Uniform mixing device for vinyl acetate-acrylic latex paint production

An ethylene-propylene latex and mixing technology, applied in mixer, transportation and packaging, dissolving and other directions, can solve problems such as affecting production quality and uneven mixing of raw materials, and achieve the effect of good practical effect, simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

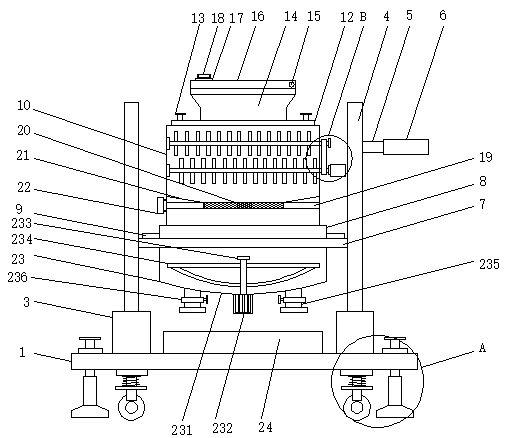

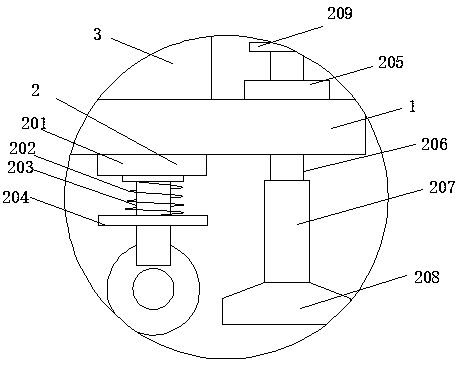

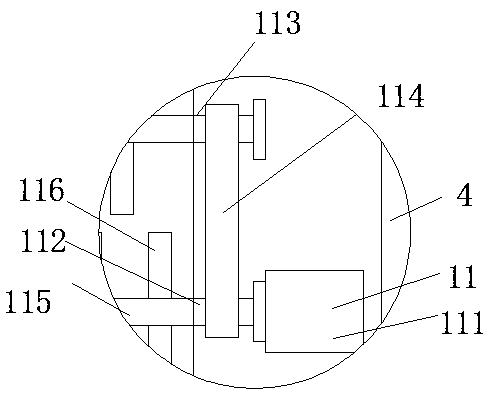

[0027] Such as Figure 1-3As shown, the present invention provides a technical solution: a mixing device for the production of ethylene-propylene latex paint, including a base plate 1, the bottom of the base plate 1 is fixedly connected with a mobile device 2, and the mobile device 2 includes a sleeve 201, and the sleeve The top of the 201 is fixedly connected to the bottom of the bottom plate 1, the bottom of the sleeve 201 is plugged with a telescopic column 202, and the outer side of the telescopic column 202 is sleeved with a shock absorbing spring 203, and the top of the shock absorbing spring 203 is fixedly connected to the top of the sleeve 201 , the bottom of the damping spring 203 is fixedly connected to the top of the roller 204, the number of the rollers 204 is four, and the four rollers 204 are symmetrically distributed at the four corners of the bottom of the base plate 1, the bottom of the telescopic column 202 is fixedly connected with the rollers 204, the base p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com