Self-adaptive micro-tension fast reaction device and method for core breaking protection of core yarn and spinning machine

A fast-response, core-spun yarn technology, used in yarn, textiles and papermaking, etc., can solve the problems of limited methods for core-spun yarn broken detection, difficult photoelectric sensing operations, and high implementation costs, achieving high price and convenience. The effect of promoting popular use and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

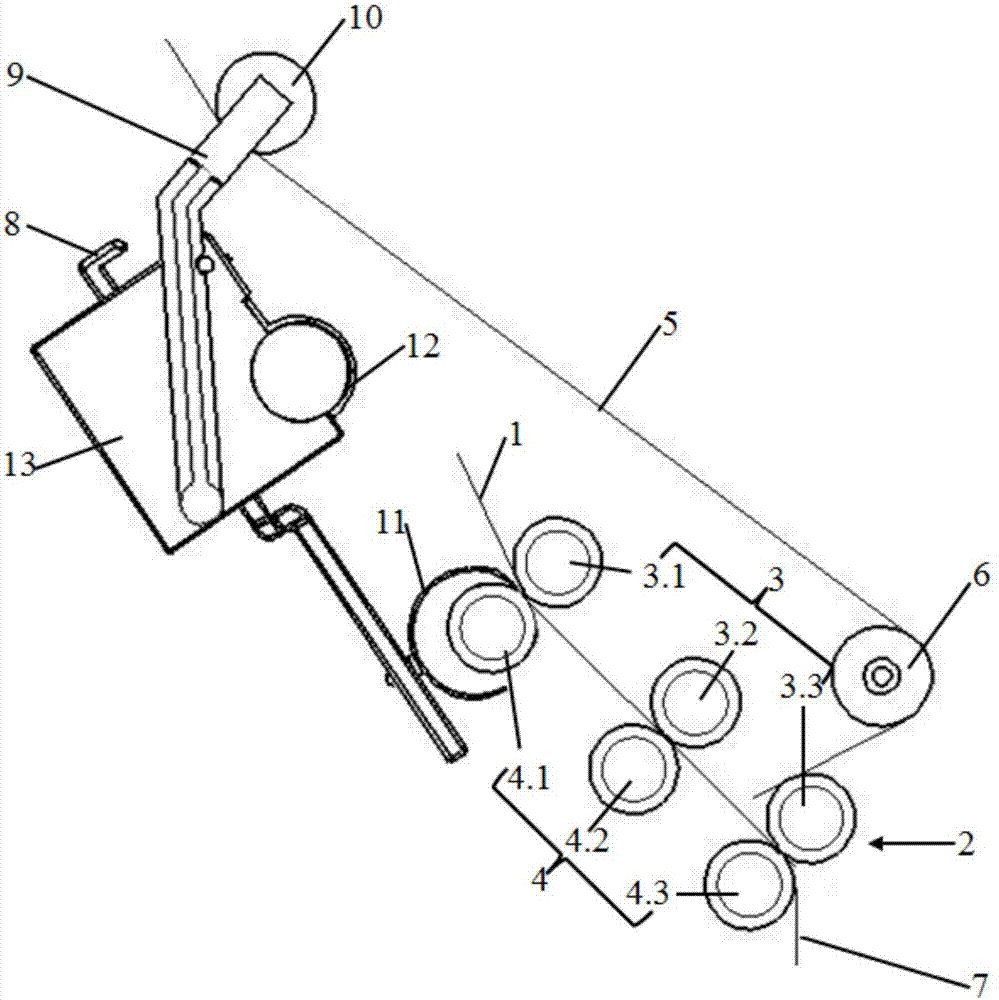

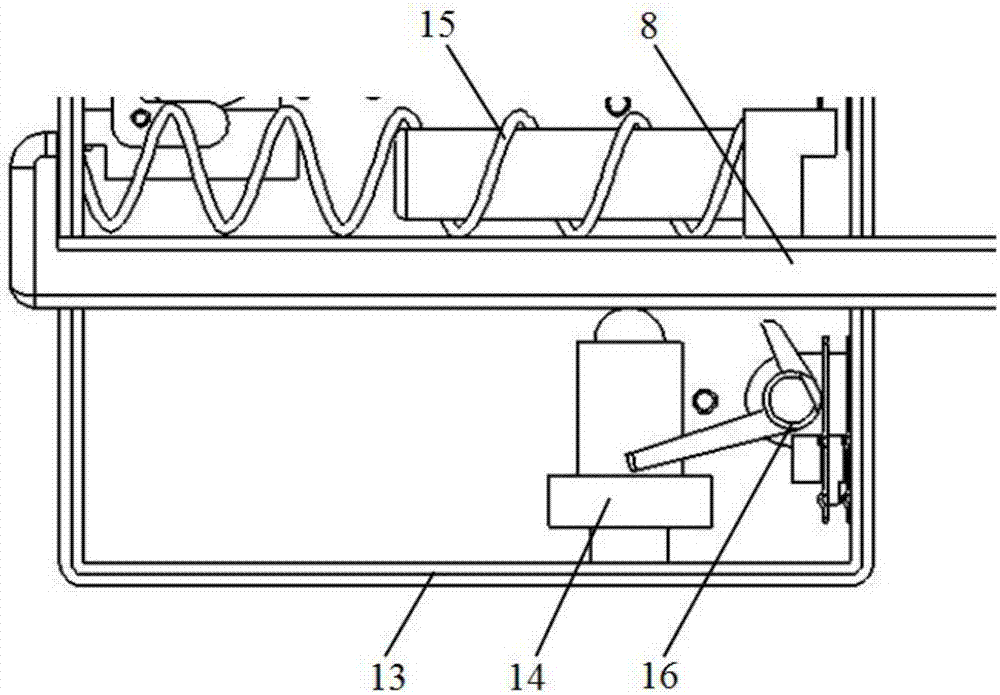

[0033] like Figure 1 to Figure 3 As shown, a self-adaptive micro-tension core-spun core broken core protection quick response device disclosed by the present invention is shown. The ball head locator 14, the first spring 17, the second spring 15, the push rod 8, and the broken yarn ring 11 are composed. like figure 1 As shown, the device is obliquely installed on the steel beam above the rear top roller 3 of the spinning frame, and the broken yarn ring 11 is located at the outer edge of the lower rear roller 3.1.

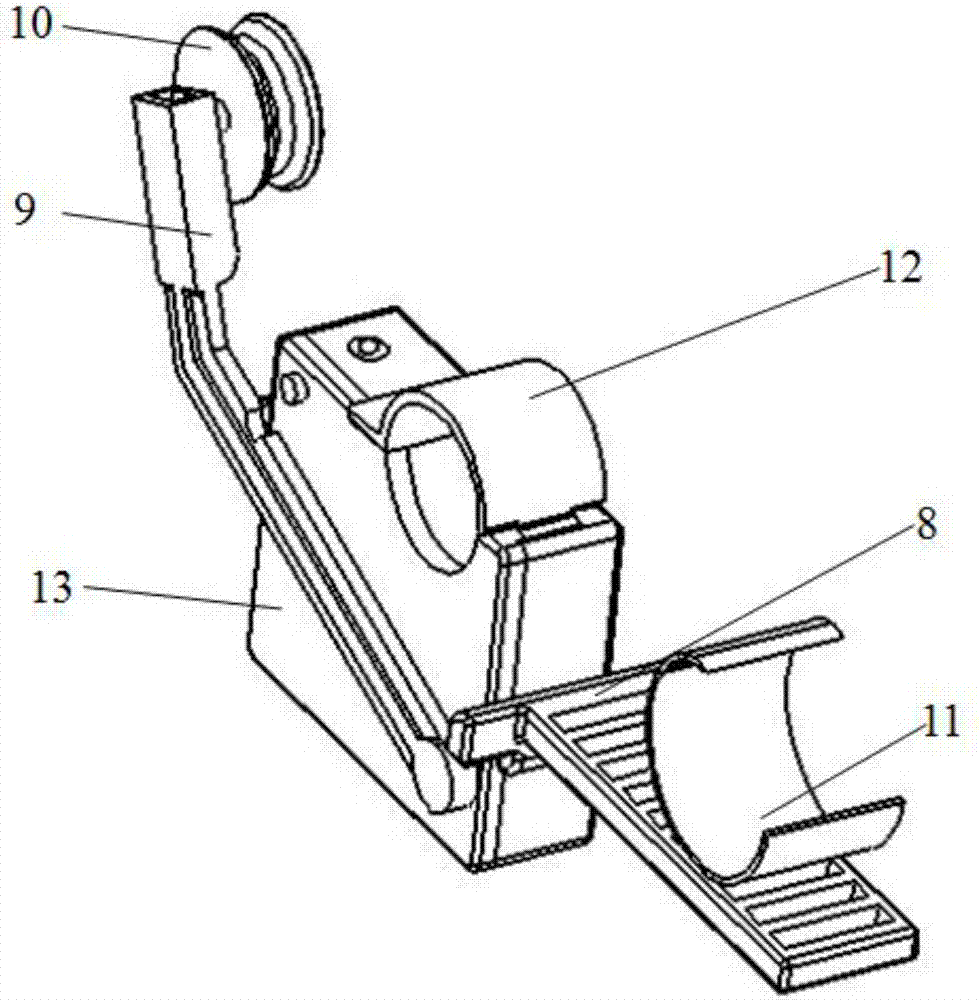

[0034] like figure 2 As shown, in an adaptive micro-tension core-spun core breakage protection rapid response device, the godet wheel 10 and the upper end of the outer swing rod 9 are connected by bolts and nuts, and the lower end of the outer swing rod 9 and the rotating shaft 16 protrude from the casing. 13 is fixedly connected, and the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com