Patents

Literature

72results about How to "Significant energy saving and environmental protection benefits" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for efficiently preparing cotton based mesoporous activated carbon fiber

InactiveCN105480973AWide range of sourcesLow priceFibre chemical featuresChemistryHydrothermal carbonization

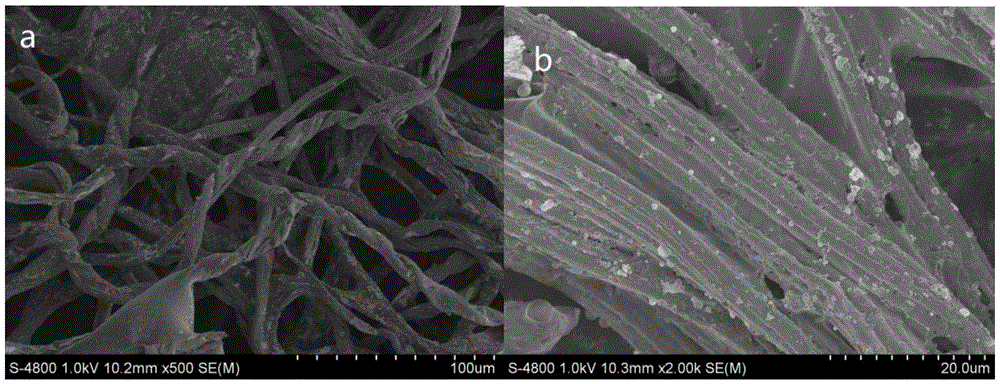

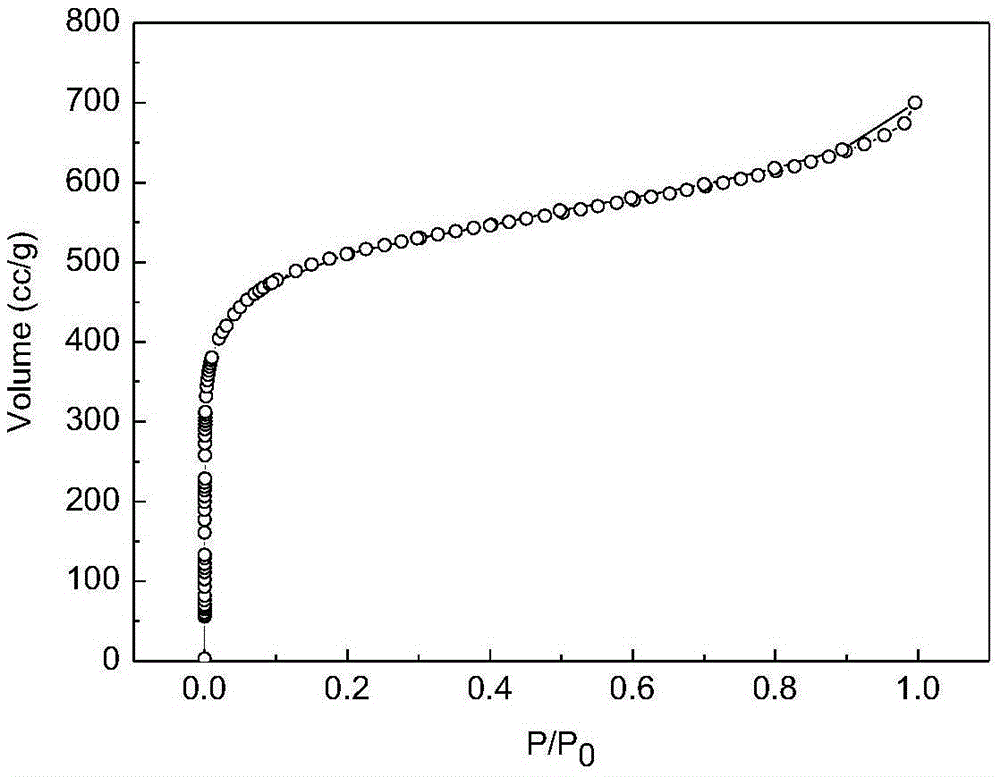

The invention relates to a method for efficiently preparing cotton based mesoporous activated carbon fiber. The method comprises a step (1) of washing cotton, placing the cotton in a hydrothermal reaction kettle, performing heating to 150-200 DEG C at the heating rate of 5-30 DEG C / min, performing hydrothermal carbonization, performing heat preservation for 1-3 hours and then performing cooling to room temperature; a step (2) of dipping carbonization materials obtained from the step (1) into activator solution, performing microwave-ultrasonic joint dipping for 5-30 minutes and then performing filtration, sending filtration materials to a microwave heating device, performing activation for 5-15 minutes at 250-350 DEG C and then stopping microwave output, and a step (3) of washing the activated materials to be neutral and performing drying to obtain the activated carbon fiber. According to the method, the characteristics of microwave inner heating and selective heating are fully utilized, the technological process is simple, the activation temperature is only 250-350 DEG C, the activation time is only 5-15 minutes, the mesoporous proportion of the activated carbon fiber of the product reaches 50-90%, and the adsorptive property is good.

Owner:HEBEI UNIV OF TECH

Nickel slag brick and preparation method thereof

InactiveCN103408277AHigh amount of slagSignificant energy saving and environmental protection benefitsSolid waste managementBrickSlag

The invention discloses a nickel slag brick and a preparation method thereof. The nickel slag brick is a novel nickel slag brick which is prepared by taking water quenching nickel slag a main material and industrial waste residue, lime, a little quantity of cement and a proper quantity of water as assistant materials in the procedures of uniformly stirring, then moulding by adopting a compression moulding forming process, and finally carrying out steam curing or natural curing. The components and mass percentage thereof are as follows: 51.1-67.4% of nickel slag, 8.5-25.0% of industrial waste residue (coal ash), 8.4-8.7% of lime, 0.3-12.9% of cement and 13.8-15.3% of water. Slag consumption rate of the unfired nickel slag brick prepared by the invention is more than 50%, therefore, not only is nickel slag waste effectively utilized, but also high temperature calcination is not needed during preparation, the mechanical strength is high, and the durability is excellent. The nickel slag brick has the prominent characteristics of waste utilization, environmental protection, regeneration, energy conservation and the like, and has wide application and development prospects.

Owner:SOUTHEAST UNIV

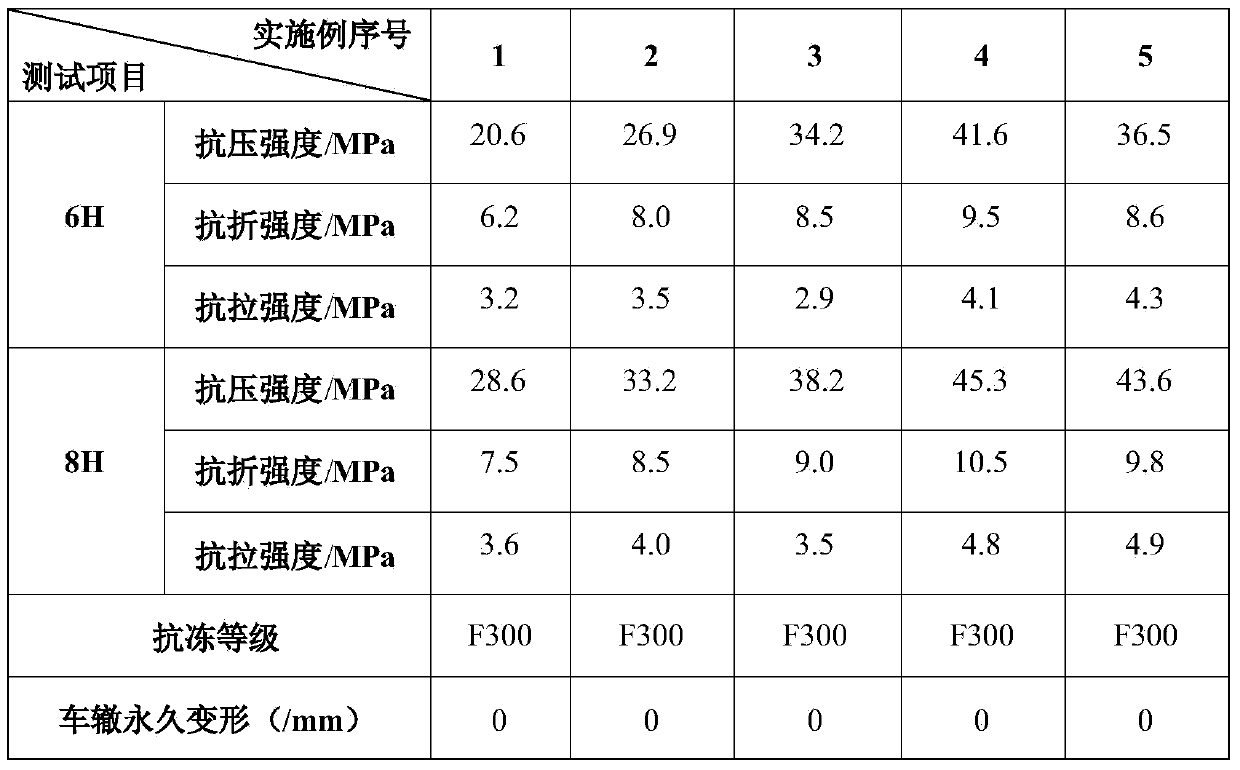

Concrete pavement material for heavy traffic roads and preparation method thereof

ActiveCN104193221AElastic modulus controllableHigh modulus of elasticitySolid waste managementMass ratioWaste rubber

The invention relates to a concrete pavement material for heavy traffic roads and a preparation method thereof. The material is composed of a component A, a component B and a component C in a mass ratio of 1:(0.2-0.6):(4-8). The component A comprises the following components in parts by mass: 40-80 parts of epoxy resin, 0-20 parts of epoxy reactive diluent, 10-50 parts of elastic modifier, 0.2 part of defoaming agent and 0.2 part of dispersing agent. The component B comprises the following components in parts by mass: 100 parts of curing agent, 0-10 parts of curing accelerator and 1 part of coupling agent. The component C comprises the following components in parts by volume: 100 parts of fine stone, 30-300 parts of fine sand, 130-800 parts of waste rubber particle, 50-100 parts of waste rubber powder and 10-20 parts of crystal whisker. Compared with the prior art, the concrete pavement material for heavy traffic roads has the advantages of high strength, favorable durability, favorable roadability, energy saving, environment friendliness and the like, and is convenient for construction.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

Eutectic salt cold-storage material

InactiveCN101434830AApplicable temperature rangeReduce cooling efficiencyHeat-exchange elementsCool storageAir conditioning

The invention provides an eutectic-salt cool-storage material, comprising sodium sulfate decahydrate (Na2SO4 question mark 10H2O), ammonium chloride (NH4Cl), sodium borate decahydrate (Na2B4O7 question mark 10H2O), and silica gel (mSiO2 question mark nH2O); the eutectic-salt cool-storage material is characterized in that: according to the mass percentage, the eutectic-salt cool-storage material comprises 72.86 percent of Na2SO4 question mark 10H2O, 12.86 percent of NH4Cl, 2.86 percent of Na2B4O7 question mark 10H2O and 11.42 percent of mSiO2 question mark nH2O. The transformation temperature of the eutectic-salt cool-storage material is 8.47 DEG C, the undercooling degree thereof is 2.41 DEG C and the transformation latent heat thereof is 136.07-182.73Kj / kg. Owning to low transformation temperature and small undercooling degree, the material is the eutectic-salt cool-storage material applicable to cold accumulation air-conditioning systems.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

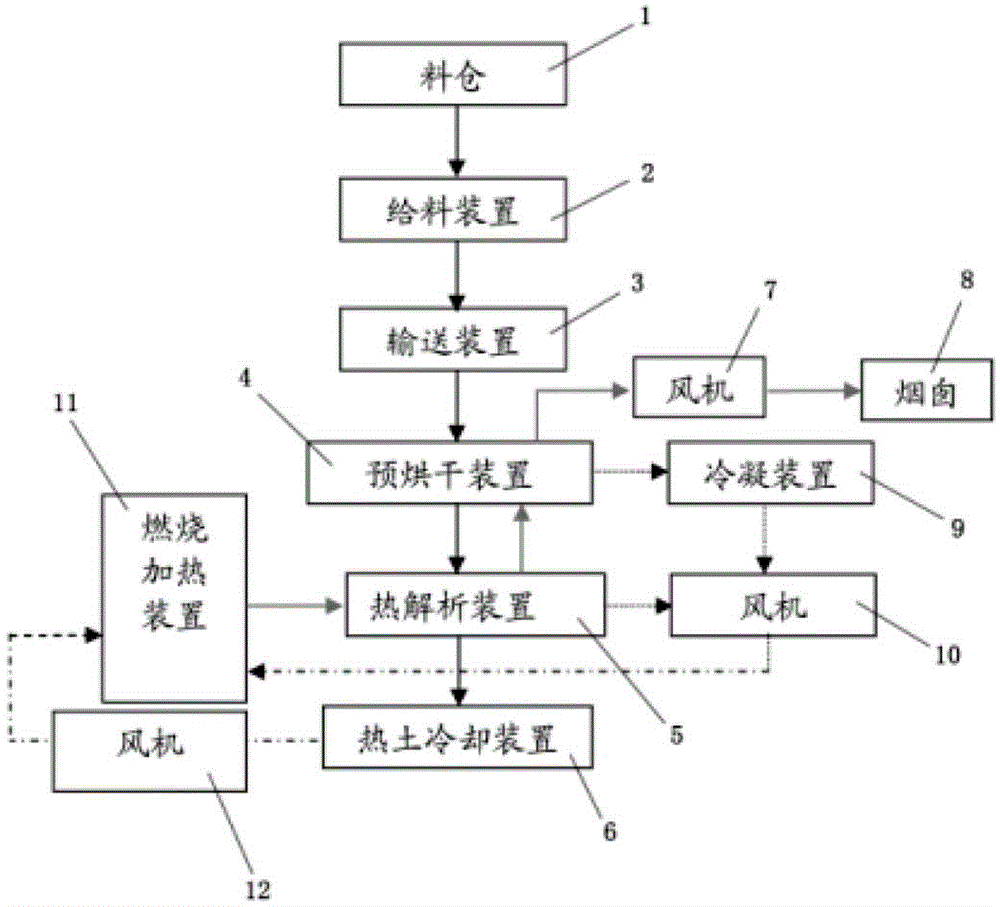

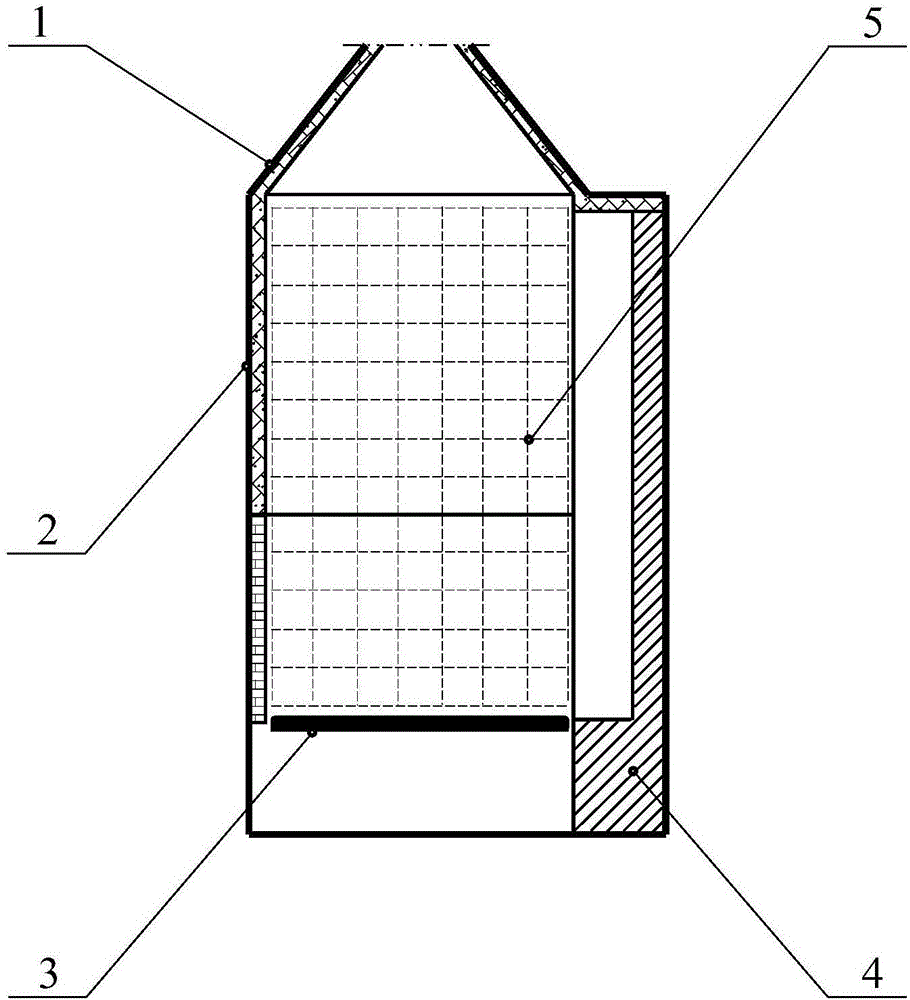

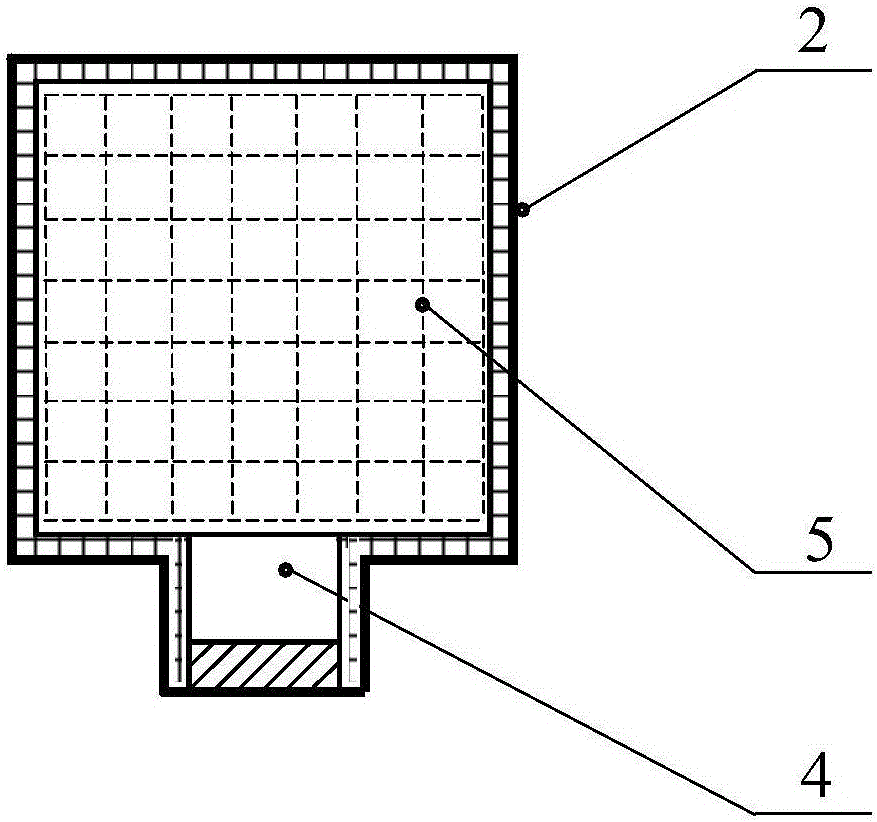

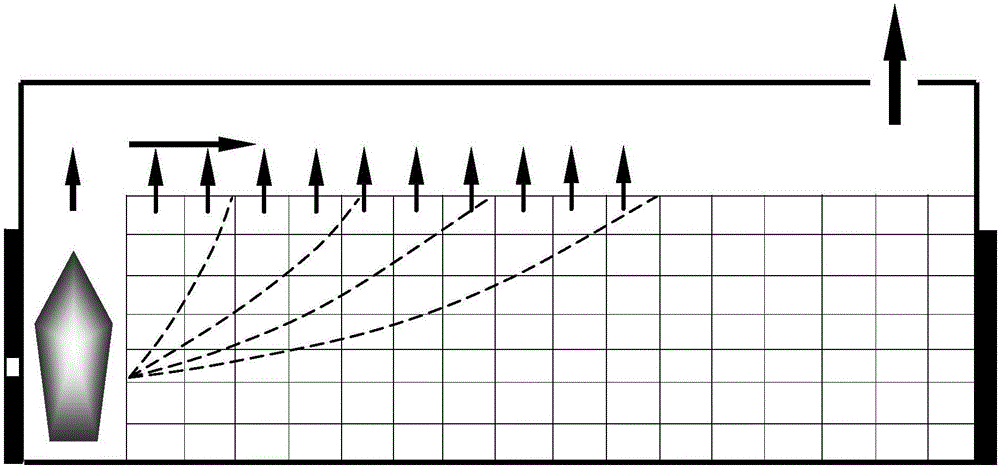

Method and device for treating organic polluted soil by two-section-type indirect thermal desorption technology

ActiveCN104874593AReduce consumptionEasy temperature controlContaminated soil reclamationThermal desorptionPollution

The invention discloses a method and a device for treating organic polluted soil by a two-section-type indirect thermal desorption technology. The method comprises the following steps: carrying out predrying and dehydrating moisture in organic polluted soil at low temperature so as to enable the moisture content to be reduced to be less than 5%; heating the predried organic polluted soil in a thermal desorption device indirectly so as to obtain altithermal soil and organic pollutant gas; directly introducing the organic pollutant gas into a combustion heating device to be combusted together with fuels at high temperature so as to achieve the complete innocent treatment of organic pollutants; cooling the high-temperature soil indirectly by a hot soil cooling device, recycling the altithermal soil to sense heat so as to preheat air for the fuel combustion for the combustion heating device, thereby obtaining raw materials for building materials for further deep processing. The technology is simple; the investment is low; the running management expense is low; the energy source efficiency is high; tail gas pollution and any other environment problem are not generated; the technical economy is feasible, and the energy conservation and environment-friendly benefit is obvious; the concept of clean production and circulation economy is shown fully.

Owner:ZHONGKE DINGSHI ENVIRONMENTAL ENG CO LTD

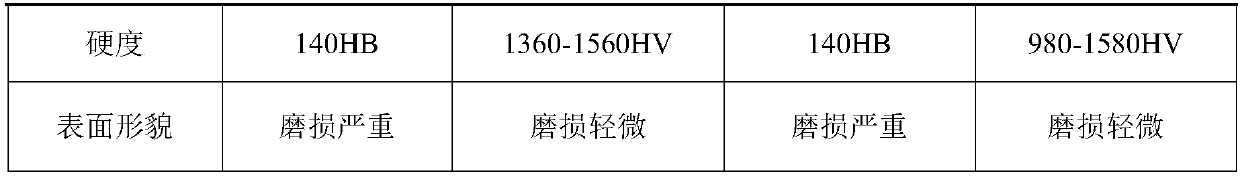

Nanometer graphene reflection thermal insulation composite multifunctional ceramic coating layer and preparation method thereof

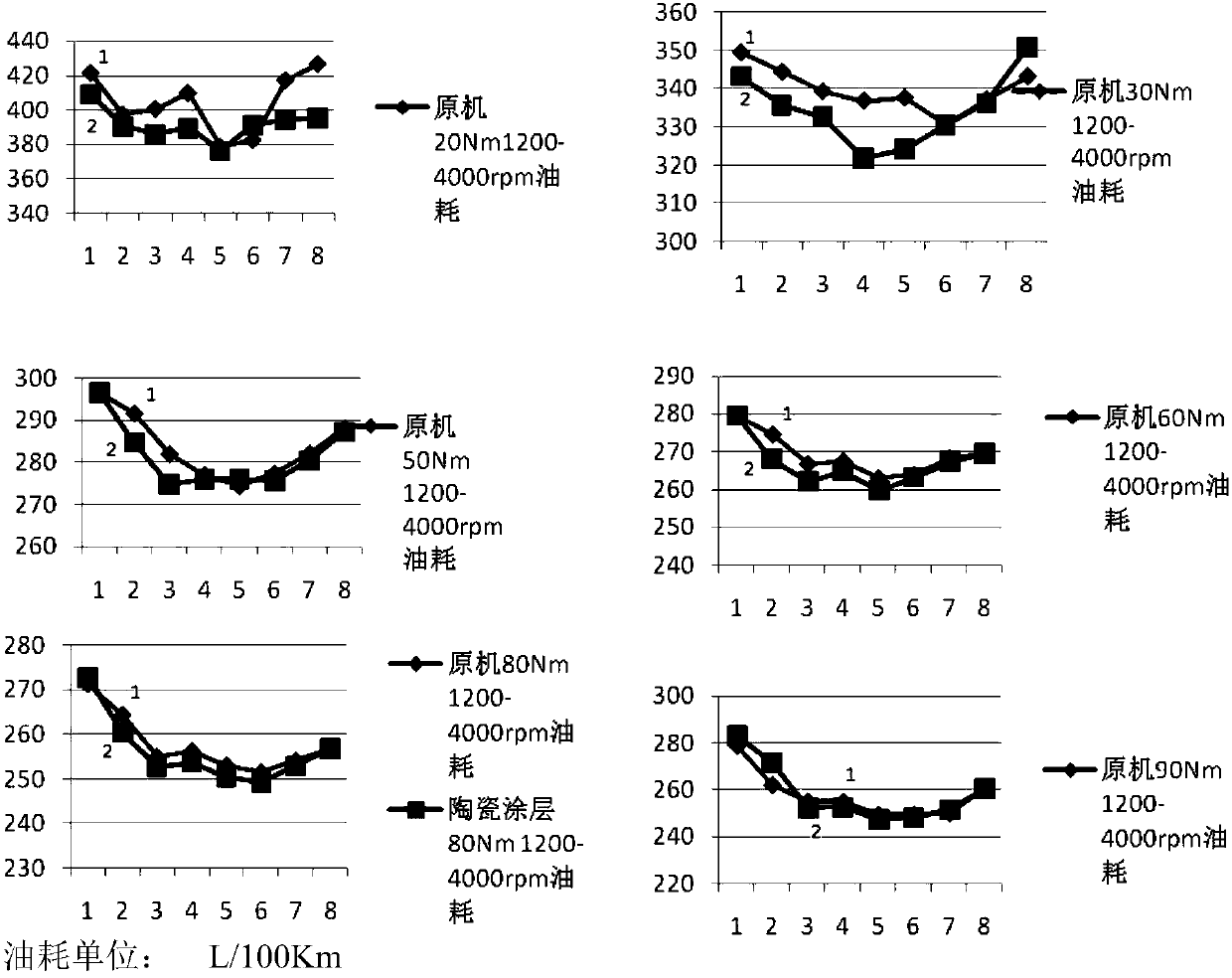

ActiveCN105951151AOutstanding heat insulationOutstanding FeaturesAnodisationCombustion chamberPlasma electrolytic oxidation

The invention discloses a reinforced alloy material; and a surface layer of the alloy material contains such elements as aluminum oxide, silicon dioxide and nanometer graphene. The alloy material is deeply extended on the basis of anodic oxidation, microarc oxidation and multi-component composite oxidation, and is a result under a complex effect of instant high temperature, multi-component composite oxidation liquid and nanometer penetrant through applying positive and negative high voltage, high current and positive and negative pulses by using unique structures, physical and chemical characteristics as ultrahigh hardness and high-temperature resistance, small size effects and surface and interface effects of such nanometer materials as nanometer graphene and nanometer silicon dioxide. The method comprises the steps of: (1) surface cleaning; (2) oxidation; and (3) penetration. The light alloy material after surface reinforcement by the method, in particular a combustion chamber of an internal combustion engine with fuel combustion consumption and generating a pollution source is prominent in reflection thermal insulation anti-carbon self catalysis function, and is higher in high-temperature erosion resistance and wear resistance.

Owner:四川鸿森达铝业科技有限公司

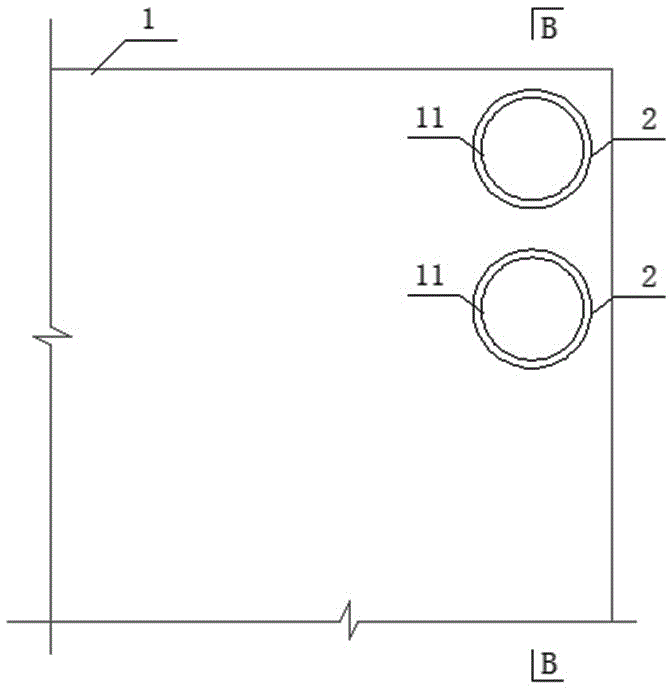

Accurately embedded water supply or water drainage casing pipe based on BIM and aluminum alloy formwork and construction method

ActiveCN106481880AGuarantee the verticality of the installationGuaranteed one-time successful installationPipe laying and repairPipesStructure of the EarthProduction drawing

Provided is a construction method for accurately embedding a water supply or water drainage casing pipe based on BIM and an aluminum alloy formwork. The construction method comprises the operation steps that 1, a model is built through the BIM technology, position collision checking of the water supply or water drainage casing pipe is conducted, and a water supply or water drainage casing pipe production drawing is deeply optimized and designed; 2, the aluminum alloy formwork of a floor or a wall or a beam where a pipeline passes through is designed through the BIM technology, and pipeline position information data are recorded and stored through a two-dimensional code; 3, the aluminum alloy formwork with a positioning clamp ring is produced according to the information model; 4, the aluminum alloy formwork of the floor or the wall or the beam is installed; and 5, concrete is poured into the floor or the wall or the beam, when the concrete strength meets the requirement, the aluminum alloy formwork is dismounted, and the water supply or water drainage casing pipe is accurately embedded in the concrete structure. The effect that pipelines on the floor are on the same straight line is ensured, and perpendicularity of later pipeline installation is ensured; pipelines on the beam or the wall can be on the same proper slope line, and gradient of later pipeline installation is ensured; and the pipelines can be installed at a time successfully, and rework caused by dimensional deviation is avoided.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

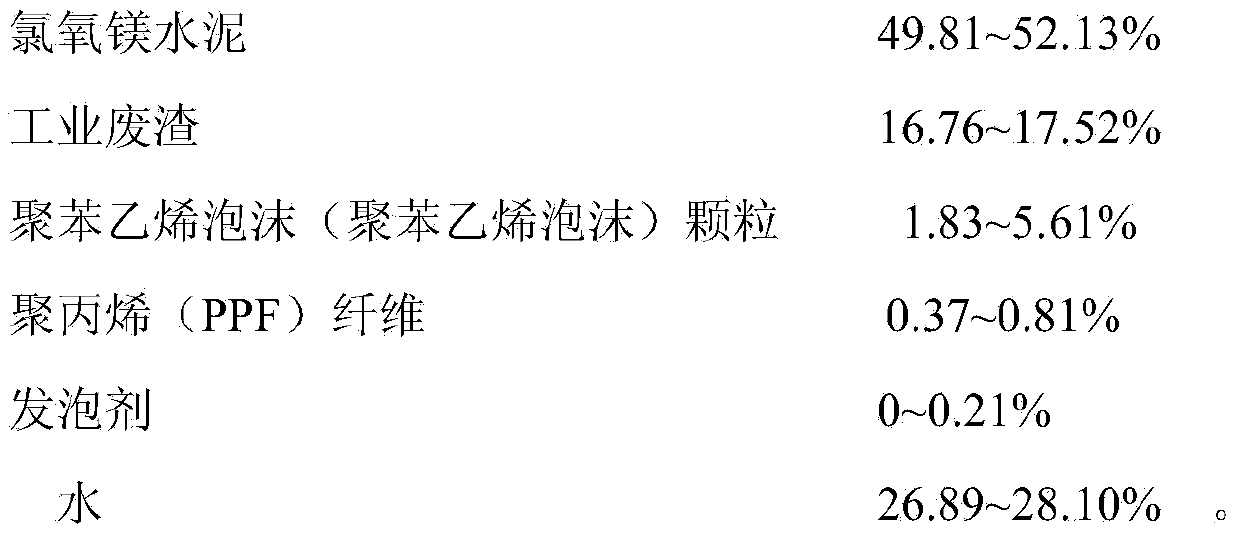

Styrene foam particle-magnesium oxychloride cement composite heat insulation material and preparation method thereof

ActiveCN103408321ALight in massImprove thermal insulation performanceCeramicwareCement compositesFoaming agent

The invention discloses a polystyrene foam particle-magnesium oxychloride cement composite heat insulation material and a preparation method thereof. The EPS (expanded polystyrene) particle-magnesium oxychloride cement composite heat insulation material is a novel lightweight organic-inorganic composite heat insulation material which is prepared by steps of firstly foaming magnesium oxychloride cement, industrial waste slag, EPS particles, PPF (polypropylene fiber) fiber, a foaming agent and water by using a slurry body of a cementing material of the magnesium oxychloride cement and further mixing with the EPS particles. The EPS particle-magnesium oxychloride cement composite heat insulation material comprises the following components in percentage by weight: 49.81-52.13% of magnesium oxychloride cement, 16.76-17.52% of industrial waste slag, 1.83-5.61% of EPS particles, 0.37-0.81% of PPF fiber, 0-0.21% of foaming agent and 26.89-28.10% of water. The EPS particle-magnesium oxychloride cement composite heat insulation material disclosed by the invention has the prominent features of low price, good heat insulation performance, energy conservation, waste recycling, environmental friendliness and the like.

Owner:SOUTHEAST UNIV

Outer-wall insulating material and preparation method thereof

InactiveCN106242426ALight in massImprove thermal insulation performanceHeat proofingCeramicwareFiberFoaming agent

The invention provides an outer-wall insulating material and a preparation method thereof. The outer-wall insulating material comprises the following components in parts by weight: 30-40 parts of polystyrene foam particles, 50-60 parts of Portland cement, 10-15 parts of mineral slag, 4-6 parts of wood fiber, 3-5 parts of sodium carboxymethylcellulose, 0-6 parts of foaming agent and 40-50 parts of water. The preparation method comprises the following steps of: firstly weighing the required Portland cement, mineral slag, wood fiber, sodium carboxymethylcellulose and water according to the proportion of a formula, stirring all the components to be uniform slurry-like substance; adding the foaming agent into a foaming machine for foaming, then injecting foam into Portland cement slurry, and stirring to be uniform; then adding the polystyrene foam particles into the Portland cement slurry in ratio, mixing and stirring to be uniform, casting, forming and then naturally curing. The outer-wall insulating material provided by the invention has the advantages that the combustion performance can meet the standard of an A-level incombustible material, the strength is higher and the heat-conductivity coefficient is low.

Owner:合肥广能新材料科技有限公司

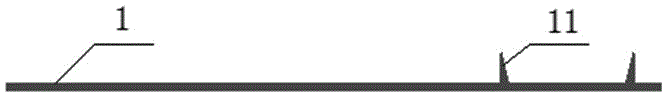

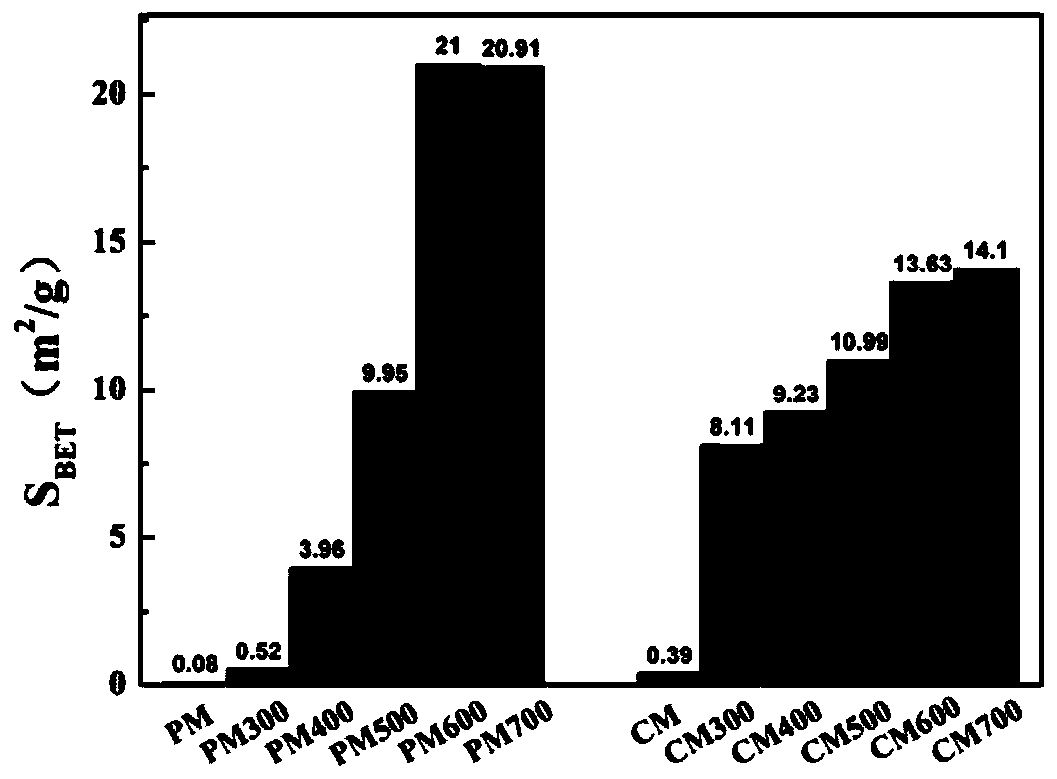

Method and device for cyclically treating breeding wastewater and/or improving soil by utilizing livestock and poultry manure

PendingCN111423096ASolving Dehydration ProblemsLow viscositySludge treatment by de-watering/drying/thickeningOther chemical processesAmmoniacal nitrogenCarbonization

The invention discloses a method and a device for cyclically treating breeding wastewater and / or improving soil by utilizing livestock and poultry manure. The method comprises the following steps: adding a conditioner into livestock and poultry manure for mixing and conditioning; then pre-drying and dehydrating at low temperature to reduce the moisture content to be less than 10% to obtain dried livestock and poultry manure, indirectly heating the livestock and poultry manure in a pyrolysis and carbonization device, indirectly cooling the obtained charcoal powder, and adding the obtained cooled charcoal into breeding wastewater; and forming charcoal particles; the invention can be directly used for soil improvement; part of COD, ammonia nitrogen, phosphorus and other effective elements andantibiotics and other micropollutants can be pre-removed, and the biochemical treatment load of the aquaculture wastewater is reduced; or the invention is used for deep adsorption and purification ofaquaculture wastewater before tail water is discharged. According to the method and device, pollution caused by simple composting of livestock and poultry manure is avoided, comprehensive treatment of breeding waste is fully achieved, and good social benefits, economic benefits and environmental benefits are achieved.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

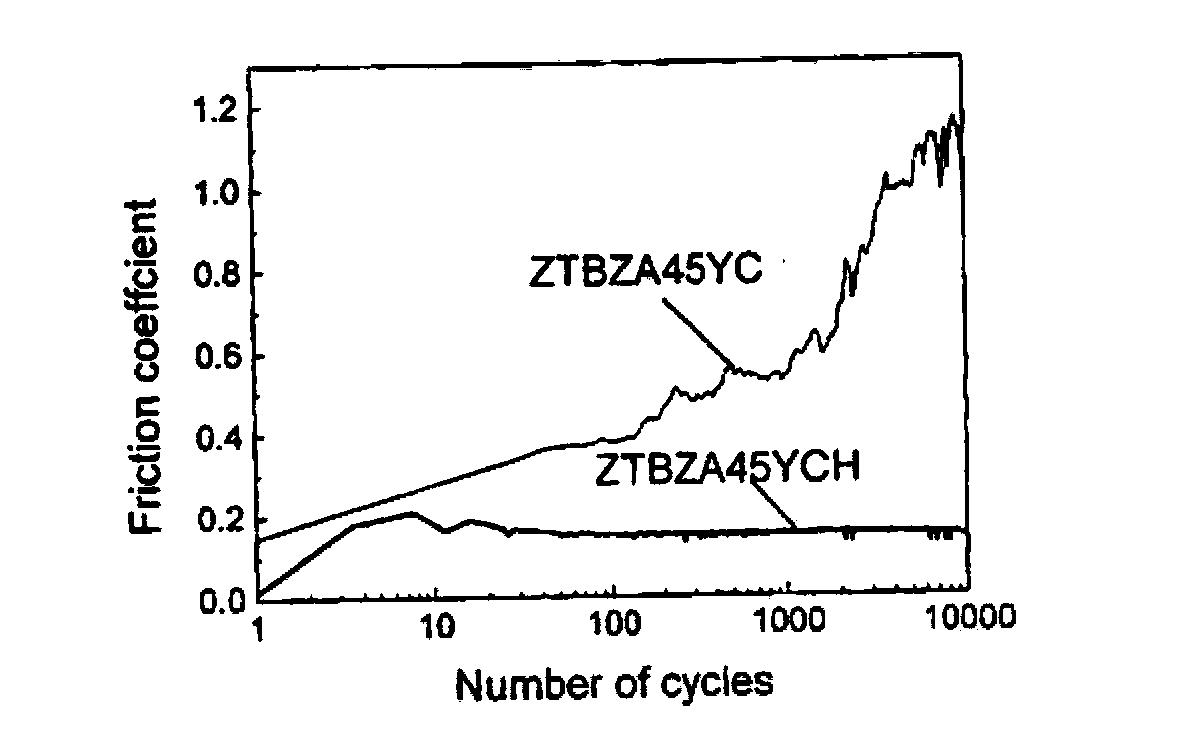

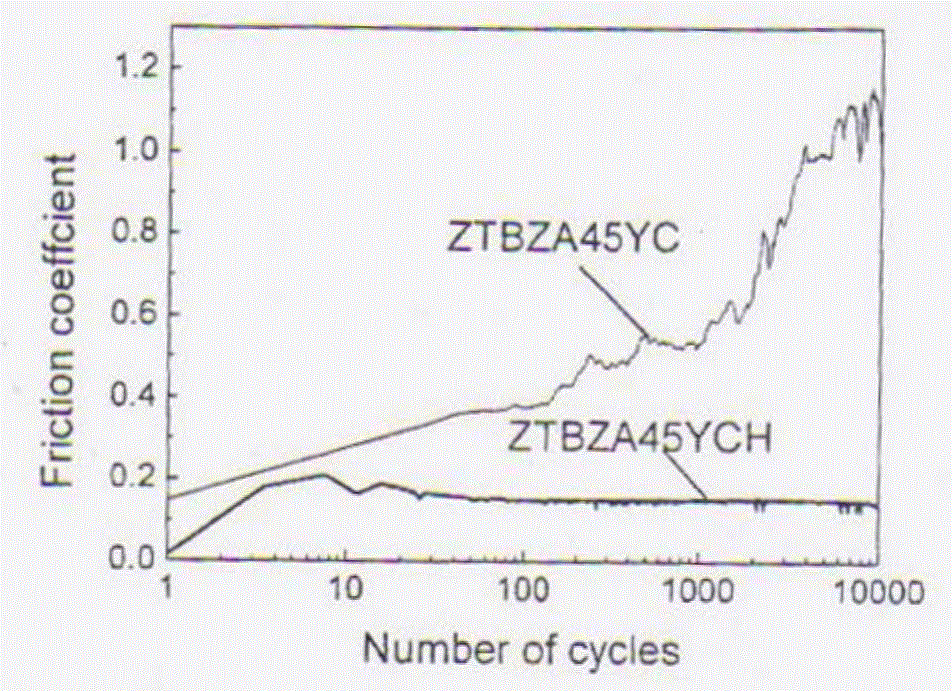

Method of processing surfaces of aluminium alloy pistons and precision friction pairs

ActiveCN103484849AHigh densityLow friction factorMaterial nanotechnologyMetallic material coating processesVolumetric Mass DensityMachining

The invention relates to a method of processing the surfaces of light alloy, in particular to a method of processing the surfaces of aluminium alloy pistons and precision friction pairs. The method comprises the steps that (1) washing is performed; (2) oxidization is performed; (3) hole plugging is performed. Nanoscale metal matrix ceramic oxidation film layers with the density up to the standard are respectively grown on the aluminium alloy pistons and precision friction pairs processed in the method, the density is increased, the diameters of blind holes are decreased obviously, nanometer penetrant blind holes are sealed, roughness is reduced, the friction coefficient is reduced, and the geometric dimensions are unchanged basically. The aluminium alloy pistons and precision friction pairs processed in the method can be installed for use in a matched mode without finish machining, industrial mass production can be achieved, and the method reduces production cost greatly compared with original technical methods.

Owner:邓才松 +1

Integrated construction method for board wall formwork and support formwork in restricted area

InactiveCN105926815AShorten construction timeShorten the timeWallsForms/shuttering/falseworksBasementEngineering

The invention relates to the technical field of building construction, in particular to an integrated construction method for a board wall formwork and a support formwork in a restricted area. A support pile is used as a shear wall outer mold, basement foundation outer wall steel bars are bound after waterproof treatment of the vertical faces of a fender post group, and then pull screws are connected between an inner side formwork and waterproof bolts; and then a basement foundation outer wall is subjected to concrete pouring. Operation is simple and rapid, the construction time of a formwork reinforcing system and construction engineering time are shortened, diversification of reinforcing of building formworks is promoted, efficiency is improved, the construction period is shortened, and the quality and performance of buildings are ensured.

Owner:东晟兴诚集团有限公司

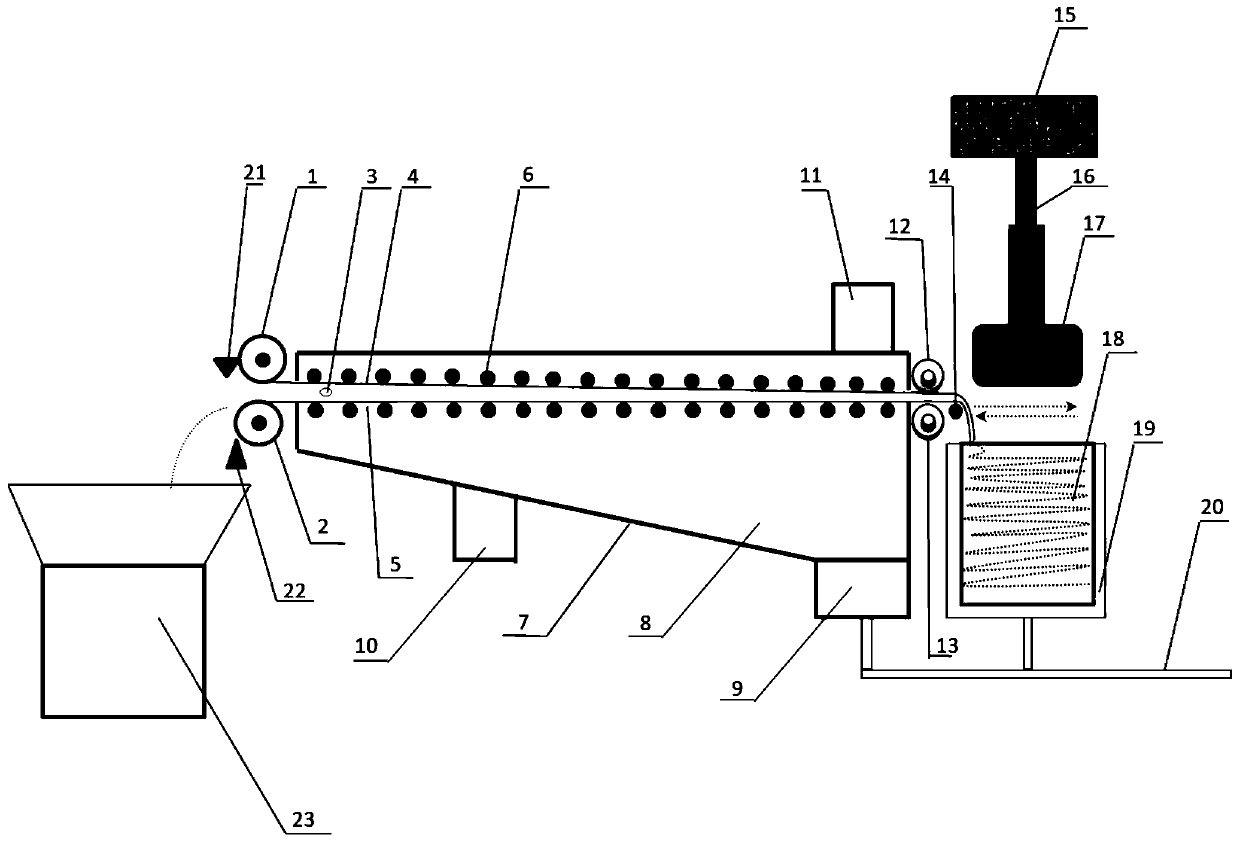

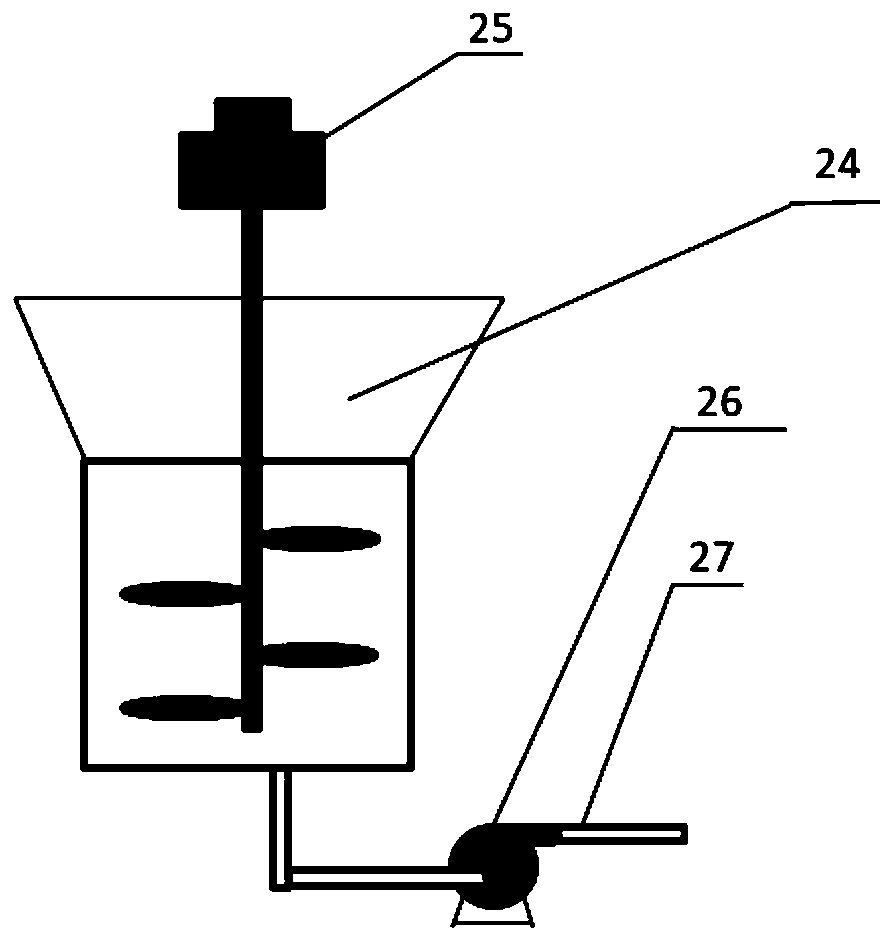

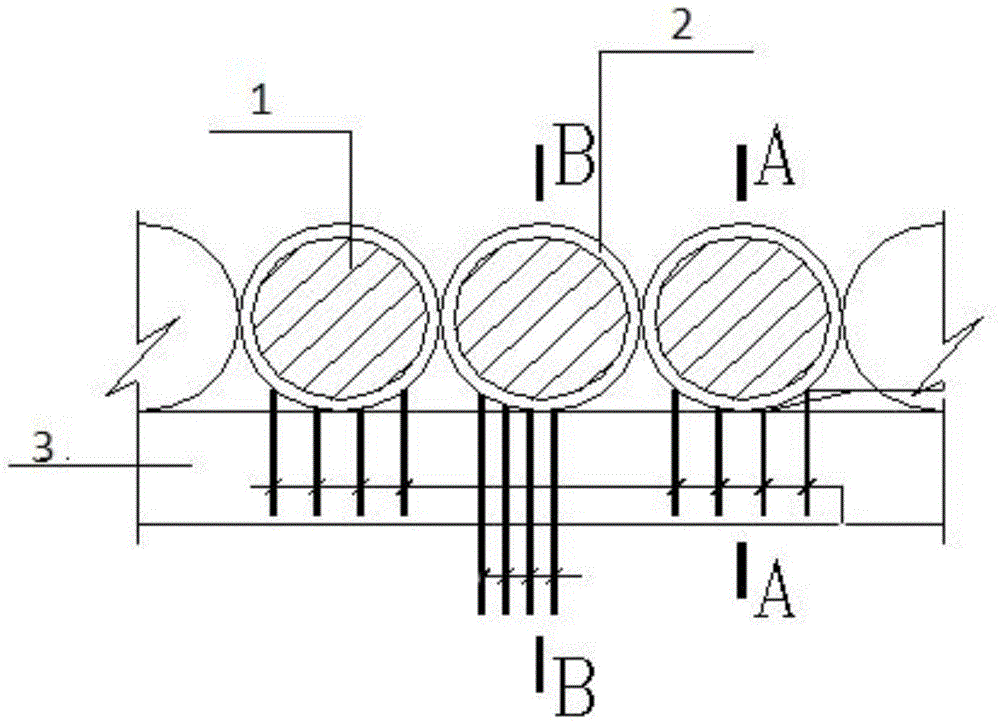

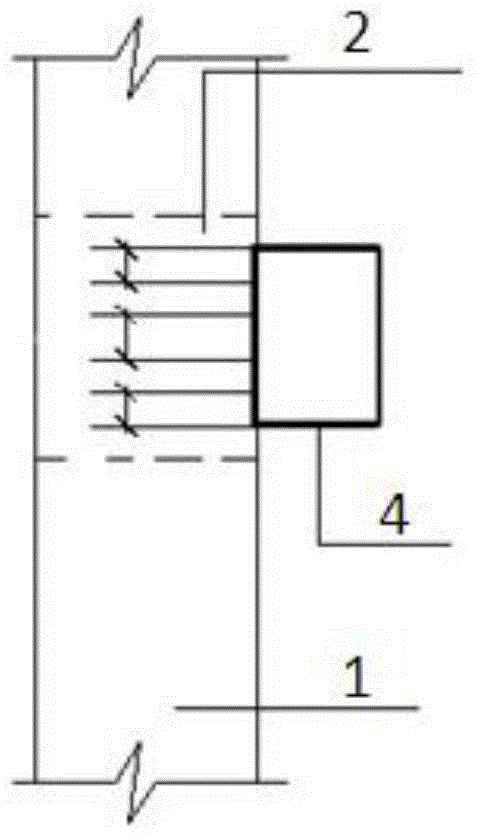

Sludge dewatering and drying device and method

PendingCN111348815AFine particleHigh viscositySludge treatment by de-watering/drying/thickeningHydraulic cylinderFlue gas

The invention discloses a sludge dewatering and drying device and method, and belongs to the technical field of sludge treatment, wherein the device comprises a heating pre-dewatering chamber, upper-layer filter cloth, lower-layer filter cloth and a high-pressure dewatering assembly, the upper-layer filter cloth and the lower-layer filter cloth penetrate through a sludge conveying channel formed by the heating pre-dewatering chamber; the upper-layer filter cloth and the lower-layer filter cloth are fed and collected along the channel; the heating pre-dewatering chamber is provided with a feeding hole for inputting sludge; sliding rollers are arranged on the outer sides of the upper-layer filter cloth and the lower-layer filter cloth; the heating pre-dewatering chamber is provided with a flue gas inlet for heating and conditioning sludge in a filter cloth interlayer on line to realize heating and pre-dewatering; a high-pressure dewatering assembly is arranged at one end of the heating pre-dewatering chamber and comprises a high-pressure dewatering tank and a matched hydraulic cylinder, a circulating material distribution mechanism is arranged on the high-pressure dewatering tank tofold the interlayer filter cloth in the high-pressure dewatering tank in a reciprocating mode, and the hydraulic cylinder presses the multiple layers of filter cloth for high-pressure dewatering. Deepdrying dewatering is achieved, the moisture content of the finally obtained sludge is less than 10%, and the device has the advantages of being high in dewatering efficiency, low in operation cost, high in practicability and the like.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

Sequential construction and reversed construction Clockwise and counter-clockwise combined construction method of irregular planar deep foundation pit

ActiveCN104594358AImprove support qualityLow costExcavationsSocial benefitsArchitectural engineering

The invention provides a sequential construction and reversed constructionclockwise and counter-clockwise combined construction method of an irregular planar deep foundation pit. The method is characterized by comprising the following steps: step 1, preparation for construction; step 2, pile driving construction of engineering piles, a building envelope and support upright piles; step 3, foundation pit dewatering; step 4, first excavation; step 5, construction of first ground floor plate bottoms and beams of an inverse operating area, and construction of first supports of a central area and a narrow and long area; step 6, second excavation; step 7, repeating the steps 5 and 6 to carry out the excavation of a second ground floor and a third ground floor; and step 8, dismantling a support device. The construction method has the advantages of being better in supporting quality of foundation pit, safer to operate and relatively lower in construction cost, and the total period of construction can be shortened; furthermore, the construction method has the characteristics of advancement, novelty, energy conservationsaving, environmental protection and the like, and the significant social benefits can be realized.

Owner:NANTONG CONSTR PROJECT GENERAL CONTRACTING

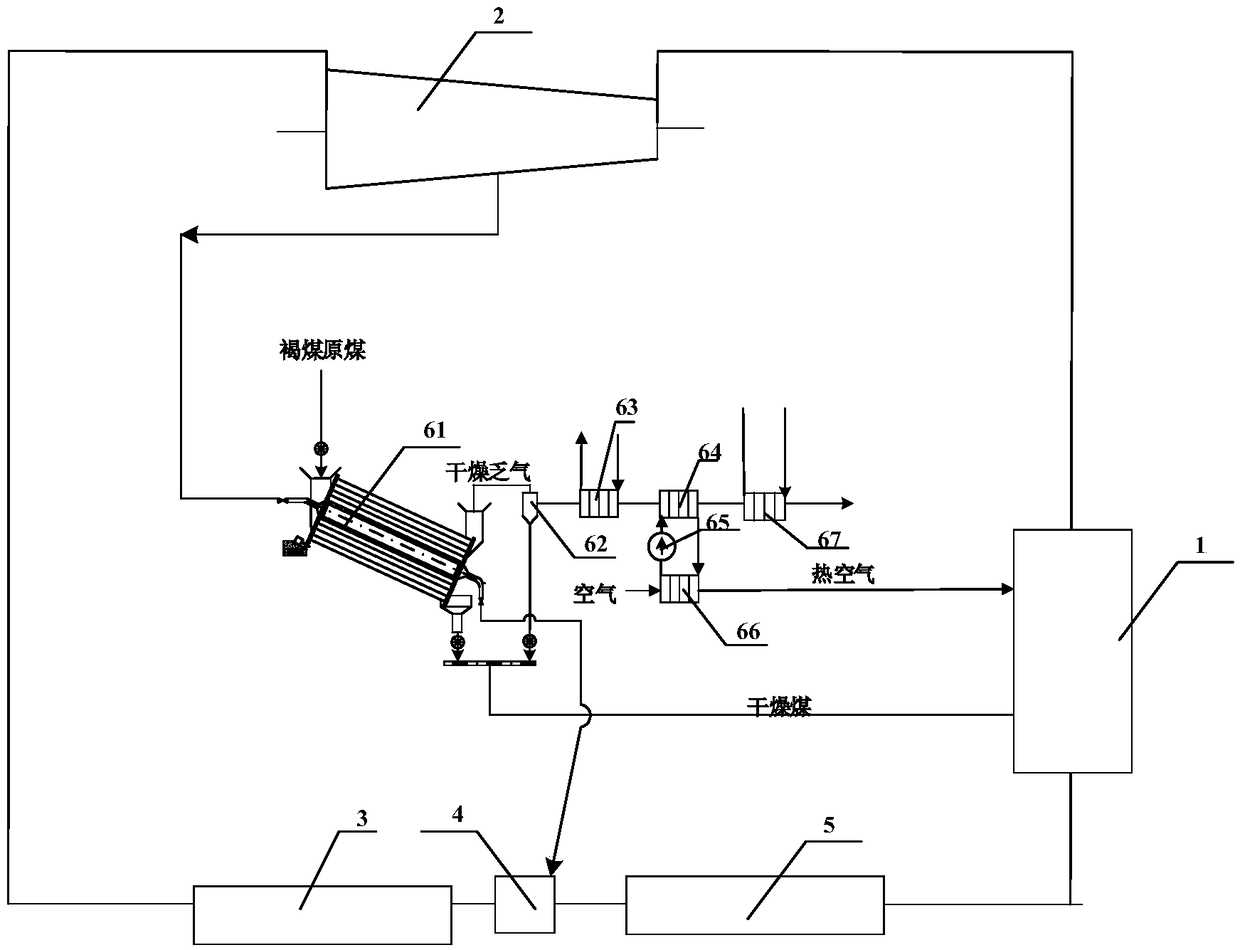

Power plant fire coal steam extraction drying and waste heat using integrated system

PendingCN108626713AImprove efficiencyCombined heat and powerLiquid degasificationSolid fuel pretreatmentCogenerationEngineering

The invention relates to a power plant fire coal steam extraction drying and waste heat using integrated system. A steam drying machine steam inlet is connected with a turbine steam extraction opening, a steam drying machine condensation water outlet is connected with a deaerator, raw coal firstly enters a steam drying machine, and a steam drying machine drying coal outlet is connected with a boiler fuel inlet; drying dead steam of a brown coal drying system is connected into a waste heat recovering system, and the waste heat recovering system comprises a first-stage dead steam cooling device,a second-stage dead steam cooling device and a third-stage dead steam cooling device; the first-stage dead steam cooling device, the second-stage dead steam cooling device and the third-stage dead steam cooling device are sequentially connected, stair waste heat for dead steam drying is used for gradually heating turbine regenerative system condensation water, heating boiler wind feeding air andsupplying heat an external heat supply network; and combined heat and power generation of brown coal is achieved, meanwhile, the boiler efficiency is improved, and the obvious energy saving and environment benefits are achieved.

Owner:DATANG BEIJING ENERGY MANAGEMENT +1

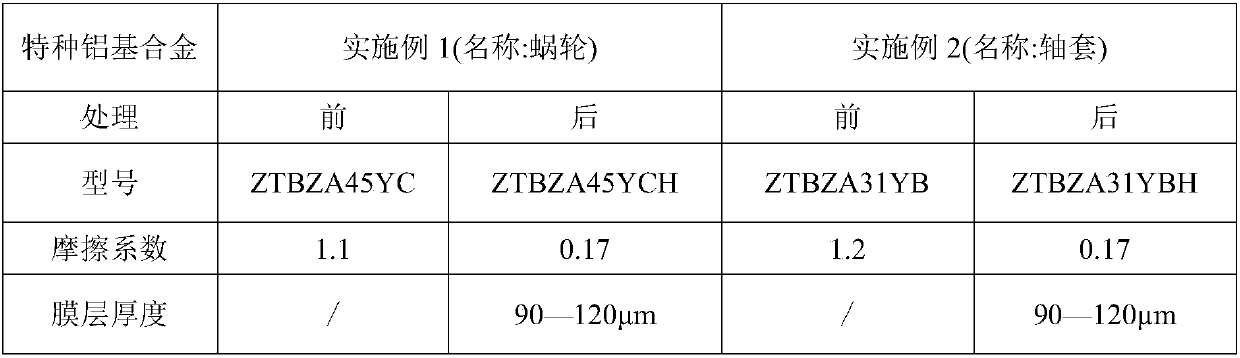

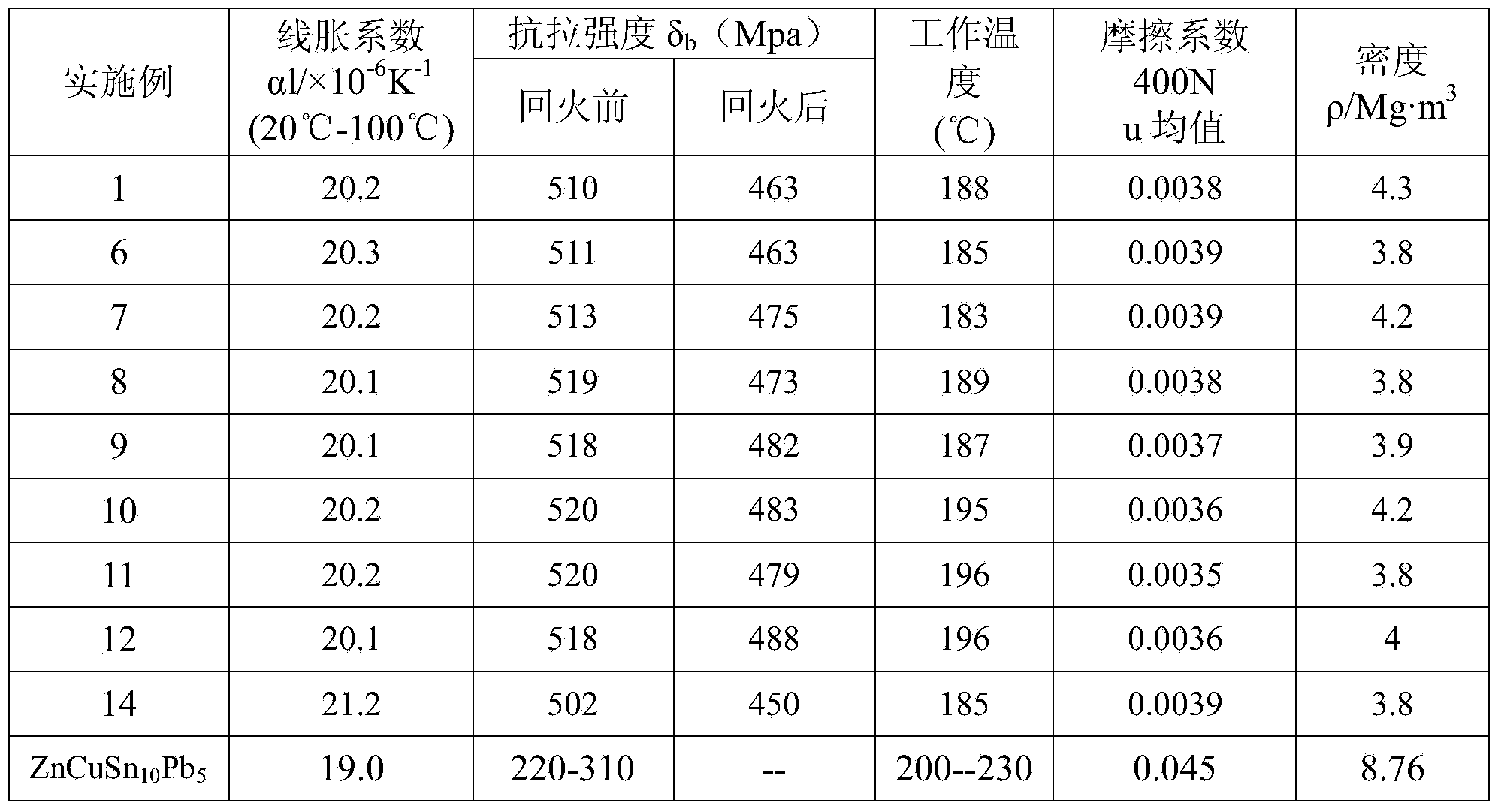

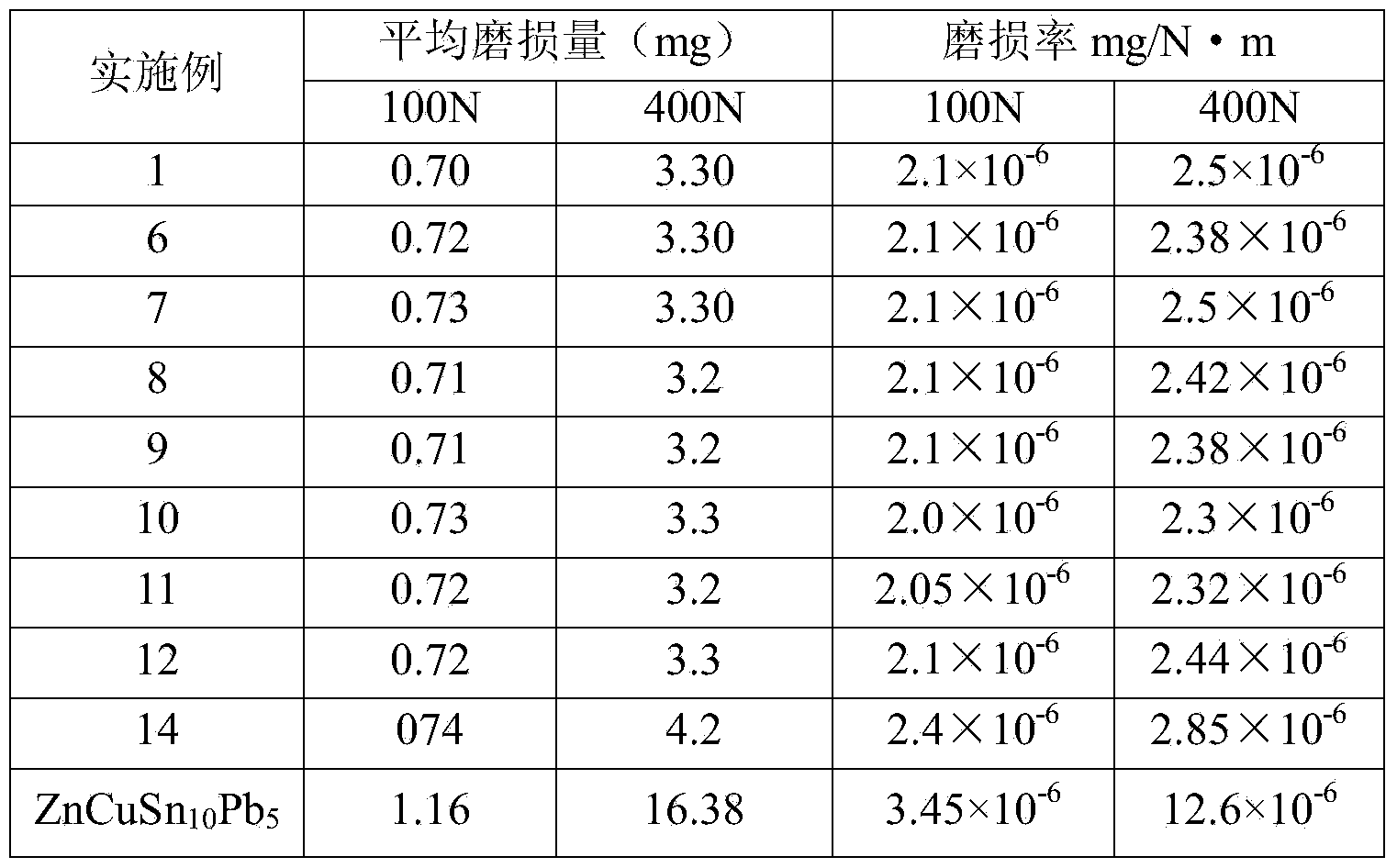

Highly wear-resisting axle-hang free aluminum base alloy and preparation method thereof

InactiveCN103436756AGrain refinementImprove wear resistance and antifriction performanceRheniumManganese

The invention discloses an aluminum base alloy which comprises the following components in percent by weight: 38-40% of zinc, 0.5-5% of silicon, 3.0-5% of copper, 0.5-1% of manganese, 0.3-0.5% of chromium, 1.2-1.8% of rhenium, 1-1.5% of boron, 0.038-0.048% of magnesium, 0.015-0.02% of titanium and the balance of aluminum. The invention further discloses a preparation method thereof. The aluminum base alloy disclosed by the invention has the advantages of high wear resistance, no axle-hang, low expansion rate, self-lubrication, anti-occluding function and high work temperature, and the low expansion rate of the alloy is realized, so that the aluminum base alloy is suitable for manufacturing various precise friction pair parts of mechanical equipment.

Owner:四川超耐磨高科技有限公司

Dense flue-cured tobacco drum type reversal combustion furnace and use method thereof

ActiveCN106108096AImprove temperature control effectEasy to operateTobacco preparationBrickHoneycomb

A dense flue-cured tobacco drum type reversal combustion furnace comprises a furnace top, a drum type bosh, a fire bar and an L-shaped furnace door. An inner cavity of the bosh has the side length of 0.8-1.0 m and the height of 1.2-1.5 m. A coal stacking area is arranged above the fire bar in the bosh, and a static pressure area is arranged below the fire bar in the bosh. No horizontal gaps exist between honeycomb briquette bricks in the coal stacking area, and vertical holes of the honeycomb briquette bricks are aligned. An operation opening the same height as the bosh is formed in the side wall of the bosh. The inner cavity of the bosh is communicated with a drum type inverted operation channel through the operation opening. An extension body at the bottom of the furnace door seals the side wall of the static pressure area. A piece of combusting small soft coal is inserted in the center of the top face of a coal bed. A temperature controller controls a draught fan to be started and stopped. All air evenly enters columnar channels of briquette bricks in a piston flow mode so that complete combustion can happen. Six to seven days of open fire reversal combustion heat supply is completed. In the tobacco curing industry, hot air generated by flue-cured tobacco can be used by the furnace. By means of the furnace, coal loading can be conducted at a time comfortably, CO emission is reduced by 75%, coal is saved by 25%, the furnace can be close to a baking curve to supply heat, the temperature drop and the draught fan burning caused by excessive temperature are avoided, and local honeycomb briquette bricks can be combusted.

Owner:LIUYANG BRANCH OF CHANGSHA COMPANY OF HUNAN TOBACCO

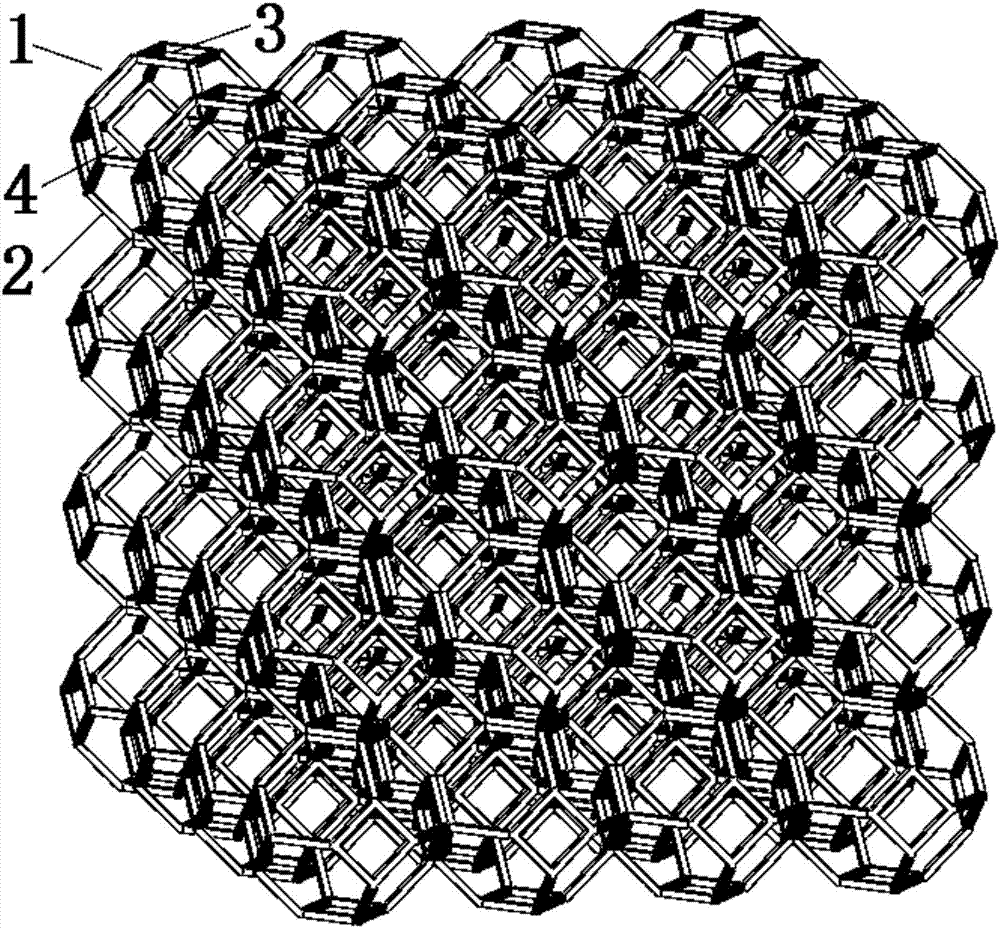

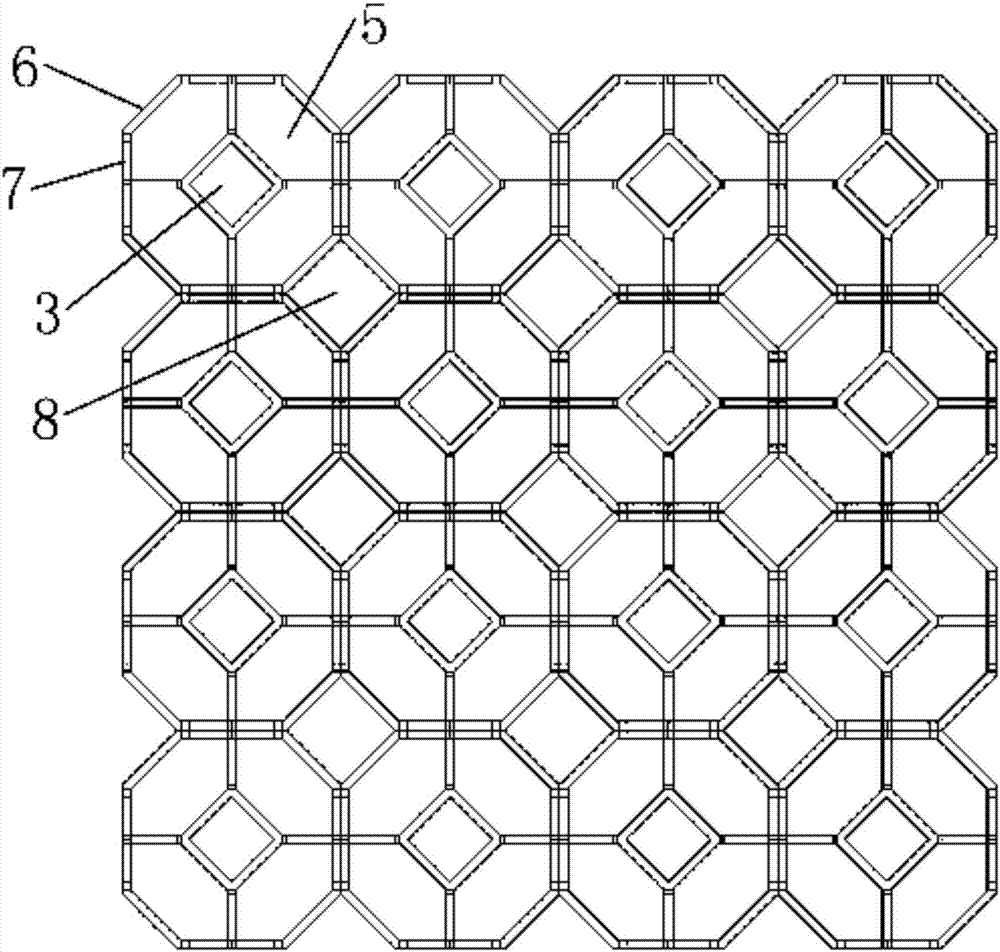

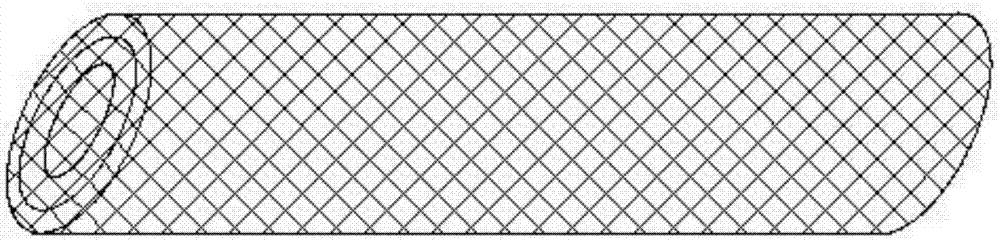

Honeycomb lamination hollow structure of 3D printing alloy material and vehicle component manufactured by same

InactiveCN106984822ALight weightSave energyAdditive manufacturing apparatusIncreasing energy efficiencyMultiple edgesHoneycomb

The invention discloses a honeycomb lamination hollow structure of a 3D printing alloy material and a vehicle component manufactured by the same. The structure comprises a hollow sphere surrounded by multiple edges; six squares 1 and eight regular hexagons are arranged on the surface of the sphere; the six squares 1 are respectively positioned in the right upper, right lower, right front, right back, right left and right directions of the surface of the sphere; every two squares 1 are connected through one regular hexagon; each square 1 and each regular hexagon share one edge; and every two adjacent regular hexagons share one edge. The honeycomb lamination hollow structure of the 3D printing alloy material can greatly improve the crushing resistance, the shock resistance and the toughness; and the vehicle component manufactured by the hollow structure can largely reduce the vehicle body weight, saves the energy, prominently improves each vehicle safety performance, and achieves the purposes of overall interweaving and tighter structure.

Owner:窦鹤鸿

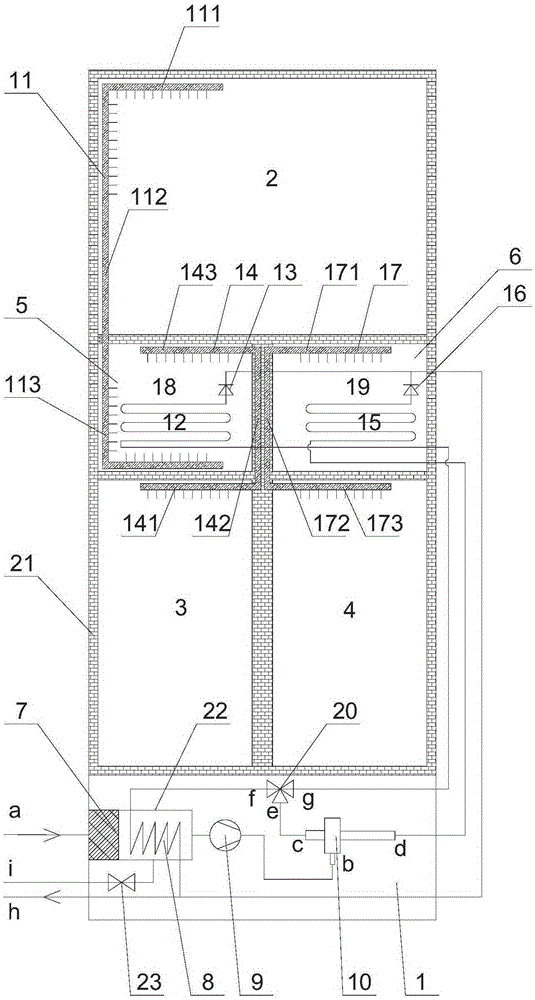

Multifunctional environment-friendly refrigerator

ActiveCN105258429ASignificant energy saving and environmental protection benefitsLighting and heating apparatusDomestic refrigeratorsThermal insulationHeat storage material

The invention discloses a multifunctional environment-friendly refrigerator which comprises a working chamber, a refrigerating chamber, a freezing chamber, a heat insulating chamber, a cold storage chamber and a heat storage chamber, wherein the cold storage chamber is arranged above the freezing chamber; the heat storage chamber is arranged above the heat insulating chamber; the refrigerating chamber is arranged above the cold storage chamber and the heat storage chamber; and the chambers are separated by a thermal insulation material; a first cooling coil tube is arranged in the air drying chamber; the air drying chamber is connected with an air compressor; the air compressor is connected with a vortex tube; the vortex tube is connected with a three-way flow regulating valve; the three-way flow regulating valve is connected with an inlet of the first cooling coil tube; a phase-change cold storage material and a second cooling coil tube are arranged in the cold storage chamber; the three-way flow regulating valve is connected with the second cooling coil tube; the second cooling coil tube is connected with a first one-way valve; a phase-change heat storage material and a heating coil tube are arranged in the heat storage chamber; the vortex tube is connected with the heating coil tube; and the heating coil tube is connected with an inlet of a second one-way valve. In a process of completing energy conversion, an environment-friendly working medium, namely air is adopted as a circulating medium, so that the multifunctional environment-friendly refrigerator has remarkable energy-saving and environment-friendly benefits.

Owner:佛山市顺德区西科电器有限公司

Styrene foam particle-magnesium oxychloride cement composite heat insulation material and preparation method thereof

The invention discloses a polystyrene foam particle-magnesium oxychloride cement composite heat insulation material and a preparation method thereof. The EPS (expanded polystyrene) particle-magnesium oxychloride cement composite heat insulation material is a novel lightweight organic-inorganic composite heat insulation material which is prepared by steps of firstly foaming magnesium oxychloride cement, industrial waste slag, EPS particles, PPF (polypropylene fiber) fiber, a foaming agent and water by using a slurry body of a cementing material of the magnesium oxychloride cement and further mixing with the EPS particles. The EPS particle-magnesium oxychloride cement composite heat insulation material comprises the following components in percentage by weight: 49.81-52.13% of magnesium oxychloride cement, 16.76-17.52% of industrial waste slag, 1.83-5.61% of EPS particles, 0.37-0.81% of PPF fiber, 0-0.21% of foaming agent and 26.89-28.10% of water. The EPS particle-magnesium oxychloride cement composite heat insulation material disclosed by the invention has the prominent features of low price, good heat insulation performance, energy conservation, waste recycling, environmental friendliness and the like.

Owner:SOUTHEAST UNIV

Bulk tobacco curing reverse-combustion hot-blast furnace and application method thereof

ActiveCN106360800AEmission reductionImprove temperature control effectTobacco preparationMetallurgyHoneycomb

The invention provides a bulk tobacco curing reverse-combustion hot-blast furnace. The bulk tobacco curing reverse-combustion hot-blast furnace comprises a furnace top, a bosh, a furnace grate, an inner furnace door and an outer furnace door; the height of an inner cavity of the drum-shaped bosh is 1.2m to 1.5m and the inner diameter of the inner cavity is 0.9m to 1.1m; the furnace grate is horizontally fixed at the height of 0.2m to 0.35m; a coal piling region is arranged above the furnace grate and a static pressure region is arranged below the furnace grate; an operation opening, which is as high as a side wall of the bosh and is 0.6m to 0.8m wide, is formed in the side wall of the bosh; the bosh is communicated with a reversed operation channel through the operation opening; the inner furnace door is used for sealing a notch in the side wall of the static pressure region and the outer furnace door is used for sealing a right end opening of the operation channel; an auxiliary ventilation hole is formed in the outer furnace door. Combusted small bituminous coal blocks are charged into the center of a top surface of a coal bed and all air enters a combustion surface in a piston flow shape to a combustion surface for complete combustion; the bituminous coal blocks are reversely combusted in open fire and heat is supplied for 6 to 7 days. A tobacco curing hot-blast furnace of a tobacco curing industry can utilize the bulk tobacco curing reverse-combustion hot-blast furnace. The coal can be comfortably charged in one step; the CO emission is reduced by 75 percent the coal is saved by 25 percent; the heat is supplied in a manner of clinging to a curing curve; temperature falling, over-temperature and a draught fan being burnt cannot occur and local honeycomb briquette balls can be combusted.

Owner:LIUYANG BRANCH OF CHANGSHA COMPANY OF HUNAN TOBACCO

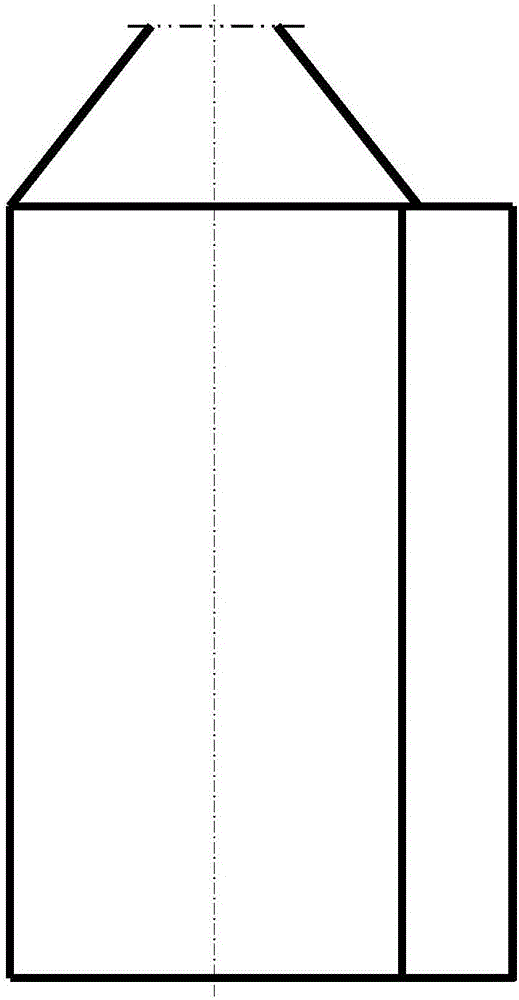

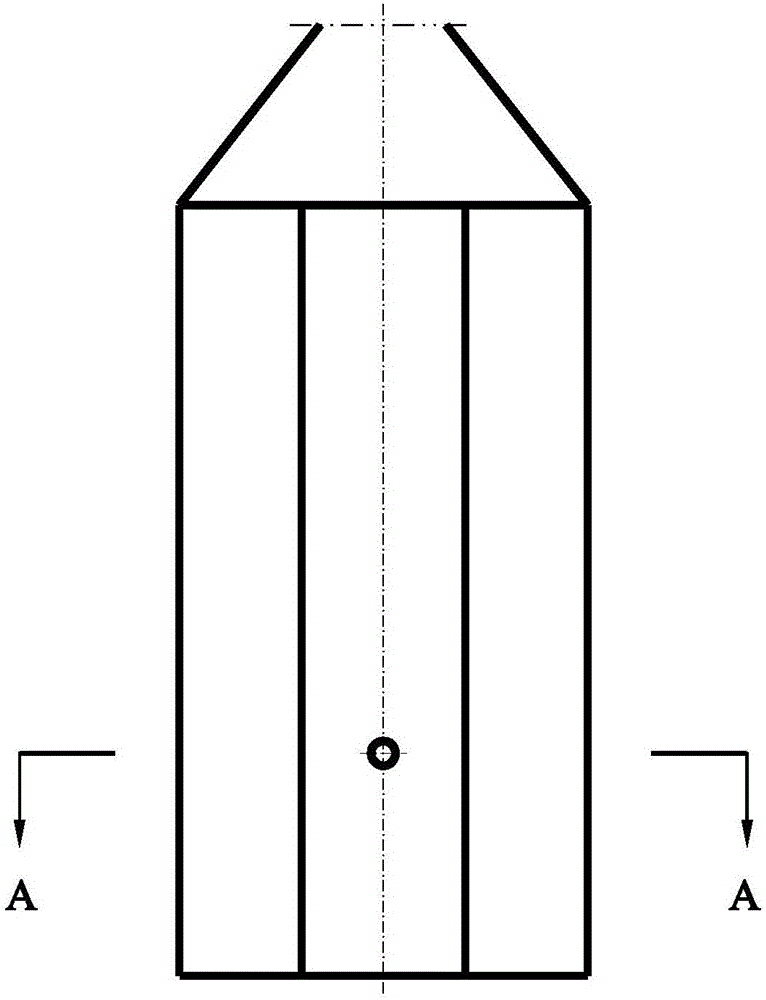

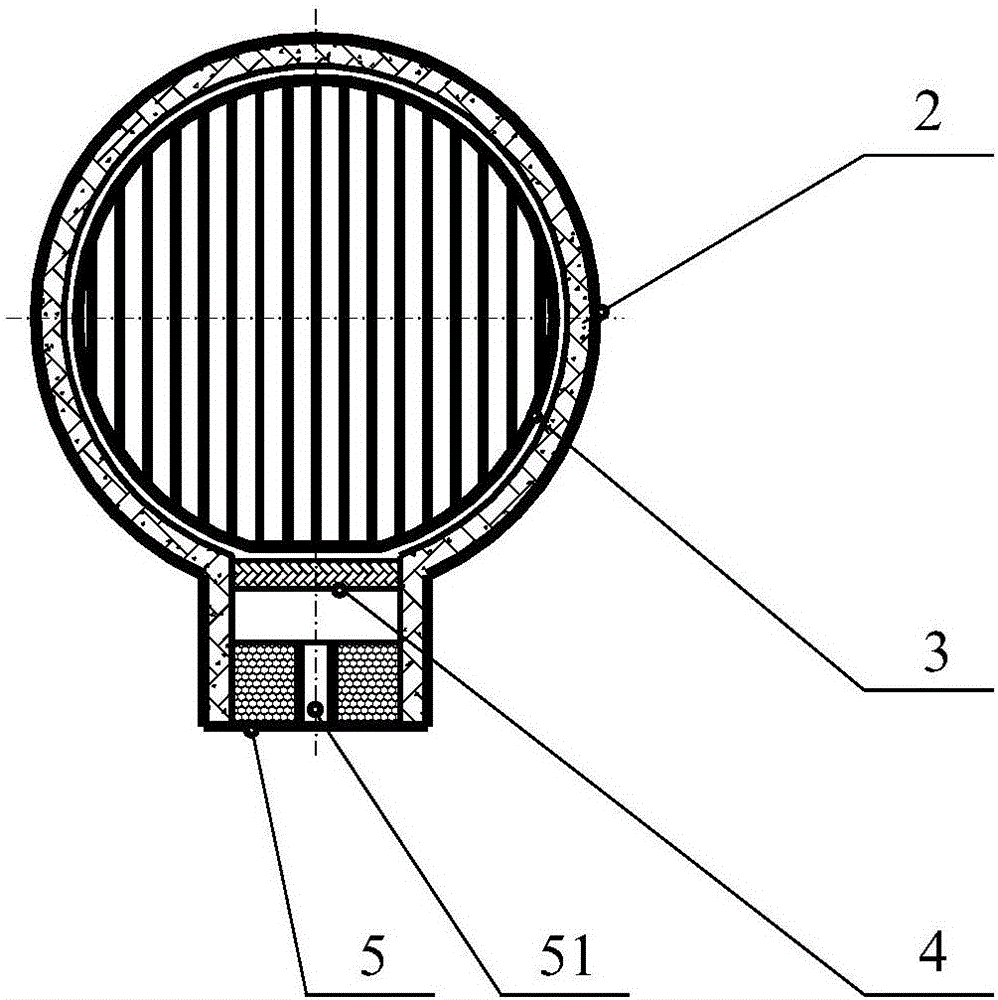

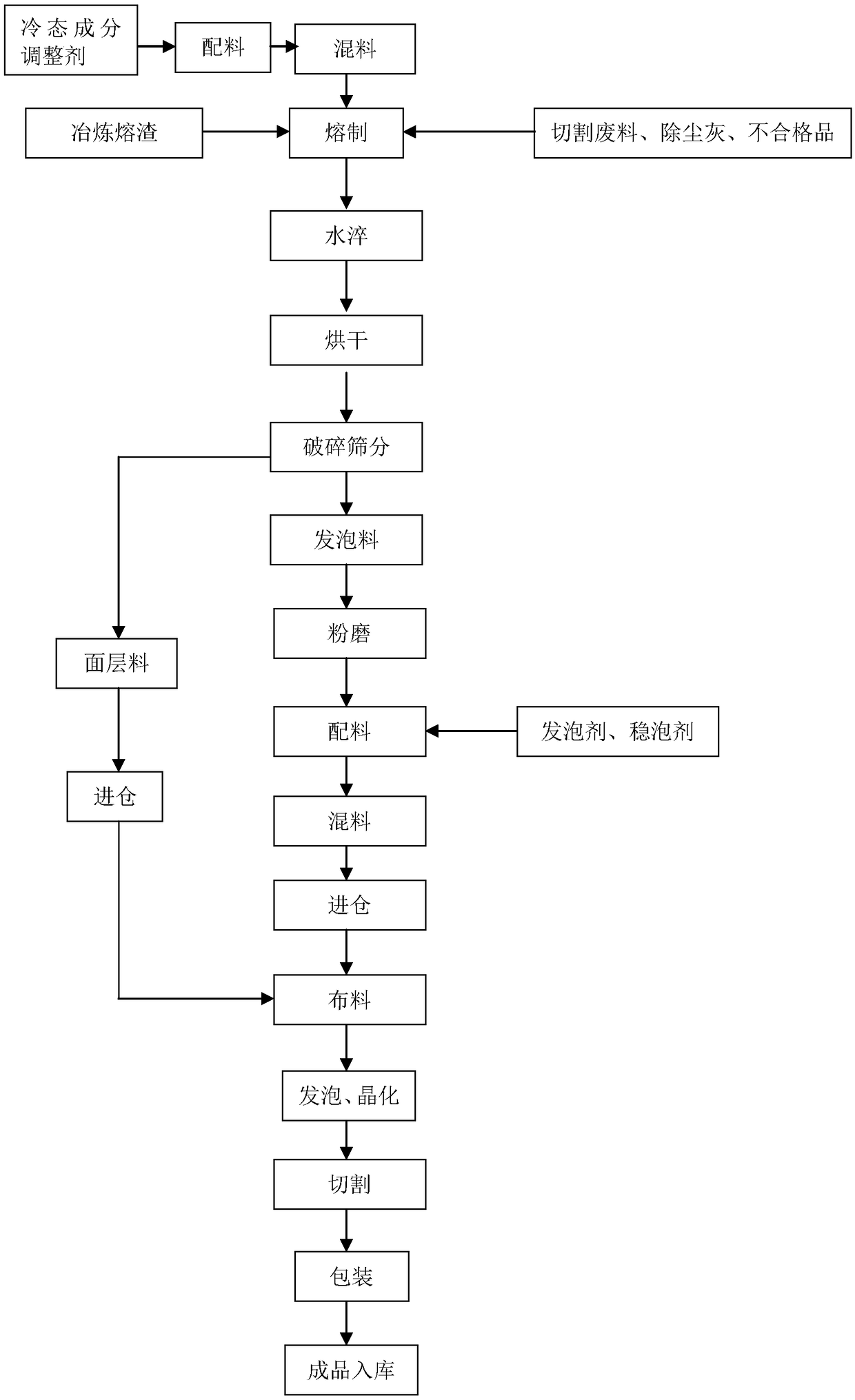

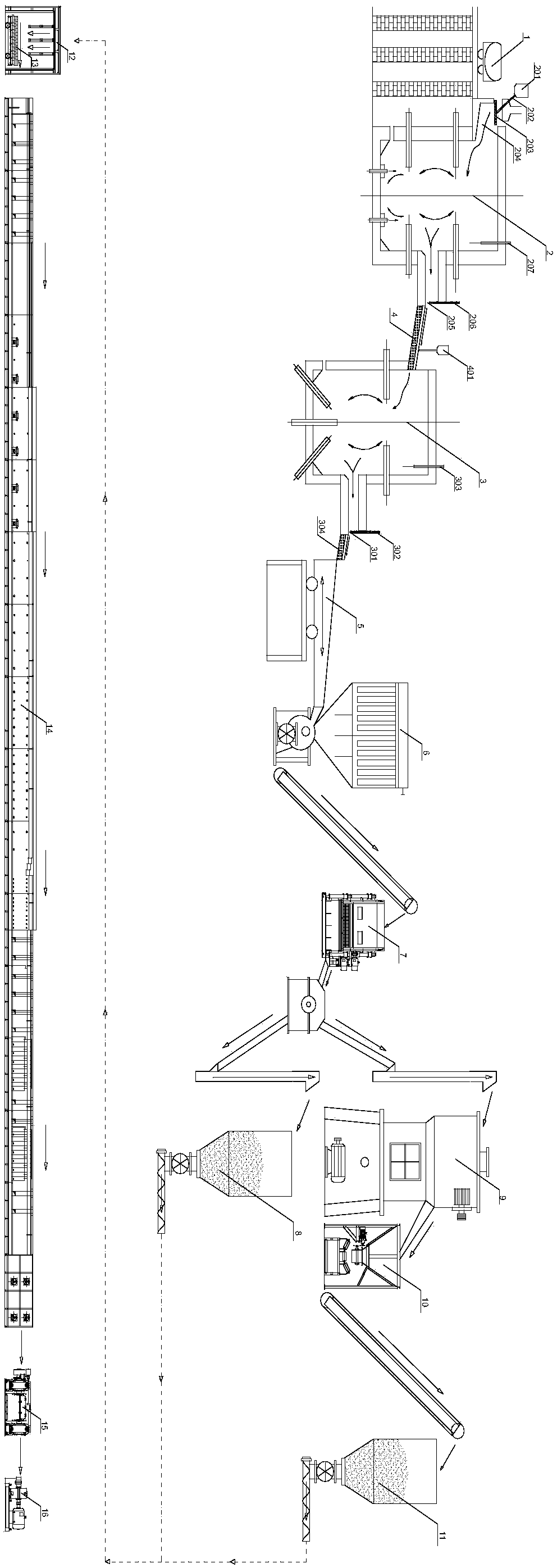

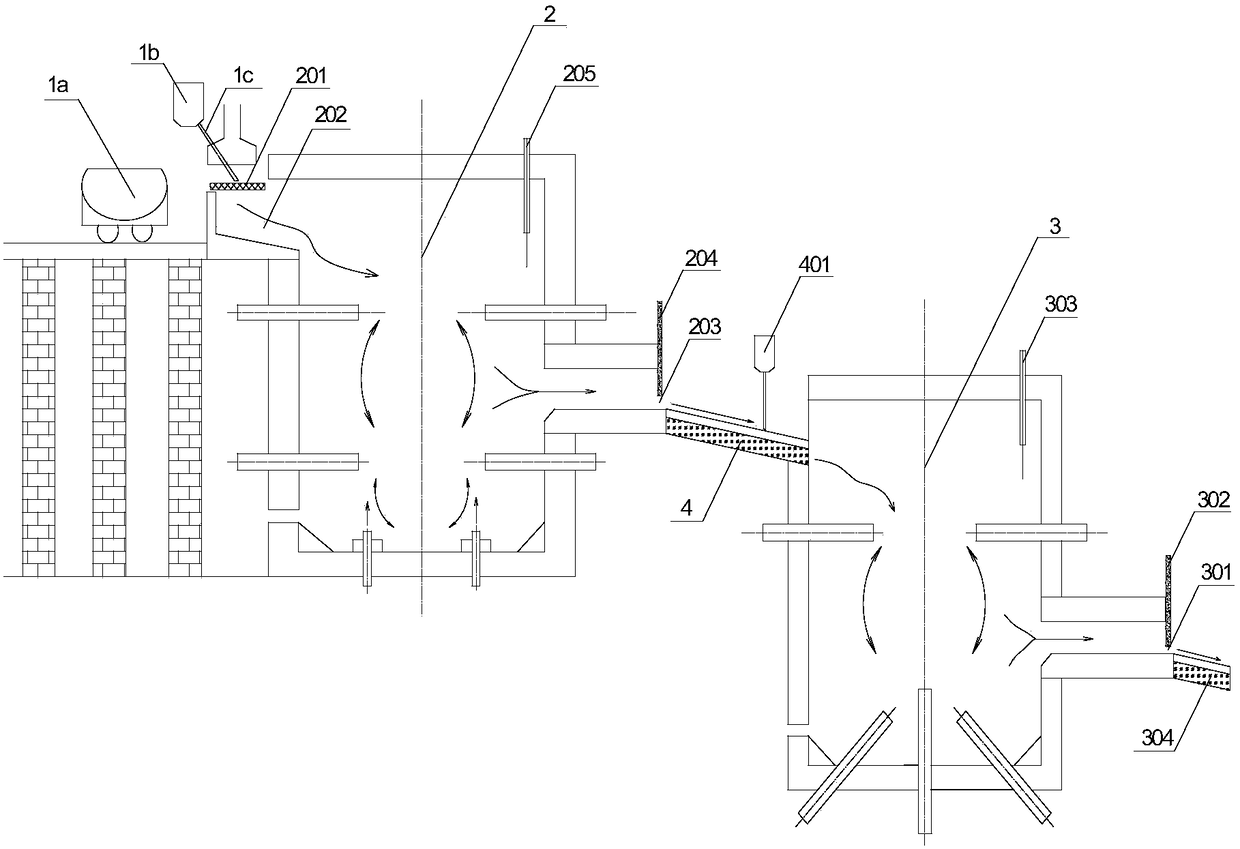

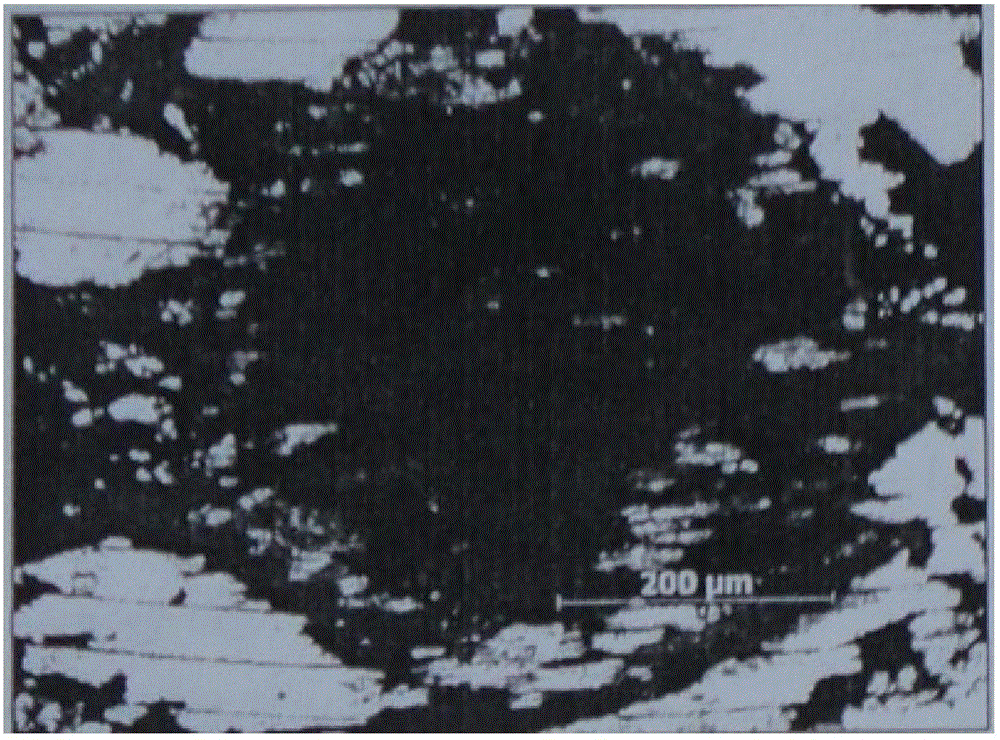

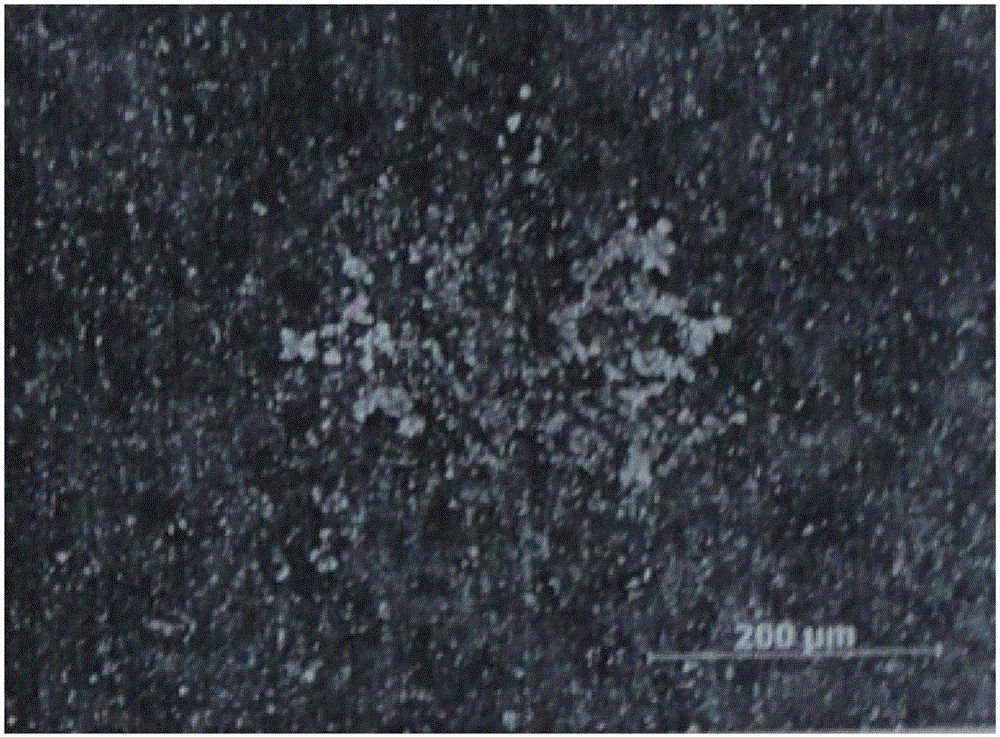

Production line for producing foam microcrystal fire protection, heat insulation and decoration integrated board through smelting slag

ActiveCN108262846AEmission reductionReduce production energy consumptionCeramic shaping plantsCeramic materials productionSlagThermal insulation

The invention discloses a production line for producing a foam microcrystal fire protection, heat insulation and decoration integrated board through smelting slag. The production line comprises a charging unit, a mixing and melting unit, a powder preparation unit, a foam sintering heat treatment unit and a post-processing unit in sequence. The comprehensive performance of the foam microcrystal fire protection, heat insulation and decoration integrated board produced through the smelting slag can meet the requirements of various public and civil buildings. The integrated board has the volume weight not greater than 200 kg / m3, the heat conductivity coefficient of 0.05-0.09 W / m.k, the compressive strength of 4-7 MPa, the fracture resistance of 3-6 MPa and the maximum heat resistance temperature of 750-800 DEG C and is an incombustible material of Grade A. Solid waste and energy dual recovery during metallurgy is achieved. the forming and crystallization process is completed in one step. Production energy consumption and cost of products are reduced. The production quantity of natural resources and environmental pollution are reduced. The virtuous cycle of an ecological system is maintained.

Owner:上海歌灵新材料科技有限公司

Surface treatment method of aluminum alloy piston and precision friction pair

ActiveCN103484849BHigh densityLow friction factorMaterial nanotechnologyMetallic material coating processesVolumetric Mass DensityMachining

The invention relates to a method of processing the surfaces of light alloy, in particular to a method of processing the surfaces of aluminium alloy pistons and precision friction pairs. The method comprises the steps that (1) washing is performed; (2) oxidization is performed; (3) hole plugging is performed. Nanoscale metal matrix ceramic oxidation film layers with the density up to the standard are respectively grown on the aluminium alloy pistons and precision friction pairs processed in the method, the density is increased, the diameters of blind holes are decreased obviously, nanometer penetrant blind holes are sealed, roughness is reduced, the friction coefficient is reduced, and the geometric dimensions are unchanged basically. The aluminium alloy pistons and precision friction pairs processed in the method can be installed for use in a matched mode without finish machining, industrial mass production can be achieved, and the method reduces production cost greatly compared with original technical methods.

Owner:邓才松 +1

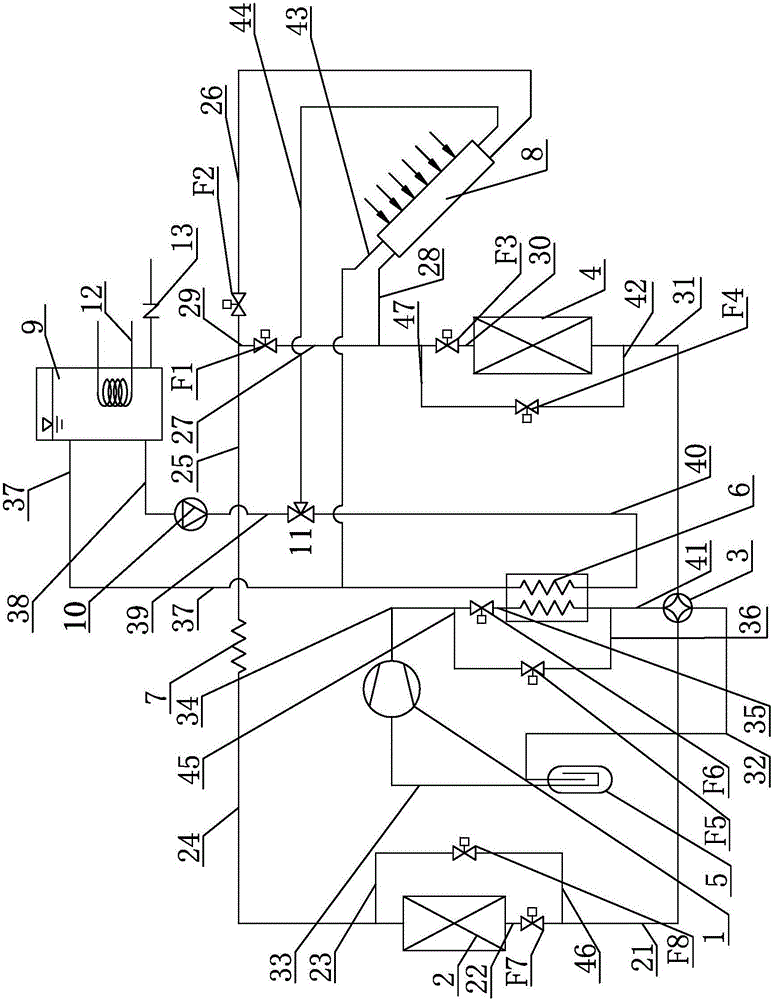

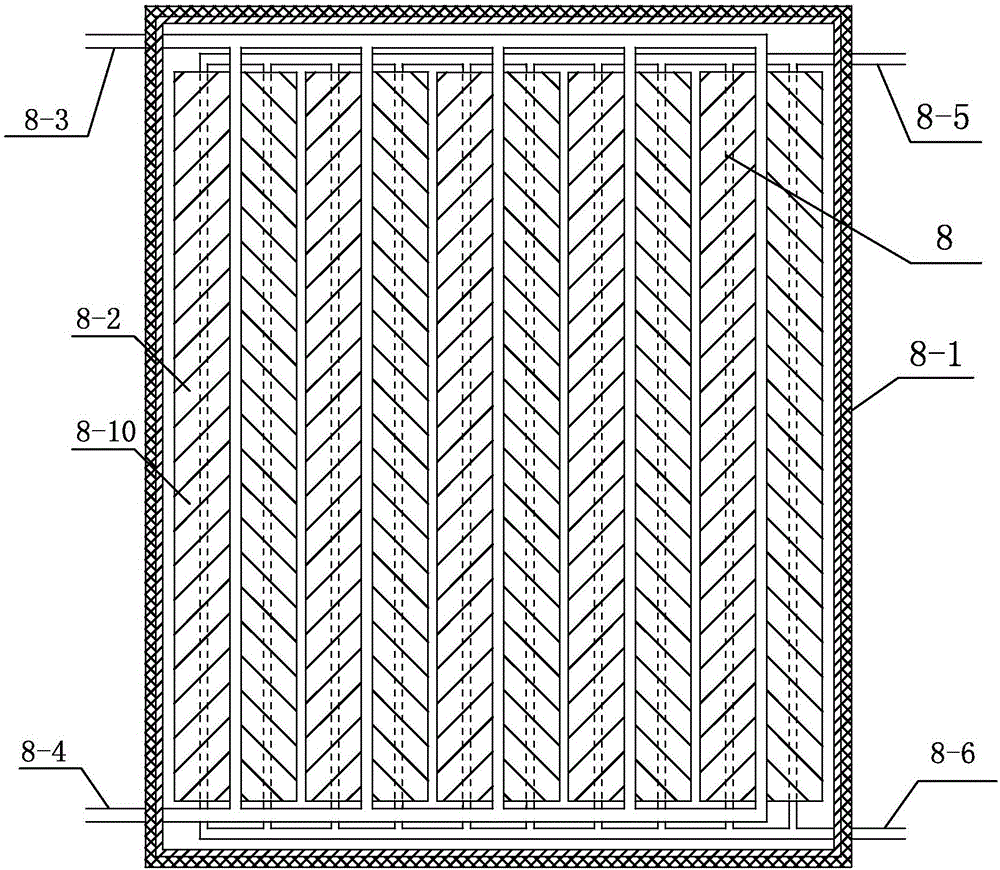

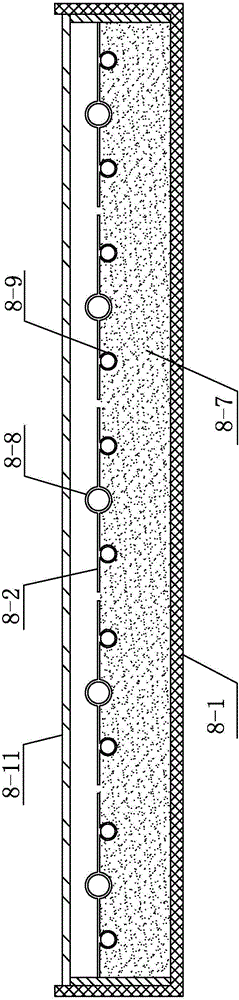

Condensing heat recovery type air source-solar energy coupling heat pump air conditioning hot water system

ActiveCN106225311ARealize integrationRealize comprehensive utilizationMechanical apparatusHeat recovery systemsFour-way valveEngineering

Owner:HARBIN INST OF TECH

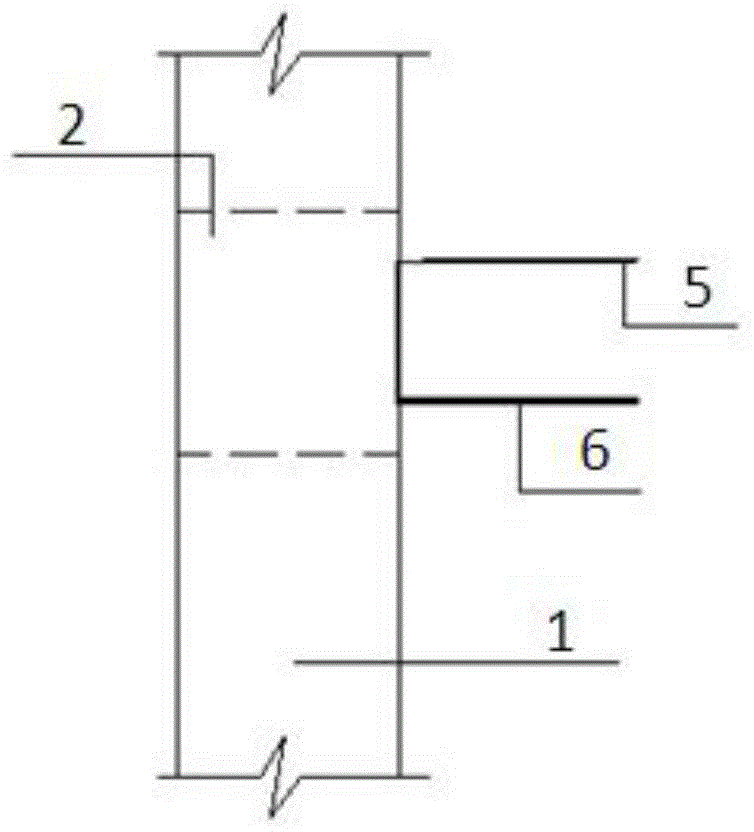

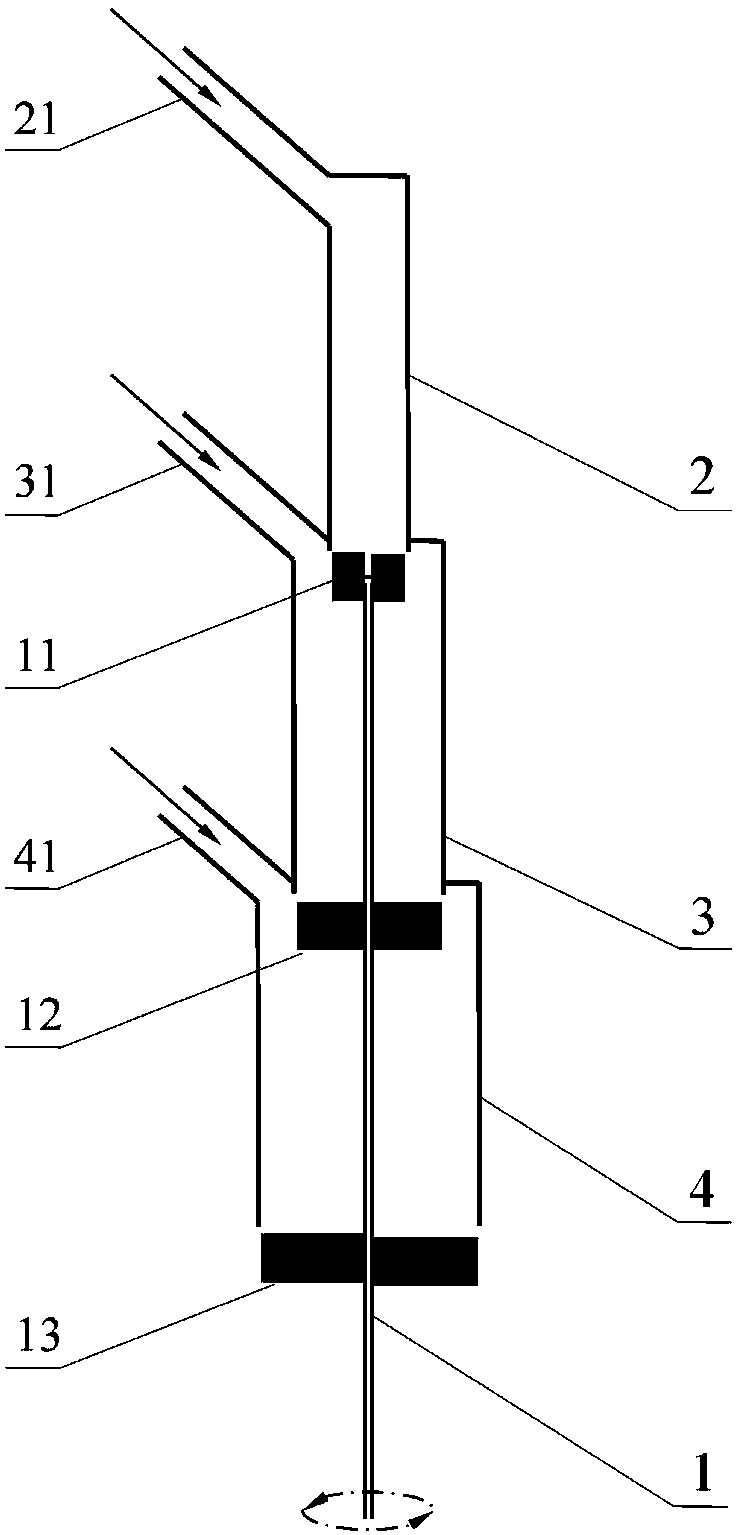

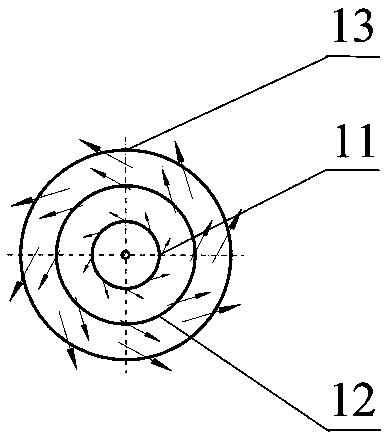

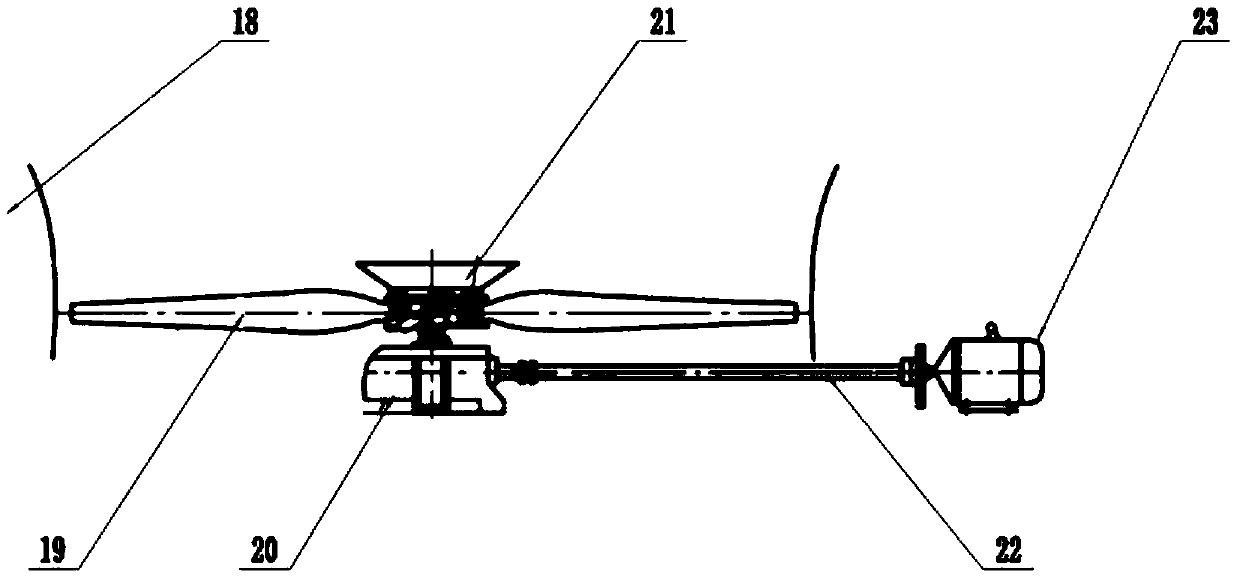

Rainwater and sewage gravity potential energy collecting device

InactiveCN108223240AEconomicalSignificant energy saving and environmental protection benefitsHydro energy generationReaction enginesImpellerPotential energy

The invention provides a rainwater and sewage gravity potential energy collecting device. The rainwater and sewage gravity potential energy collecting device comprises a water turbine, a roof drainagepipe, a second-floor drainage pipe and a first-floor drainage pipe, wherein the water turbine main shaft, the roof drainage pipe, the second-floor drainage pipe and the first-floor drainage pipe sequentially sleeve from inside to outside by taking the central axis of the water turbine main shaft as the center, a water turbine is sequentially provided with an upper impeller, a middle impeller anda lower impeller from top to bottom along the main shaft, and the distances of the positions of the highest points of the upper impeller, the middle impeller and the lower impeller lower than the bottom surfaces of an upper middle floor drain pipe and a lower middle floor drain pipe are 10-20 mm, the central axis of a sewage diversion pipe in one building is located on the same horizontal plane with the intersection point of the outer wall of the drainage pipe of the building and the highest point of the middle impeller, and the central axis of a second-floor sewage flow guide pipe is locatedon the same horizontal plane with the intersection point of the outer wall of the second-floor drainage pipe and the highest point of the upper impeller. Scattered distribution is collected in the rural and town energy-saving emission reduction resource recycling field, the gravity potential energy of the rain sewage and the small-power distributed energy station can be continuously discharged, and the device can be used. The rainwater and sewage gravity potential energy collecting device is little in investment, convenient to install, and compact in arrangement, and the converting efficiencyfrom the gravity potential energy to the rotating energy is 75%.

Owner:CENT SOUTH UNIV

Comprehensive utilization method of wastes from production of polycrystalline silicon

InactiveCN107555931ASignificant energy saving and environmental protection benefitsReduce energy consumptionSolid waste managementSlagSlurry

The invention belongs to the technical field of waste residue recycling and particularly relates to the technical field of preparation of building blocks by recycling of polycrystalline silicon wasteresidues. The method comprises the following steps: putting wastes produced in the production process of the polycrystalline silicon into a leaching pool, after hydrolysis, alkali liquid spraying andabsorption and neutralization, primarily forming waste residues in the leaching pool, adding tap water according to the mass ratio of leached waste residues to water being (1-3):1, and stirring to obtain slurry; and adding the following components: 20-26 parts of phosphorus slag residues, 17-19 parts of organic silicon waste residue slurry, 14-16 parts of natural siderite, 4-11 parts of cement, 5-7 parts of gypsum into feed liquid, carrying out filtering press to obtain insoluble residues, storing, rolling uniformly by using wheels, then carrying out compression molding, and carrying out autoclaved curing to prepare an unfired type building block. The preparation of the building blocks consumes a large amount of polycrystalline silicon waste residues and tailing sand, the utilization rateof the waste residues is 86% or above, the wastes are changed into valuables, and chemical pollution sources are changed into usable resources, so that the energy-saving and environment-friendly benefits are obvious.

Owner:WUHAN XINGTIANYU ENVIRONMENTAL ENG

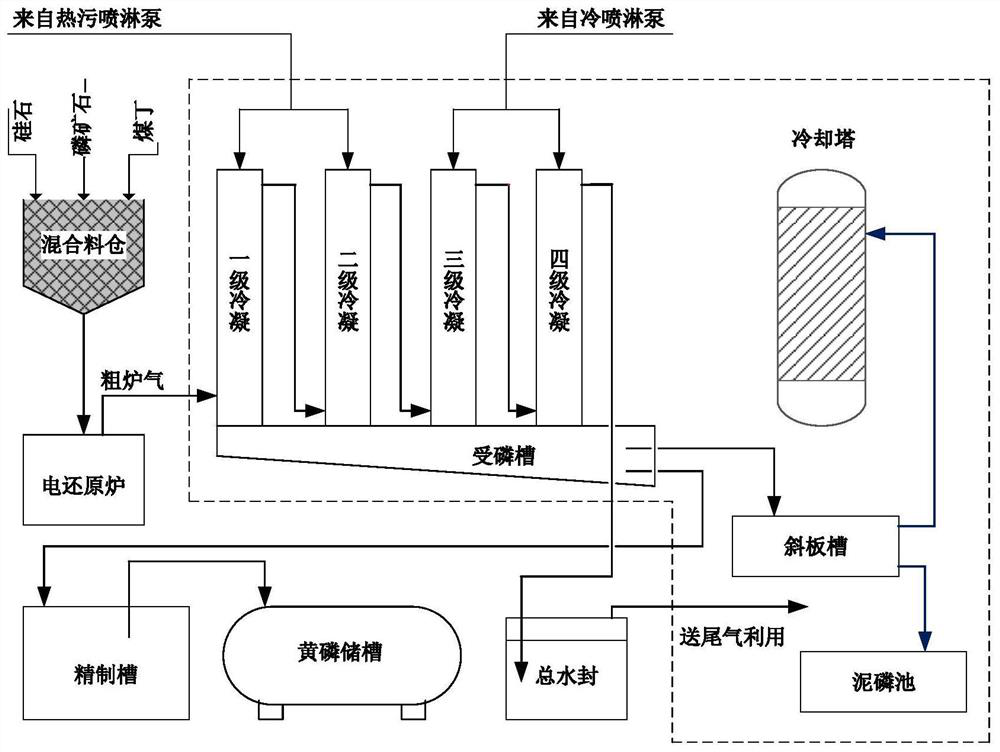

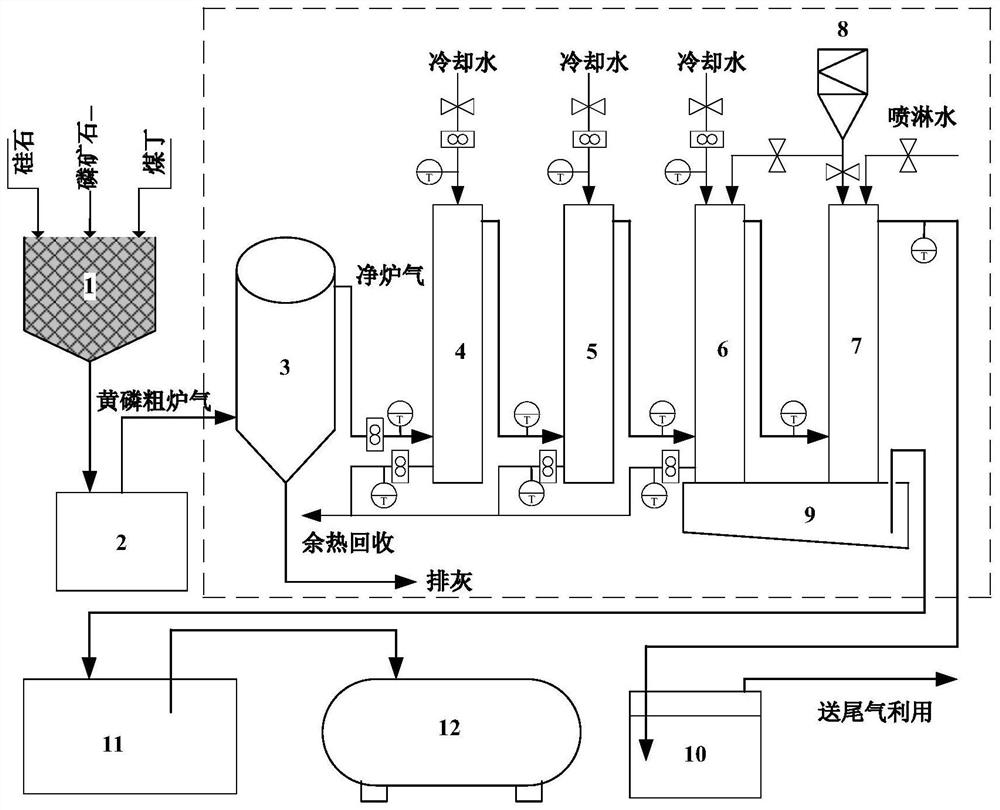

Dedusting and phosphorus collecting system and dedusting and phosphorus collecting method

PendingCN114644323AIncrease productionAvoid lostCombination devicesPhosphorus compoundsWater savingSludge

The invention belongs to the technical field of green production of yellow phosphorus industry, and particularly relates to a dust removal and phosphorus collection system and a dust removal and phosphorus collection method.The dust removal and phosphorus collection system comprises a high-temperature dust remover, an n-stage heat exchanger, a spraying condenser, an atomization spraying device and a phosphorus collection tank; a gas inlet of the high-temperature dust remover is connected with a yellow phosphorus crude furnace gas conveying pipe, and the high-temperature dust remover is connected with the n-stage heat exchanger and the spraying condenser in series; the bottom of the nth-stage heat exchanger and the bottom of the spraying condenser are both communicated with the phosphorus receiving tank; each stage of heat exchanger of the n stages of heat exchangers is provided with a cooling water inlet and a cooling water outlet, and the cooling water outlet is connected with a waste heat recovery device; the atomization spraying device is respectively communicated with the top of the nth-stage heat exchanger and the top of the spraying condenser; and the top of the spray condenser is also communicated with a spray water input pipe. The method has the advantages of water saving, coal saving, emission reduction of wastewater discharge, emission reduction of phosphorus-containing sludge and the like.

Owner:CECEP INDAL ENERGY CONSERVATION

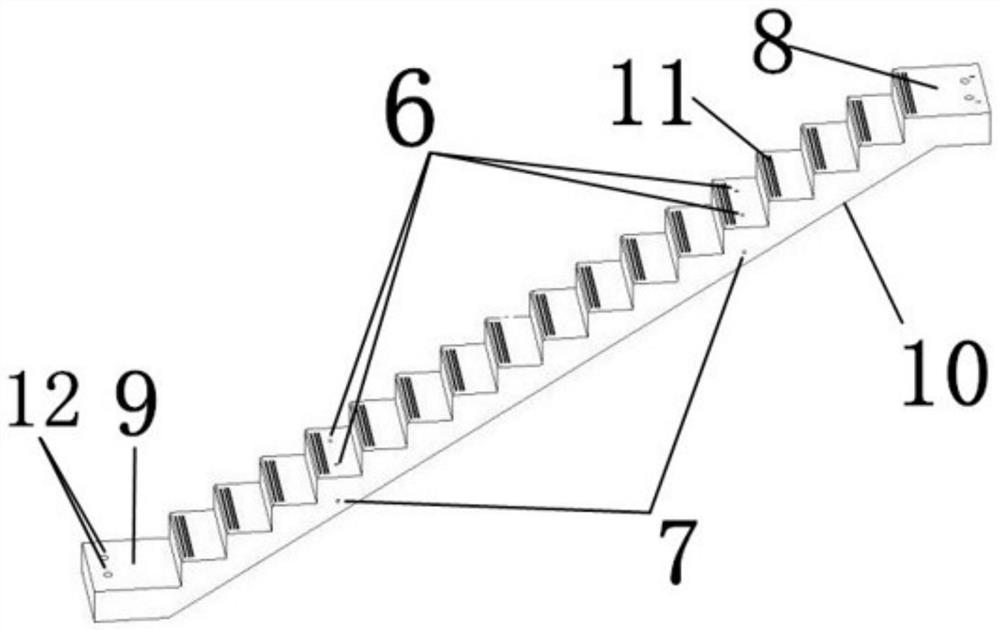

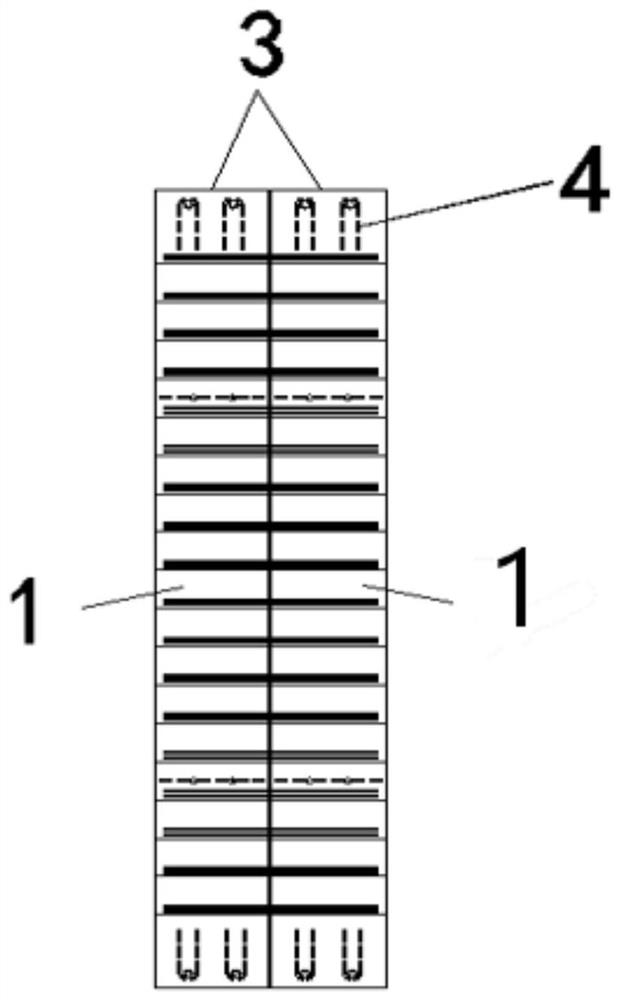

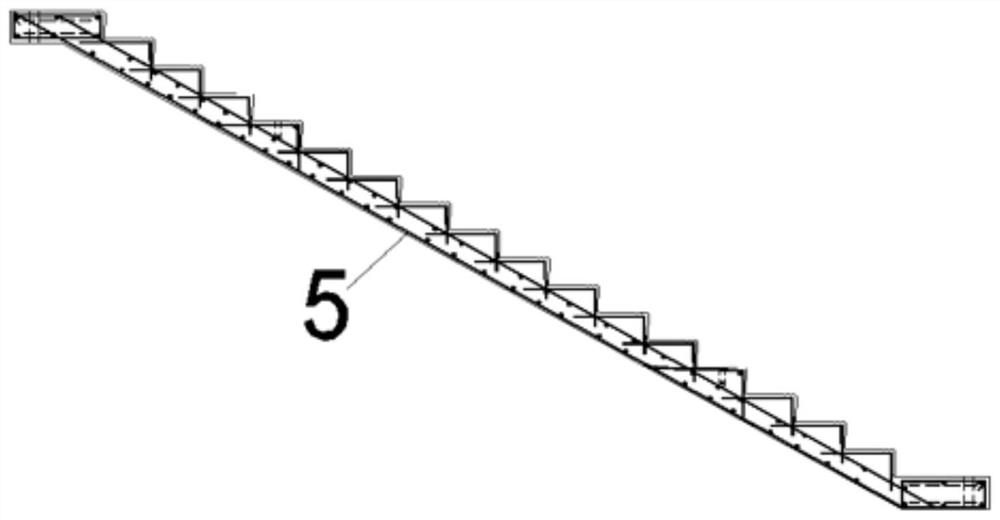

Separated precast prestressed concrete slab type stairway and production process thereof

PendingCN111958815AQuick demolitionAchieve thinningMouldsStairwaysPre stressArchitectural engineering

The invention relates to the technical field of prefabricated buildings, in particular to a separated precast prestressed concrete slab type stairway and a production process thereof. An existing slabtype stairway is large in dead weight and complicated in production process. The separated precast prestressed concrete slab type stairway comprises a stairway body, wherein the stairway body sequentially comprises an upper platform plate, stair section plates and a lower platform plate from top to bottom; prestressed reinforcing steel bars are arranged on the lower part in the stairway body along the length direction; reserved installation holes and reserved hole reinforcing ribs are respectively arranged on the surfaces of the upper platform plate and the lower platform plate; the stair section plates are provided with hoisting points and demoulding hoisting points; and the prestressed reinforcing steel bars are provided with reserved prestressed reinforcing steel bar plugging slots atreinforcing steel bar outlet holes of flat planels. Compared with a traditional precast stairway, 20 percent of concrete can be saved, 30 percent of reinforcing steel bars can be saved, the dead weight is light, fast production can be realized, and the separated precast prestressed concrete slab type stairway and the production process thereof have a favorable development prospect in the technicalfield of prefabricated buildings.

Owner:河南清水建设科技有限公司 +1

Mechanical transmission-free jet flow spray-adjustable cooling method and device

PendingCN109611997AEliminate structureNo maintenanceMechanical apparatusLighting and heating apparatusCooling towerJet flow

The invention discloses a mechanical transmission-free jet flow spray-adjustable cooling method and device, and belongs to the technical field of jet flow ventilation cooling. The device comprises a mechanical transmission-free jet flow spray-adjustable cooling device body, and a middle water distribution topological pipeline and a bottom water distribution topological pipeline are sequentially arranged at the position from the high position to the low position along the gravity potential energy of a pipeline system topological layout adopted a topological layout; and the middle water distribution topological pipeline is provided with first-stage multilayer mechanical transmission-free fixed jet spray cooling spray head sets which are distributed in the circumferential direction, secondarymultilayer mechanical transmission-free fixed jet spray cooling spray head sets are arranged on the bottom water distribution topological pipeline, and a main water inlet pipeline is in communicationwith the middle water distribution topological pipeline and the bottom water distribution topological pipeline. The mechanical transmission-free jet flow spray-adjustable cooling method and device aim to break through bottlenecks of the prior art and subvert the traditional design, the traditional mechanical transmission air draft part device is completely replaced with the water return pressure,and thus a stable and reliable maintenance-free cooling tower is formed.

Owner:重庆浪格节能环保科技有限公司

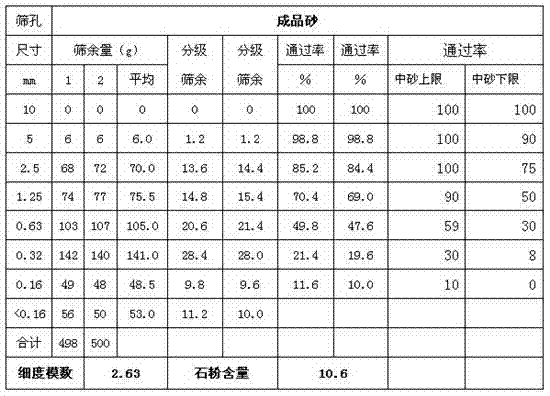

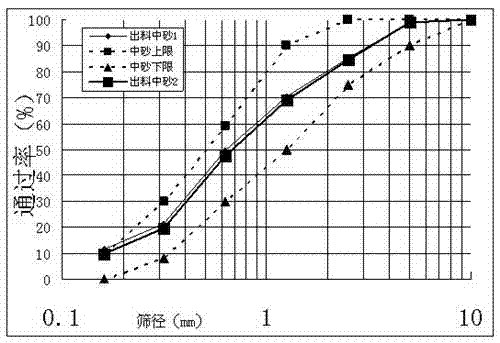

Novel roller-compacted concrete for dams and preparation method thereof

ActiveCN103253898BVC value advantageAdvantages of impermeability gradeRoller-compacted concreteSuperplasticizer

The invention discloses a novel roller compacted concrete for dams and a preparation method thereof. The novel roller compacted concrete comprises the following components by weight: 60-110 parts of water, 51-59 parts of cement, and 70-70 parts of fly ash 120 parts, 500-700 parts of river sand, 1400-1500 parts of coarse aggregate, 0.876-1.46 parts of retarding superplasticizer and 0.02-0.04 parts of air-entraining agent; The river sand is crushed to form finished sand; then the finished sand is mixed with other components to obtain a new type of roller compacted concrete. The invention effectively improves the quality of the sand, does not consume water resources, does not generate dust, and is energy-saving and environmentally friendly.

Owner:THE GUANGDONG NO 3 WATER CONSERVANCY & HYDRO ELECTRIC ENG BOARD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com