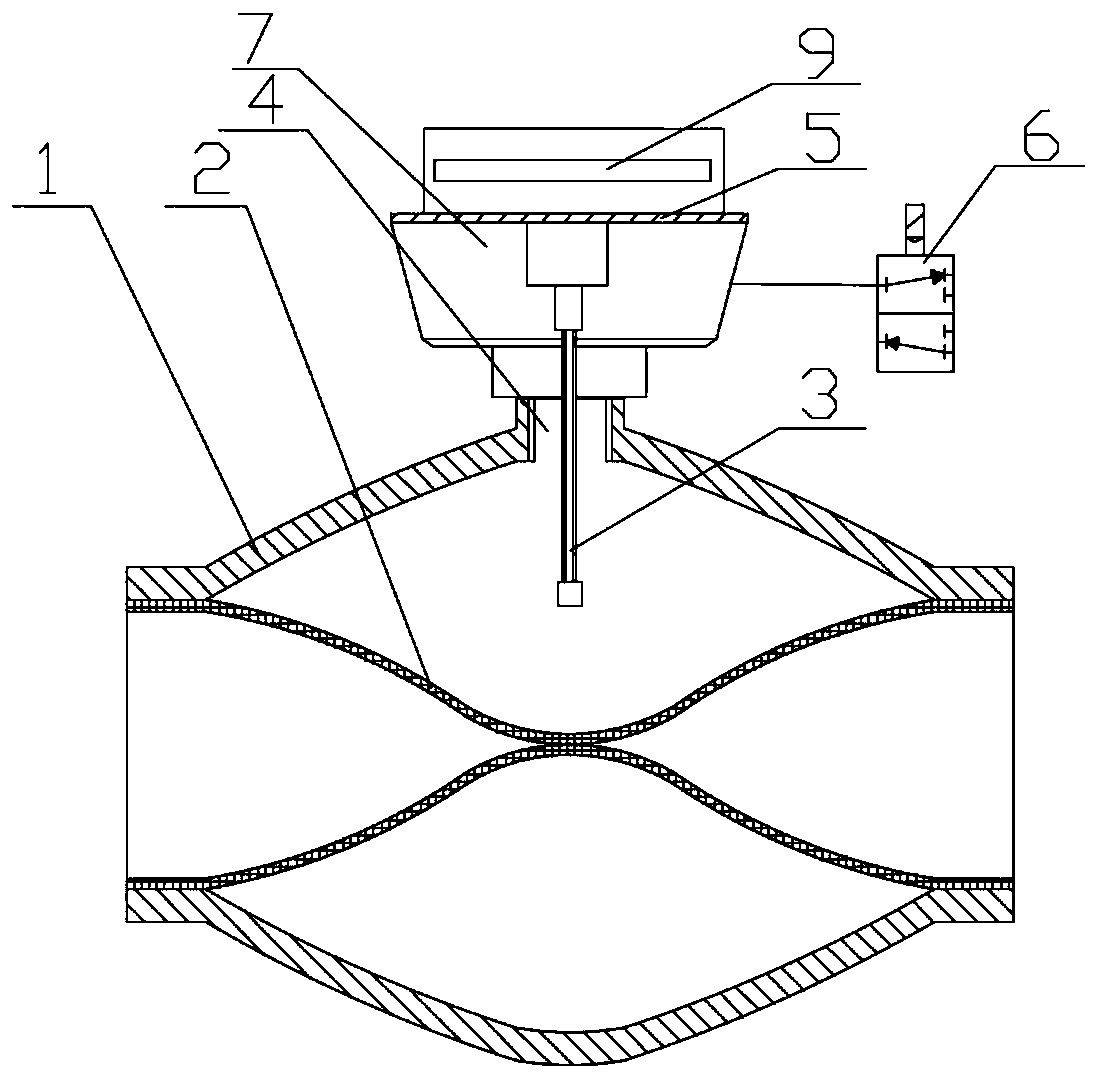

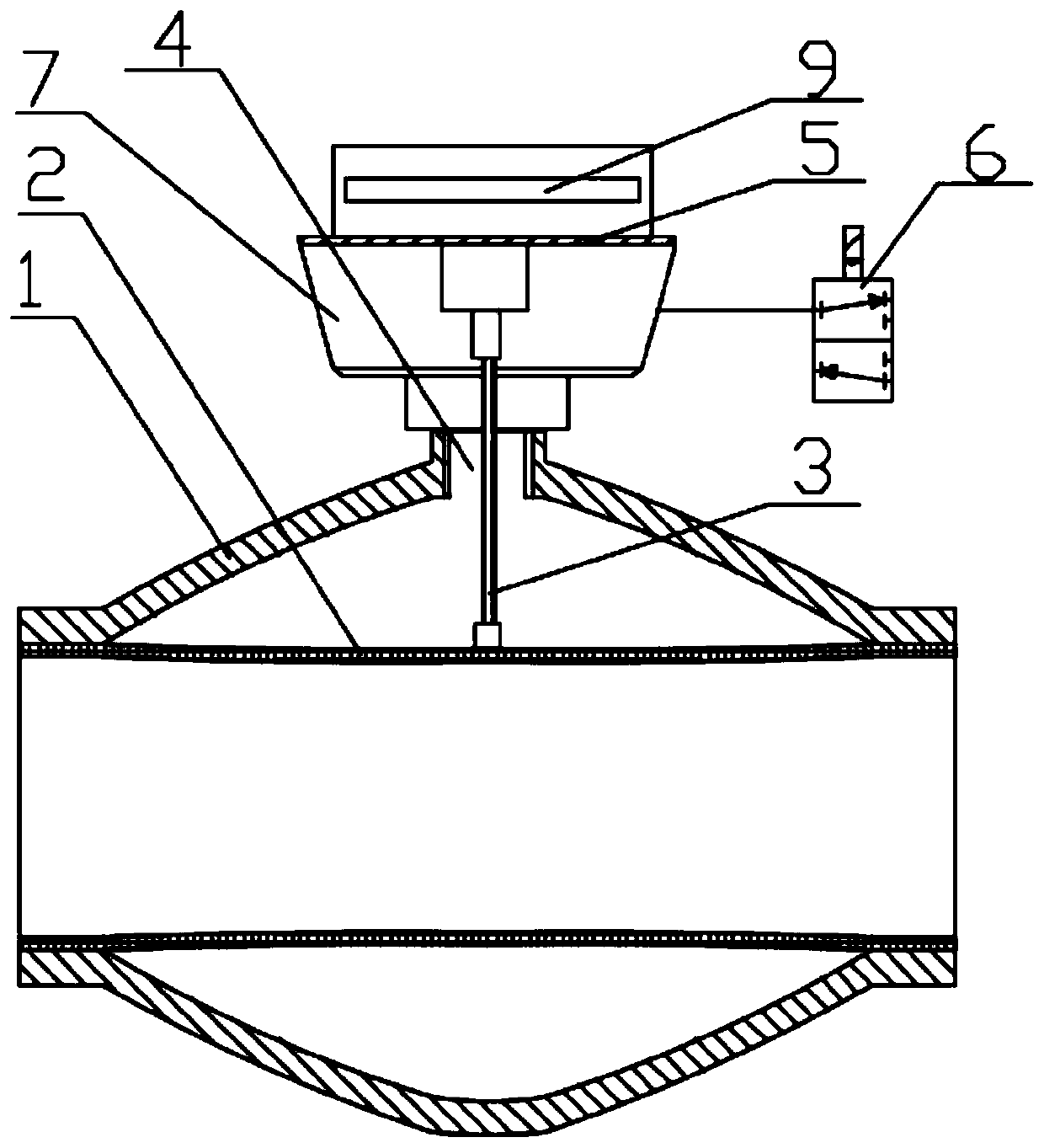

[0036] This embodiment discloses a method for detecting the working state of a pinch valve. In this embodiment, the position of the rubber tube sleeve 2 in the valve is detected through the capacitance probe 3. The specific control strategy is shown in the following table:

[0037]

[0038] The control system detects the solenoid valve power supply voltage, the pressure sensor signal and the radial position signal of the hose sleeve in the valve in real time.

[0039] 1. When both the solenoid valve 2 power supply voltage signal and the pressure sensor signal (can be detected by the pressure sensor diaphragm 5) are detected, and the radial position of the hose sleeve in the valve is at the preset closed position, it is considered to control the air source Normally, the solenoid valve 6 is in the open state and the hose sleeve 2 in the valve is in the closed position preset by the system. At this time, the pinch valve is judged as the valve closed state.

[0040] 2. When it is detect...

Embodiment 2

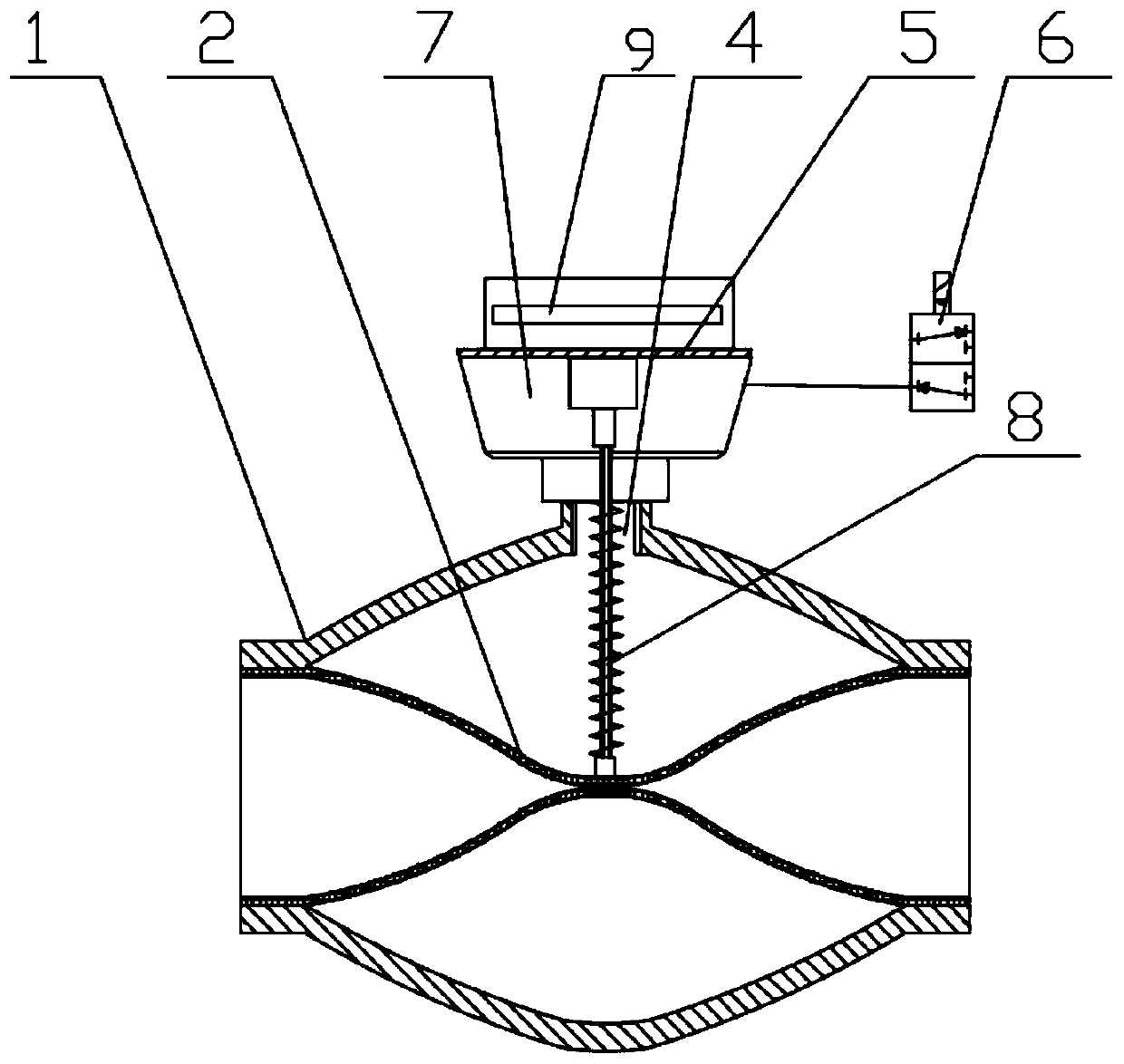

[0047] In this embodiment, the position detection of the hose sleeve 2 in the valve is performed by the spring probe 8. The specific control strategy is shown in the following table:

[0048]

[0049] Compared with the first embodiment, this embodiment adopts the spring probe 8 and the working principle of the capacitance probe 3 is different. Therefore, the fourth detection result in the first embodiment does not exist. The remaining detection results and principles are the same as those in the embodiment. Numbers 1, 2, 3, and 5 in One are the same.

[0050] Compared with the prior art, the present invention can monitor the working status and fault status of the pinch valve in real time and feed it back to the user. The present invention collects the air source status (including solenoid valve power supply voltage and pressure sensor signal) and the radial position signal of the hose sleeve in the valve, and fully considers the possible failures of the pinch valve during operatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com