Resin roller grinding wheel based on 3D printing forming

A 3D printing, roller technology, applied in 3D object support structures, additive manufacturing, manufacturing tools, etc., can solve problems such as low automation and harsh production environment, and achieve high practicability, improved quality stability, and high production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

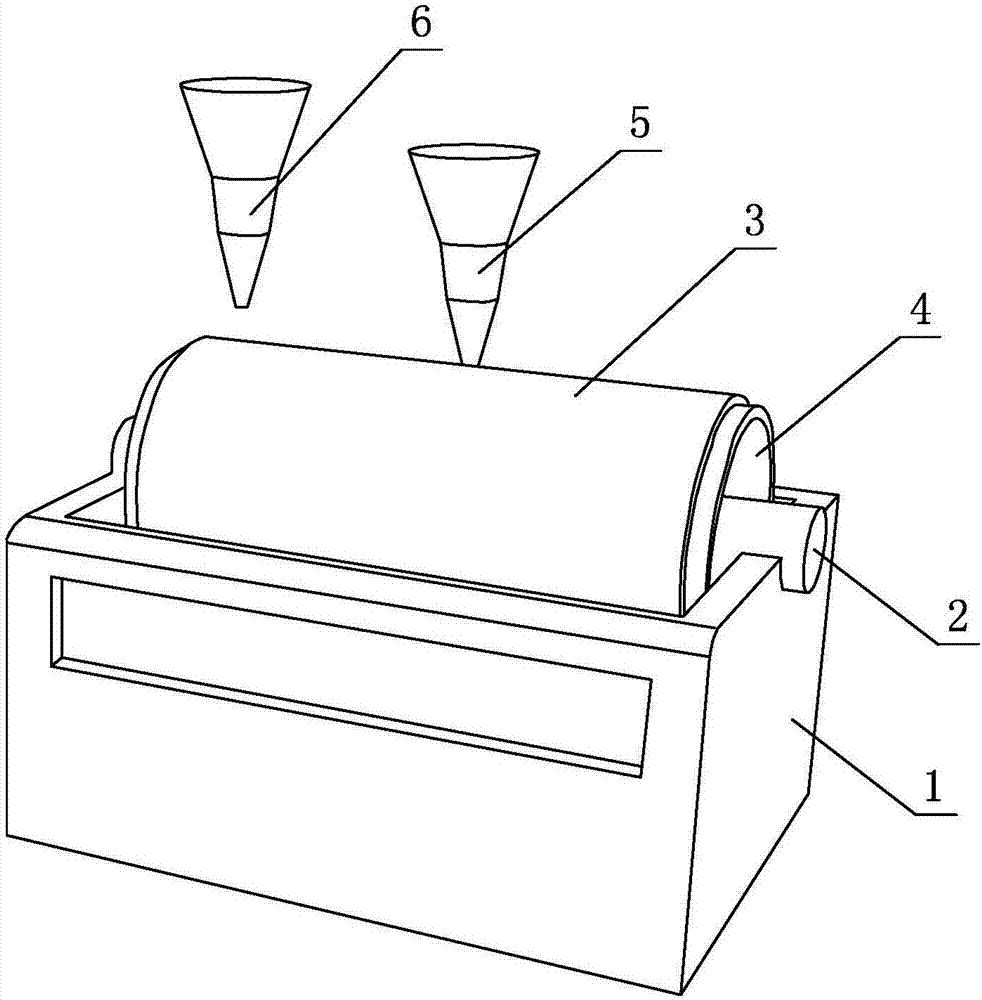

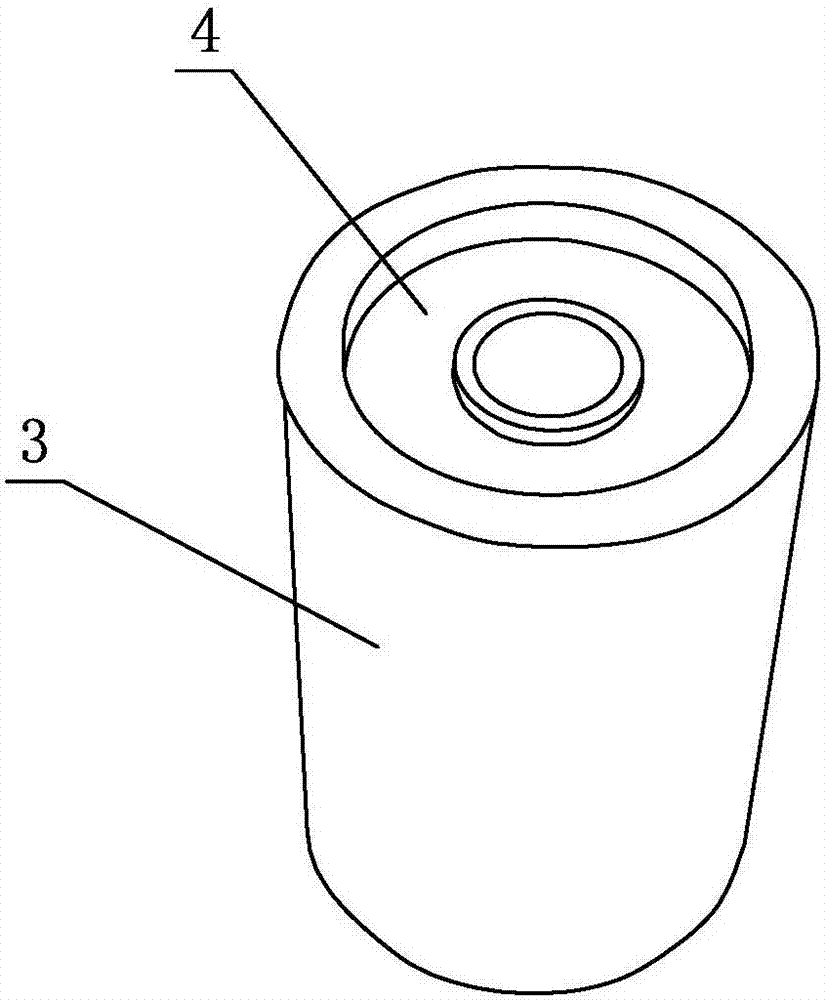

[0014] see figure 1 , figure 2 , the resin roller grinding wheel based on 3D printing, including computer three-dimensional modeling machine, printer table 1, substrate and extrusion nozzle working layer, the substrate is elastic roller 3, and the rolling is set on printer table 1, computer three-dimensional modeling machine Design the three-dimensional solid model of the product to be produced, and calculate the working path of the working layer of the extrusion nozzle. round surface.

[0015] Furthermore, a rotating shaft 2 is provided on the printer table 1 , and the elastic cylinder 3 is rolled on the printer table 1 through the rotating shaft 2 .

[0016] Furthermore, the inner cylinder of the elastic cylinder 3 is provided with a wear-resistant steel 4, which is pierced on the rotating shaft 2, and the elastic roller 3 is set on the printer ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com