Patents

Literature

100results about How to "Achieve the purpose of mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intelligent electrical device

InactiveCN103676735AReduce computing pressureImprove system scalabilityProgramme controlComputer controlProgrammable logic controllerBackplane

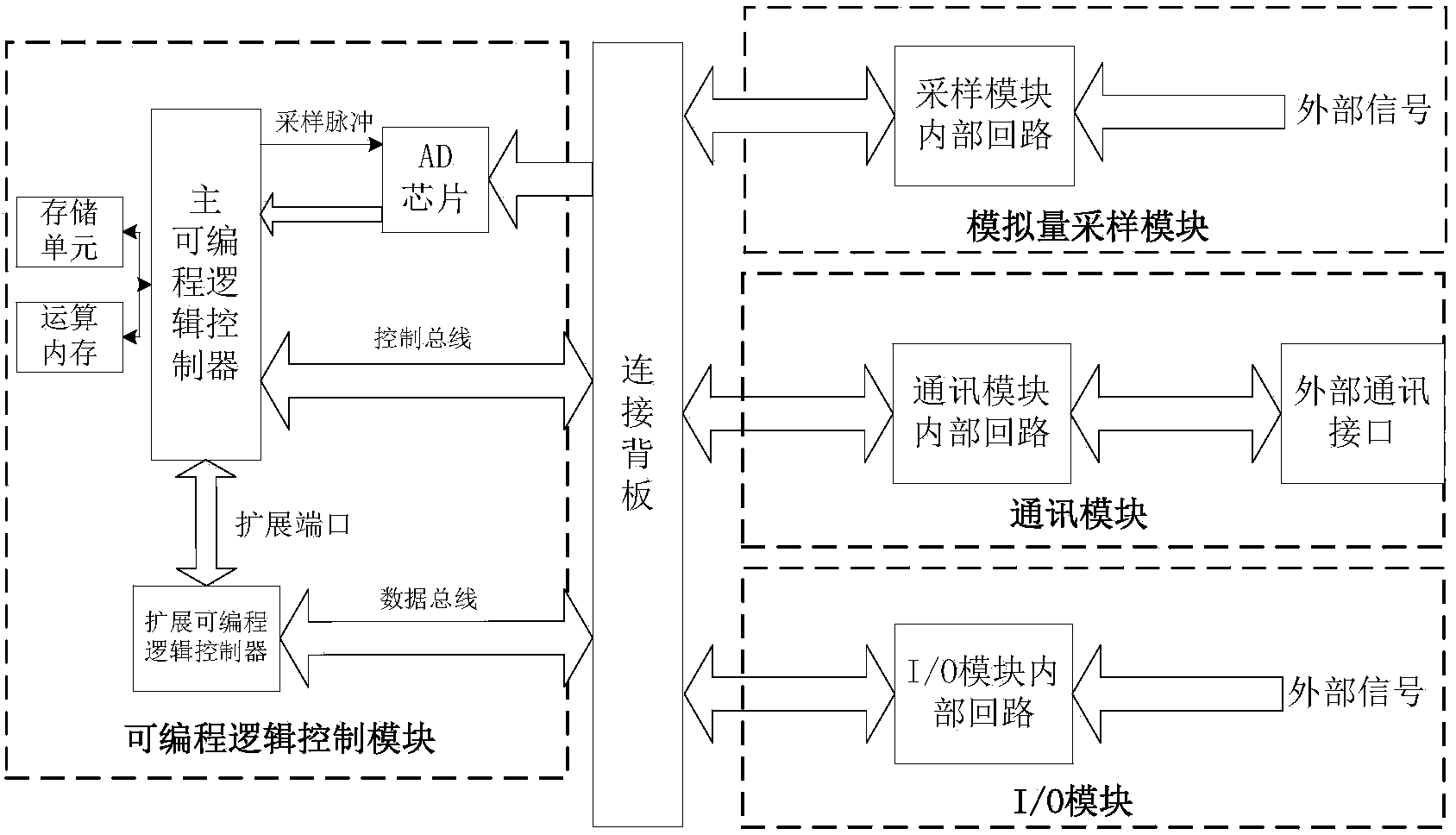

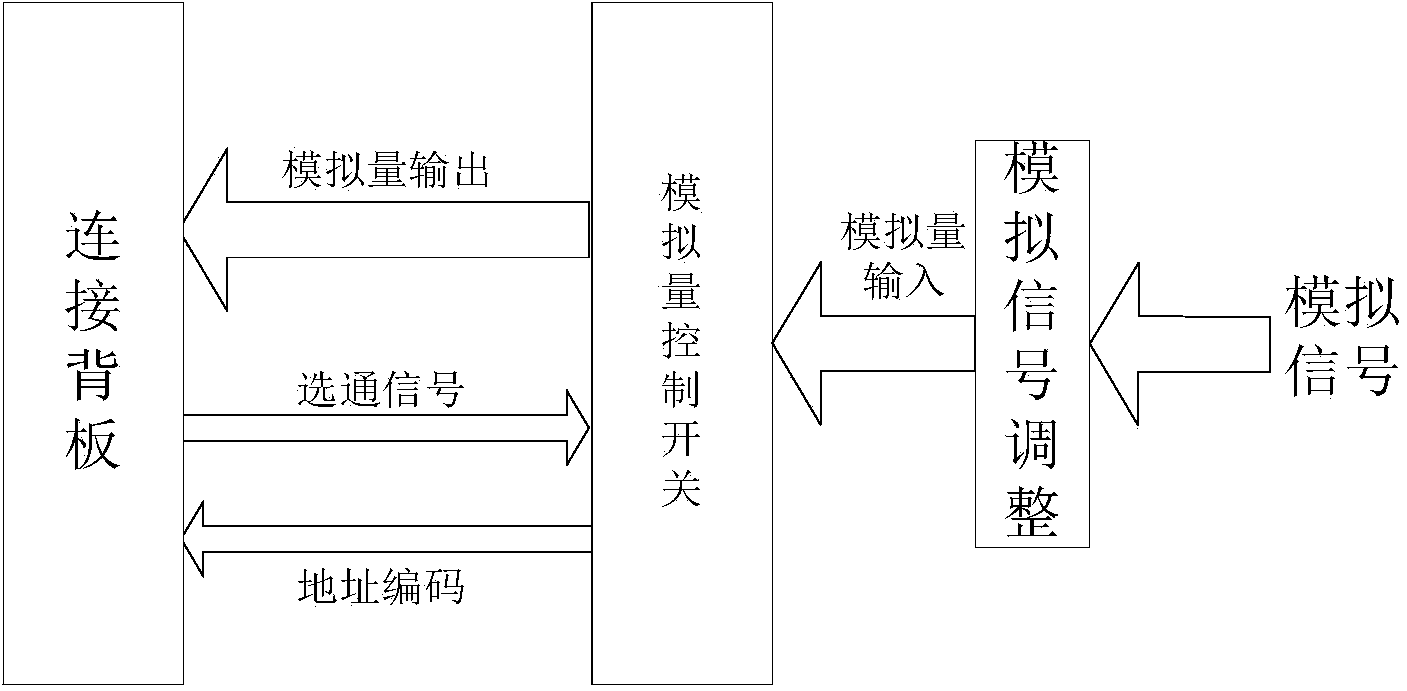

The invention relates to an intelligent electrical device, and belongs to the technical field of intelligent power distribution stations. The intelligent electrical device has the advantages that I / O (input / output) inserts and sampling inserts are not separated on a backboard, and card information are exchanged through connection among modules, so that the objective of mixed inserting of the I / O inserts and the sampling inserts can be achieved, and the number of the inserts can be flexibly set according to project needs; programmable logic controllers are introduced into slave modules, so that operation pressure of a programmable logic controller in a master module is relieved greatly, and system expansibility is remarkably enhanced; the programmable logic controller in the master module does not participate in early-stage data processing, so that system resources are reduced; in occasions with large external extension demands, a low-level processor can be considered so as to reduce system cost moderately.

Owner:XJ ELECTRIC +1

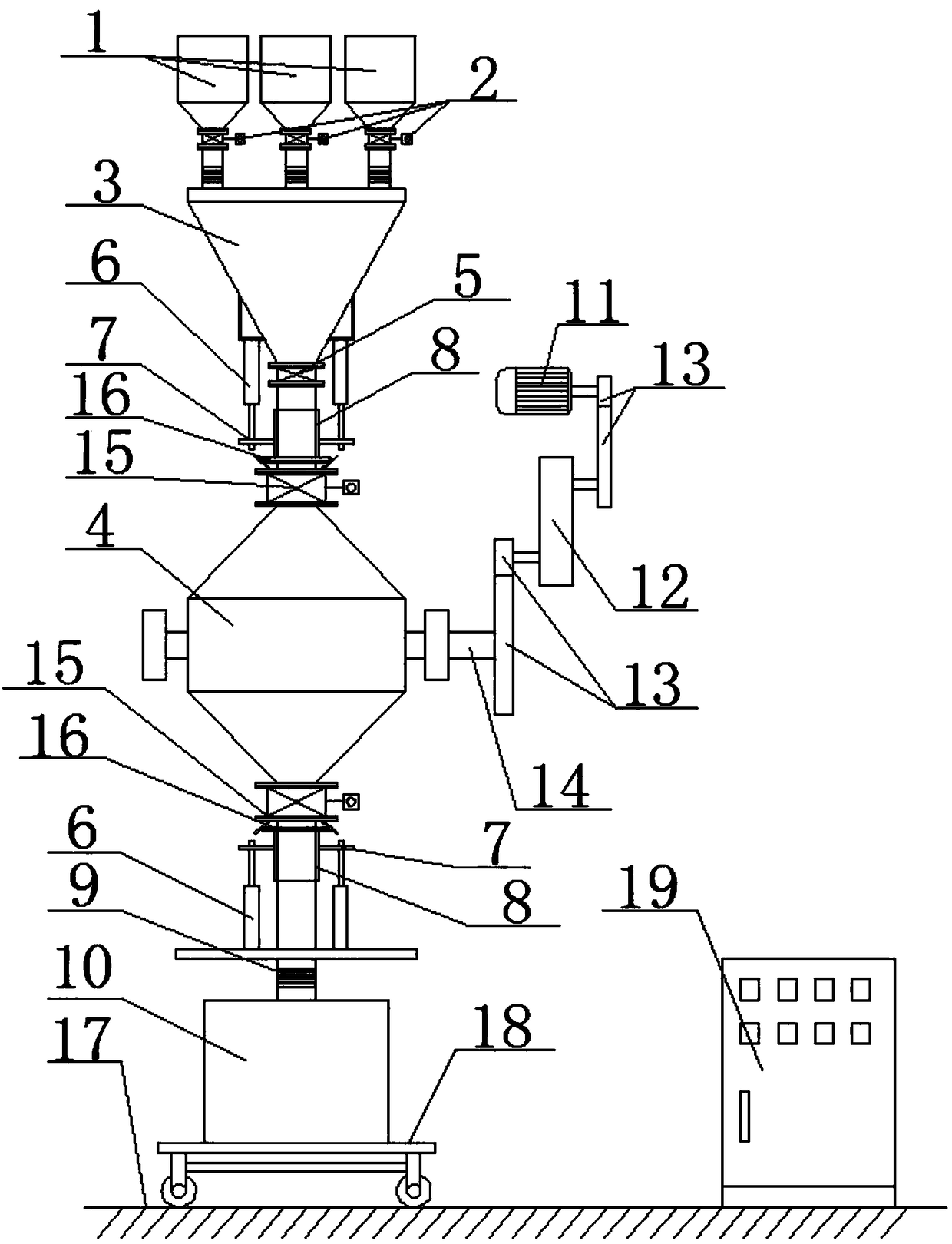

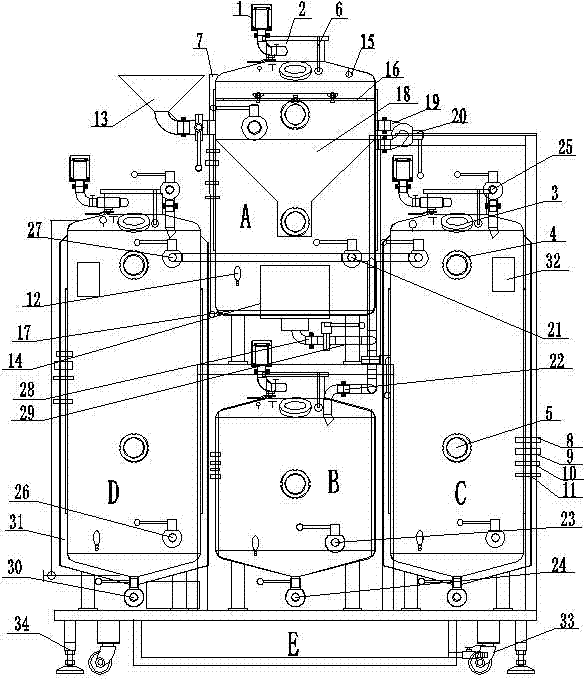

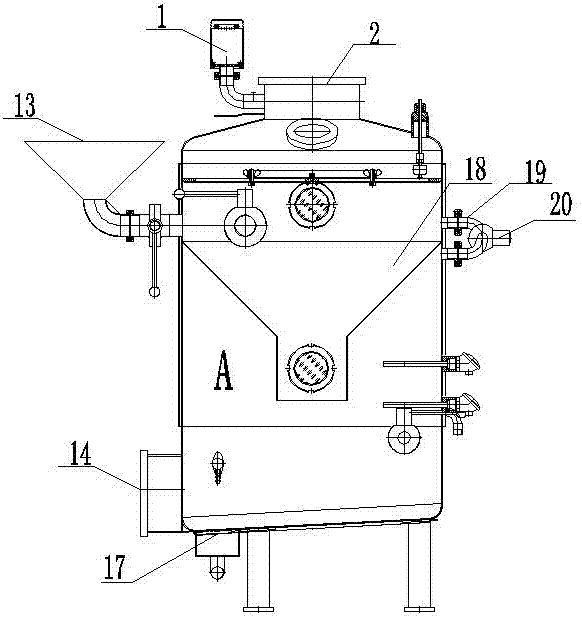

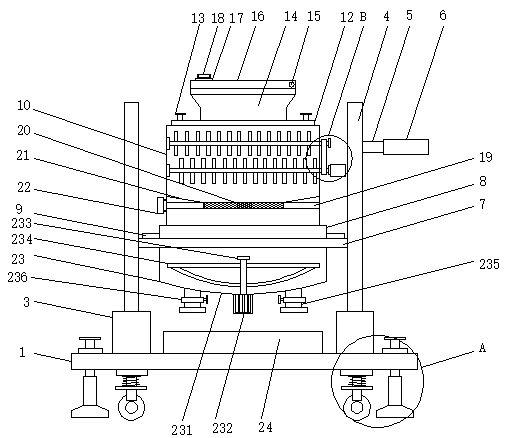

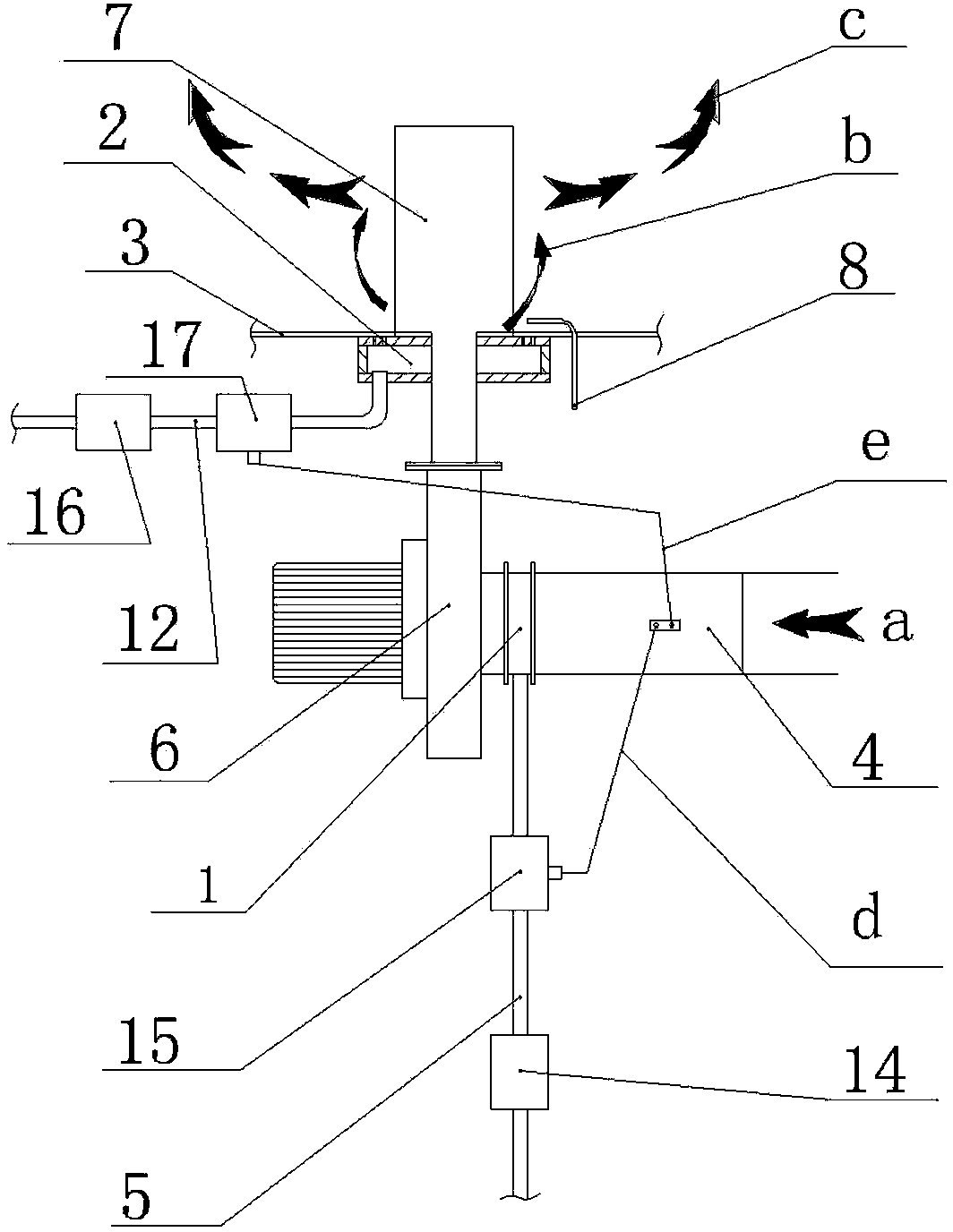

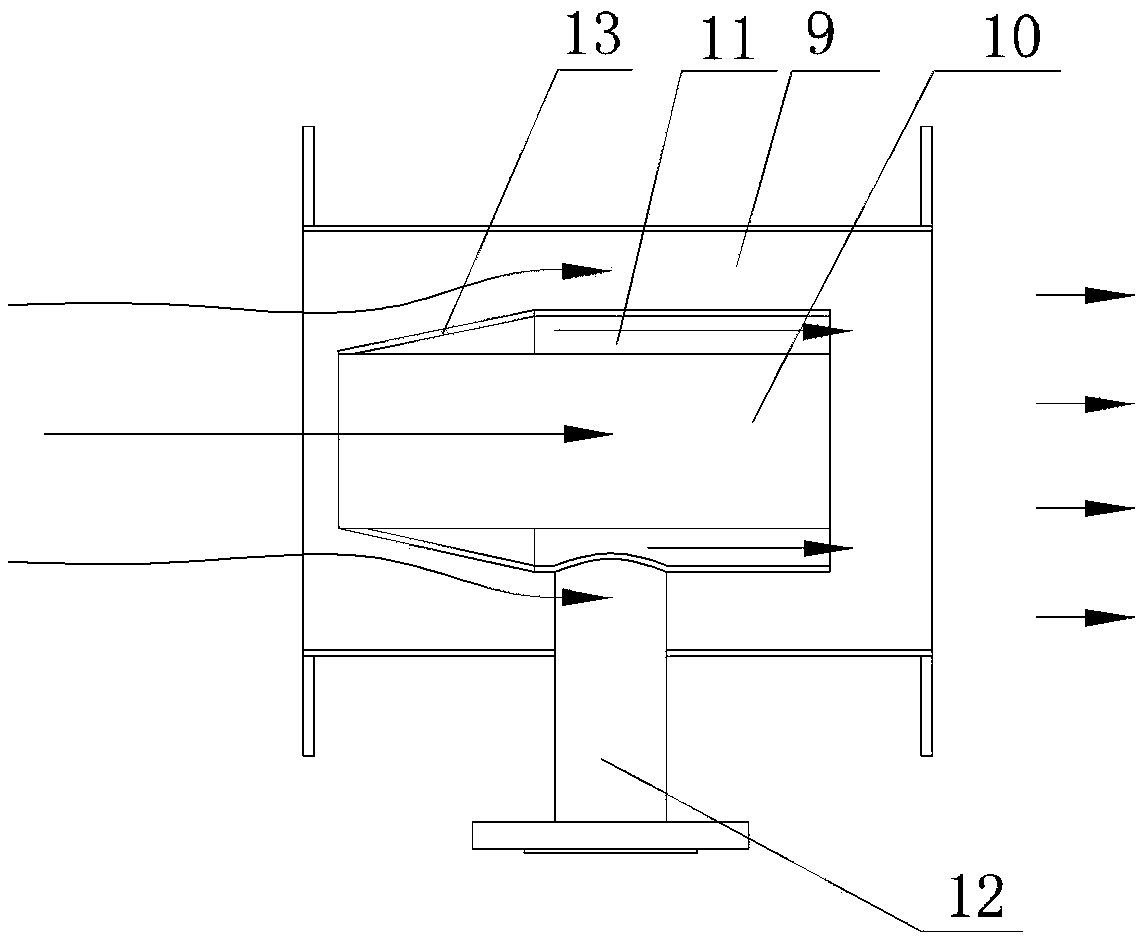

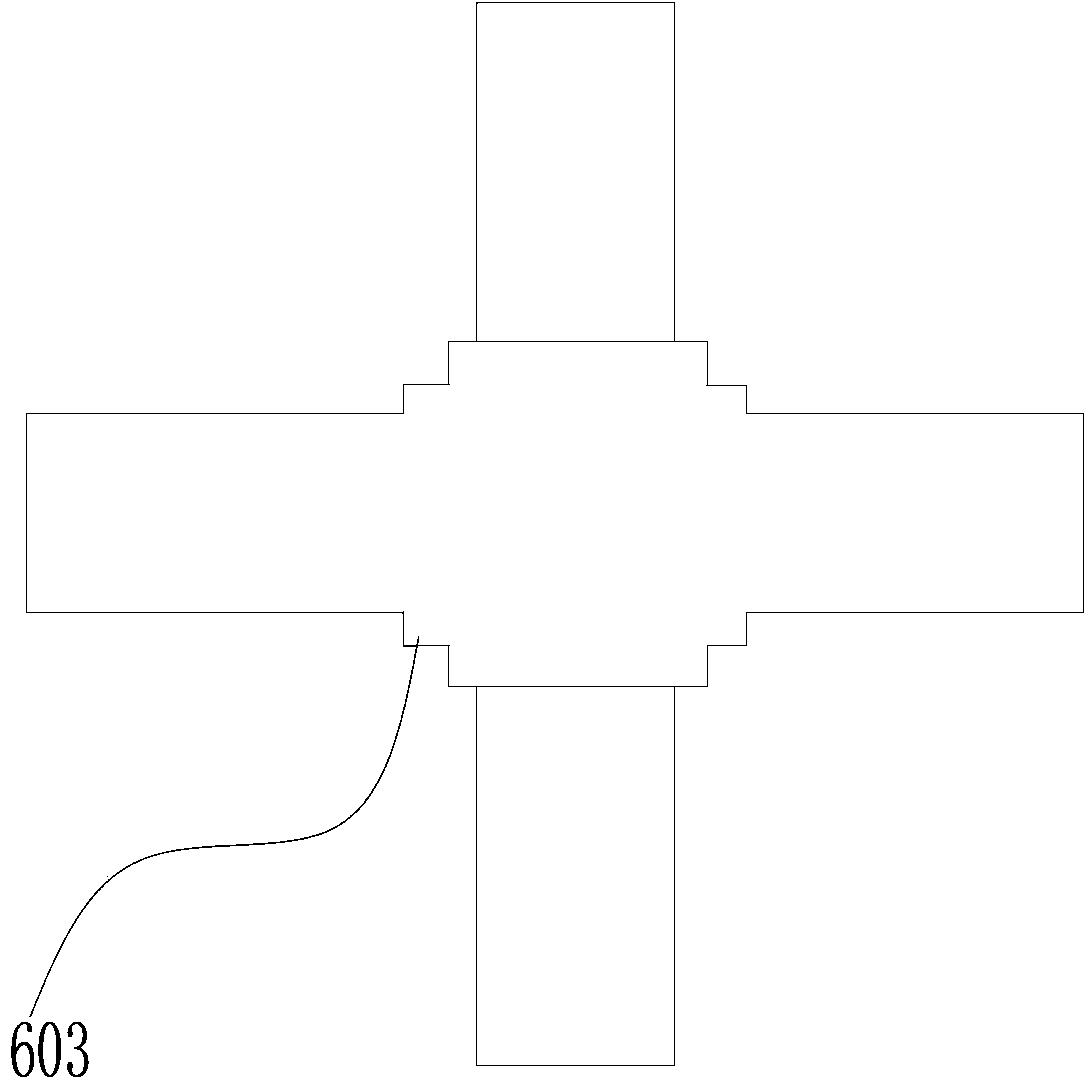

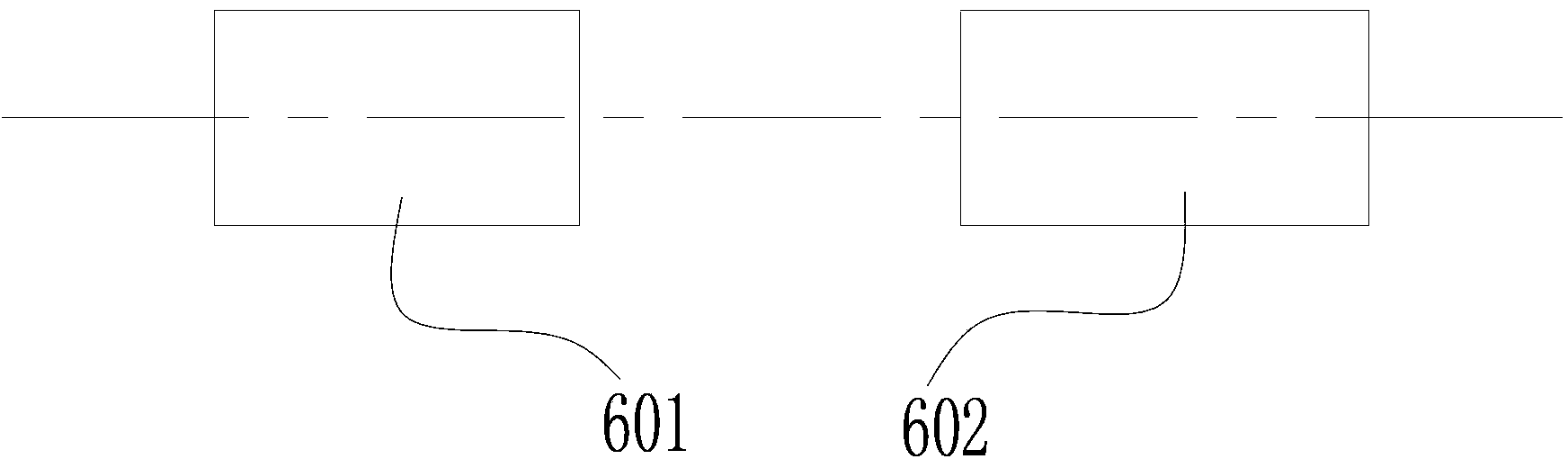

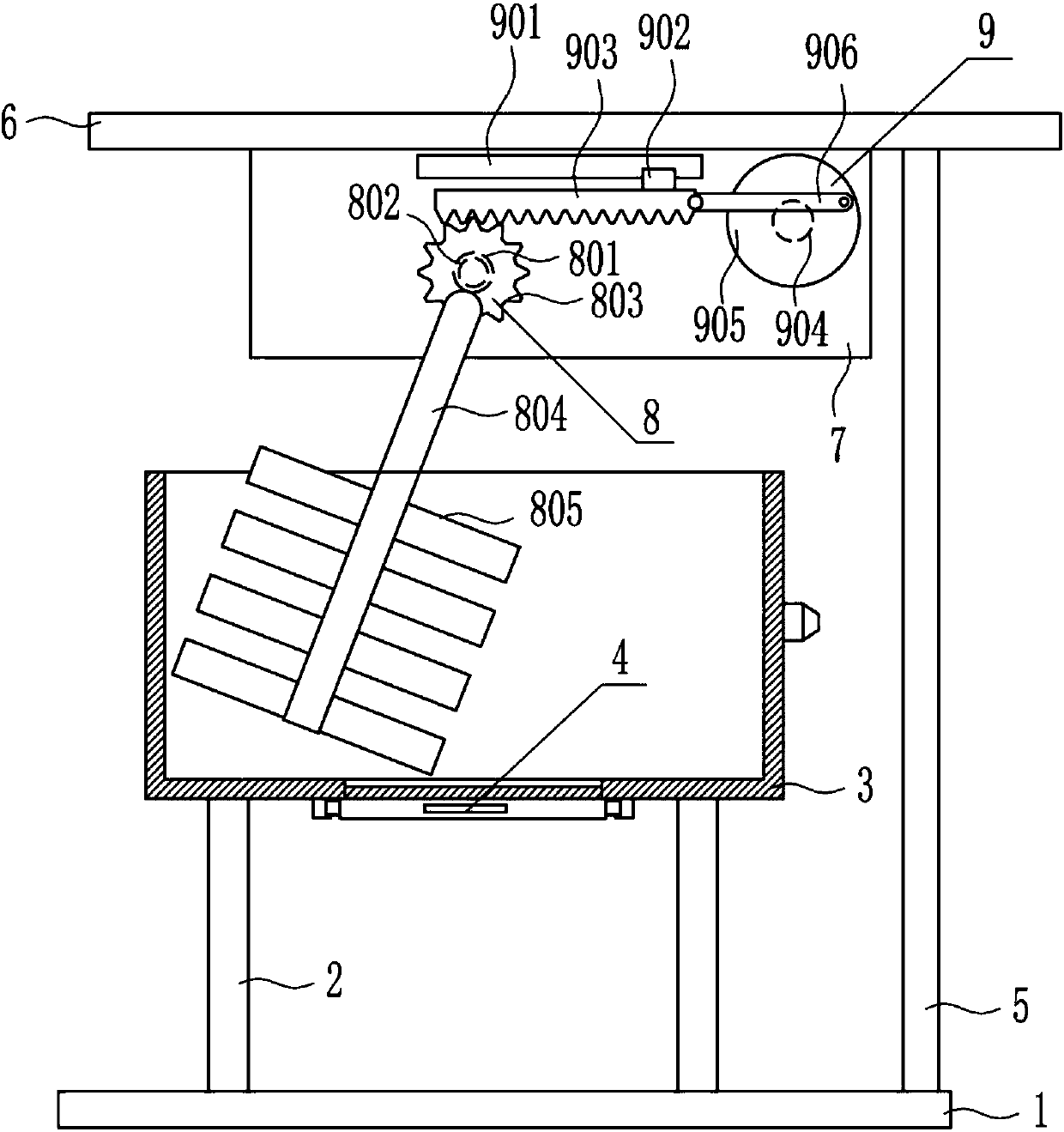

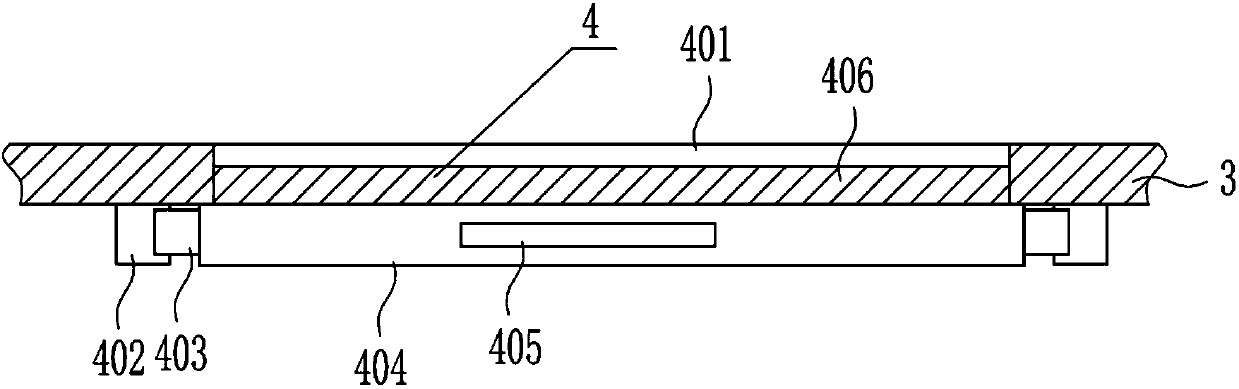

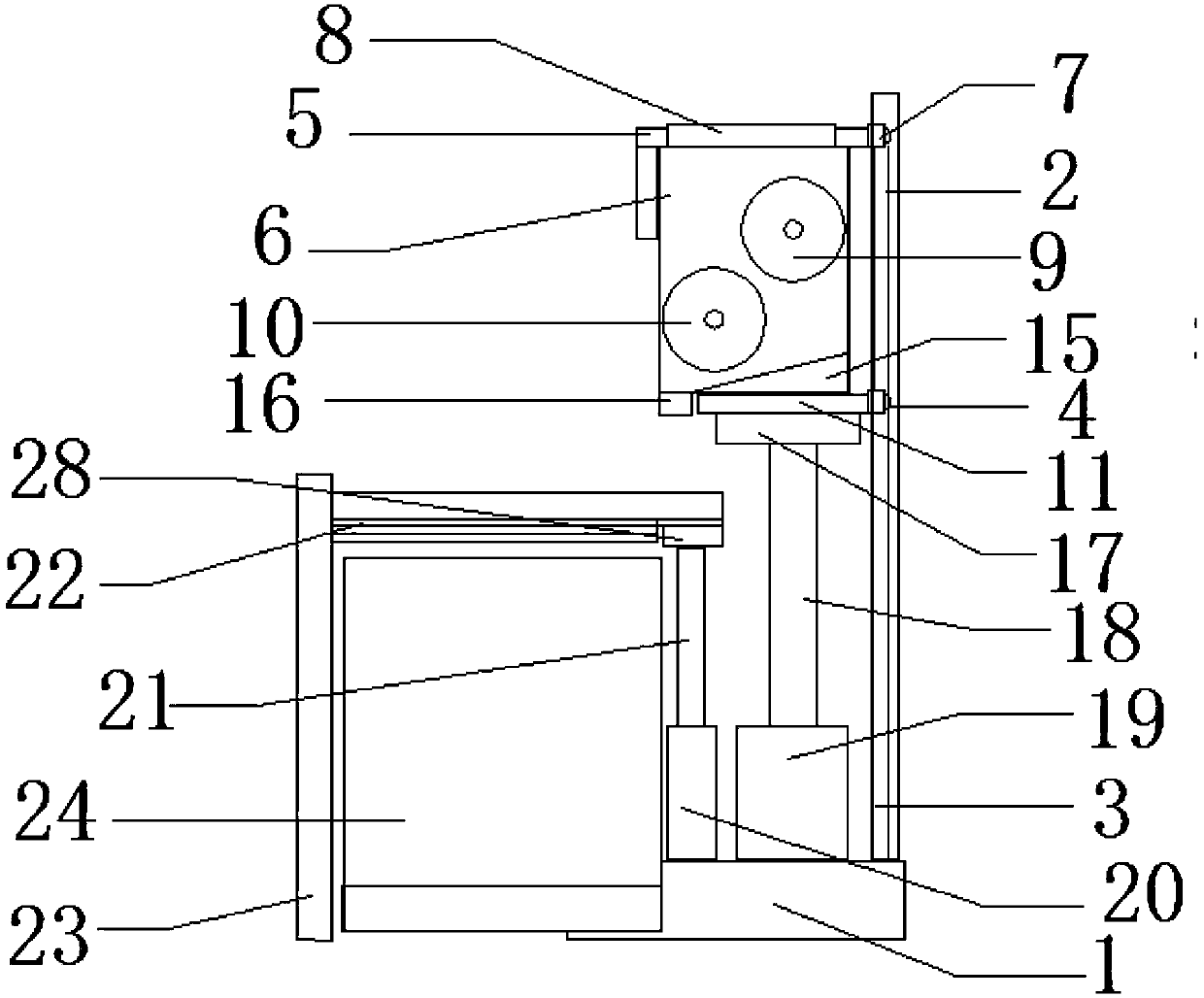

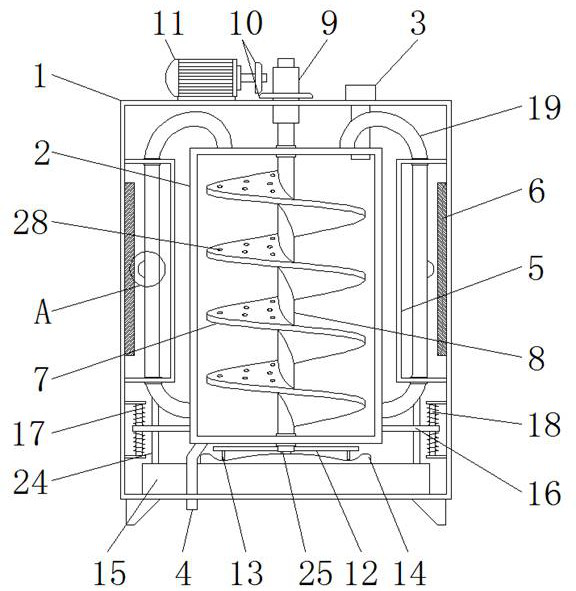

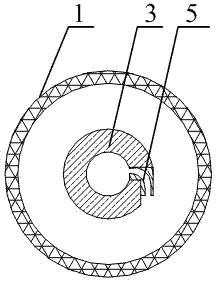

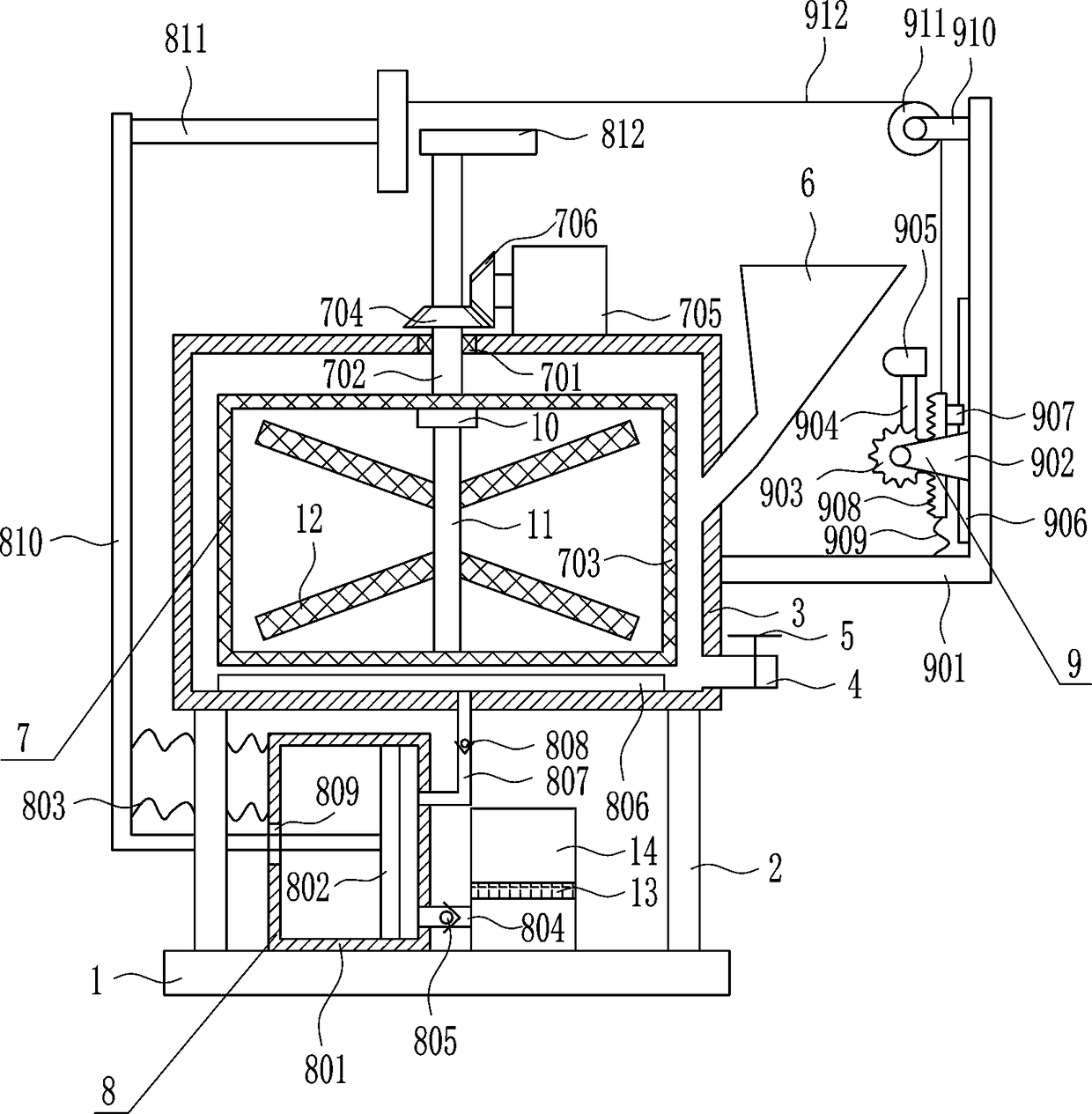

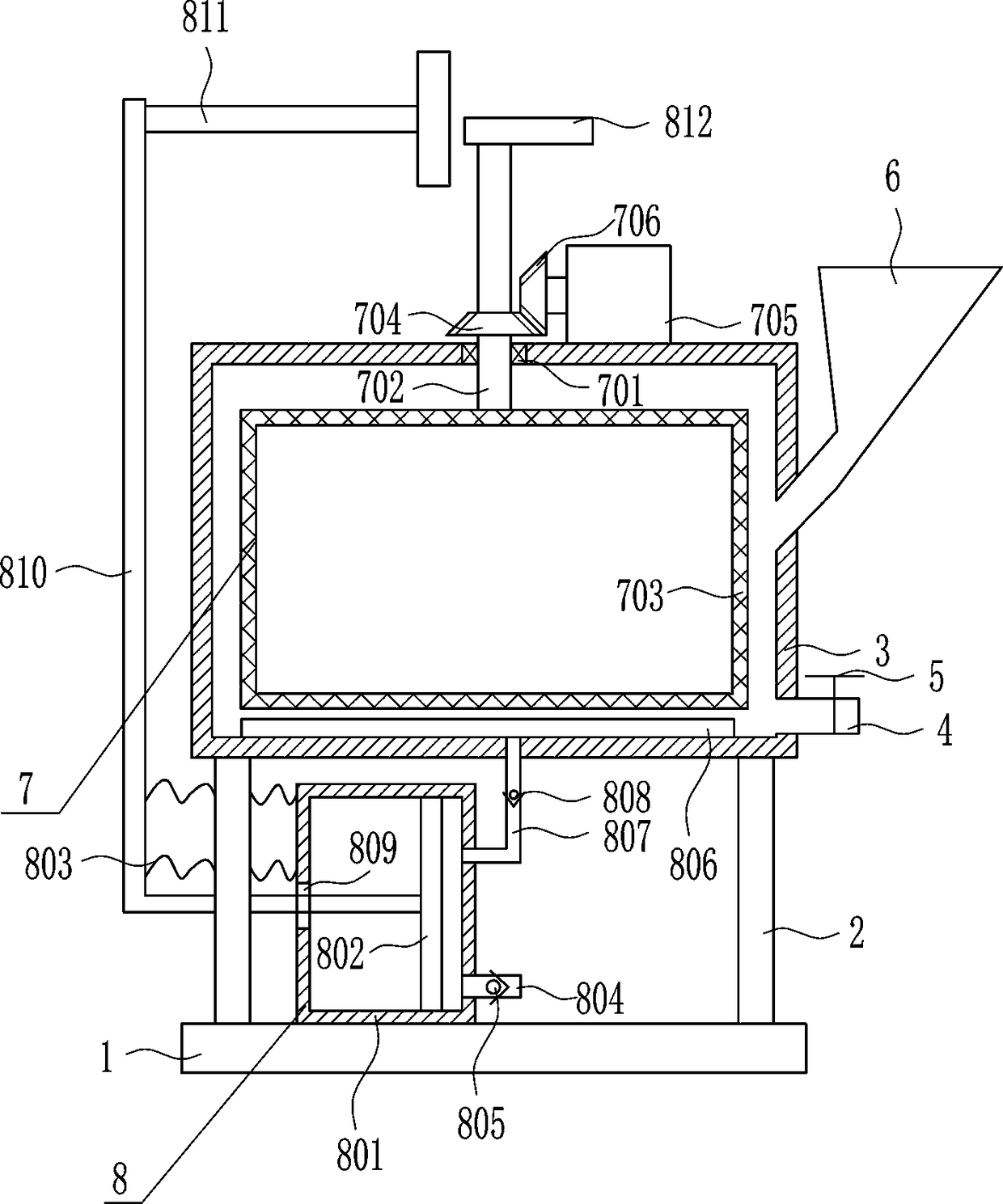

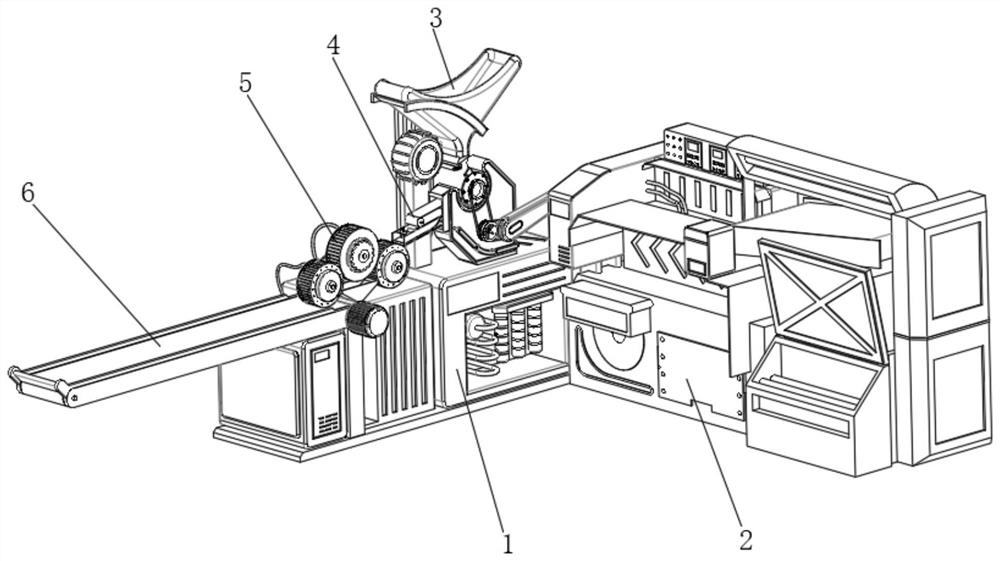

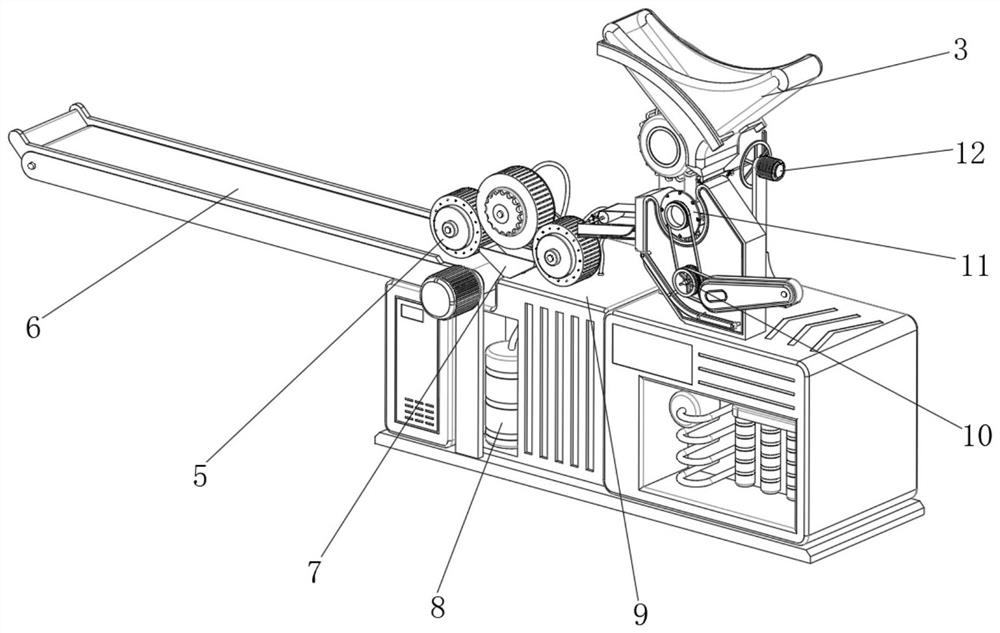

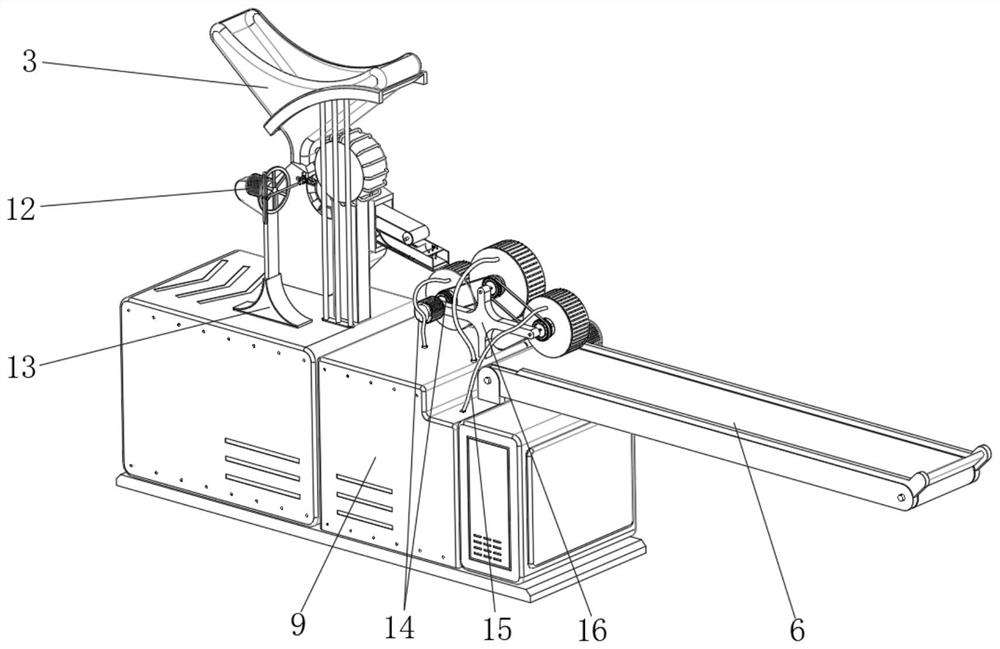

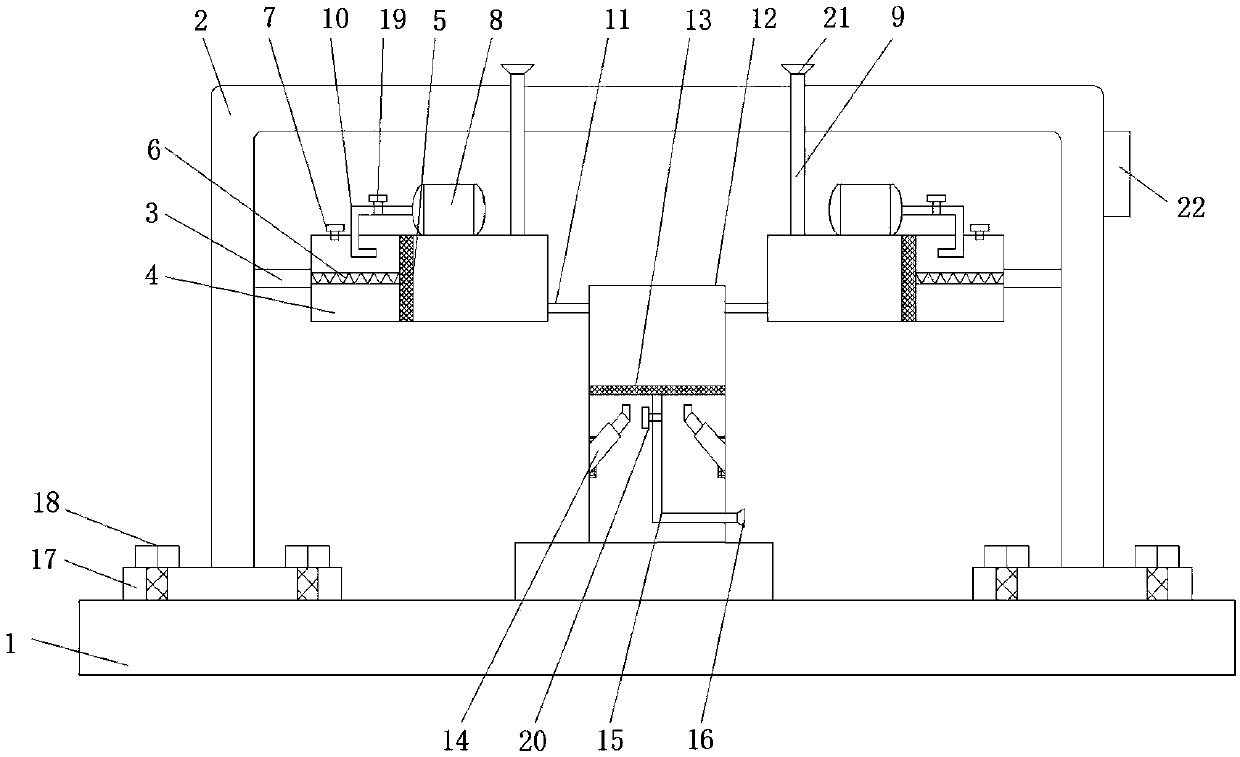

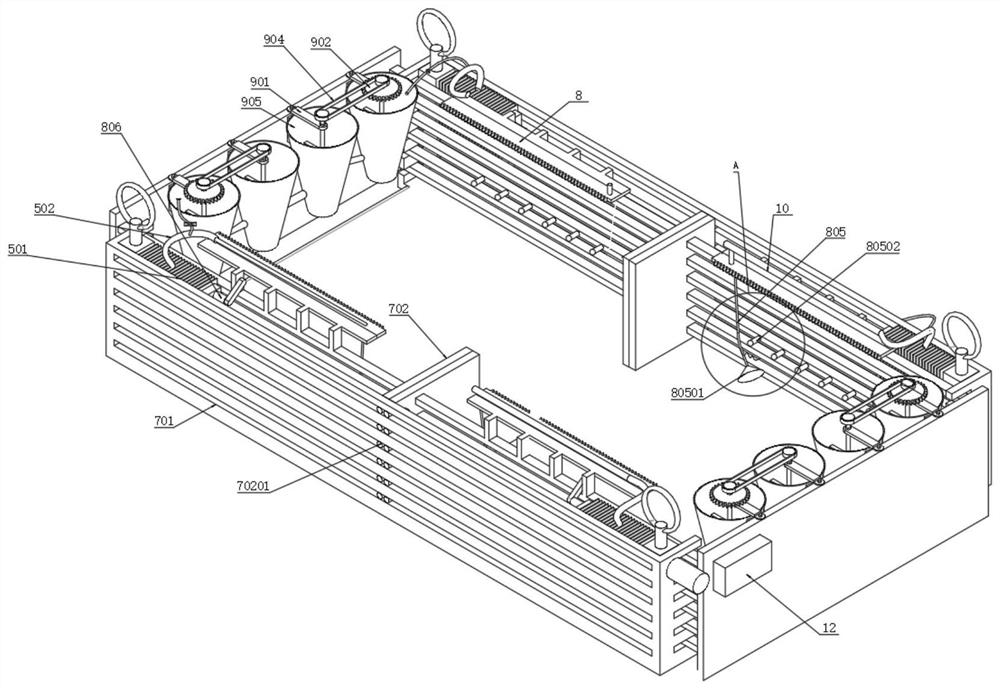

Ceramic fiber raw material automatic matching, mixing and charging device and control method

PendingCN109395642AImprove sealingAchieve the purpose of mixingRotating receptacle mixersMixer accessoriesFiberPhysical well being

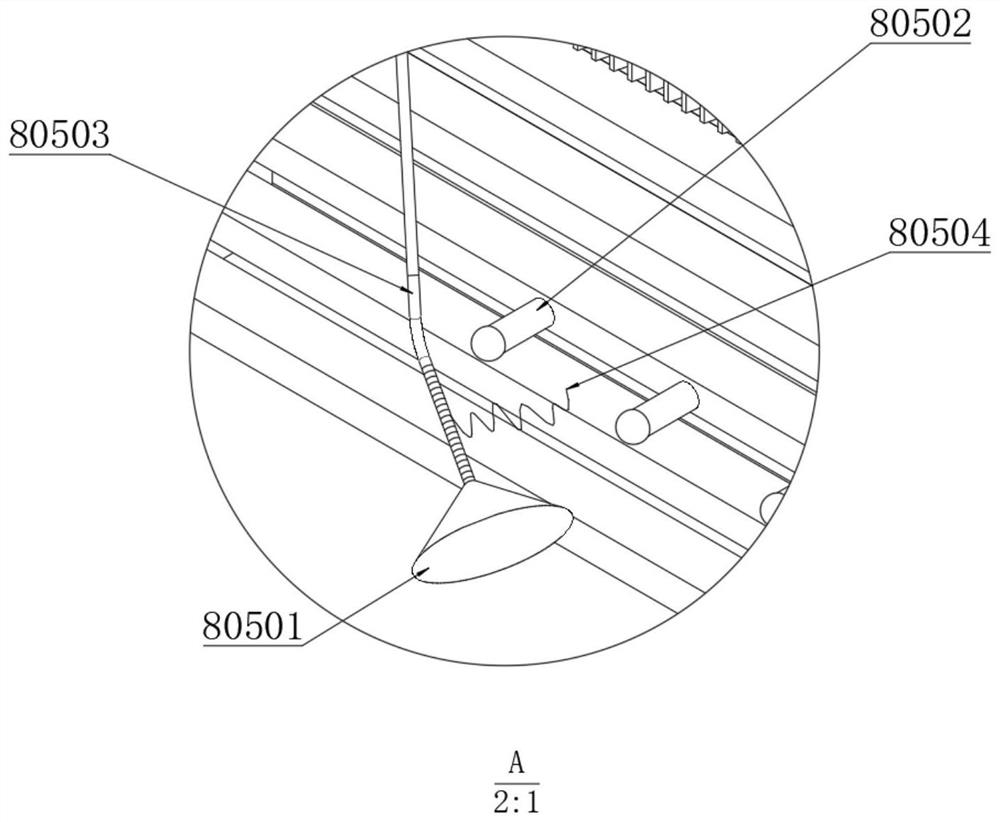

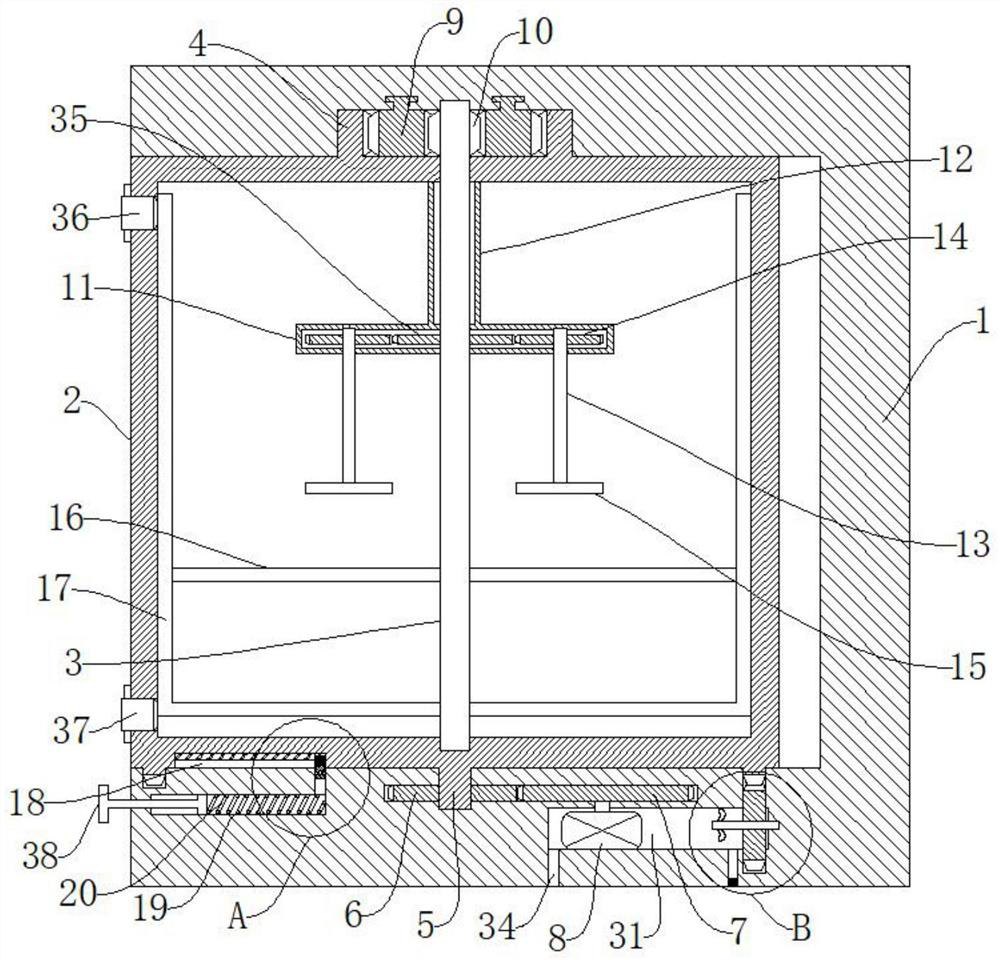

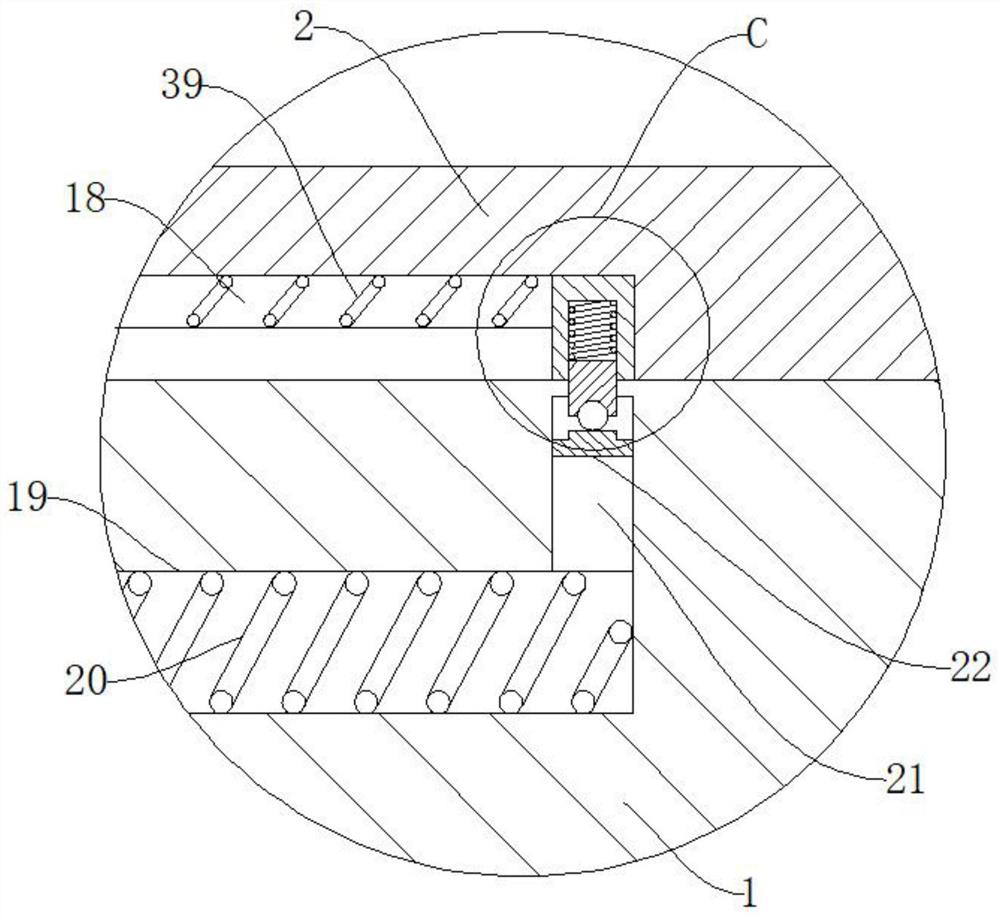

The invention discloses a ceramic fiber raw material automatic matching, mixing and charging device and a control method, and belongs to the technical field of refractory fiber production equipment. The device and the control method solve the problem in the prior art that the ratio of ceramic fiber raw materials is inaccurate, a lot of dust is generated in manual charging and discharging, the labor intensity is high, the environment and the health of workers are affected, the manufacturing cost is high, the work efficiency is low, the charging and discharging modes of the traditional mixing equipment are not environmentally friendly, and the degree of automation is low. The device comprises a storage device, a weighing device, a mixing device, a packaging device, a transportation device and an electrical control system arranged in sequence from top to bottom. The ceramic fiber raw material automatic matching, mixing and charging device and the control method are high in degree of automation, stability and safety factor, improve the working environment, achieve automatic charging and discharging of raw materials and mechanical lifting of the raw materials, greatly reduce labor intensity of the workers, save manpower and electricity and is short in mixing time, safe, sanitary and environmentally friendly.

Owner:INNER MONGOLIA HONGYANG HIGH TEMPERATURE THERMAL INSULATION MATERIAL TECH CO LTD

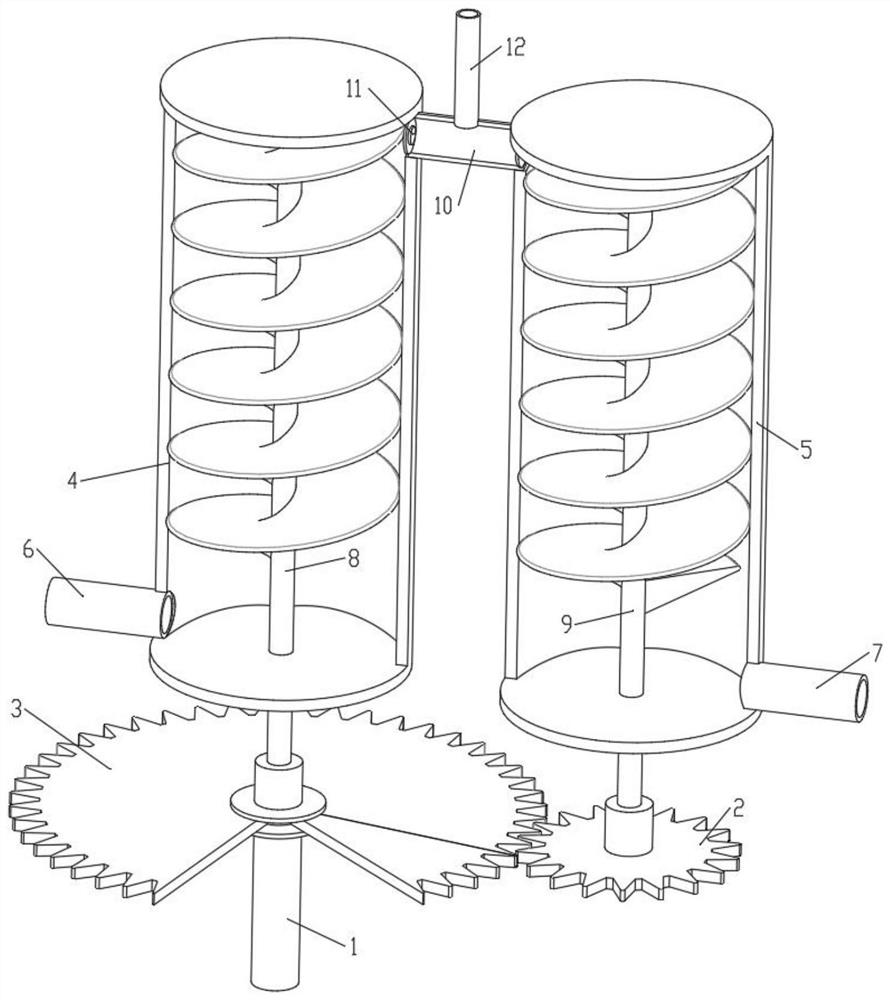

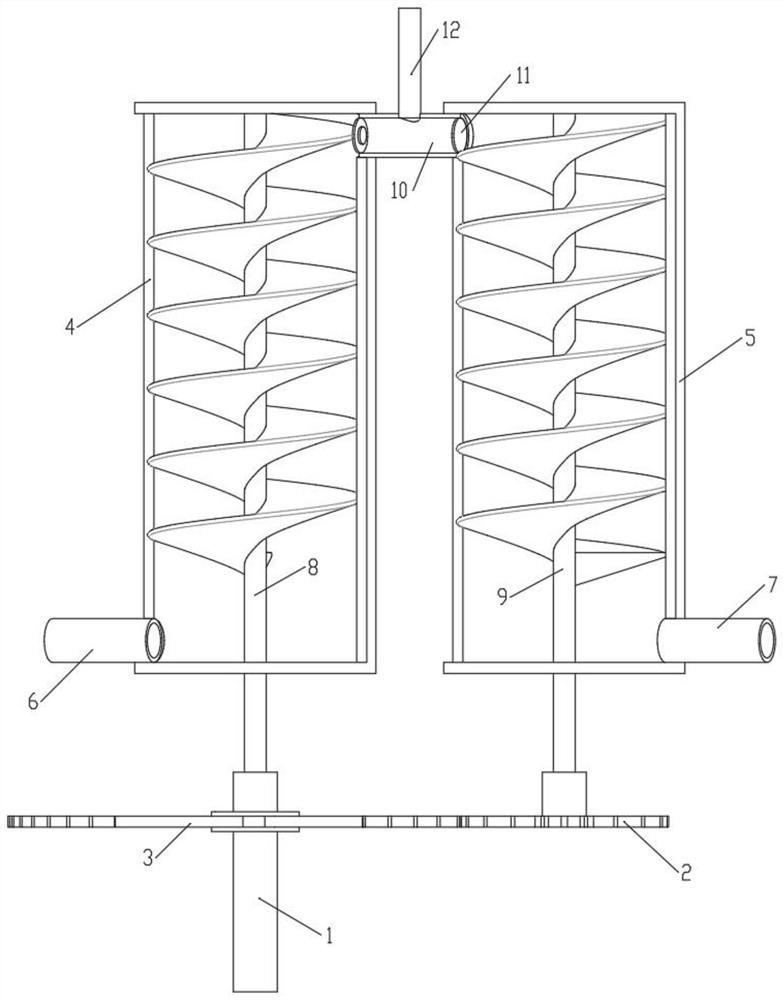

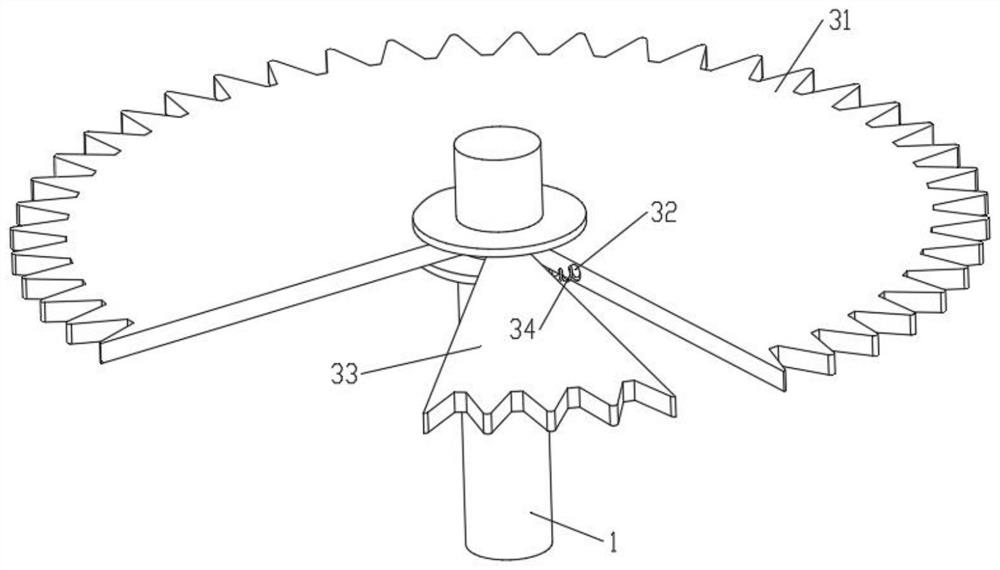

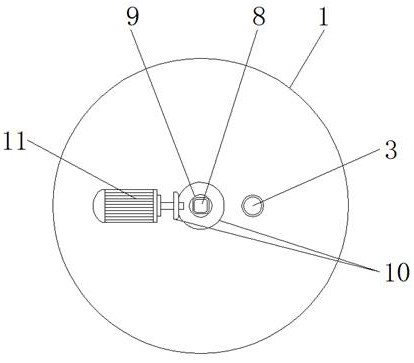

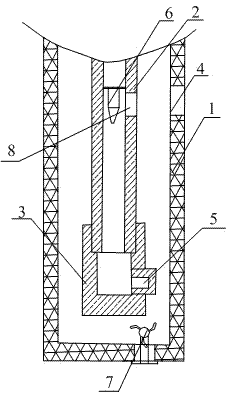

Self-circulation fermentation tank and multifunctional fruit wine brewing device

The invention discloses a self-circulation fermentation tank and a multifunctional fruit wine brewing device with the fermentation tank. The self-circulation fermentation tank is provided with a self-circulation apparatus for realizing automatic circulation stirring, the self-circulation apparatus includes a gas collecting unit disposed in the fermentation tank, a by-pass pipe disposed on the outer side wall of the fermentation tank and an autocontrol bypass-valve, as well as a liquid level sensor, an upper slag stopping movable sieve plate and a bottom slag stopping movable sieve plate that are disposed in the fermentation tank. The self-circulation fermentation tank can realize automatic circulating stirring of mash without additional circulating stirring equipment and power consumption, the fermentation process can be carried out smoothly, and the skin residue cover can be completely eliminated. In addition, the invention also discloses a multifunctional fruit wine brewing device integrating fermentation, filtration, pressing, clarification, wine storage and on-line real-time monitoring of temperature, pH value, alcohol content and residual sugar, and the multifunctional fruit wine brewing device has the advantages of perfect function, sealed whole course, energy saving and environmental protection, high yield of high-quality wine, and good wine quality.

Owner:王冠轶

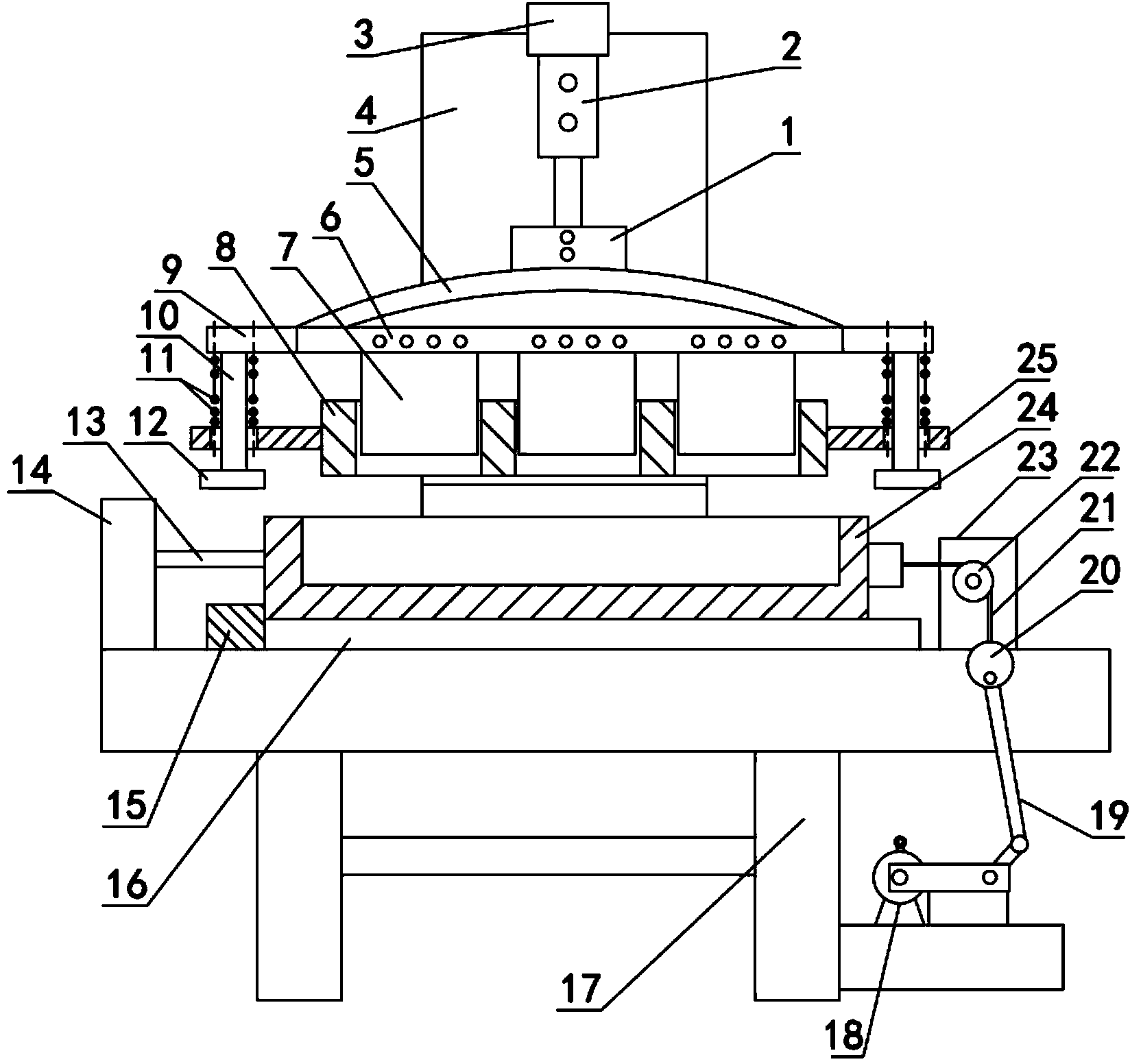

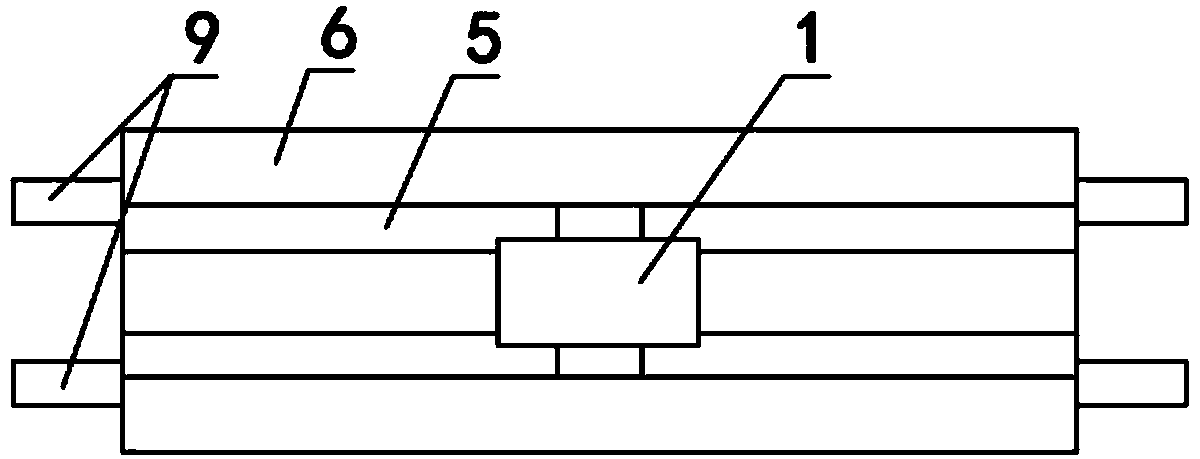

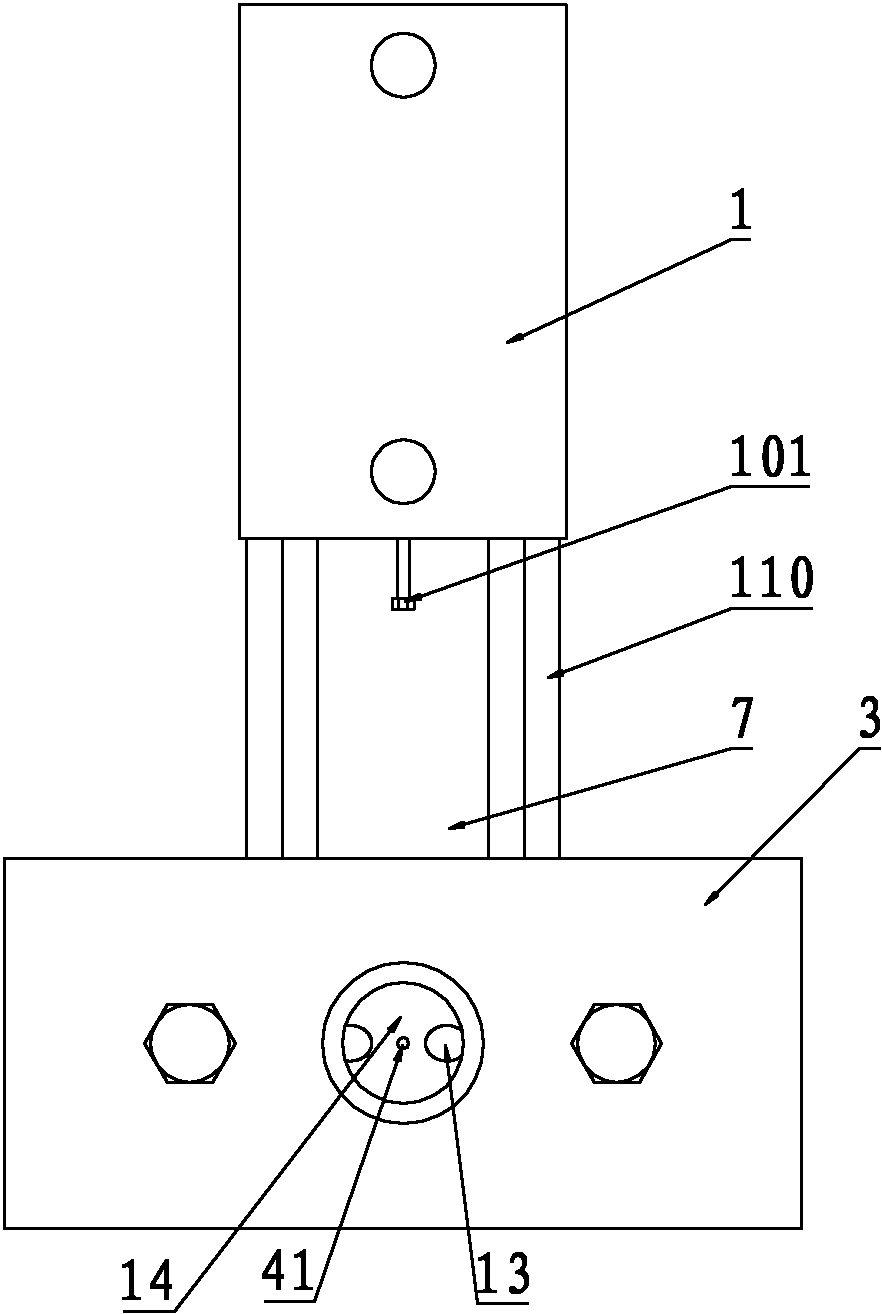

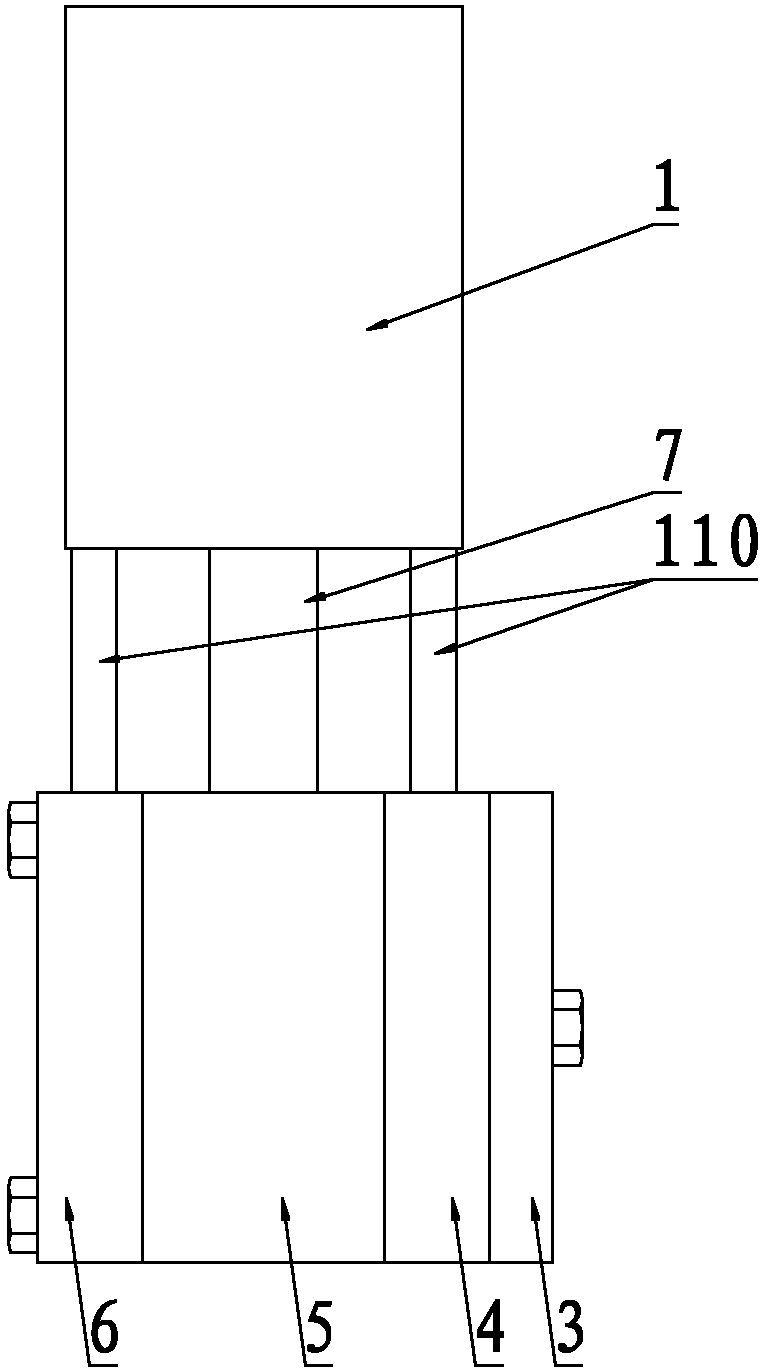

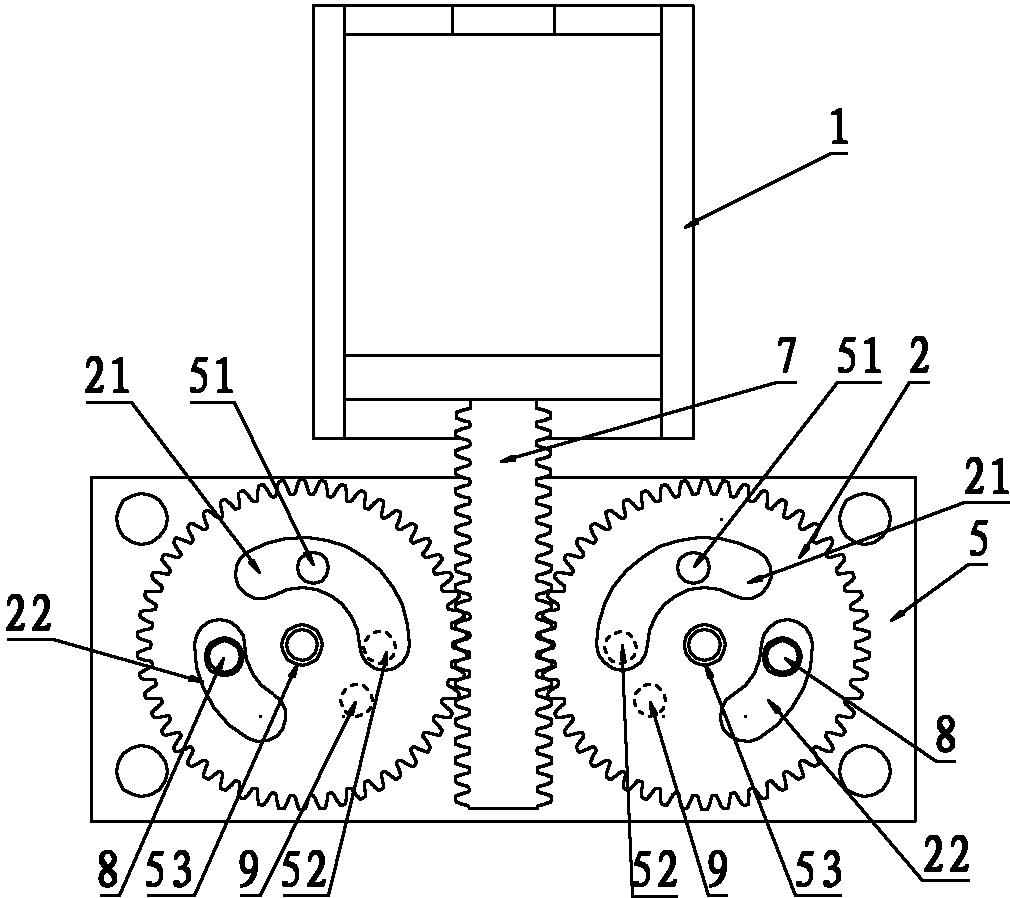

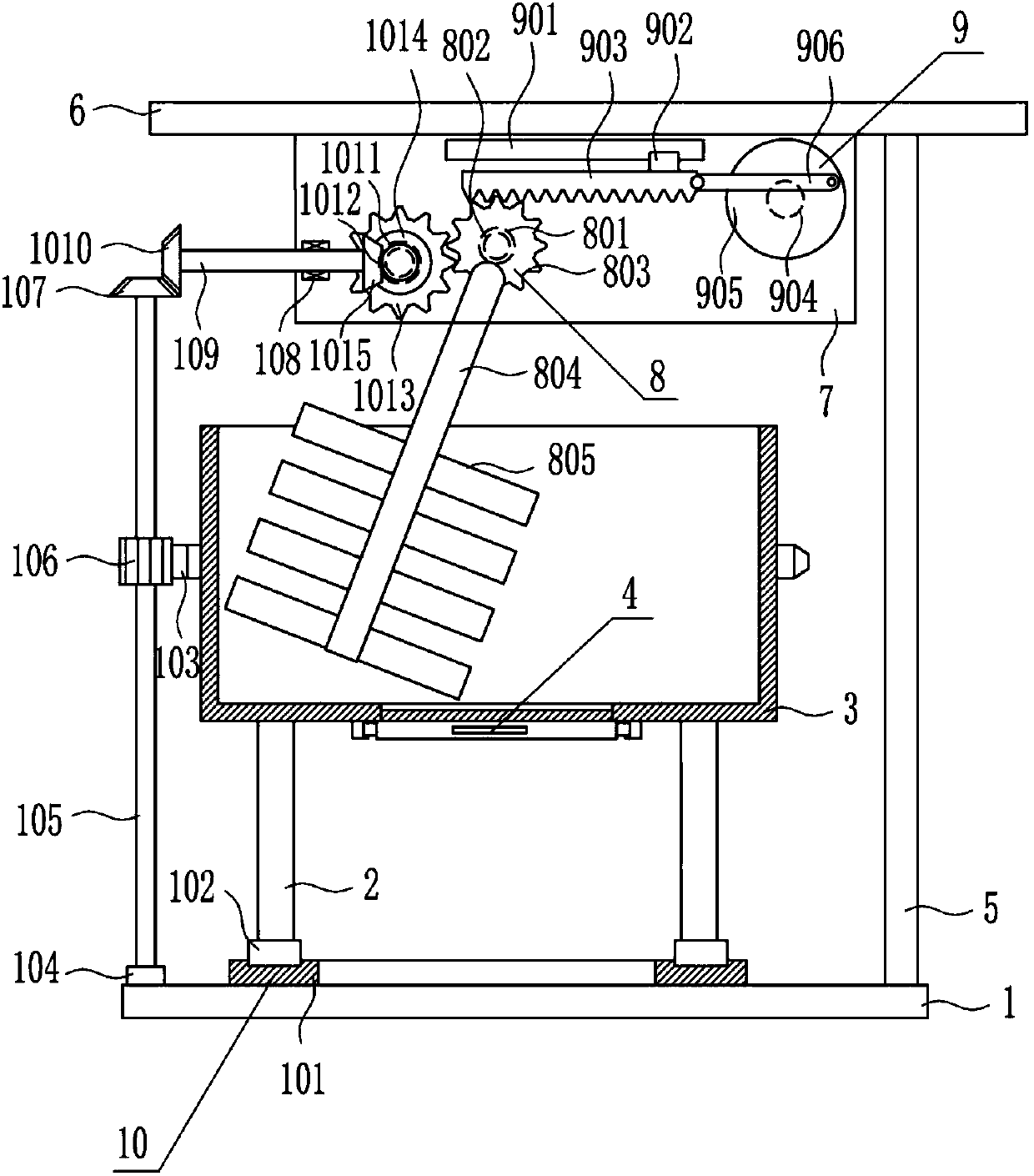

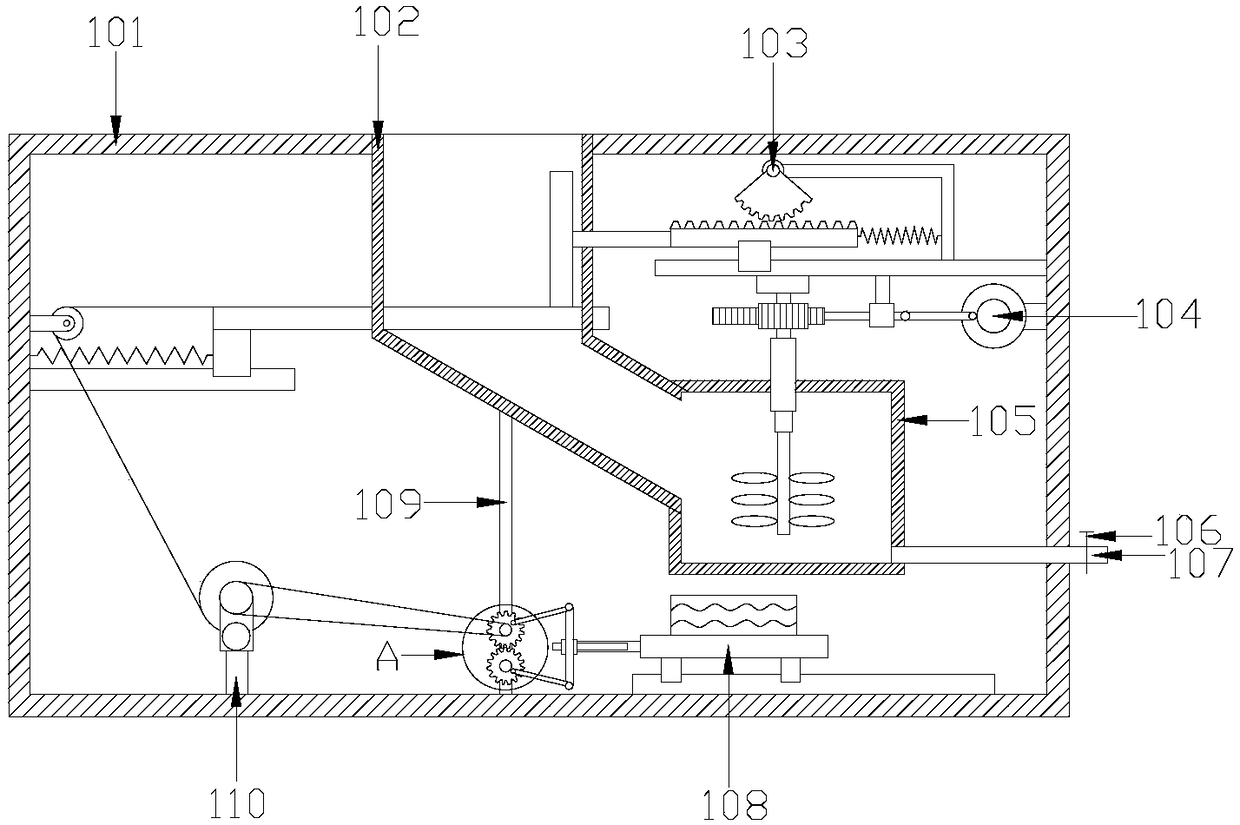

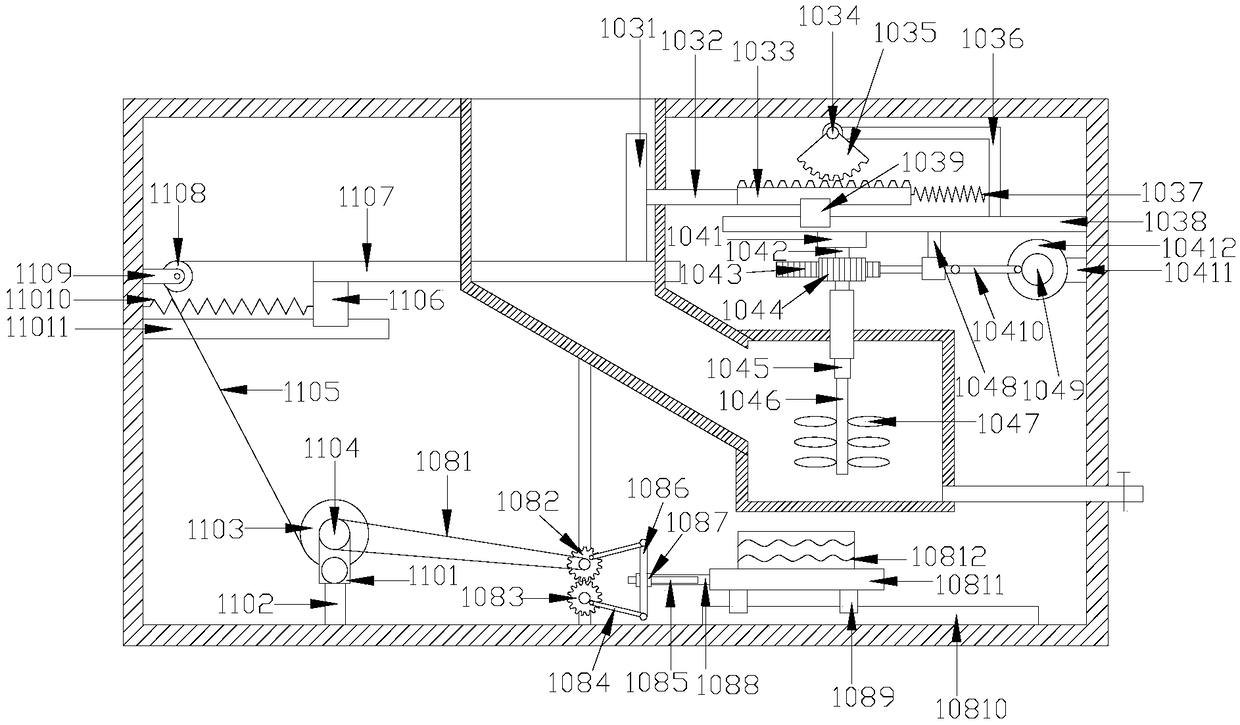

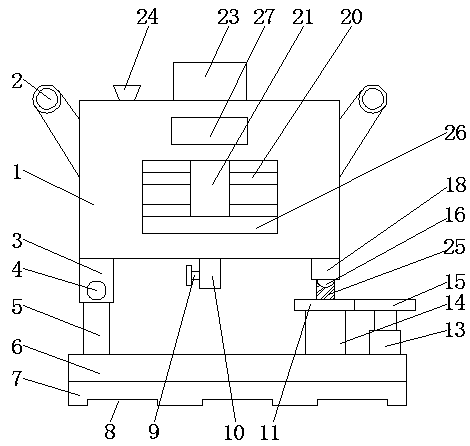

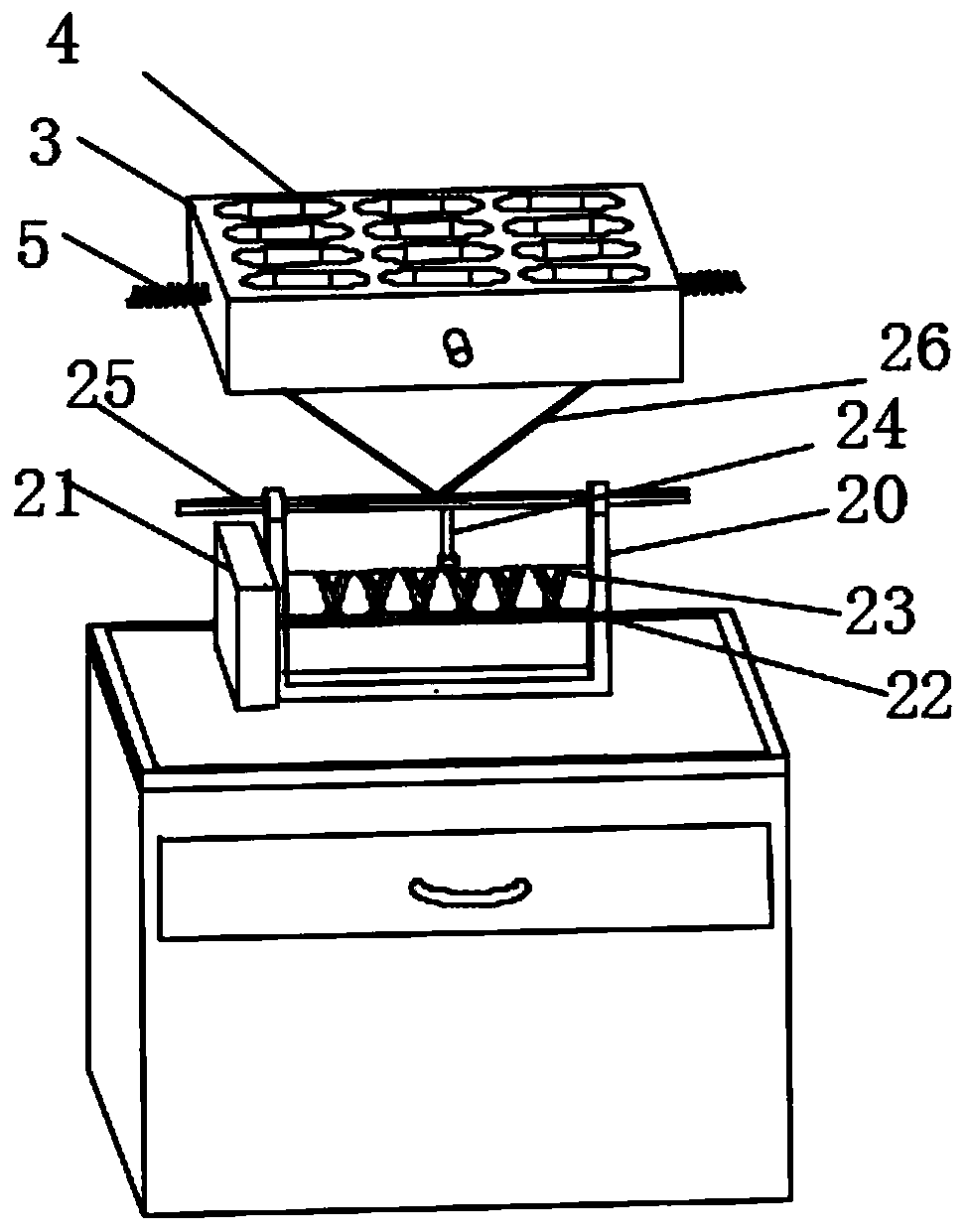

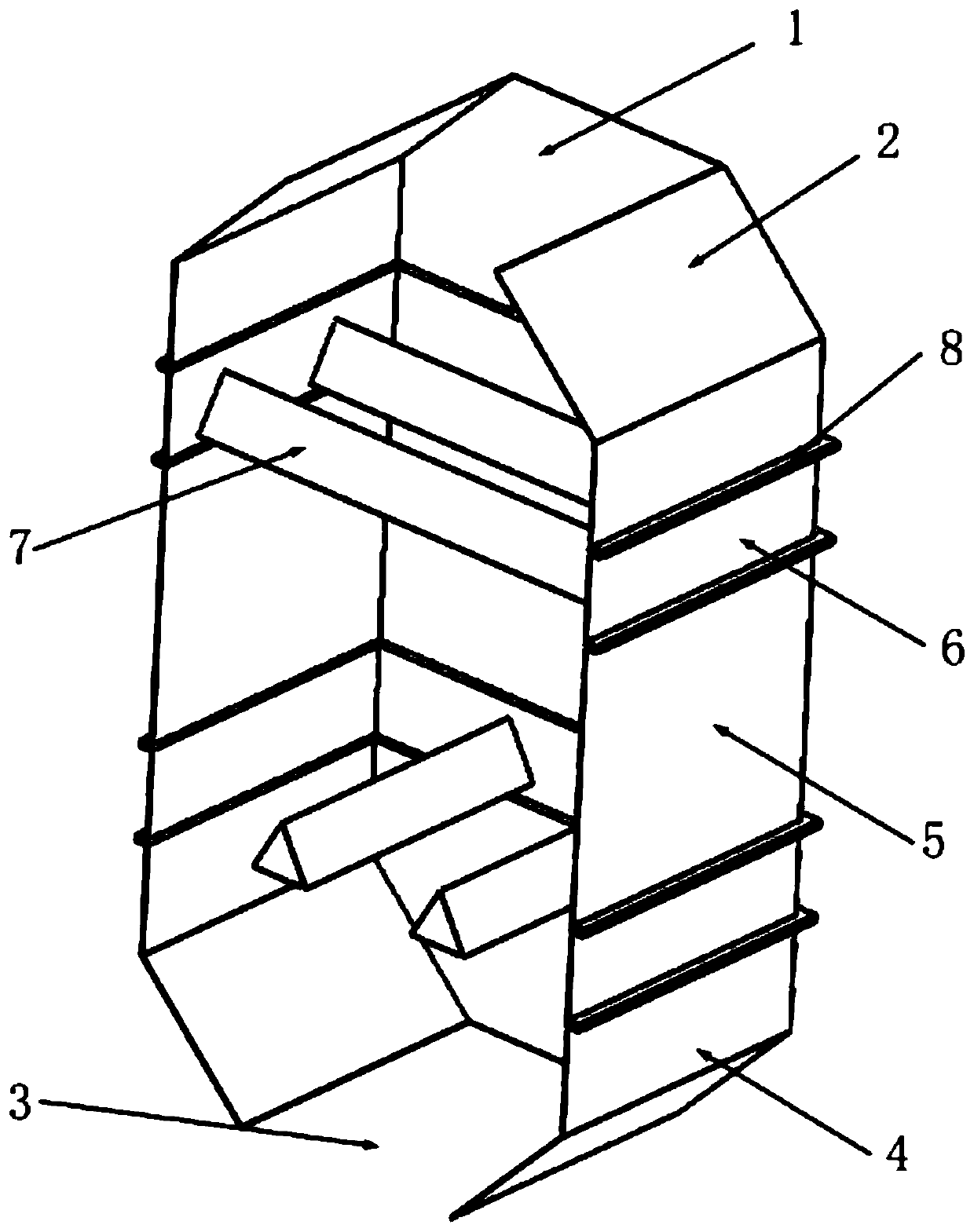

Pressing-cutting integrated type roam raw material cutting device capable of mixing materials through crankshaft and connection rod

ActiveCN103962203AAchieve the purpose of mixingSimple structureGrain treatmentsHydraulic cylinderPulp and paper industry

The invention relates to a pressing-cutting integrated type foam raw material cutting device capable of mixing materials through a crankshaft and a connection rod and belongs to the technical field of the foam raw material cutting. The pressing-cutting integrated type foam raw material cutting device comprises a working table, wherein a supporting leg is vertically fixed on the working table; a mounting bracket is mounted at the top of the supporting leg; 2-4 guide rails are transversely arranged on the working table in parallel; cutting grooves capable of sliding are formed in the guide rails; driving mechanisms are arranged on the right sides of the cutting grooves and used for pulling the cutting grooves rightwards; a cutting mechanism and a pressing mechanism are arranged above the cutting grooves and mutually matched; the cutting mechanism comprises a vertical hydraulic cylinder and a horizontal cutter base; cutter groups in equidistant arrays are mounted at the bottom of the cutter base; a cylinder body of the hydraulic cylinder is fixed at the bottom of the mounting bracket; a piston rod of the hydraulic cylinder is connected with the cutter base through a pushing bracket; return mechanisms are arranged on the left sides of the cutting grooves. The pressing-cutting integrated type foam raw material cutting device is simple in structure, simple to operate, short in cutting time, low in use cost and maintenance cost, time-saving and labor-saving.

Owner:CHONGQING GUOHUA PACKAGING PROD

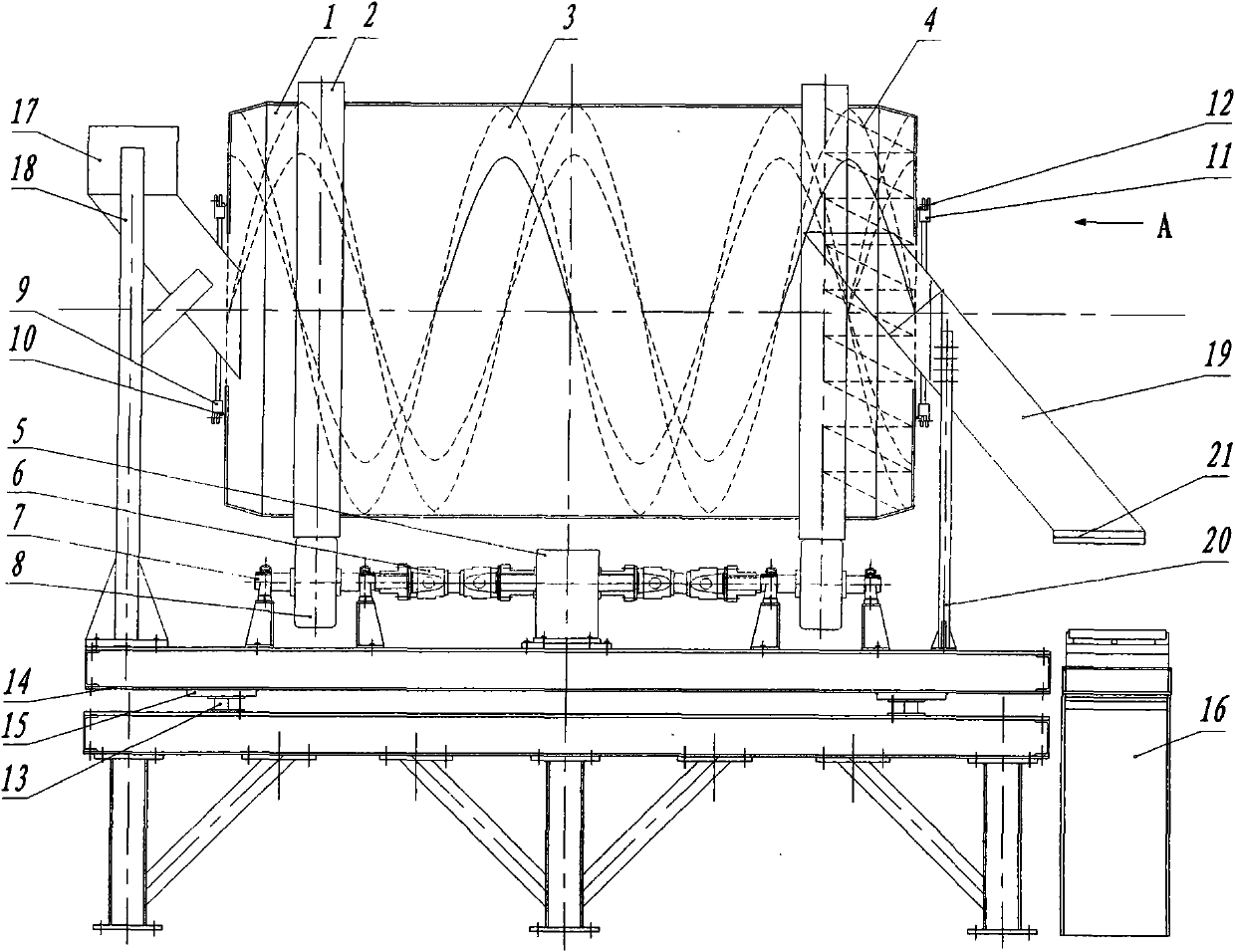

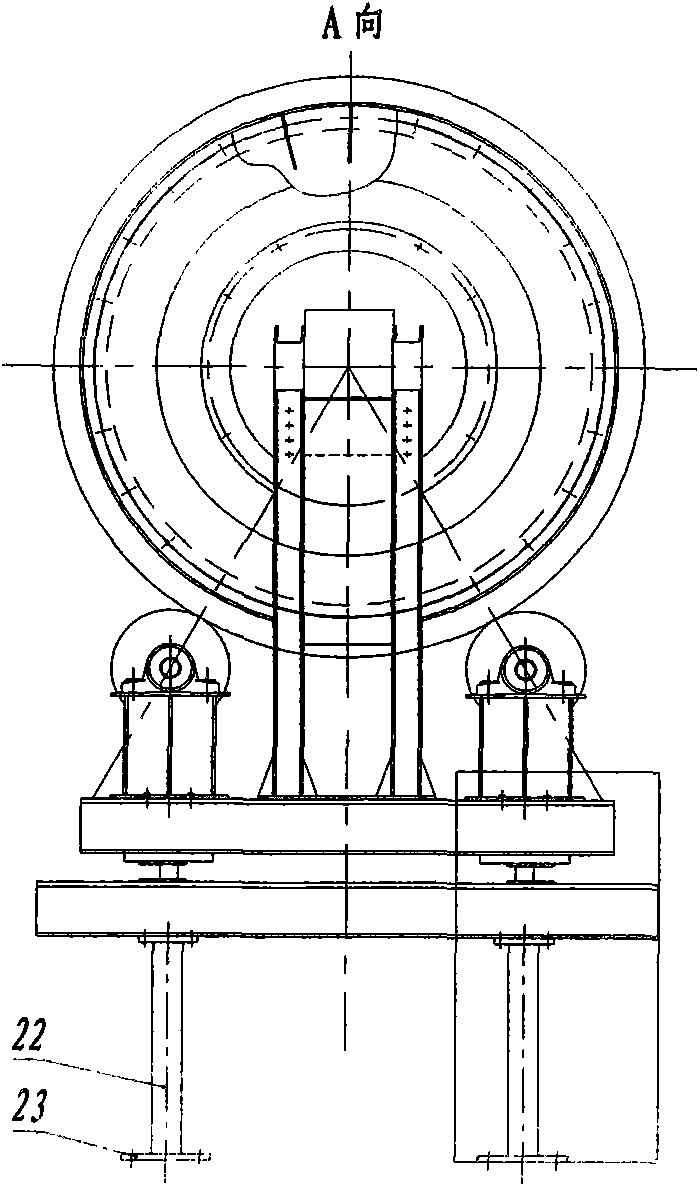

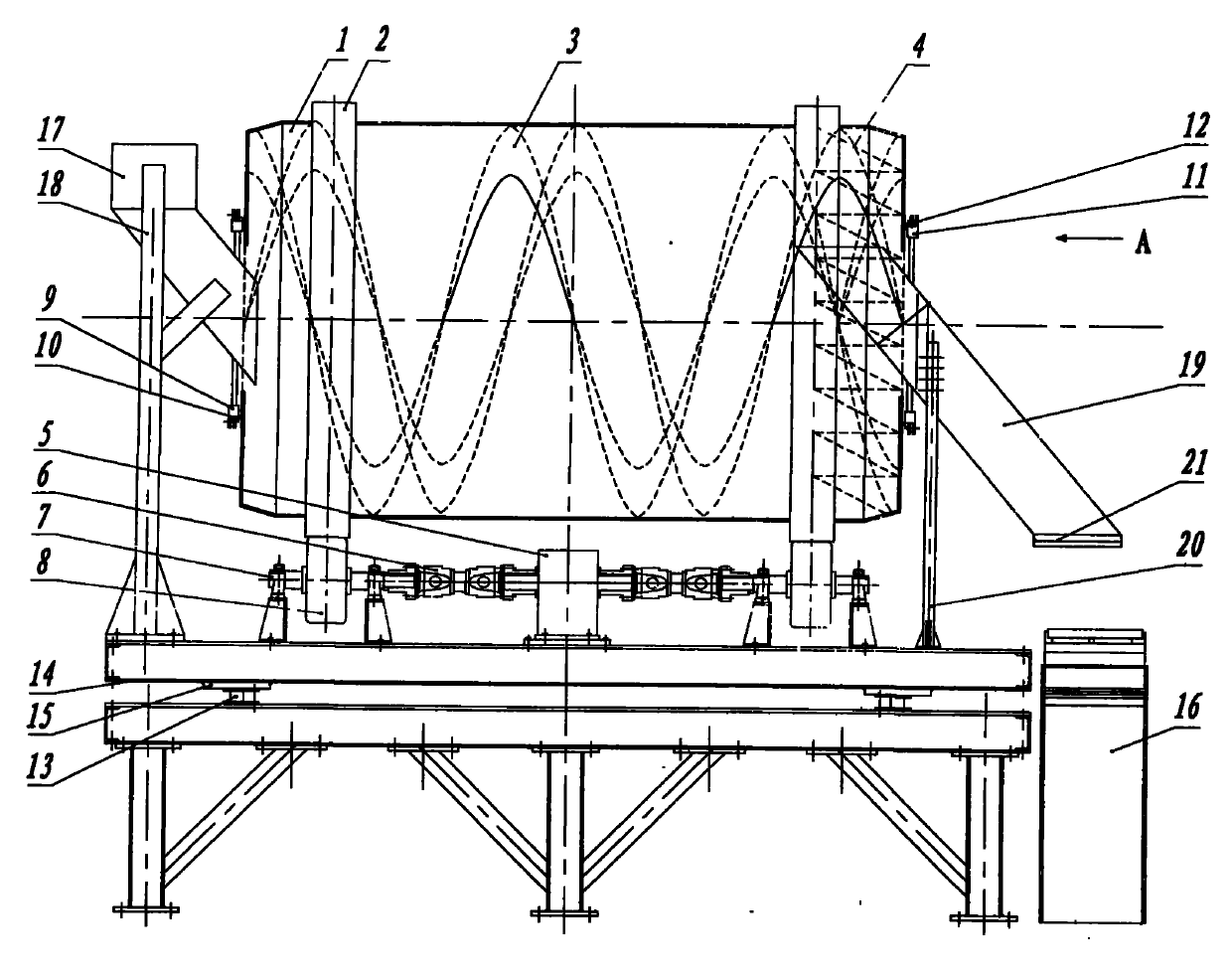

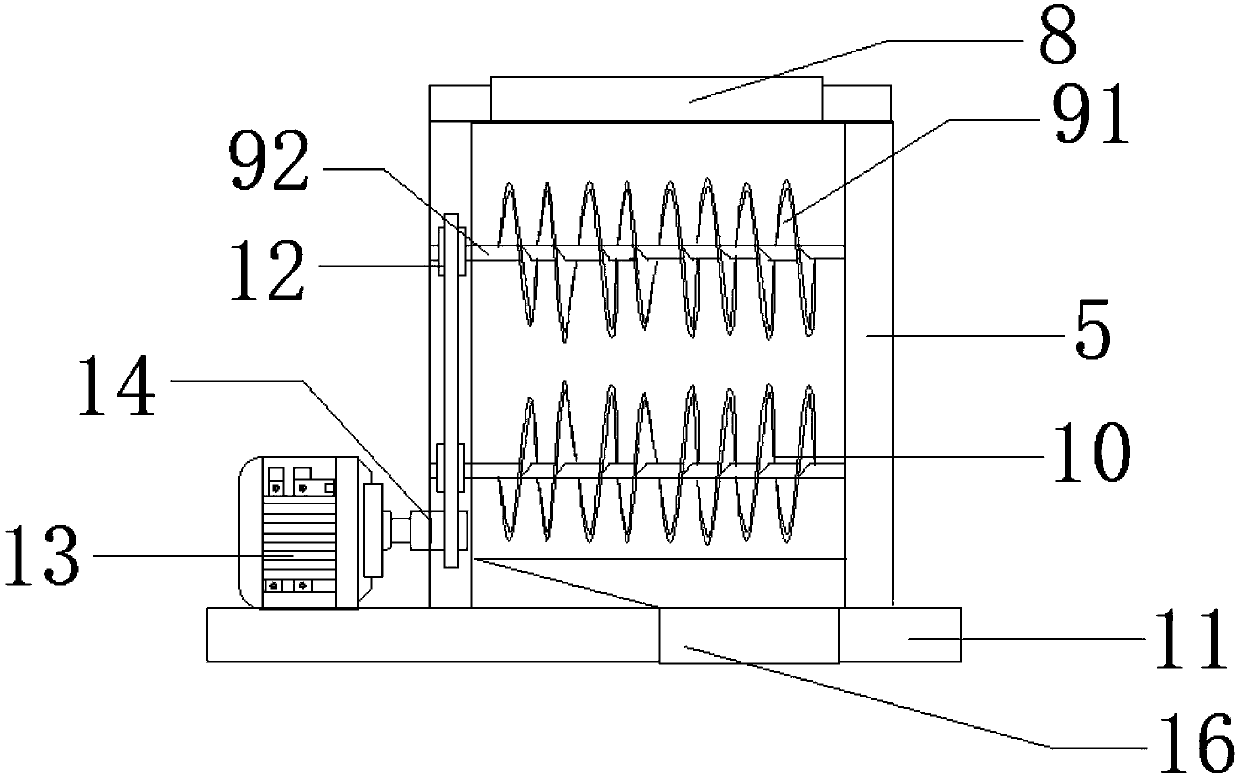

Mixer for mixing rubber and plastic particles

The invention relates to a mixer for mixing rubber and plastic particles, which comprises a mixing roller device and a transmission device which are matched with each other. Both the mixing roller device and the transmission device are arranged on a weighing device which is arranged on a support base. The weighing device, the mixing roller device and the transmission device are respectively connected with a control system which is arranged on one side of the support base through circuits. The mixing roller device is driven by a driving wheel through a rolling ring to rotate. The roller has positive rotation and reverse rotation. During positive rotation, an inner spiral pushing auger drives material particles in the roller to lift, rotate, roll and move tangentially and axially along the roller to uniformly mix the materials. Meanwhile, the materials move to the side of a discharge outlet axially under the action of a spiral thrusting force, and the materials are discharged from the discharge outlet through a material lifting plate finally. The mixer for mixing the rubber and plastic particles has the characteristics of high production efficiency, excellent mixing effect, high discharge speed, adjustable speed, accurate discharge, capacity of preventing the material particles from re-bonding, full-automatic control, full closeness, no dust or noise pollution, and the like.

Owner:SHANDONG UNIV

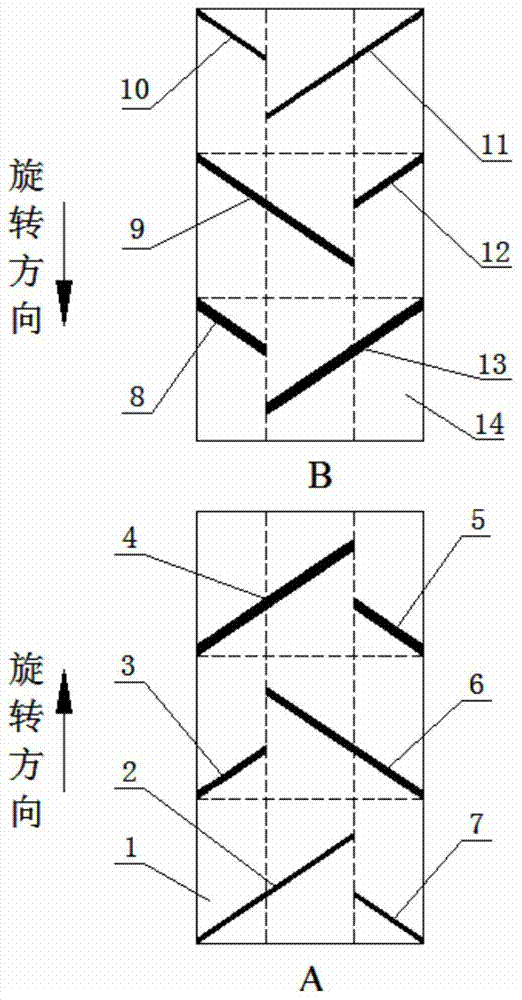

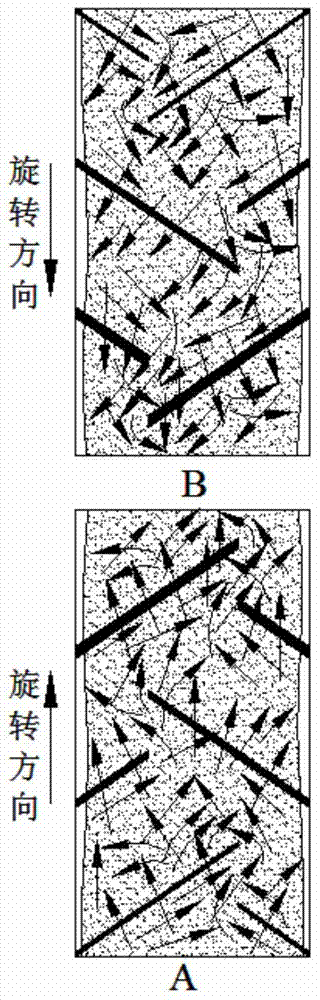

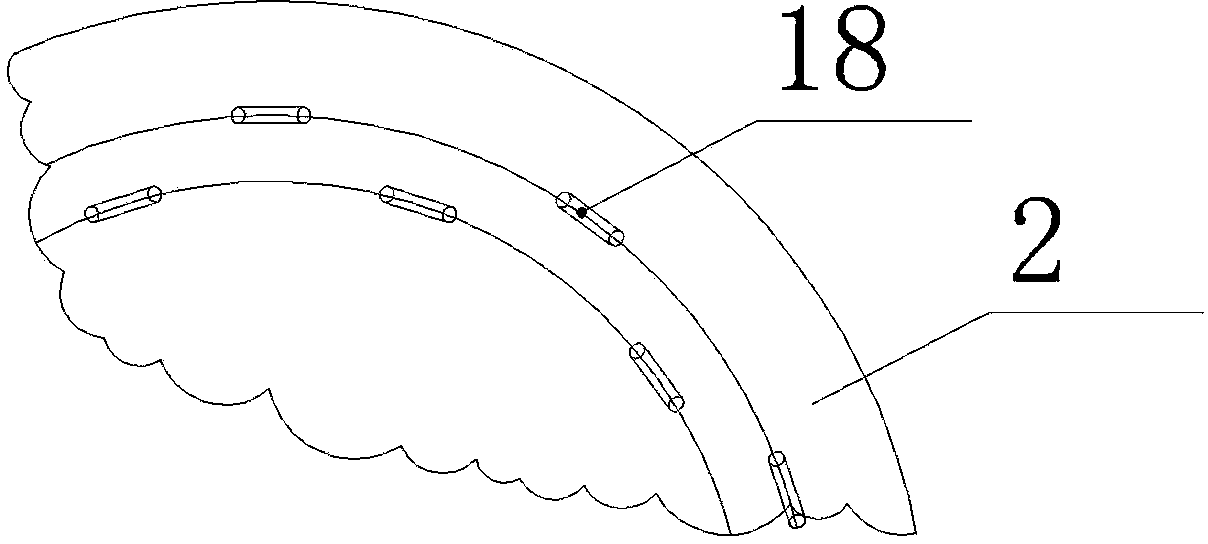

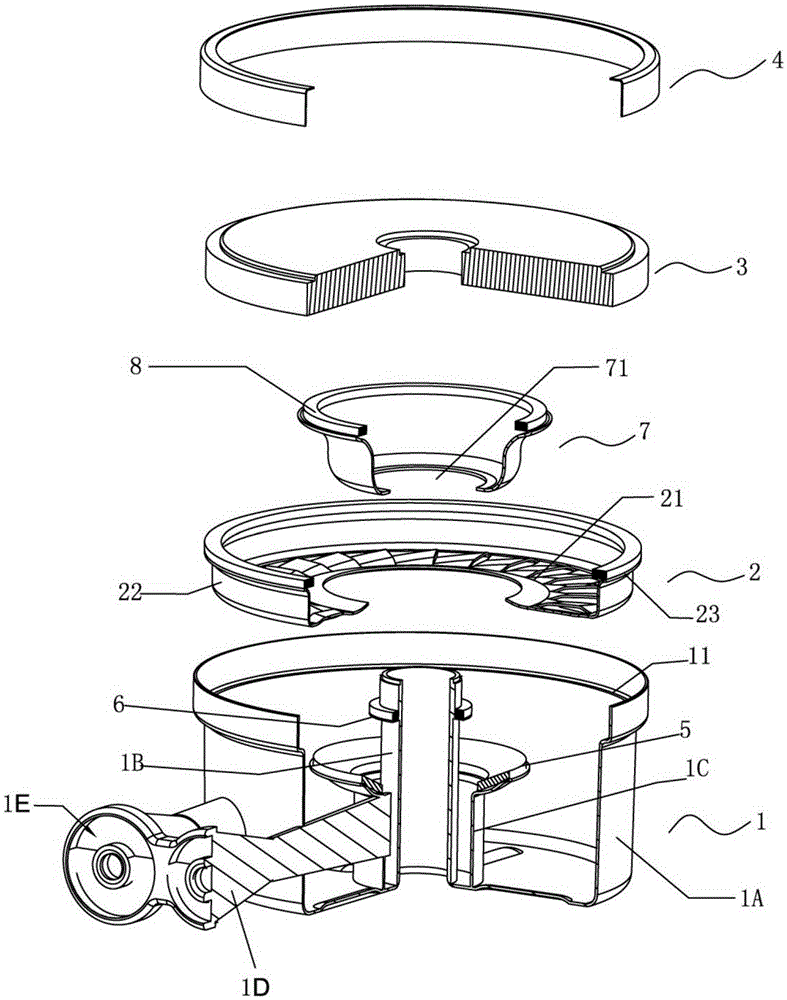

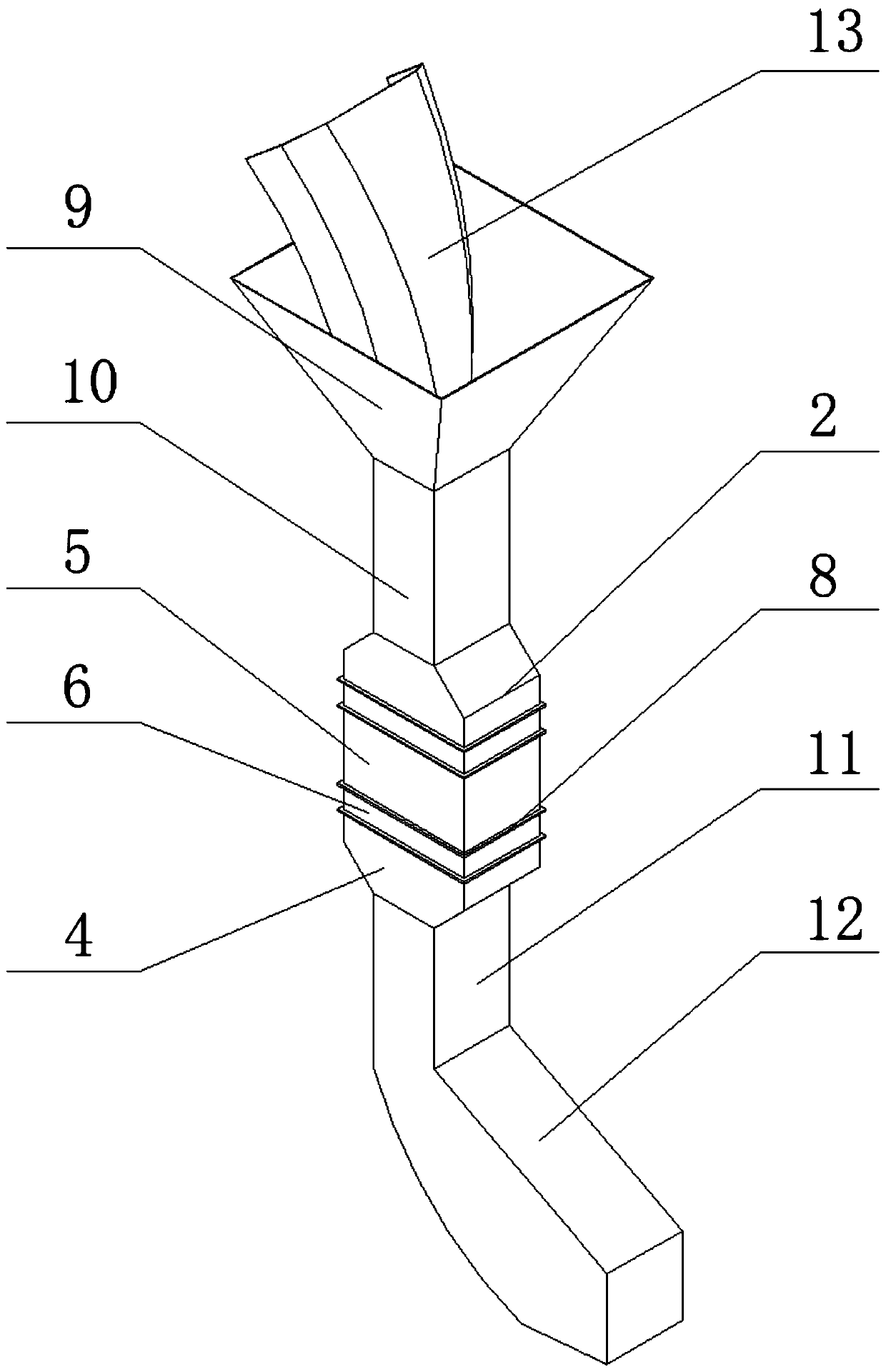

Internal mixer rotor for mixing short fiber rubber composite materials

The invention relates to an internal mixer rotor for mixing short fiber rubber composite materials, which is used for mixing the short fiber rubber composite materials and realizing uniform dispersing and distributing of short fibers in a rubber matrix. The internal mixer rotor comprises a front rotor and a rear rotor, which are used in a paired manner. The front rotor adopts the structure that a small clearance long rotor edge, a middle clearance short rotor edge and a big clearance long rotor edge are distributed on the left side of a rotor block and are in left-handed rotation; a small clearance short rotor edge, a middle clearance long rotor edge and a big clearance short rotor edge are distributed on the right side of the rotor block and are in right-handed rotation; the rear rotor adopts the structure that a small clearance long rotor edge, a middle clearance short rotor edge and a big clearance long rotor edge are distributed on the right side of a rotor block and are in left-handed rotation; a small clearance short rotor edge, a middle clearance long rotor edge and a big clearance short rotor edge are distributed on the left side of the rotor block and are in right-handed rotation. The internal mixer rotor is suitable for mixing various rubber materials of different formulas containing short fibers, the uniform dispersing and distributing of the short fibers in the rubber matrix are realized, the mixing process is optimized, and the quality of a rubber compound is improved.

Owner:青岛国程中嘉高新科技开发有限公司

Mixing head device

ActiveCN103008170ASolve the problem of reduced production efficiencyAchieve the purpose of mixingLiquid surface applicatorsCoatingsFour-way valveEngineering

The invention discloses a mixing head device. According to the mixing head device, a two-position four-way valve is additionally arranged in each material branch path in a feeding part; due to the two-position four-way valves, when the mixing head is in a working state, feeding ports and discharge ports are communicated, and return material ports and washing ports are closed; when the mixing head is in a washing state, the feeding ports and the return material ports are communicated, the discharge ports are communicated with the washing ports, and discharge ports of the two-position four-way valves are communicated with the inlets of a mixing main body through pipelines, and the inlets of the mixing main body are communicated with the outlets of the mixing main body after being gathered together so as to be in the washing state, the material returns to a material storage device through the two-position four-way valves, the mixing device and the pipelines are washed through the two-position four-way valves by using a cleaning agent, and therefore the mixing head provided by the invention is washed in an on line manner; and the purpose of accomplishing the washing task without halting the machine and the production is achieved.

Owner:HENAN TIANFON ENERGY SAVING PANEL SCI & TECH

Uniform mixing device for vinyl acetate-acrylic latex paint production

PendingCN108465429ASimple structureEasy to useTransportation and packagingMixer accessoriesEngineeringRaw material

The invention relates to the technical field of latex paint processing equipment, in particular to a uniform mixing device for vinyl acetate-acrylic latex paint production. The uniform mixing device comprises a bottom plate, wherein moving devices are fixedly connected with the bottom of the bottom plate; fixed seats are fixedly connected with the two sides of the top of the bottom plate; side plates are fixedly connected with tops of the fixed seats, a push rod is fixedly connected with one side of each side plate, a grip is fixedly connected with one side of the push rod, a supporting plateis fixedly connected between the two side plates, a baffle plate is fixedly connected with the top of the supporting plate, and a mixing box is inserted in the supporting plate. The supporting plate fixedly connected between the two side plates is conveniently matched with hanging racks on two sides of the mixing box for placement of the mixing box, the limiting effect is realized under the matching with the baffle plate, raw materials are mixed through dual stirring under the matching of a first stirring device and a second stirring device, the purpose of uniform mixing is achieved, and the uniform mixing device for vinyl acetate-acrylic latex paint production is simple in structure, convenient to use and good in practical effect.

Owner:临沂市旭展化工有限公司

Gas staged combustion super-low nitrogen oxide emission combustor

ActiveCN104266186AWell mixedReasonable proportionFuel supply regulationGaseous fuel burnerCombustion chamberLow nitrogen

The invention discloses a gas staged combustion super-low nitrogen oxide emission combustor. The combustor comprises a hearth plate, an igniter and a combustion chamber, wherein the combustion chamber is connected with an air-gas mixer through a pipeline; the air-gas mixer is provided with an air inlet and a first gas inlet; an air flow meter is arranged at the air inlet; a first gas valve block is arranged at the first gas inlet; a second gas inlet is also formed in one side of the combustion chamber; a second gas valve block is arranged at the second gas inlet; the first gas valve block comprises a first gas flow regulating valve; a second gas valve block comprises a second gas flow regulating valve; a signal transmitting end of the air flow meter is connected to the first gas flow regulating valve and the second gas flow regulating valve respectively. According to the combustor, correct proportion of an air-fuel ratio can be realized; thus, the full mixing of the air and the fuel can be guaranteed, and meanwhile graded combustion is performed to realize fuller combustion of the mixed gas and reduce the nitrogen oxide emission.

Owner:浙江力巨热能设备有限公司

Automobile differential mechanism

InactiveCN103438179AAchieve the purpose of mixingReduce weightDifferential gearingsGearing detailsControl theory

The invention relates to an automobile accessory, and particularly relates to an automobile differential mechanism. The automobile differential mechanism comprises a shell, a half axle gear, an output shaft, a driven gear and planet gear shaft groups, wherein each planet gear shaft group is composed of a planet gear shaft A and a planet gear shaft B, and the planet gear shaft A and the planet gear shaft B of each group are disconnected to form a gap. Because each planet gear shaft group of the automobile differential mechanism is composed of each planet gear shaft A and each planet gear shaft B, the purpose of mixing components of the straight and cross shaft-shaped planet gear shaft group can be achieved only by manufacturing the planet gear shafts A and the planet gear shafts B. Especially, when the specification of each planet gear shaft A is the same as that of each planet gear shaft B, the straight and cross shaft-shaped planet gear shaft group can be assembled only by producing one kind of the planet gear shaft A or the planet gear shaft B.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

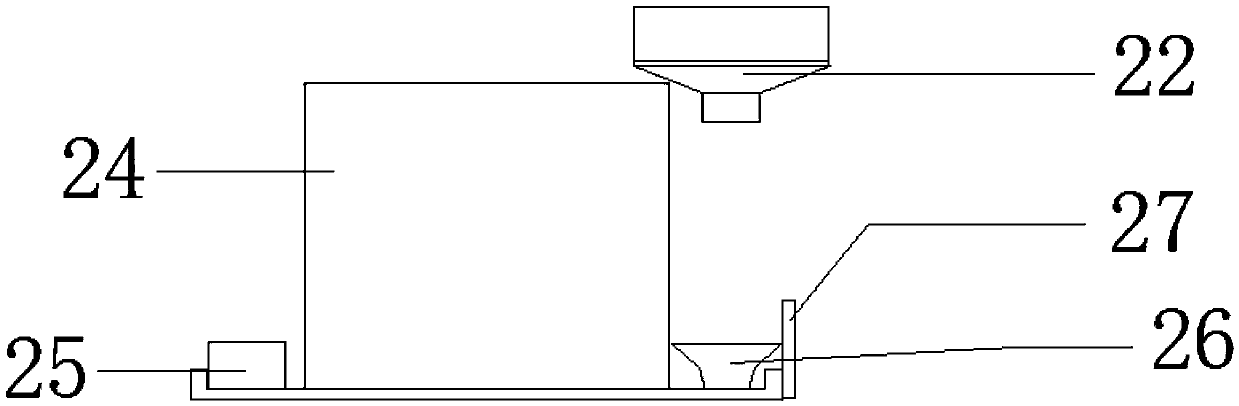

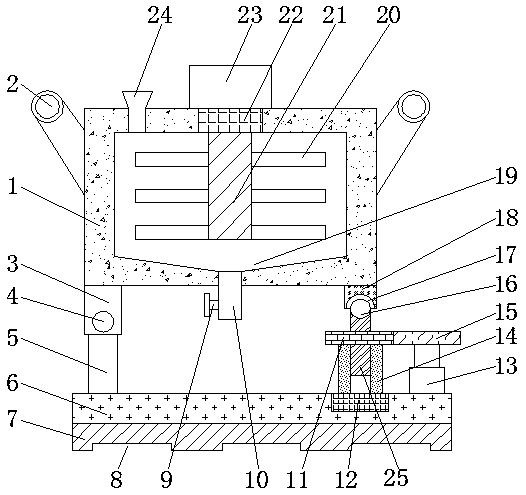

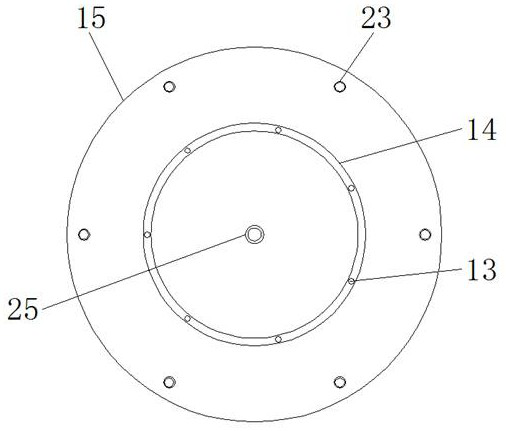

Raw material mixing machine for producing petroleum-refining catalyst zeolite molecular sieve

InactiveCN107754699APrevent overflowAchieve the purpose of mixingShaking/oscillating/vibrating mixersTransportation and packagingMolecular sievePetroleum

The invention relates to a raw material mixing machine for petroleum refining and particularly relates to a raw material mixing machine for producing a petroleum-refining catalyst zeolite molecular sieve. The raw material mixing machine has the beneficial effects that the time and the labor are saved, the mixing speed can be increased, and the production efficiency of the zeolite molecular sieve can be improved. The raw material mixing machine comprises a base plate, support rods, a mixing tank, an unloading device and the like, wherein the two support rods are vertically connected to the middle of the top of the base plate through bolts and are symmetrical left and right, and the mixing tank is connected between the top ends of the two support rods. According to the raw material mixing machine, a mixing device can be driven to work by a driving device, and then the raw materials are mixed by virtue of a mixing part of the mixing device, so that the time and the labor are saved, the mixing speed can be increased, and the production efficiency of the zeolite molecular sieve can be improved.

Owner:聂新杰

Automatic mixing and feeding apparatus for poultry culturing

The invention discloses an automatic mixing and feeding apparatus for poultry culturing, comprising a fixed support table; one side of the bottom end of the fixed support table is fixedly connected with a wall, a support slide rod is fixedly connected to one side of the top end of the fixed support table close to the wall, one side of the support slide rod far away from the wall is provided with aslide channel, the slide channel is slidably connected with a rotary fixator through a slide wheel, a box protection support frame is fixedly connected to one end of the rotary fixator far away fromthe slide channel, a feed mixing lifting box is fixedly connected within the box protection support frame, and the top end of the feed mixing lifting box is provided with a feed port. The invention relates to the technical field of mechanical equipment for culturing of live poultry. The automatic mixing and feeding apparatus for poultry culturing is capable of automatically mixing various feeds and capable of automatically adding the feeds, automation level of a feeding farm is increased, and waste of manpower resources is reduced.

Owner:湖州绿昌生态农业有限公司

Device with intermittent solution blending function

InactiveCN112844141AGood stopping effectAchieve the purpose of mixingTransportation and packagingRotary stirring mixersDrive shaftGear wheel

Owner:李一峰

Method for treating industrial plastic waste

InactiveCN105565916AReduce pollutionHarm reductionBio-organic fraction processingWaste based fuelDecompositionPlastic waste

The invention relates to a method for treating industrial plastic waste. The method comprises the following steps: picking out recyclable substances; crushing the rest waste; adding animal waste and plants into the waste powder to obtain a mixture; putting the mixture into a biogas tank for fermentation; adopting generated biogas for heating or power generation; taking out biogas residue from the biogas tank; preparing a mushroom cultivation material comprising 5000 kg of the biogas residue, 1500 kg of straw or haulm, 15 kg of cotton seed hulls, 60 kg of gypsum and 25 kg of lime for cultivation of mushroom; finally, carrying out microbial decomposition to obtain an organic fertilizer for crops. The method adopts a whole set of a systematic technical scheme and a biochemical utilization method which can treat the industrial plastic waste completely, and the industrial plastic waste which is an international public hazard is treated biochemically, changed into valuable, eliminated permanently for people, and changed into treasure according to a scientific biologic chain biochemical method, so as to benefit the people, and return a clean environment, a clean space, and a beautiful and healthy world to the people. According to the method, neither land occupation nor environmental pollution is caused.

Owner:HEILONGJIANG JULONG QIANKUN AGRI TECH DEV

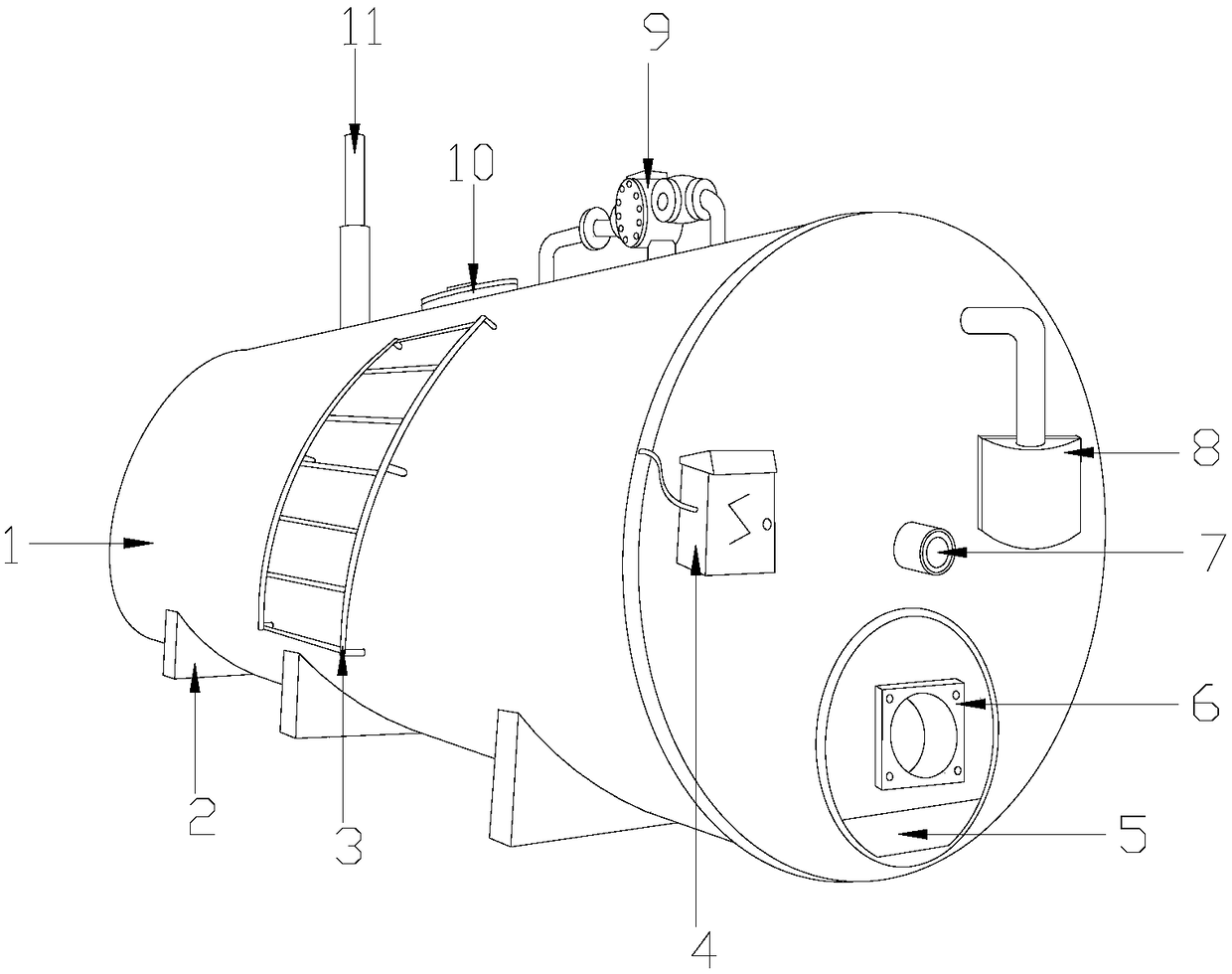

Petroleum asphalt fast melting equipment

InactiveCN108485695AEvenly heatedAchieve the purpose of mixingWorking-up pitch/asphalt/bitumen by meltingCombustionHeating furnace

The invention discloses petroleum asphalt fast melting equipment, which structurally comprises a high-temperature melting mechanism, two or more balance support feet, a crawling ladder, a power distribution box, a coal-firing heating furnace, a combustion supporter connection flange, a temperature indicator, a steam generator, a gear asphalt pump, a repair window and an air inlet pipe, wherein thetwo or more balance support feet are horizontally welded on the bottom of the high-temperature melting mechanism; the crawling ladder is fixedly welded at the left side surface of the high-temperature melting mechanism and is subjected to reinforced connection through screw bolts. The petroleum asphalt fast melting equipment has the advantages that the goal of driving blades to rotate by a stirring rod is achieved; the blades are used for stirring the asphalt in a melting box, so that the melting is fast; after the complete melting, the asphalt flows out through a discharging pipe; after thecompletely molten asphalt completely flows out, an electrical valve is controlled to be closed; then, workers treat the completely molten asphalt; the fast melting of the petroleum asphalt is realized; the operation is simple and convenient; the time and the labor are saved; the work efficiency can be effectively improved.

Owner:莆田市荔城区浩旺贸易有限公司

Method for producing fibrous protein-removed original blood from newborn calf blood

ActiveCN104546913AAchieve the purpose of mixingImprove stabilityAerosol deliveryOintment deliveryFiberFiltration

The invention discloses a method for producing fibrous protein-removed original blood from newborn calf blood. The method comprises the following steps: (1) receiving the blood of a newborn calf by a blood bottle and starting to stir the blood by a glass rod with a bulge at the stirring end at a speed of 110-140 rpm when the blood flows to 1 / 6 to 1 / 4 of the holding volume of the blood bottle; (2) stopping the stirring when the blood achieves the holding volume of the blood bottle and sealing the blood bottle; (3) stirring at a speed of 160-200 rpm for 2-4 min, stopping the stirring, standing for 3-4 min, stirring at 110-140 rpm for 5-8 min, stopping the stirring, and taking out the glass rod and the fibrous protein wound on the stirring end. The method provided by the invention has the advantages that the stability is high and the homogenization degree is high; the automatic stirring is realized so as to avoid the interferences of human factors; the standard operation and industrial production can be realized; the fibrous protein can be removed to a relatively complete extent without filtration, so that the time and the labor are saved; the bottle does not need to change and the blood bottle is a storage bottle for the non-solidified original blood; the recovery rate of the original blood is high and has an average of 93%.

Owner:内蒙古维克生生物技术股份有限公司

Chemical stirring device

ActiveCN108435077AEasy to liftEasy to install, disassemble and overhaulShaking/oscillating/vibrating mixersTransportation and packagingEngineeringRaw material

Owner:SHANDONG LONGSHENGHE CHEM CO LTD

A kind of degradable plastic bag raw material processing equipment

ActiveCN112428470BAchieve the purpose of mixingImprove the heating effectProcess engineeringHeating effect

The invention discloses a degradable plastic bag raw material processing equipment, which comprises an equipment shell, a stirring inner cylinder, a material inlet, a material outlet and a heating box. A feed inlet is installed on the side of the top end, and a discharge outlet is installed at the bottom of the mixing inner cylinder. At the same time, both the feed inlet and the discharge outlet extend through the shell wall of the equipment shell to the outside, and the guide plate is distributed in a ring. A slide plate is installed on the side wall of the bottom end of the stirring inner cylinder, and the outer end of the slide plate is slidably connected to the slide bar through a spring. This degradable plastic bag raw material processing equipment can use the conveying function of the auger plate during the rotation process to disperse the whole accumulated raw materials into each raw material dispersion pipe to achieve the purpose of stirring. By placing the raw material dispersion pipe in each heating box The heating operation is performed on the dispersed plastic raw materials in various parts, and the heating effect is better.

Owner:富岭科技股份有限公司

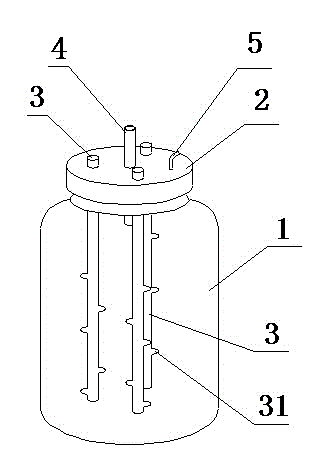

Stirrer with stretch-in stirring vane arranged outside bottom of stirrer

InactiveCN102872787ASimple structureLow costMixersChemical/physical/physico-chemical nozzle-type rreactorsEngineeringRaw material

The invention discloses a stirrer with inserted stretch-in stirring vane arranged outside the bottom of the stirrer, which overcomes the defects in the prior art that inadequate reaction and poor mixing uniformity are caused by directly feeding raw materials, and an equipment structure is complicated by filling air directly, and the production cost is high. The stirrer with the stretch-in stirring vane arranged outside the bottom of the stirrer comprises a cylindrical reaction vessel, a flow guide column positioned in the reaction vessel, a round joint arranged at the lower end of the flow guide column, and an outflow hole formed at the upper end of a surface wall of the reaction vessel, wherein an inner cavity communicated with the flow guide column is arranged in the round joint, an arc-shaped flow guide hole is formed in a surface wall of the round joint, a tapered nozzle is also arranged at the upper end of the flow guide column, the stirring vane is arranged at the bottom of the reaction vessel, and an air intake hole is formed at the upper end of the flow guide column. The stirrer is simple in structure, low in cost and convenient to realize and operate, and therefore suitable for popularization and application.

Owner:成都益友科技发展有限公司

Chemical dye compounding device

InactiveCN108159927AEvenly mixedAchieve the purpose of mixingTransportation and packagingRotary stirring mixersEngineering

The invention relates to a compounding device, in particular relates to a chemical dye compounding device, and solved the technical problem to provide a chemical dye compounding device capable of saving time and labor, improving the compounding efficiency, and protecting the health of workers. In order to solve the above technical problem, the chemical dye compounding device comprising a base, support rods, and the like is provided; the left and right sides of the top of the base are vertically connected with the support rods, and a mixing box is connected between the top ends of the two support rods. The lower right side of the mixing box is connected with a liquid outlet pipe. The liquid outlet pipe is provided with a valve. The upper right side of the mixing box is equipped with a feeding hopper, and the mixing box is internally provided with a mixing device. An air agitator is arranged on the top of the base between the two support rods. The compounding device uses the mixing device and the air agitator to compound chemical dyes, manual compounding is replaced, and the effects of saving the time and labor, improving the compounding efficiency, and protecting the health of the workers can be achieved.

Owner:深圳高佳研机械研究设计有限公司

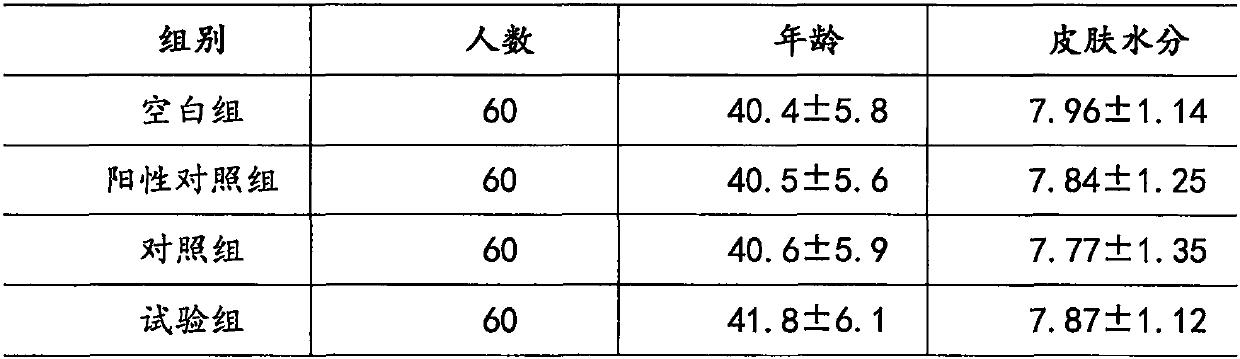

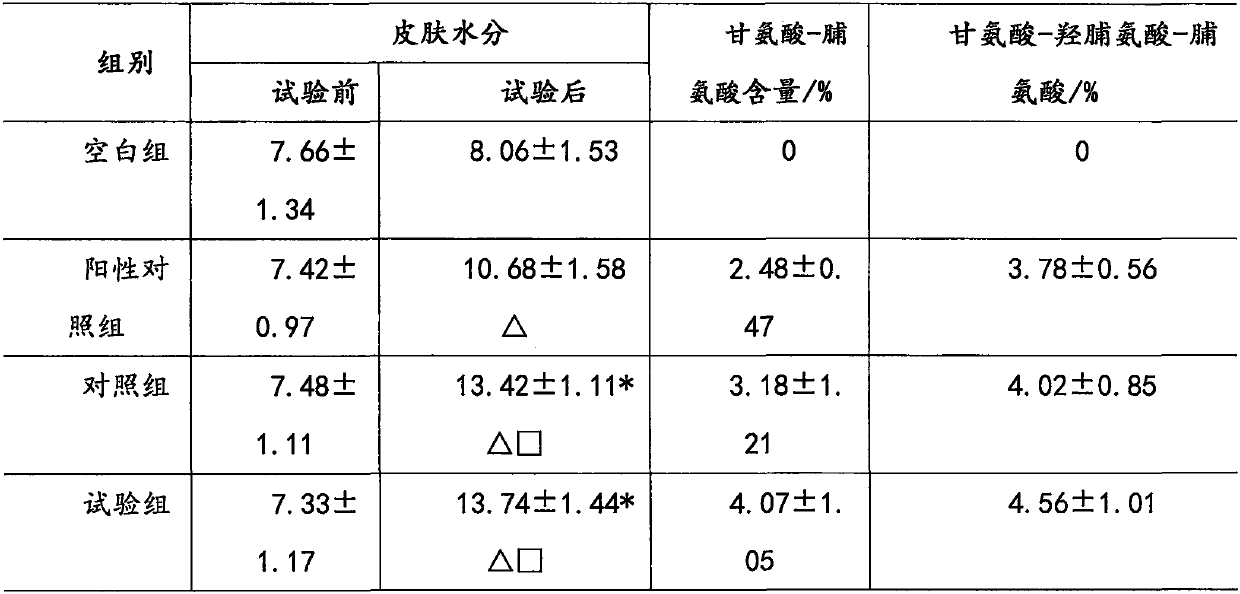

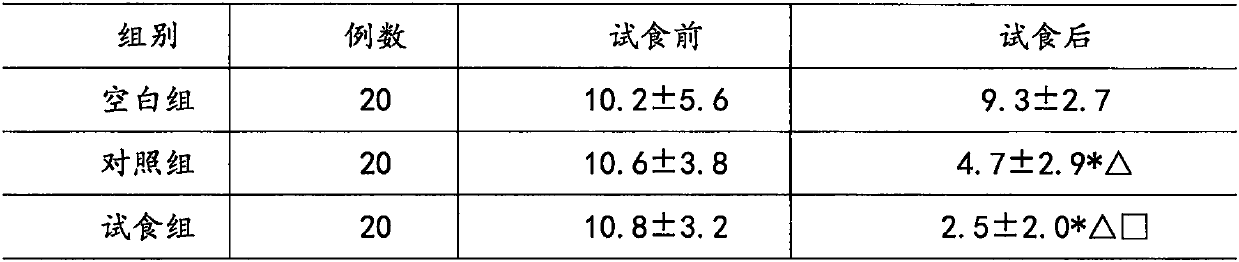

Collagen solid beverage for improving 'screen skin' and preparation method thereof

PendingCN110279054ASolve many problems of mixingUniform colorProtein composition from fishFood ingredient functionsBeta-CaroteneCollagen VI

The invention discloses a collagen solid beverage for improving'screen skin' and a preparation method thereof. The collagen solid beverage comprises the following components in parts by weight: 0-90 parts of marine fish oligopeptide, 0-90 parts of collagen peptide powder, 1-50 parts of orange juice concentrate, 5-40 parts of maltodextrin and 0.5-20 parts of beta-carotene, 0.5-20 parts of lutein ester, 0.05-5 parts of citric acid and 0.05-5 parts of sucralose; the collagen solid beverage is prepared into a final product through mixing, spray-drying, fluidized bed granulation and other processes. The collagen solid beverage provided by the invention can effectively improve symptoms of skin roughness, dryness, acne, dark yellow and the like, has the effects of resisting oxidation, resisting aging and the like, and can also effectively relieve asthenopia and protect skin and eyesight from blue light damage.

Owner:北京姿美堂生物技术股份有限公司

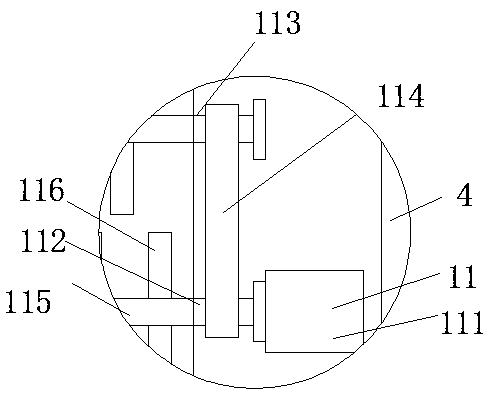

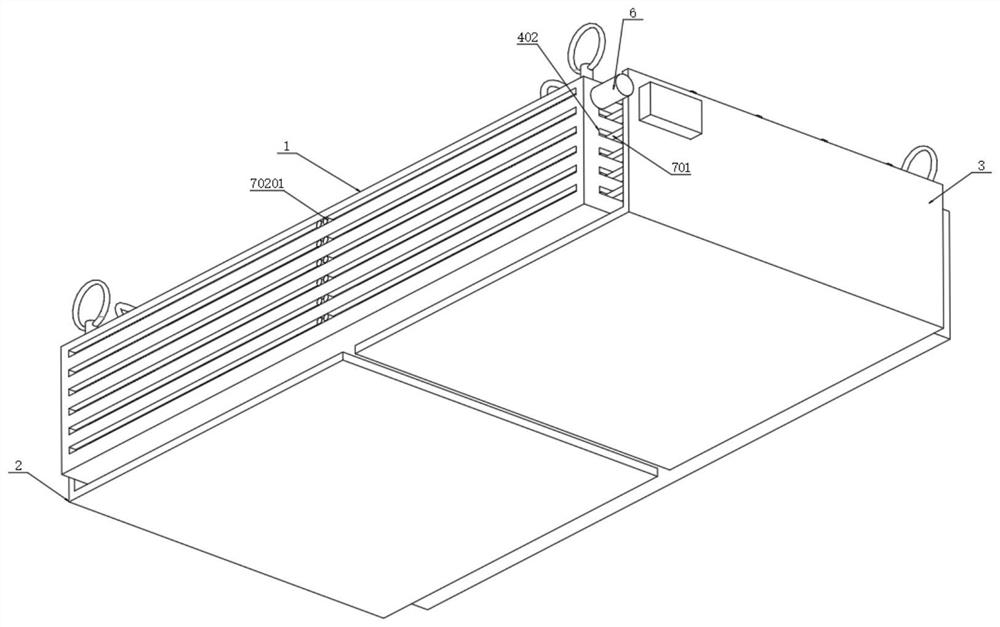

Suaeda glauca tea rolling machine and technology thereof

ActiveCN114431513AGuarantee fillingGuarantee product qualityTobacco treatmentCigarette manufactureProcess engineeringTea leaf

The invention discloses a suaeda glauca tea rolling machine and a process thereof, and relates to the technical field of tea rolling machines. The quality of tea rolls is improved. The tea rolling machine comprises tea rolling equipment and rolling equipment, the tea rolling equipment is arranged on one side of the output end of the rolling equipment, a feeding hopper is installed on the tea rolling equipment, a tea plugging mechanism is arranged at the bottom of the feeding hopper, and the tea plugging mechanism comprises a plugging rod and a driving part for driving the plugging rod to do reciprocating linear motion; the technology comprises the following steps: material selection: selecting a rolled tea raw material; cleaning the raw materials, and steaming the cleaned raw materials for 15-25 minutes; and flaking the steamed raw material, and then performing shredding to obtain a filamentous raw material. By arranging the feeding hopper, the rotating disc, the plug rod and other structures, tea rolling paper into which tea leaves are to be plugged can be fixed to the fixing head, processed tea leaves are added into the feeding hopper, the tea leaves are stacked in the tea plugging chamber through the feeding hopper, the tea leaves in the tea plugging chamber are pushed into the tea rolling paper through linear motion of the plug rod, and a tea roll is formed.

Owner:安徽天鹅茶业有限责任公司

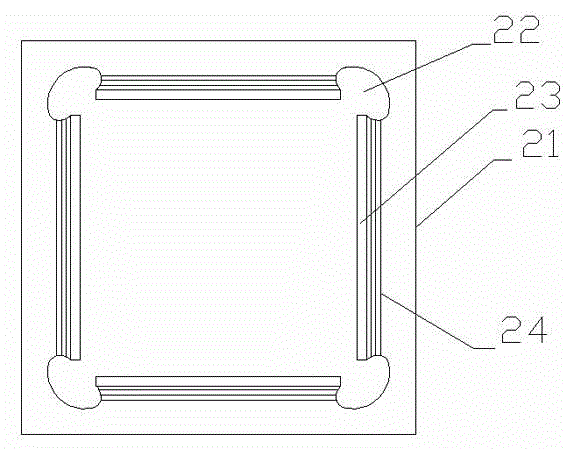

Electromagnetic stirring device

An electromagnetic stirring device comprises a rectangular body, a stirring cavity is arranged in the rectangular body, a rectangular-ambulatory-plane cavity is arranged between the stirring cavity and the rectangular body, electromagnet is arranged in the rectangular-ambulatory-plane cavity and around the stirring cavity, four corners in the inner side of the iron corn of the electromagnet are both provided with a wire duct, two neighbored wire ducts form a winding plate for winding the coils, the coil can be divided into two coil groups, each coil group comprises two coils with the same winding direction, wherein the two coils are connected and arranged on two opposite winding plates; and the rectangular body delivers alternating current in regular change to the coils through a controller, so that the electromagnet can form a rotary uniform strong magnetic field in the stirring cavity. The device generates a rotary uniform strong magnetic field with orderly changed directions in the stirring cavity through optimizing the iron core structure and introducing current in regular change to the coils to drive a plurality of permanent magnetic stirrers to rotate so as to achieve the goal of stirring multiple samples at the same time.

Owner:河南荣展生物科技有限公司

Medicine liquid mixing device for medical treatment

InactiveCN107583545AReduce shockAvoid inconvenienceShaking/oscillating/vibrating mixersMixing methodsEngineeringMedical treatment

The invention discloses a medicine liquid mixing device for medical treatment. The medicine liquid mixing device comprises a base and a casing, wherein the casing is arranged at the top part of the base; the opposite inner walls of the casing are fixedly connected with support rods; one side, away from the casing, of each support rod is fixedly connected with a sealing tube; the interior of each sealing tube is glidingly connected with a sealing disc in a sealing way; one side, near each support rod, of each sealing disc is fixedly connected with a connecting spring; one end, away from each sealing disc, of each connecting spring is fixedly connected with the inner wall, near the corresponding support rod, of the sealing tube; an air pipe is arranged at the output end of an air compressor;the outer wall of one end, away from each support rod, of each sealing tube is communicated with a connecting tube; one end, away from the sealing tube, of the connecting tube is communicated with amixing cylinder; the inner wall of the top end of the mixing cylinder is fixedly connected with a medical membrane. The medicine liquid mixing device has the advantages that the medicine liquid for medical treatment can be mixed without traditional stirring shafts and stirring blades, the inconvenience in the traditional stirring type is effectively avoided, and the working efficiency of the wholestirring procedure is improved.

Owner:隗阳

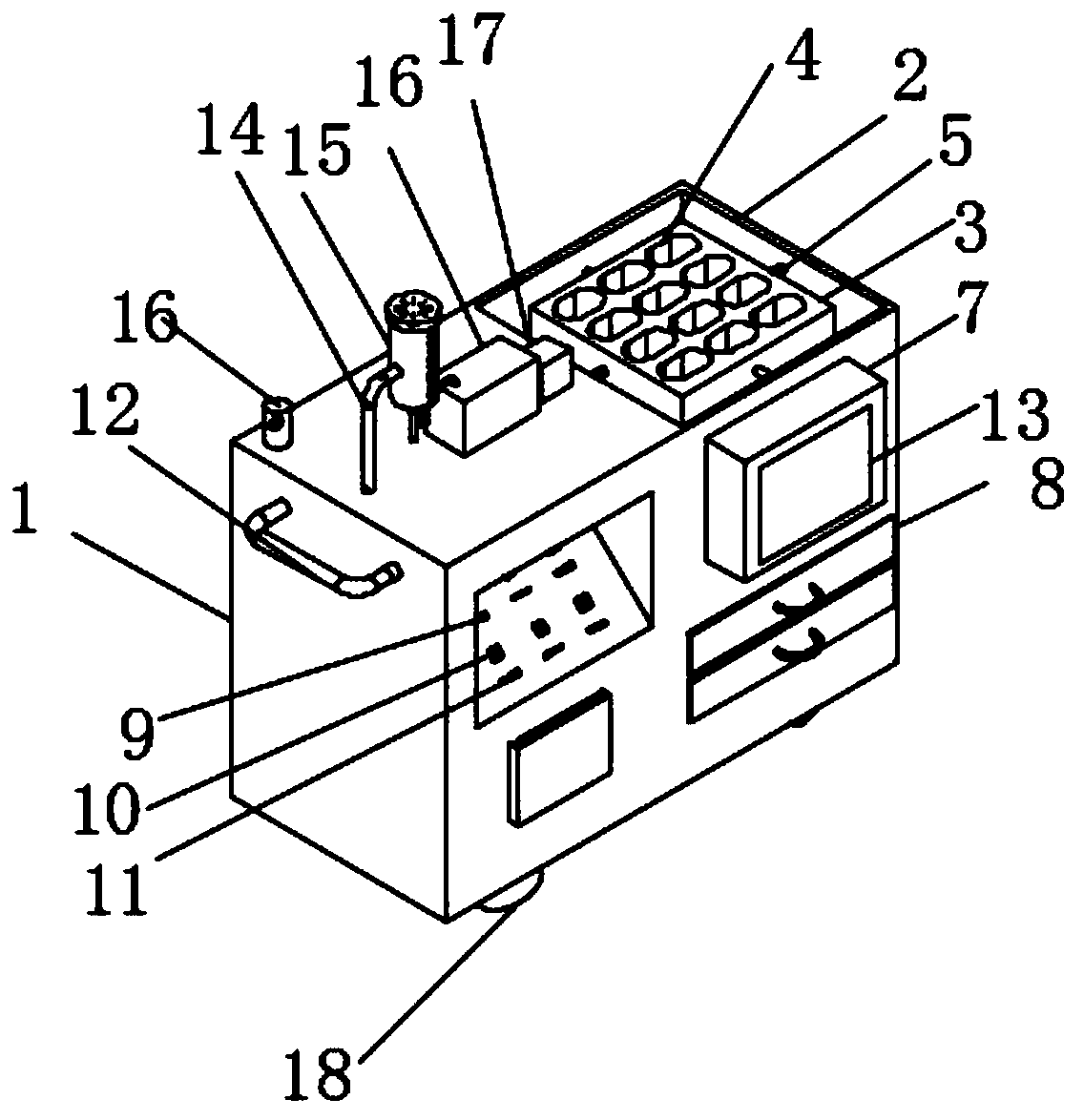

Multifunctional medical device based on 5G equipment

ActiveCN111557818APromote shakingSave the trouble of manually shaking the medicineShaking/oscillating/vibrating mixersTransportation and packagingEngineeringMedical device

The invention discloses a multifunctional medical device based on 5G equipment, comprising a device body, wherein a shaking-up bin is formed in the position, close to one side, of the outer surface ofthe upper end of the device body; a shaking-up box is arranged in the shaking-up bin, a containing groove is formed in the shaking-up box, reset springs are welded to the outer surfaces of the two sides of the shaking-up box, and connecting columns are welded to the outer surface of the front end and the outer surface of the rear end of the shaking-up box; a main control box and a medicine storage box are fixedly installed at the position, close to one side, of the outer surface of the front end of the device body, the medicine storage box is arranged below the main control box, and a touch screen is embedded in the outer surface of the front end of the main control box. A supporting frame is fixedly installed on the outer surface of the upper end of the device body, a medicine mixing pipe is fixedly installed at one end of the supporting frame, and a gas conveying box is arranged on one side of the supporting frame. The multifunctional medical device has the beneficial effects that the multifunctional nursing bed has more functions, different use requirements of medical staff can be met, and the safety is higher.

Owner:上海然芯信息科技有限公司

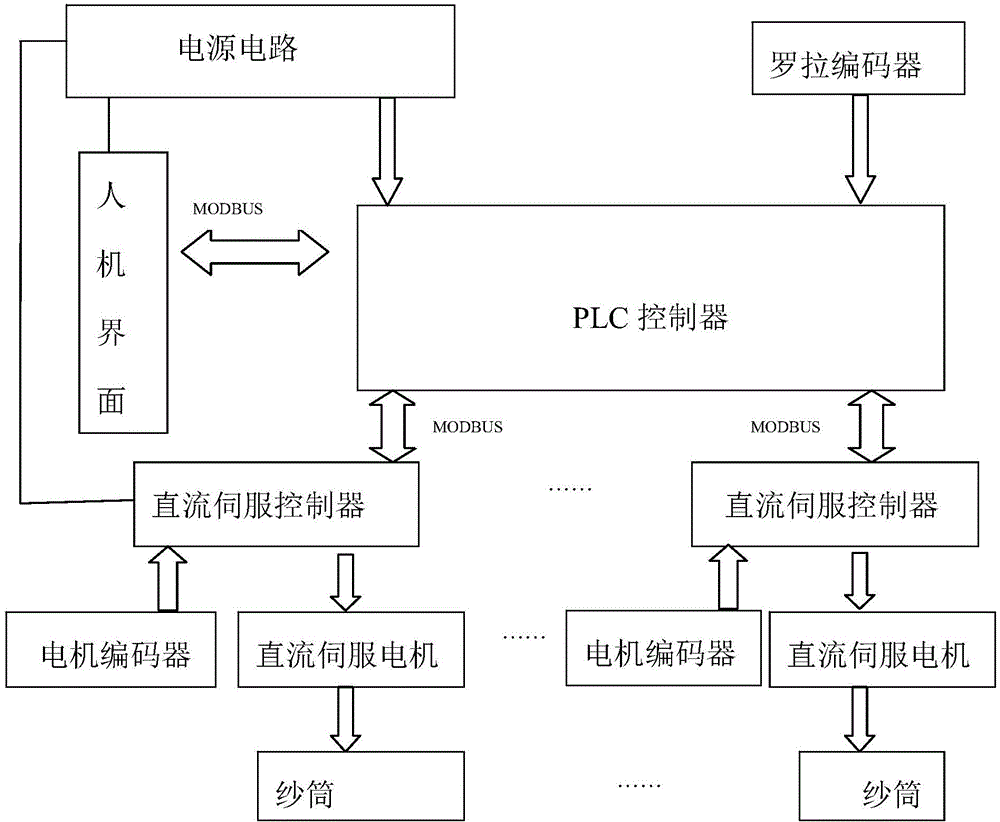

Large bobbin and small bobbin mixed control method

ActiveCN104088055AConstant yarn tensionAchieve the purpose of mixingWarping machinesOther manufacturing equipments/toolsHuman–machine interfaceBobbin

The invention relates to a large bobbin and small bobbin mixed control method. Tension F is set on a human-computer interface and transmitted to a PLC controller, the tension F and yarn linear velocity V obtained through calculation are transmitted to a direct current servo controller through the PLC controller, the measured bobbin revolution number R is transmitted to the direct current servo controller, the revolution number R is the number of bobbin rotating rings in unit time, N is calculated by the direct current servo controller according to formulas: the practical bobbin rotating diameter D=V / (R*pi), and the servo motor output torque N=DF / 2, namely N=FV / (2R*pi), and finally the output torque of the direct current servo motor is controlled by the direct current servo controller according to calculation results. By means of the large bobbin and small bobbin mixed control method, the aim that bobbins different in diameter are the same in yarn producing tension is achieved, the aim that the tension is kept constant in the process that the bobbins are gradually reduced is guaranteed, the warp knitting beaming quality is improved, and the production difficulty and the production cost are reduced.

Owner:CHANGZHOU DIBA TEXTILE MACHINERY

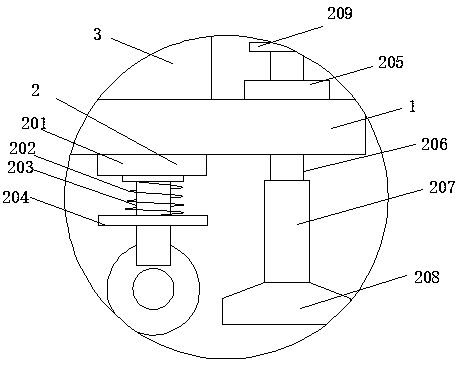

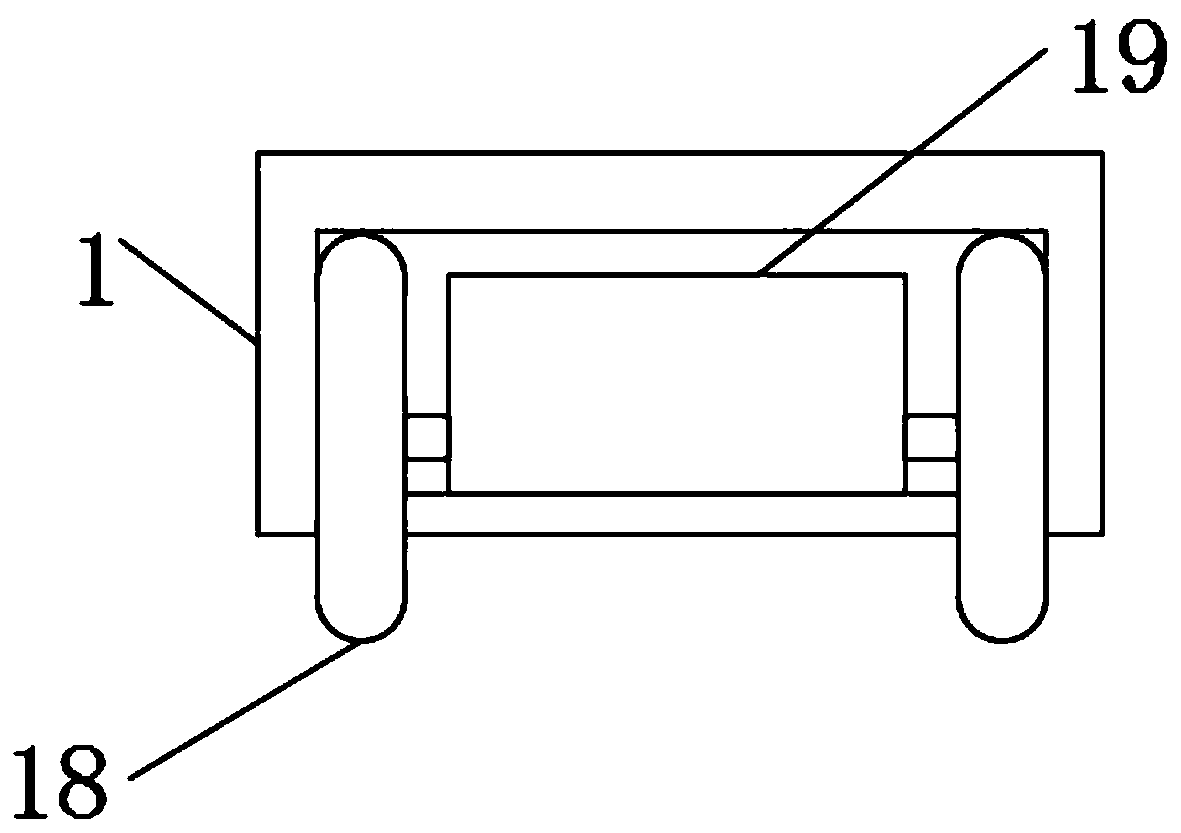

Hanging basket for building construction

ActiveCN112096043AIncrease working spaceImprove flexibilityScaffold accessoriesBuilding support scaffoldsTap waterArchitectural engineering

The invention relates to a hanging basket for building construction. The hanging basket comprises an inner basket frame, a bag pressing mechanism, a synchronous tooth mechanism, a material mixing setmechanism and an electric cylinder. A first side basket frame and a second side basket frame are each formed by welding a bottom plate and a side plate, and each side plate comprises welding rod setsat the front side and the rear side and an inner plate welded to the inner sides of the two welding rod sets; the first side basket frame and the second side basket frame are assembled at the two endsof a two-way threaded rod through threaded sleeves on the inner plates in a matched manner, and inner areas of the first side basket frame and the second side basket frame are guided by moving wheelsat the outer ends of the inner plates to move on a guide groove of an inner border; and the material mixing set mechanism can receive tap water in the bag pressing mechanism at the same time to enable concrete to be located at a high position to achieve the purposes of mixing and stirring, so that no matter how high the hanging basket is located, constructors can be located at the high position to prepare the concrete by themselves, the constructors do not need to worry about solidification and hardening of a carried concrete mixture during ascending, and the practical purpose of immediate preparation while using is achieved.

Owner:内蒙古融达建设集团有限公司

Efficient stirring device for food production

ActiveCN112169651AImprove scraping effectAvoid echoingRotating receptacle mixersTransportation and packagingDrive shaftGear wheel

The invention discloses an efficient stirring device for food production, and belongs to the technical field of mixing devices. The efficient stirring device for food production comprises a supportingpiece and a mixing barrel, wherein the mixing barrel is located in the supporting piece and rotationally connected with the supporting piece, a containing groove is formed in the bottom end of the supporting piece, a driving motor is connected into the containing groove, and the output end of the driving motor is fixedly connected with a driving gear; the bottom end of the mixing cylinder is fixedly connected with a transmission shaft, the transmission shaft is fixedly connected with a driven gear, the driven gear is meshed with the driving gear, the upper end of the mixing cylinder is fixedly connected with a transmission ring, and the transmission ring is rotatably connected with the supporting piece. According to the wall scraping device, through the mixing cylinder, the first rotatingshaft, the driving motor, the driving gear, the driven gear and the stirring rod, the purpose of mixing the mixing cylinder with a large size is achieved, meanwhile, the stirring effect is improved,and through the supporting rod and the scraping rod, wall scraping is conducted on the inner wall of the mixing cylinder.

Owner:湖南童记三利和食品有限公司

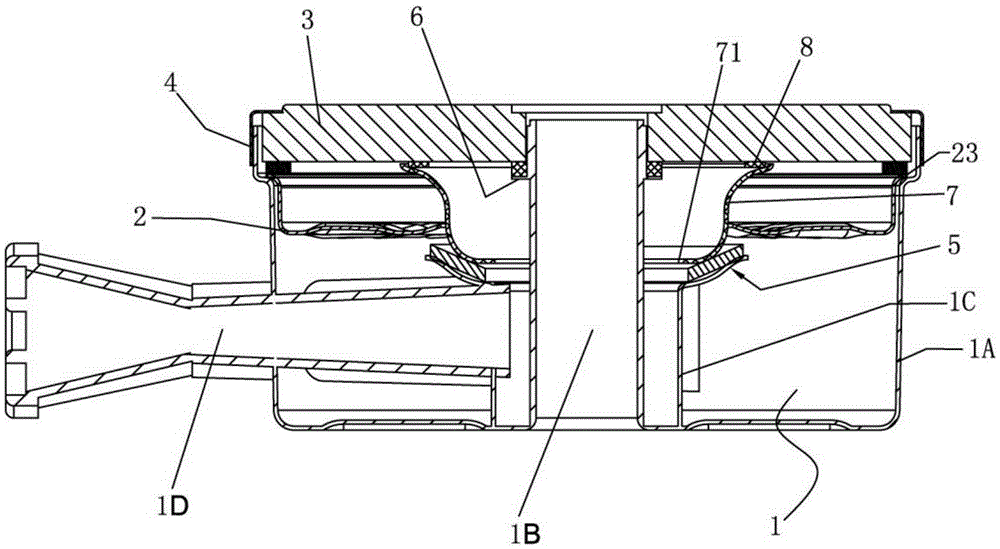

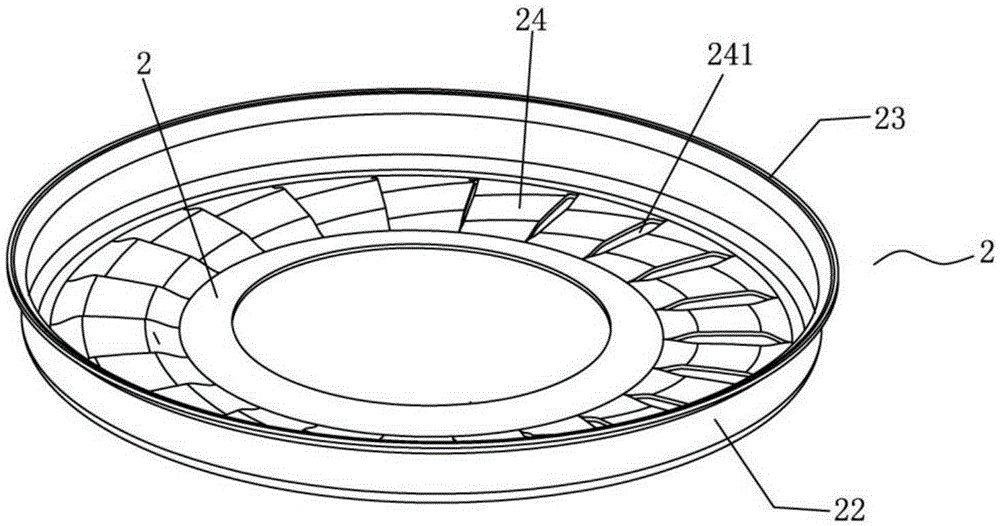

Infrared burner of gas cooking appliance

InactiveCN105318329AUniform firepowerAchieve the purpose of mixingGaseous fuel burnerInfraredEngineering

The invention discloses an infrared burner of a gas cooking appliance. The infrared burner comprises a furnace head, a flow stabilizing element, an infrared combustion plate and a fixing ring. A supporting plate is arranged on the upper portion of a center pipe of the furnace head. The flow stabilizing element comprises an annular flow stabilizing plate, a barrel-shaped wall plate and an outer folding edge. The annular flow stabilizing plate is provided with a flow stabilizing hole. The burner further comprises a diffusion cup with an upper opening, and a compression hole is formed in a bottom plate of the diffusion cup. The supporting plate and the infrared combustion plate are attached to each other and in gas-tight sealing. The outer folding edge of the flow stabilizing element is arranged on a step of a cup body of the furnace head. The infrared combustion plate is disposed on the outer folding edge of the flow stabilizing element. The diffusion cup is arranged on an annular base plate of the furnace head and is in gas-tight sealing. The upper open end of the diffusion cup and the lower surface of the infrared combustion plate are attached to each other and are in gas-tight sealing. The compression hole of the diffusion cup and the center pipe of the furnace head form an annular compression hole. By the adoption of the structure, air and gas are mixed evenly, and the infrared burner has the advantages that fire distribution of the infrared combustion plate is uniform, and an inner fire area and an outer fire area are obvious.

Owner:梁觐和 +1

Material mixing device and material mixing and transferring chute

PendingCN110898701AAdjustable distanceIncrease or decrease the quantityFlow mixersTransportation and packagingSpoilerMaterial transfer

The invention discloses a material mixing device and a material mixing and transferring chute. The material mixing device comprises a feeding shell with a feeding port at the top, connecting shells, adischarging shell with a discharging port at the bottom and a plurality of distributors, which are communicated with one another, the plurality of distributors are arranged between the feeding shelland the connecting shells, between every two adjacent connecting shells and between the connecting shells and the discharging shell correspondingly, each distributor comprises a mounting shell and a plurality of spoiler rods of which the two ends are fixedly connected with the inner wall of the mounting shell, the plurality of spoiler rods of each distributor are parallel to one another and are positioned on the same horizontal plane, and the spoiler rods of two adjacent distributors are arranged at an angle, so materials are blocked and shunted by the spoiler rods in the free falling process,the material mixing effect is achieved without external power, thereby energy is saved, the structure is simple, and the maintenance and use cost is saved; and the material transferring chute comprises the material mixing device, a feeding groove and a discharging groove, so the beneficial effects can also be achieved.

Owner:和瑞健盛环境工程技术(海南)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com