Cooking method and cooking equipment

A cooking method and technology of cooking equipment, applied to cooking utensils, multi-unit cooking utensils, timing control ignition mechanism, etc., can solve the problems of inability to realize standardized operation, inability to restart heating, poor consistency of cooking taste, etc., and achieve improvement Dish efficiency, avoid cleaning, maintain consistency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

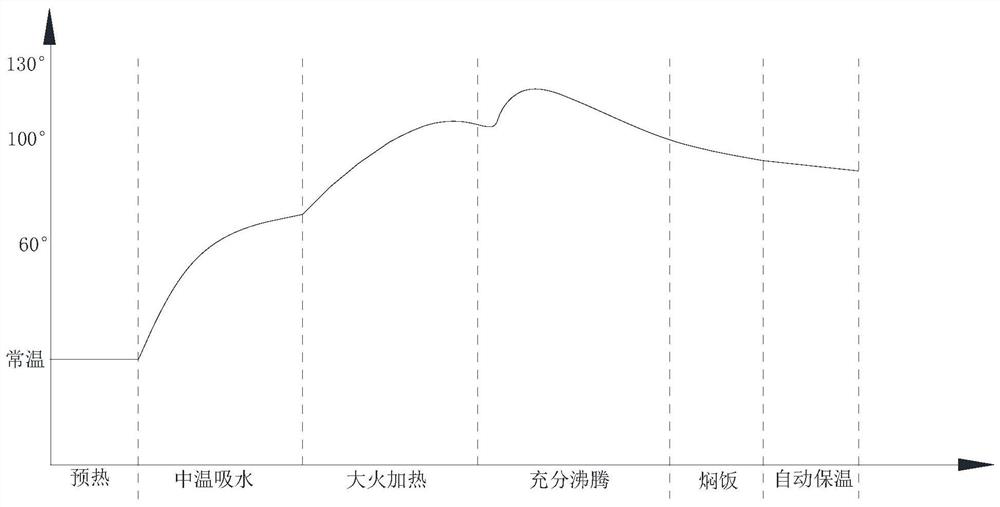

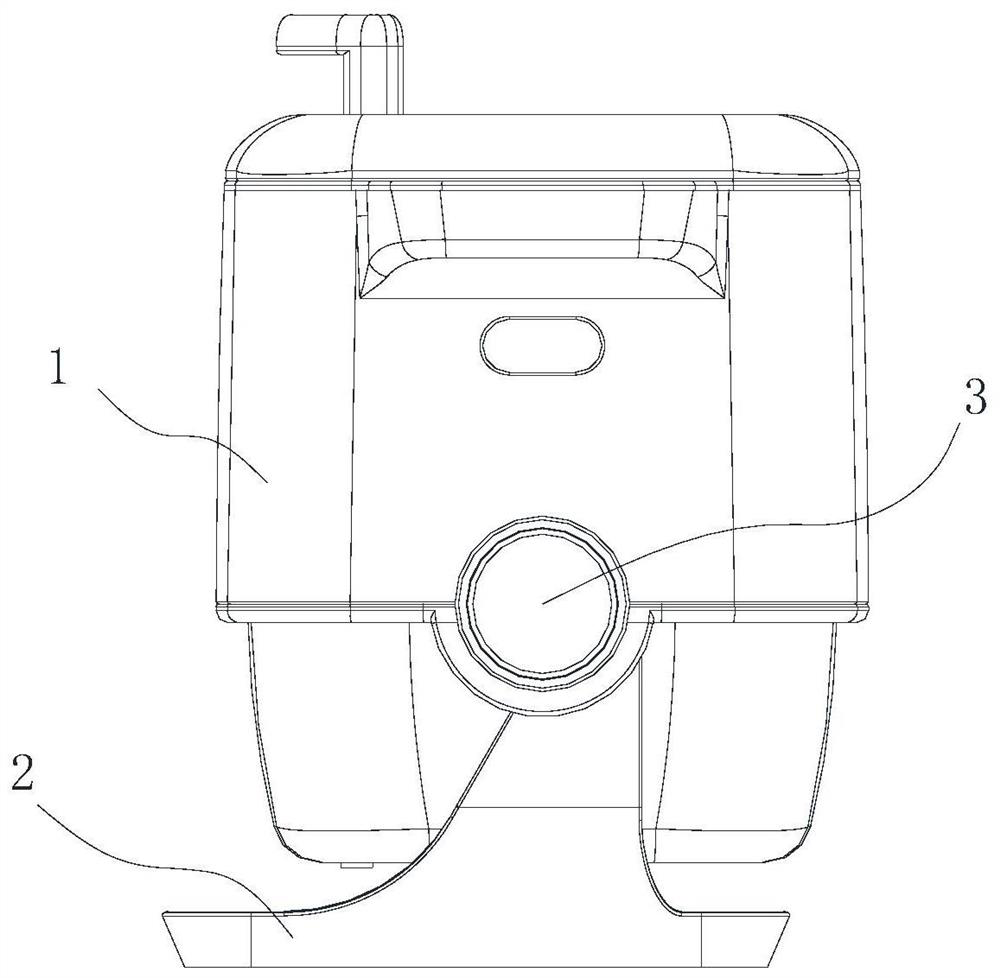

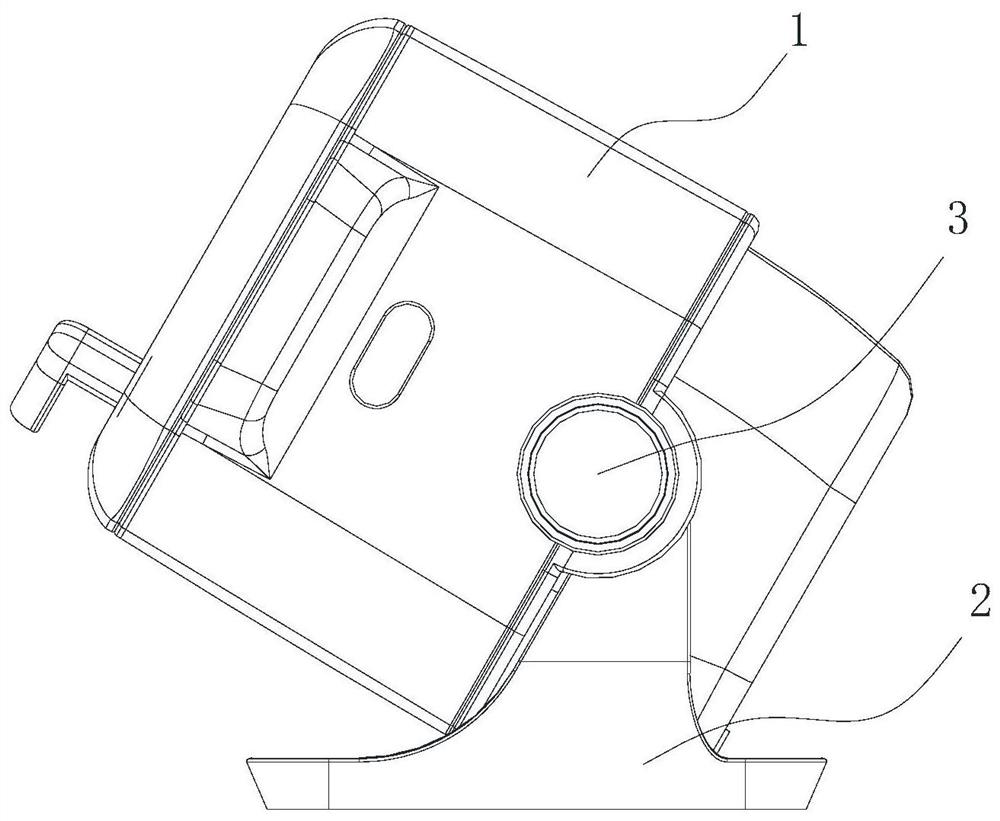

[0062] Implementation mode 1: if figure 2 and image 3 As shown, the cooking equipment includes a pot body 1 and a base 2, the inner container is placed in the pot body 1, and the pot body 1 is rotationally connected with the base 2 through a first rotating shaft 3. In this embodiment , the first rotating shaft 3 is perpendicular or substantially perpendicular to the axis of the inner container. The so-called "approximately perpendicular to" refers to the tolerance between the first rotating shaft 3 and the inner container after assembly due to processing errors and assembly errors. The included angle between the axes has a slight angle difference, such as ±5°. The first rotating shaft 3 is connected to the driving device (such as a motor), and can be driven to rotate by the driving device, thereby driving the pot body 1 and the inner tank in the pot body 1 around the first rotating shaft 3 rotate. In this embodiment, the soup in the side dish and / or sauce penetrates into ...

Embodiment approach 2

[0063] Embodiment 2: The inner container or pot body 1 is connected to the driving device through a second rotating shaft. The difference from the above embodiment is that in this embodiment, the axis of the second rotating shaft is aligned with the axis of the inner container. The axes are parallel or approximately parallel. The so-called "approximately parallel" means that the angle between the second rotating shaft and the inner liner axis after assembly is allowed to have a slight angle difference caused by machining errors and assembly errors of each component, such as ± 5°, the second rotating shaft is connected with the driving device (such as a motor), and can be driven to rotate by the driving device, thereby driving the pot body or the inner tank to rotate around the second rotating shaft.

Embodiment approach 3

[0064] Embodiment 3: On the basis of Embodiment 2 above, the driving device in this embodiment further includes a driving member for driving the pot body from a vertical state to an inclined state, that is, after the rice cooking operation is performed, The driving part drives the pot to tilt to one side. Preferably, the driving part can drive the pot to rotate around the first axis 3. After tilting, the clamp between the axis of the liner and the horizontal direction The angle is 30°-60°. Afterwards, the driving device drives the inner container and / or the pot body to rotate around the second rotating shaft. Penetrate into the rice under action.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com