Diamond abrasive wheel mechanism based on 3D printing

A 3D printing and diamond technology, applied in the direction of improving process efficiency, improving energy efficiency, additive manufacturing, etc., to achieve the effects of fast heat dissipation, stable performance, and high degree of automated production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

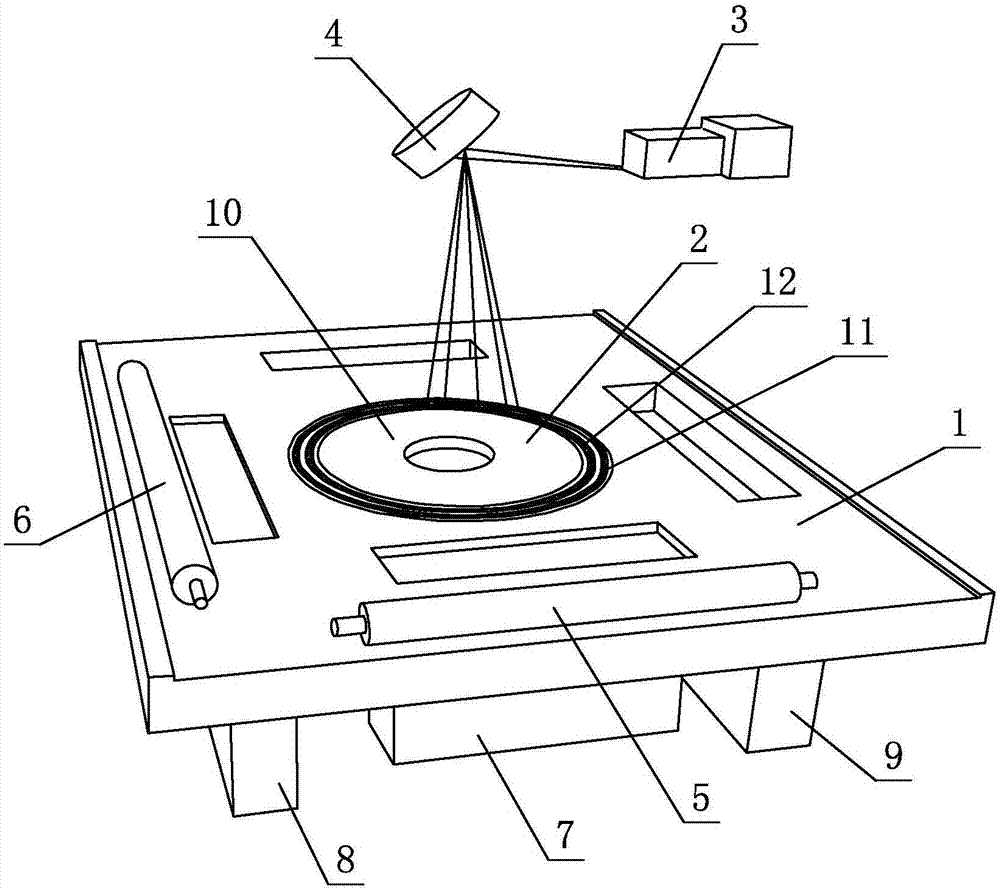

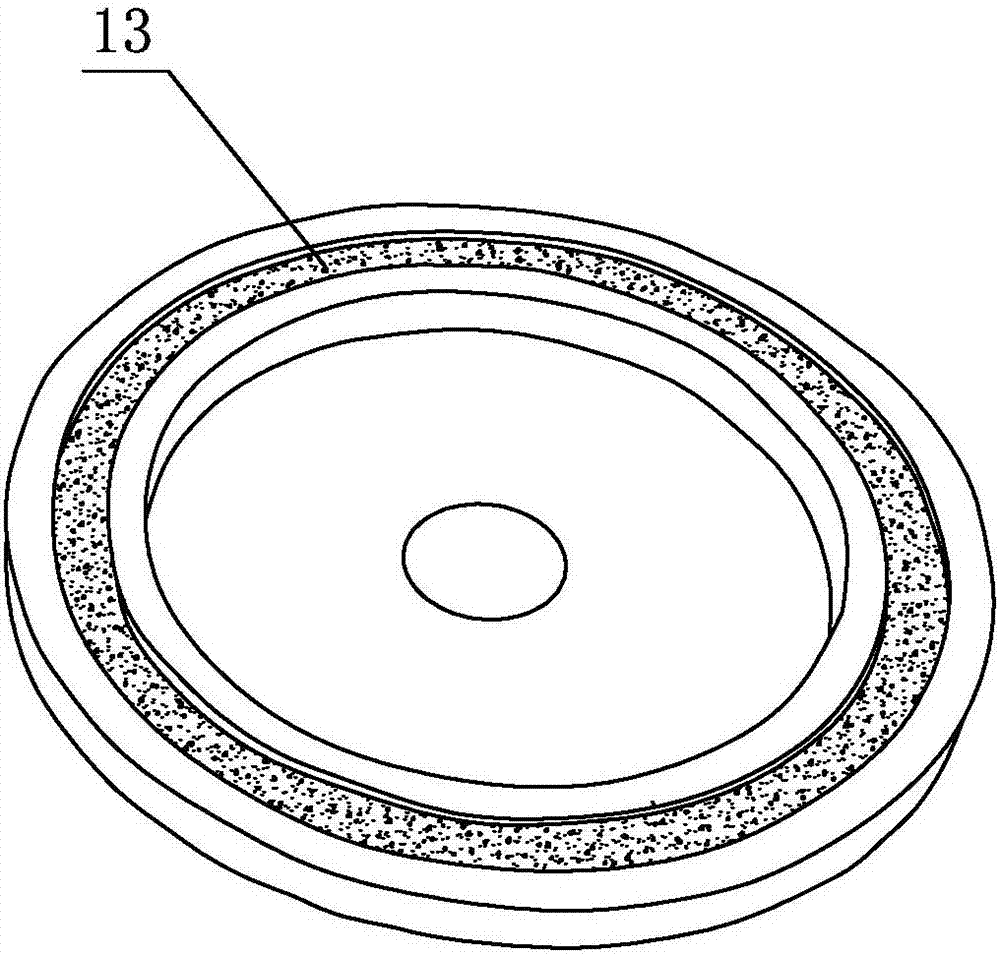

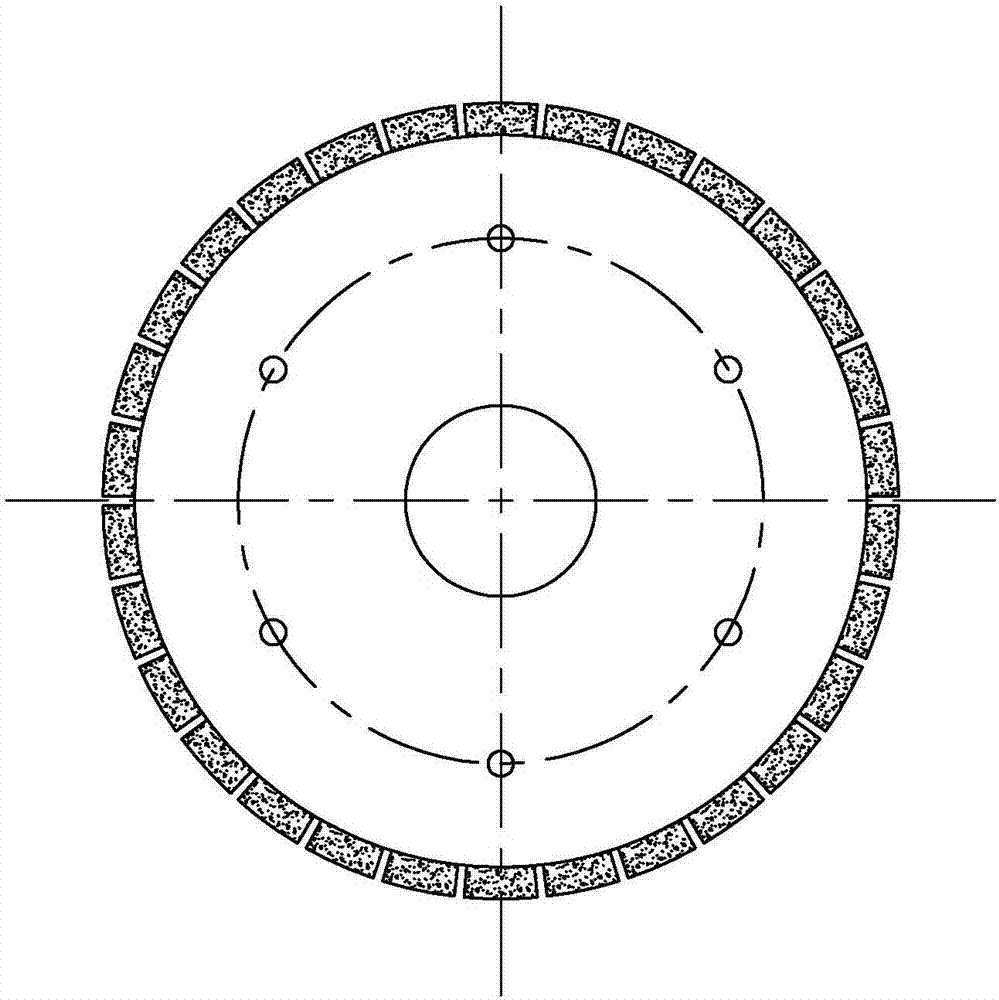

[0020] see figure 1 , figure 2 , the diamond grinding wheel mechanism based on 3D printing includes a computer three-dimensional modeling machine, a printer table 1 and a laser generating assembly, and the printer table 1 is provided with a powder spreading assembly, a powder feeding assembly and a matrix working layer 2; wherein, the matrix working layer 2 It is a sandwich structure; the computer 3D modeling machine designs the 3D solid model of the product, and calculates the working path of the laser generating component; the powder spreading component is set on one side of the printer table 1, and powder is spread on the working layer 2 of the substrate The powder feeding assembly is connected with the powder spreading assembly, and the powder feeding operation is performed on the powder spreading assembly; the laser generating device is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com