Multi-pump hydraulic station control system and method with self-protection function

A technology of control system and hydraulic station, applied in the direction of fluid pressure actuated system components, comprehensive factory control, comprehensive factory control, etc., can solve problems such as unreasonable distribution of working time between main motor and backup motor, system state imbalance, etc., to achieve expansion and easy maintenance, improved service life and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

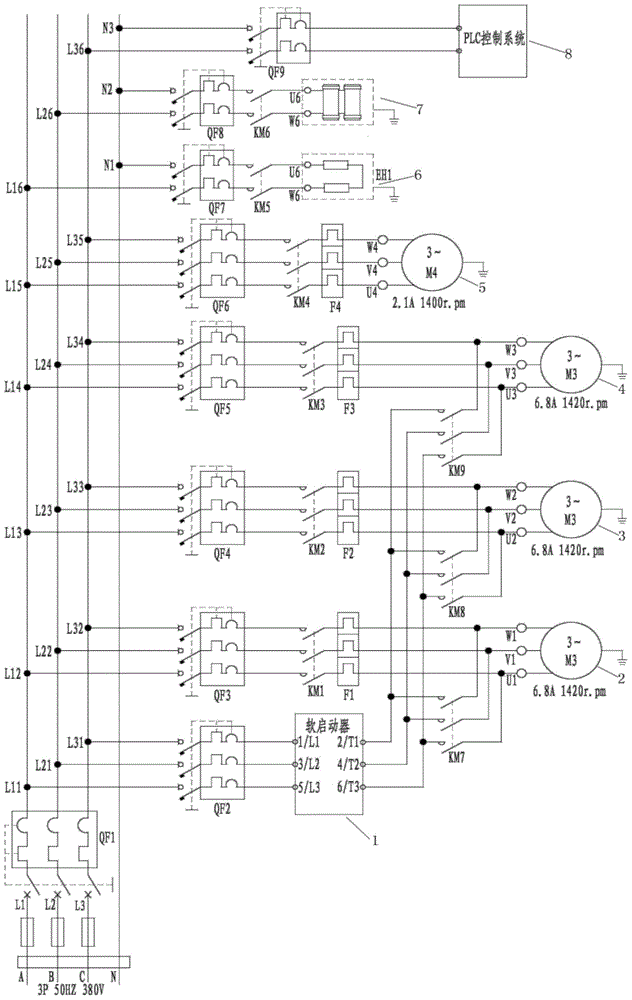

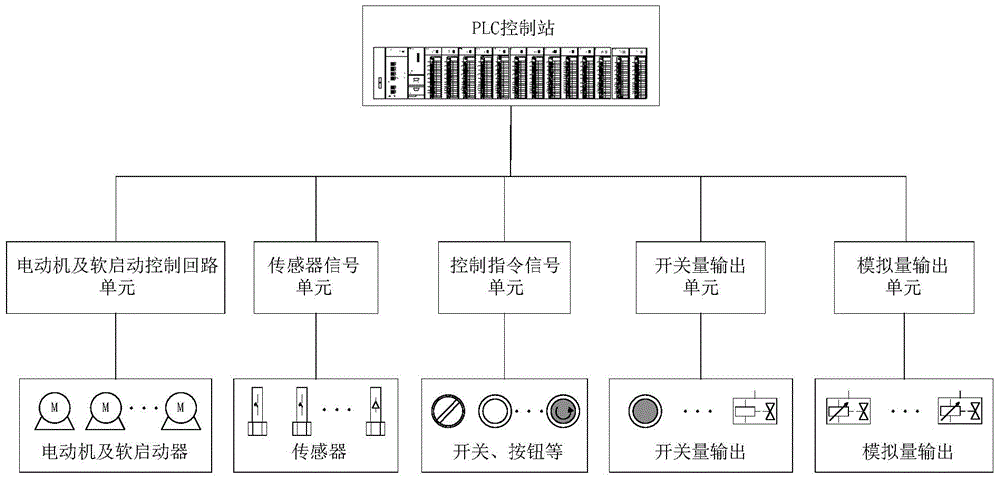

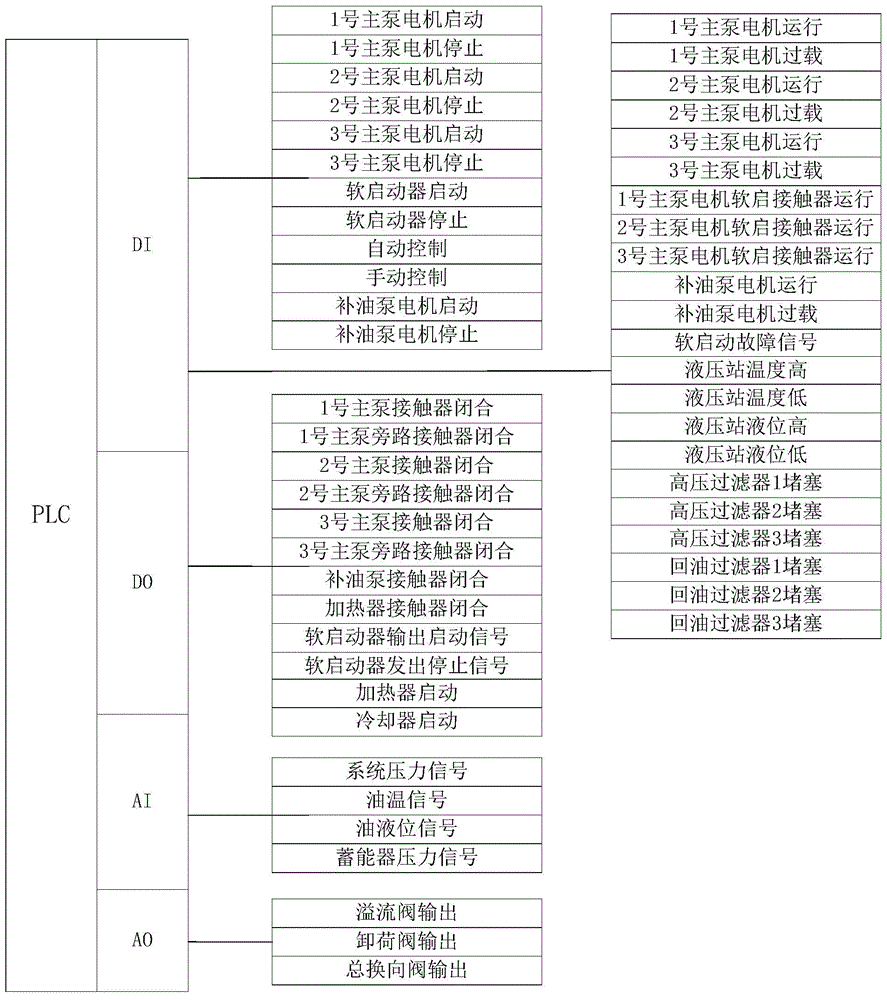

[0033] In the hydraulic station control system of the present invention, in order to avoid grid voltage fluctuations caused by motor startup, a soft starter 1 is introduced in the structure of the present invention; in order to realize automatic control of the hydraulic station, a PLC control system 8 is also introduced in the structure; by constructing the PLC control system 8 Realize the separate control and conversion of automatic mode and manual mode, which improves the automatic control level of the hydraulic station. Still works reliably.

[0034] see figure 1 The structure of the embodiment of the hydraulic station control system of the present invention is to include a soft starter 1, one end of the soft starter 1 is connected to the power line through the circuit breaker QF2 (nodes are L11, L21, L31 respectively), and the power line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com