Method for comprehensively reclaming quartz vein polymetallic oxidized ore resources

A technology of polymetallic oxide ore and recovery method, which is applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of slime, low ore grade, and inability to use directly, so as to improve the recovery rate and improve the taste. , significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

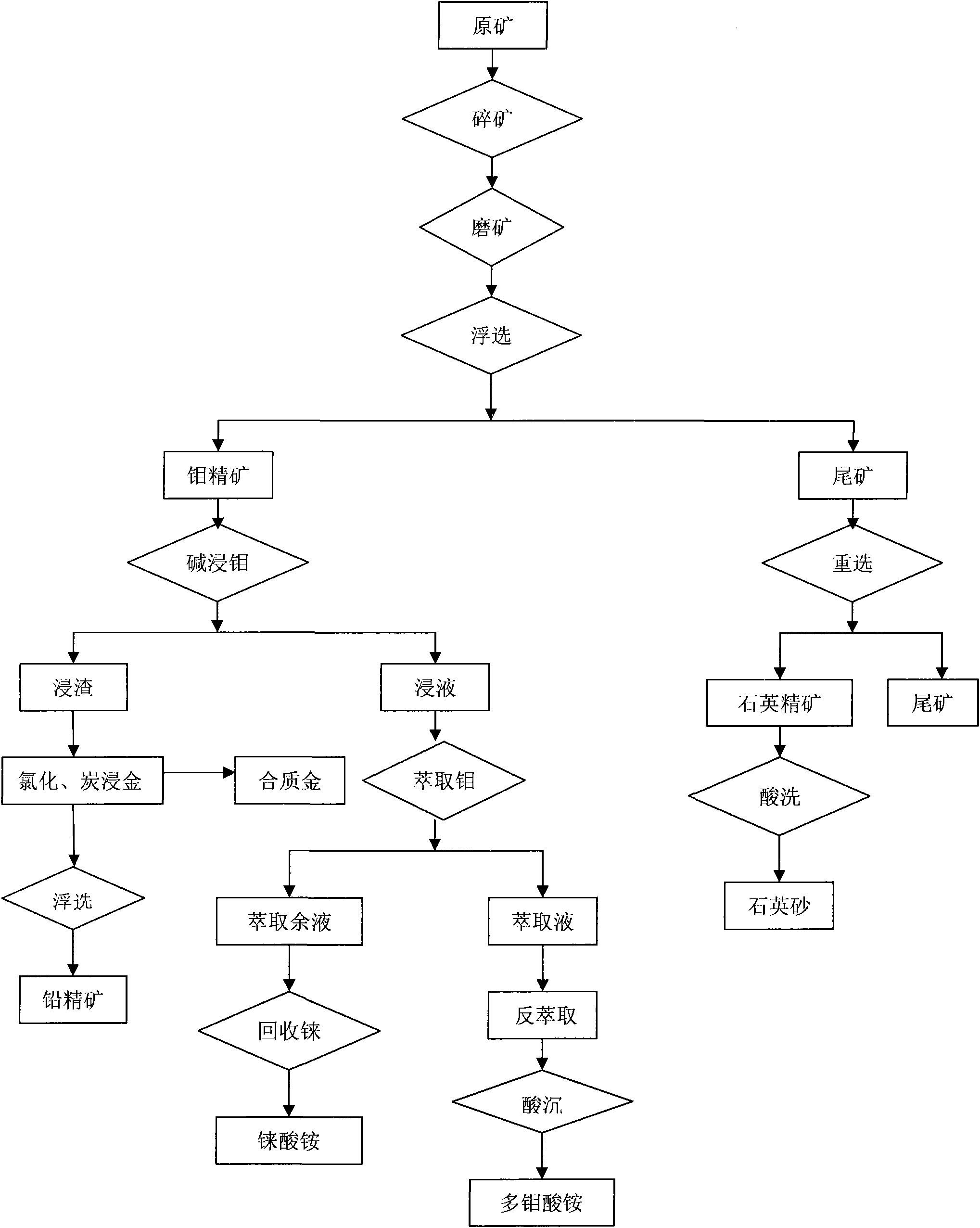

Image

Examples

Embodiment 1

[0018] Embodiment 1: the comprehensive recovery method of quartz vein polymetallic oxide ore resources according to the present invention comprises the following steps: (1) crushing and grinding the raw ore of quartz vein polymetallic oxide ore, and then carrying out flotation, the The agent added in the first step flotation is the regulator sodium sulfide 150g / t 原矿 , slime dispersant water glass 100g / t 原 矿 , sodium hexametaphosphate 100g / t 原矿 , Inhibitor kerosene 200g / t 原矿 , sodium oleate 100g / t 原矿 , active agent copper sulfate 100g / t 原矿 , Foaming agent No. 2 oil 100g / t 原矿 , collector black medicine 50g / t 原矿 And collector xanthate 100g / t 原矿 , separated into molybdenum concentrate and tailings; (2) adding sodium carbonate 100kg / t to molybdenum concentrate 钼精矿 And sodium hydroxide 25kg / t 钼精矿 , control the PH value to 11, form leaching residue and immersion liquid, use carbon slurry method to extract alloy gold from leaching residue, and the agent used for carbon slurry...

Embodiment 2

[0019] Embodiment 2: the comprehensive recovery method of quartz vein polymetallic oxide ore resources according to the present invention comprises the following steps: (1) crushing and grinding the raw ore of quartz vein polymetallic oxide ore, and then carrying out flotation, the The agent added in the first step flotation is the regulator sodium sulfide 600g / t 原矿 , Slime dispersant water glass 200g / t 原 矿 , sodium hexametaphosphate 200g / t 原矿 , Inhibitor kerosene 500g / t 原矿 , sodium oleate 100g / t 原矿 , active agent copper sulfate 300g / t 原矿 , Foaming agent No. 2 oil 300g / t 原矿 , collector black medicine 150g / t 原矿 And collector xanthate 300g / t 原矿 , separated into molybdenum concentrate and tailings; (2) Add sodium carbonate 200kg / t to molybdenum concentrate 钼精矿 And sodium hydroxide 60kg / t 钼精矿 , control the PH value to 12, form the leaching residue and the leaching liquid, and extract alloy gold from the leaching residue by the carbon slurry method, and the agent used for ...

Embodiment 3

[0020] Embodiment 3: the comprehensive recovery method of quartz vein polymetallic oxide ore resources according to the present invention comprises the following steps: (1) crushing and grinding the raw ore of quartz vein polymetallic oxide ore, and then carrying out flotation, the The agent added in the first step flotation is the regulator sodium sulfide 1000g / t 原矿 , Slime dispersant water glass 300g / t 原矿 , sodium hexametaphosphate 300g / t 原矿 , Inhibitor kerosene 800g / t 原矿 , sodium oleate 300g / t 原矿 , active agent copper sulfate 500g / t 原矿 , Foaming agent No. 2 oil 500g / t 原矿 , collector black medicine 300g / t 原矿 And collector xanthate 500g / t 原矿 , separated into molybdenum concentrate and tailings; (2) Add sodium carbonate 300kg / t to molybdenum concentrate 钼精矿 And sodium hydroxide 100kg / t 钼精矿 , control the PH value to 14, form leaching residue and immersion liquid, use carbon slurry method to extract alloy gold from leaching residue, and the agent used for carbon slurry e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com