Self-circulation fermentation tank and multifunctional fruit wine brewing device

A fruit wine brewing and fermenting tank technology, applied in the field of multi-functional fruit wine brewing devices, can solve the problems of increasing manufacturing cost and operating cost, not being able to truly eliminate the skin dregs cover in the whole process, increasing the possibility of bacterial contamination, etc., and achieving easy operation and convenience Effective regulation, energy saving and environmental protection have remarkable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

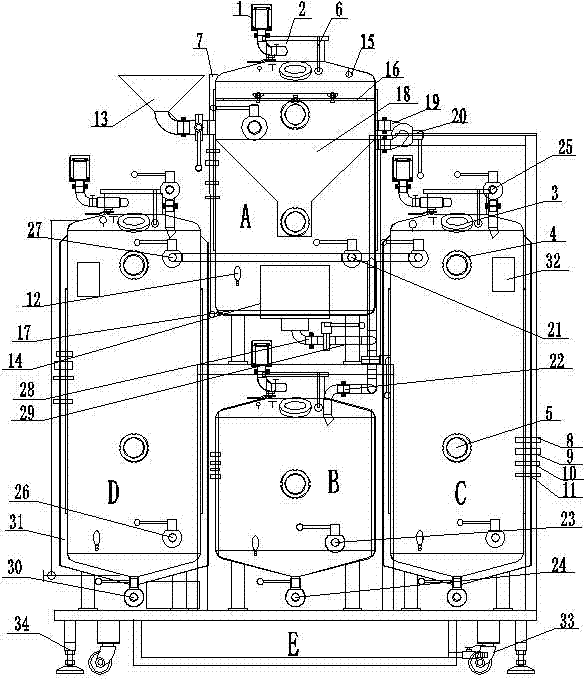

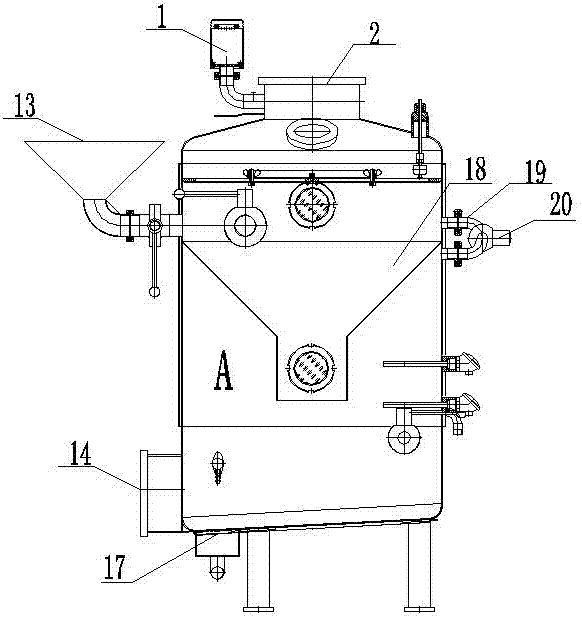

[0023] like figure 1 Shown is a schematic diagram of the overall structure of the multifunctional fruit wine brewing device in the present invention, which mainly includes a self-circulating fermenter A arranged on the upper part, a sake tank B arranged below the self-circulatory fermenter A, and a sake tank B arranged under the sake tank B or connected with Sake tank B is a multifunctional wine storage tank arranged horizontally side by side, the number of multifunctional wine storage tanks can be adjusted according to actual needs, preferably two, namely figure 1 In C and D, when it is arranged below the sake tank B, the present invention is a multi-layer arrangement, when it is arranged side by side with the sake tank B horizontally (such as figure 1 As shown, when the multifunctional wine storage tanks C and D are located on both sides of the sake tank B), the present invention is a two-layer layout; the present invention also includes a support platform arranged at the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com