Aluminum electrolysis inert anode

An inert anode, aluminum electrolysis technology, applied in the field of aluminum electrolysis, can solve the problems of difficult connection, poor thermal shock resistance of cermet inert anode, insufficient corrosion resistance, etc., and achieves the effect of easy connection, avoiding large consumption and good processing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

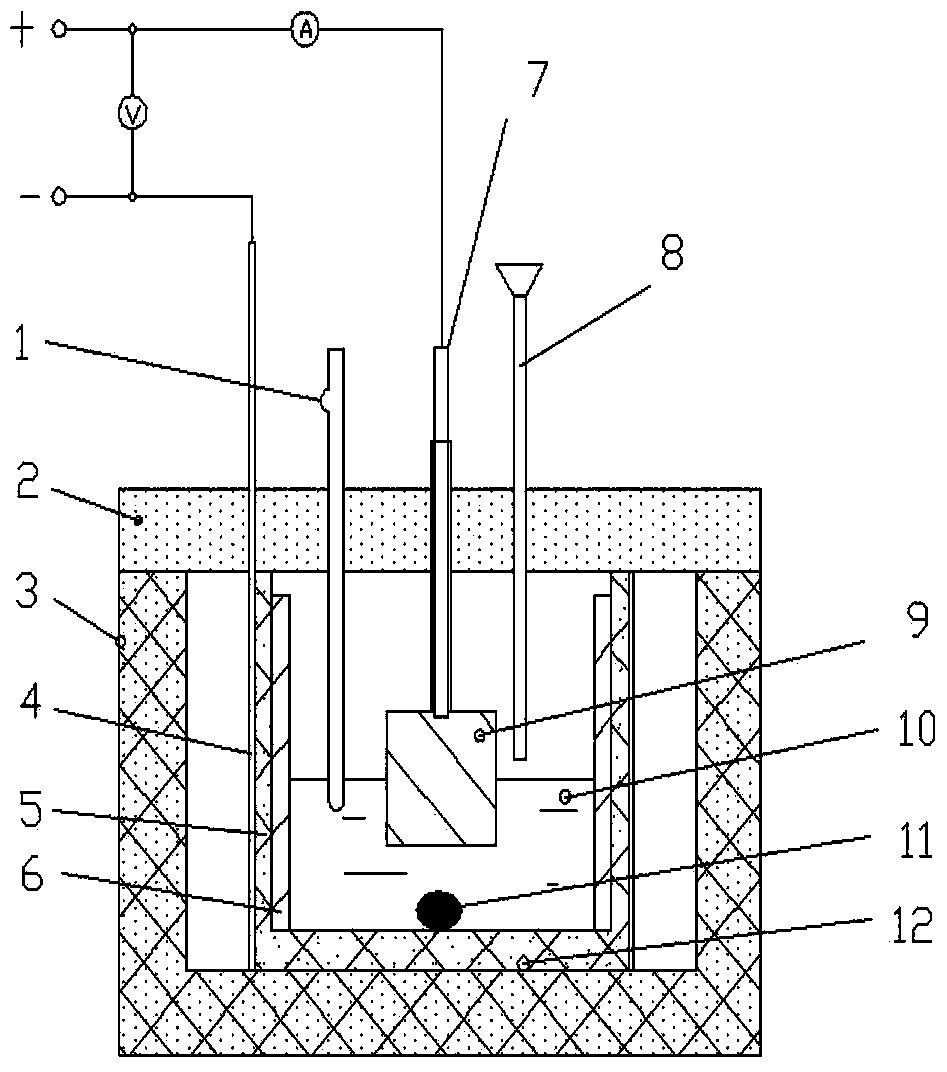

[0021] See figure 1 As shown, the present invention will be described in detail below.

[0022] The present invention adopts high-entropy alloy to prepare aluminum electrolysis inert anode, and designs high-entropy alloy composition design, alloy melting and processing, and aluminum electrolysis. The specific implementation steps are as follows:

[0023] 1. High-entropy alloy composition design: The chemical composition is designed according to the high-entropy alloy composition design principle and converted into mass percentage. The high-entropy alloy inert anode material contains at least 5 elements of Fe, Cr, Ni, Co, Cu, Al, Mo, Nb, Mn, Ti, V, Zr, and Ta, and the molar ratio of each alloy element can be the same, It can also be different. If different, the atomic ratio of each element is between 5%-35%. In order to further adjust or improve performance, non-metal or semi-metal elements C, B, and Si can be added. If the composition of the alloy is AlFeCoCrNi, Al 0.5 FeCoCrNi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com